Preparation method and applications of ferrous sulfide/biological carbon composite material

A technology of composite materials and ferrous sulfide, applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc., can solve the problem of no reduction ability, insufficient growth of nanometer zero-valent iron particles, no FeS/ BC composite materials and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

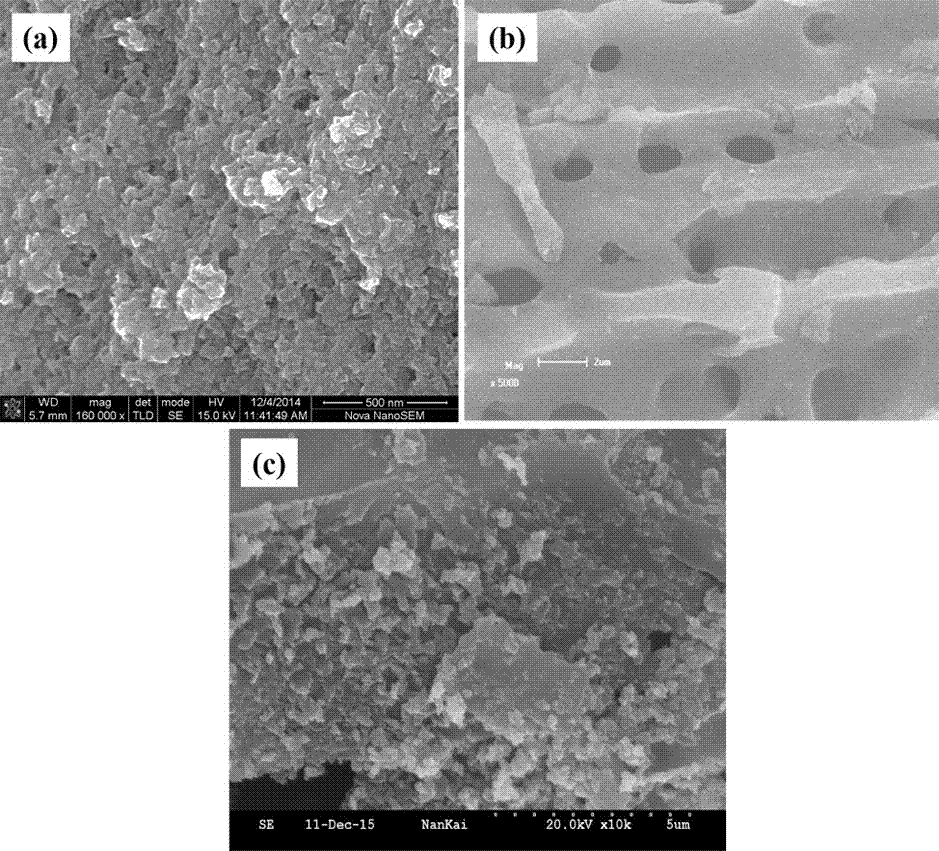

[0025] Example 1: This implementation provides a simple preparation method of FeS / BC composite material.

[0026] 1. Preparation of biochar (BC) material

[0027] Dry and crush the wheat straw to a particle size of ~2 mm, weigh 10 g of the crushed wheat straw into a ceramic crucible (as full as possible to reduce the presence of oxygen), and put it into an oven (DGG-9023A, Shanghai Senxin Experimental Instrument Co., Ltd. company, China) at 80 ºC. Nitrogen was vented on the surface of the dried straw, sealed with aluminum foil and covered, and the above system was placed in a muffle furnace (SX-GO7102, Tianjin Zhonghuan Experimental Electric Furnace Co., Ltd., China) for 2 h at 600 ºC with limited oxygen . After the lysis, the prepared BC was treated with 500 mL of 1.0 M HCl solution for 24 h, and then the BC was washed repeatedly with distilled water until the pH was neutral (the pH could reach neutral after about 10 washes). The cleaned BC was then dried in an oven at 80 ...

Embodiment 2

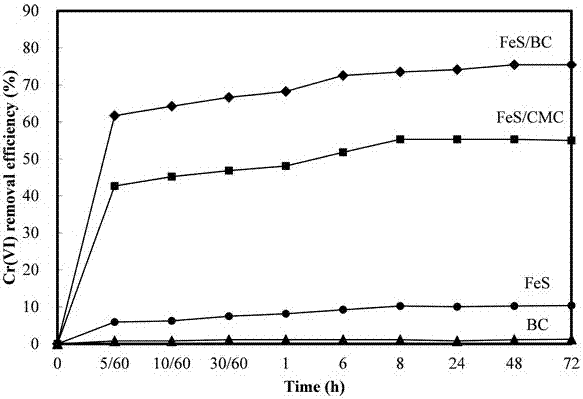

[0035] Embodiment 2: FeS / BC composite material is to Cr ( ) removal effect experiment

[0036] In order to investigate the effect of FeS / BC on Cr( ) removal effect, the experimental grouping is set as follows: (1) BC; (2) FeS; (3) FeS / CMC; (4) FeS / BC (it should be noted that in the material named FeS / BC here containing CMC); (5) the control group, only wastewater (CK).

[0037] Add 42 mL of 100 mg / L Cr( ) solution, and arrange experiments according to the above settings, the dosage of each material is set according to its proportion in the composite material, namely: BC 238 mg / L, FeS 238 mg / L, FeS / CMC 476 mg / L, FeS / BC 714 mg / L. The pH of the reaction system was 5.5, and nitrogen was passed through during the experiment preparation to prevent the material from being oxidized. The vials were equilibrated on a rotary shaker at 40 rpm for 3 days at room temperature. All experimental groups and control groups were set up in three parallel groups. During the experiment, sa...

Embodiment 3

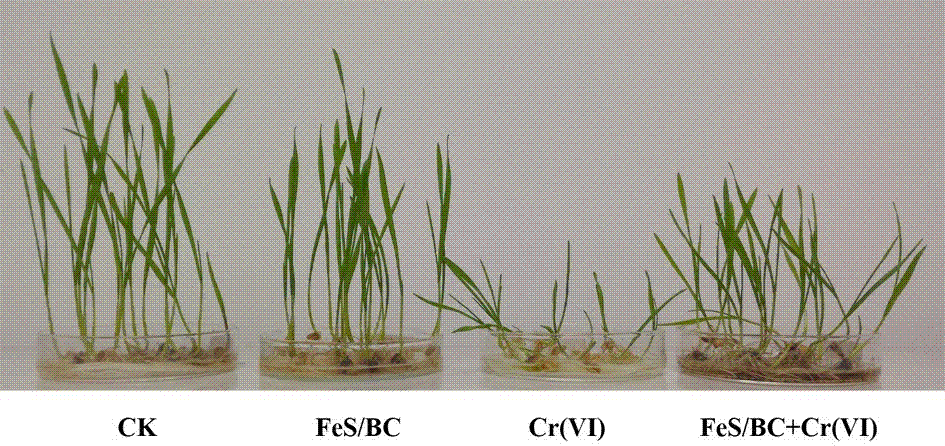

[0039] Embodiment 3: FeS / BC composite material is to Cr ( ) Toxic effect experiment on wheat seed growth under the action of

[0040] In order to investigate the biotoxicity of FeS / BC composites, the experiment selected wheat seeds, and studied the addition of Cr( ), the effect of FeS / BC composites on the germination of wheat seeds. 20 wheat seeds were added to the plate respectively, and the experimental settings were as follows: (1) control group, only 6 mL distilled water was added; (2) 6 mL distilled water and 16 mg FeS / BC composite were added; (3) 6 mL concentration of 300 mg / L Contains Cr( ) waste water (ie: Cr( ) is 1.8 mg); (4) Add 6 mL of 300 mg / L Cr( ) wastewater and 16 mg of FeS / BC composite. Two parallel samples were set up for each group of experiments, and the growth of wheat germ was observed after 14 days. The results were as follows: image 3 shown. From image 3 It can be seen that compared with CK, the FeS / BC composite has no obvious inhibitory ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com