Biological ferrous sulfide and uranium-polluted underground water treatment permeation reaction wall based on same

A technology of osmosis reaction wall and biological iron sulphur, applied in biological water/sewage treatment, polluted groundwater/leachate treatment, water/sludge/sewage treatment, etc., can solve the problem of low removal efficiency of heavy metals and low product stability , poor adaptability and other problems, to achieve the effect of increasing the amount of groundwater intercepted, high degree of automation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

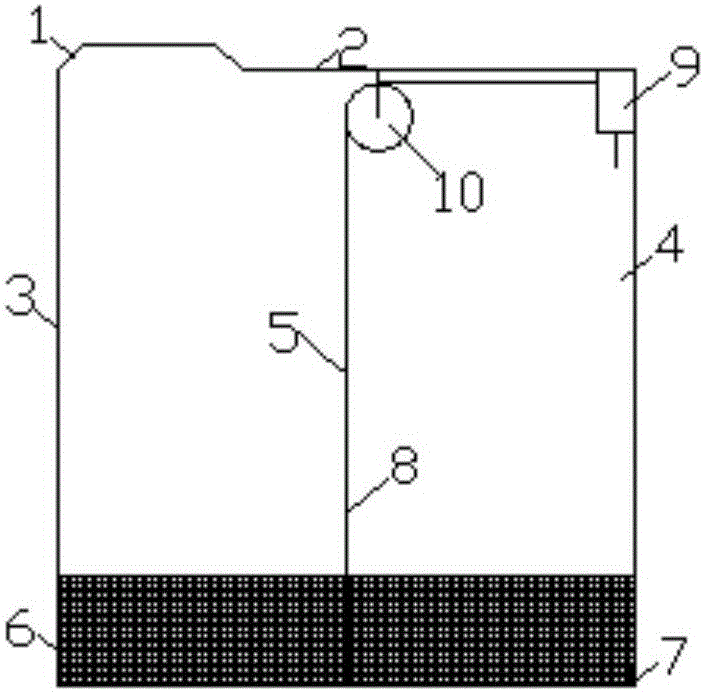

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of biosulfur iron composite material provided by the invention specifically comprises the following steps:

[0041] Step 1: Using the anaerobic sludge to obtain the complex flora liquid in the fermentation medium through the method of enrichment-screening-enrichment. Fermentation medium: 2g / lMgSO 4 , 5g / l sodium citrate, 1g / l CaSO 4 , 1g / lNH 4 Cl, 0.5g / lK 2 HPO 4 , 3.5g / l sodium lactate, 1g / l yeast extract, 2ml / l 5% ferrous ammonium sulfate (FAS) solution. Adjust the pH of the medium to 7.5 and sterilize in an autoclave at 121° C. for 20 minutes, and add ferrous ammonium sulfate after autoclaving.

[0042] Step 2: Configure a compound culture medium containing complex flora containing carbon and nitrogen sources and inorganic elements, adjust the pH of the medium to 7.5 and sterilize it in an autoclave at 121°C for 20 minutes, and add ferrous ammonium sulfate after autoclaving to prevent ferrous Iron ions oxidize at high temperatures. The c...

Embodiment 1

[0057] Embodiment 1: Preparation of biological sulfur iron composite material

[0058] The complex flora was isolated and enriched from the anaerobic sludge sample from the lotus pond bottom of Nanhua University.

[0059] Configure fermentation medium: 2g / lMgSO 4 , 5g / l sodium citrate, 1g / l CaSO 4 , 1g / lNH 4 Cl, 0.5g / lK 2 HPO 4 , 3.5g / l sodium lactate, 1g / l yeast extract, 2ml / l 5% ferrous ammonium sulfate (FAS) solution. Adjust the pH of the medium to 7.5 and sterilize in an autoclave at 121° C. for 20 minutes. After autoclaving, add ferrous ammonium sulfate, because ferrous ions are easily oxidized at high temperatures.

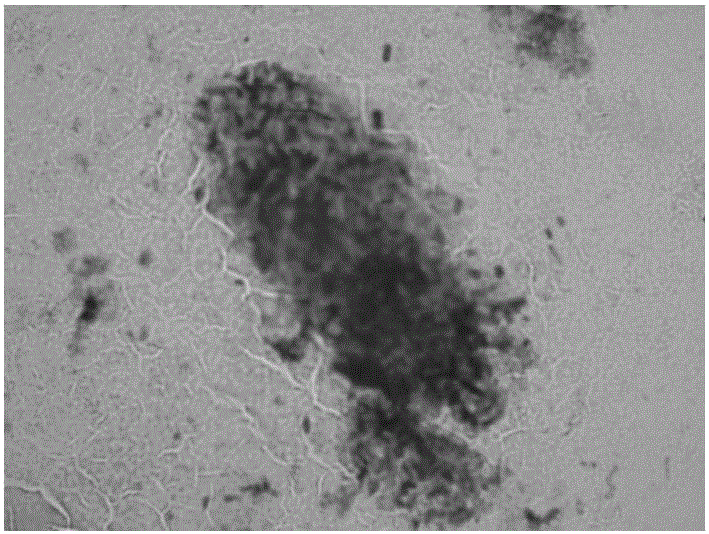

[0060] The complex flora is a facultative anaerobic bacteria, which can reduce sulfur oxides such as sulfate, sulfite, thiosulfate, and elemental sulfur into hydrogen sulfide. In the medium with ferrous salts, the liquid The culture medium turned black completely; while the solid medium had black colonies in the presence of ferrous iron salts. In this...

Embodiment 2

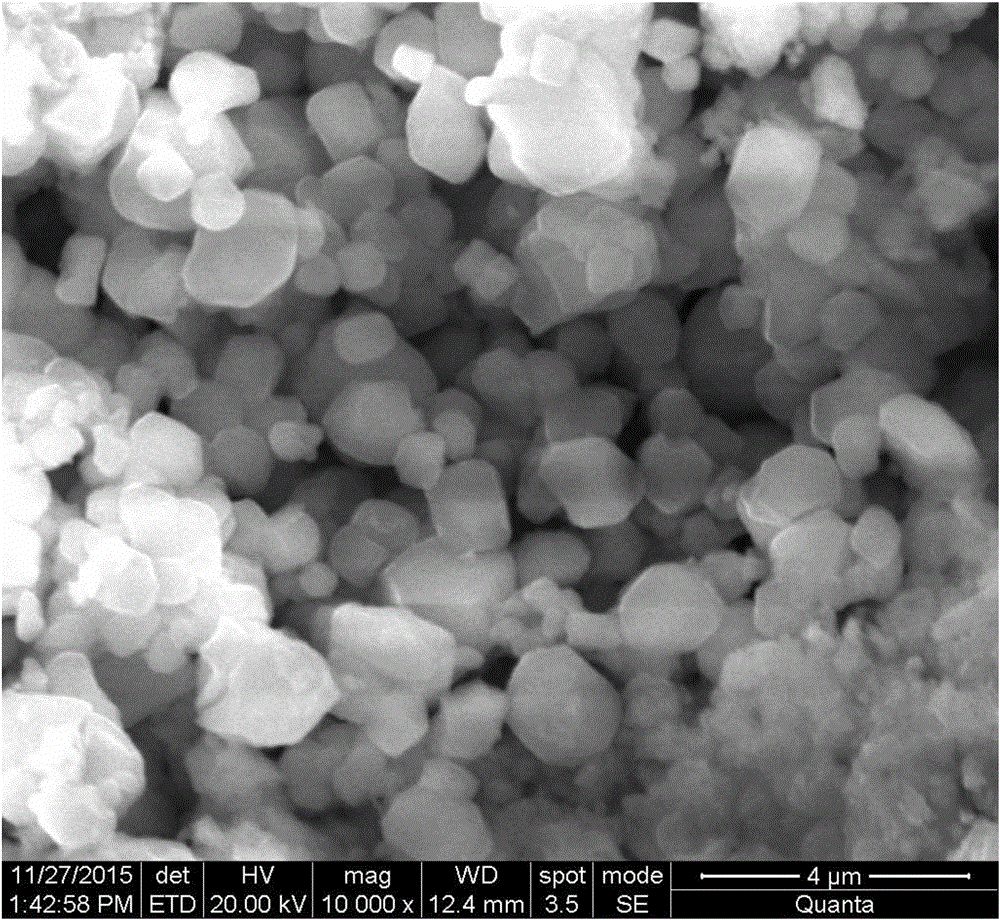

[0067] The present invention provides a kind of bio-iron sulfur composite material, comprising ferrous sulfide and the composite flora combined on the ferrous sulfide, the ratio of the number of the composite flora to the ferrous sulfate per unit mass is 4×10 7 , the composite flora includes Desulfovibrio, Clostridium, Citrobacter, Trichococcus, Acinetobacter, Pseudomonas, Geobacter, Desulfurispora and Sulfurospirillum. The composite flora includes 15 parts of Desulfovibrio, 9 parts of Clostridium, 1 part of Citrobacter, 0.2 part of Leuconostoc, 0.05 part of Acinetobacter, 0.02 part of Pseudomonas, 0.02 part of Geobacter, desulfurization Bacillus 0.01 part, sulfurmonas 0.01 part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com