Preparation method and application of nano-silica introduced magnetic vulcanized nanometer zero-valent iron

A nano-silica, nano-zero valent iron technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of difficult separation, non-magnetic, easy to oxidize, etc., to achieve synthesis The method is simple and fast, the chemical properties are stable, and the removal ability is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

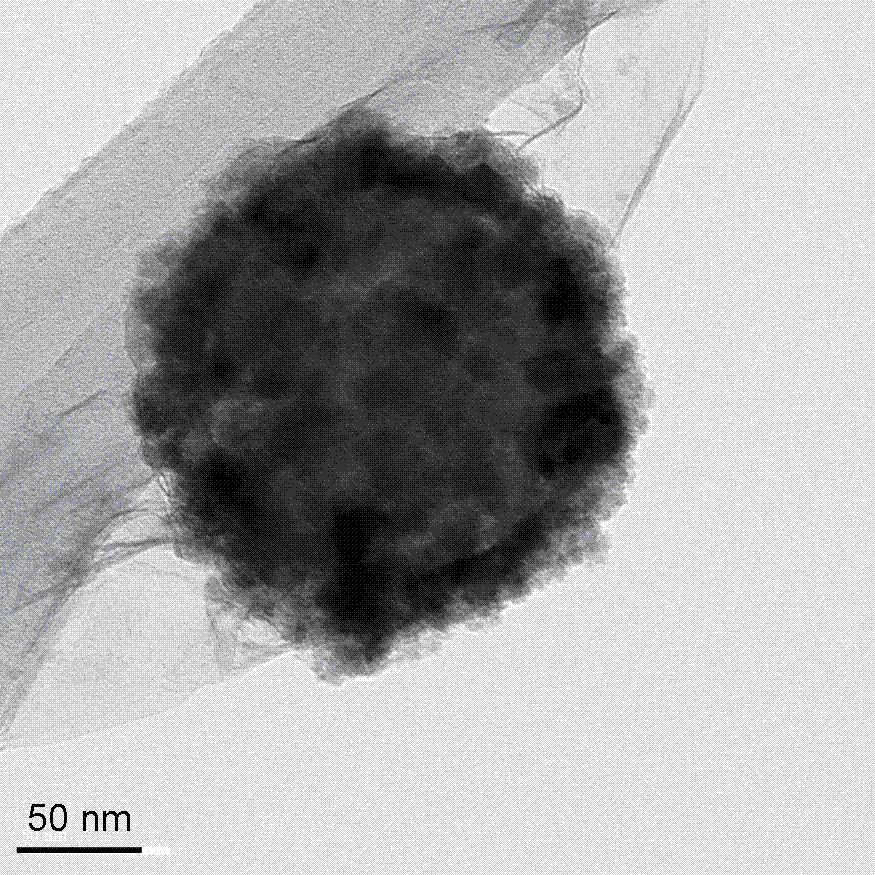

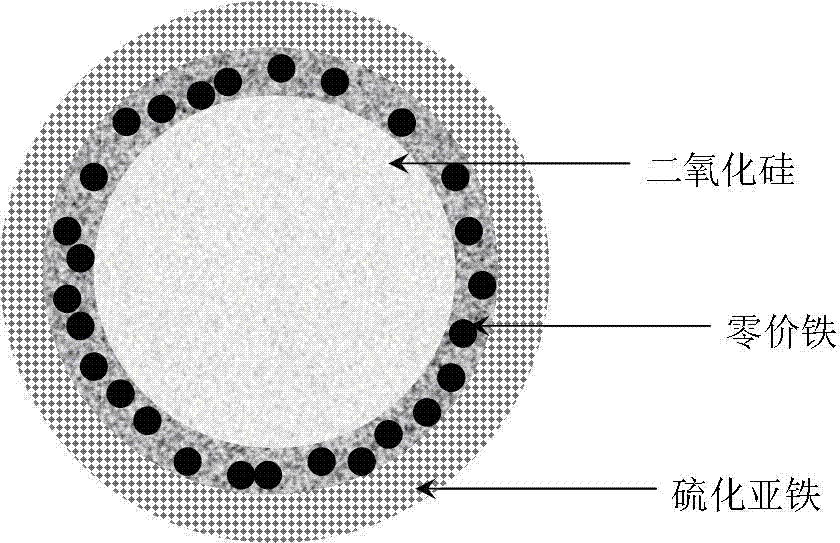

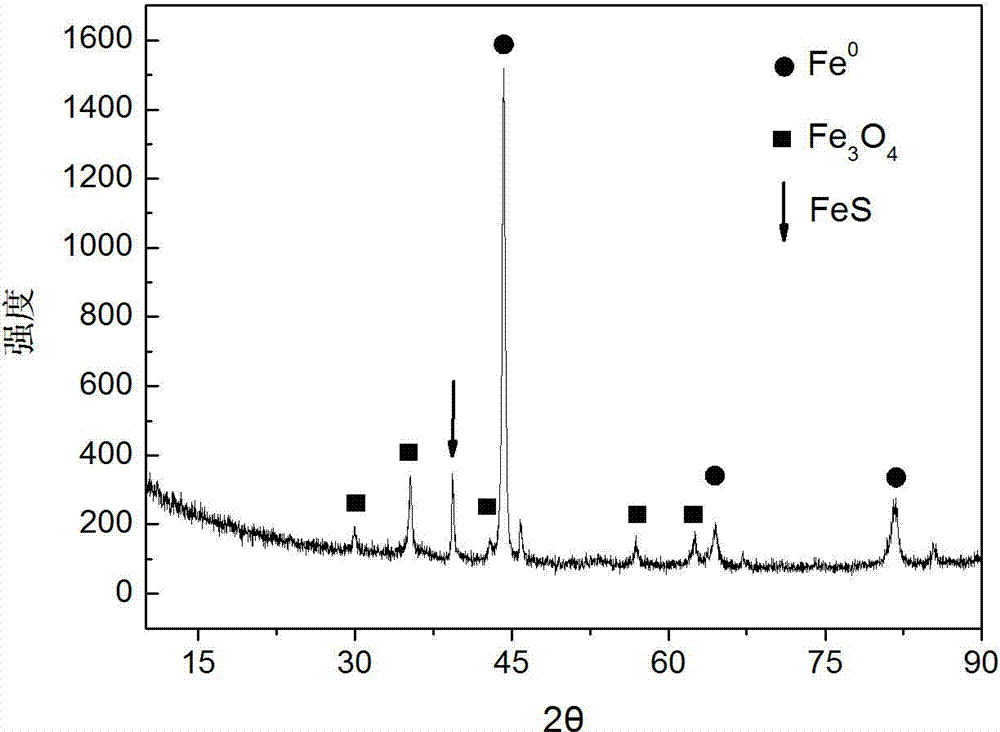

[0024] Weigh 9.6 g of ferric chloride containing six crystal waters and dissolve it in 500 ml of deionized water, use mechanical stirring, and continuously stir at 1200 rpm; weigh 1 g of sodium persulfate and 7.6 g of sodium borohydride Dissolve in 500 ml of deionized water, stir mechanically at 250 rpm, and add 0.4 ml of silica suspension with a mass fraction of 30% and an average particle size of 120 nm; the latter is pumped to Add it dropwise into the ferric chloride solution at a flow rate of 0.8 L / min, and the whole process lasts for 38 min; after the reaction, continue to stir for 8 min, use a magnet to complete solid-liquid separation, wash with deionized water and absolute ethanol three times, and store in In 20% ethanol solution, the concentration of wet nanomaterials was 30 g / L. The material was carefully analyzed using a transmission electron microscope (with electron spectrometer attached), figure 1 is a representative picture of the nanomaterial, figure 2 V...

Embodiment 2

[0026] In this preparation, different volumes of nano-silicon peroxide (0.2, 0.4, 0.6, 0.8 ml) suspensions were selected, and the rest of the synthesis conditions were unchanged. 3-FeSSi, 4-FeSSi) have different removal abilities for metal cadmium ions. Experimental results such as Figure 4 As shown, it can be seen that the material synthesized by adding 0.4 ml nano-silica suspension has the highest ability to remove cadmium ions.

Embodiment 3

[0027] Example 3 Heavy metal wastewater treatment

[0028] According to the removal effect of metal cadmium ions of different materials in Synthesis Example 2, the volume of nano-silicon dioxide suspension added was selected to be 0.2 ml synthetic material and used in this example and subsequent examples. Wastewater containing lead, cadmium, nickel, copper, and cobalt was prepared using lead acetate, cadmium acetate, nickel chloride, copper chloride, and cobalt chloride as pollutant sources, and tap water was used as a solvent to prepare respectively, and the concentration of each pollutant was 50 mg. / L. Add 100 ml of wastewater into 100 ml glass bottles with stoppers (each wastewater contains 3 parallel samples), add 1.67 ml of nanomaterials with a wet concentration of 30 g / L, and the actual concentration of nanomaterials is 500 mg / L, Stoppered and placed in a constant temperature shaker, the reaction temperature was set at 25°C, the shaker speed was 200 rpm, and the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com