Preparation method and application of chitosan-stabilized zirconium-modified nanometer ferrous sulfide composite material

A technology of ferrous sulfide and composite materials, applied in chemical instruments and methods, other chemical processes, contaminated groundwater/leachate treatment, etc., can solve problems such as easy aggregation, easy oxidation, and poor stability of nano-scale ferrous sulfide. Achieve low price, increase adsorption capacity, and improve the effect of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Present embodiment provides a kind of chitosan stabilized zirconium modified nano ferrous sulfide composite material (the mol ratio of zirconium oxide and ferrous sulfide is 1:2, the mass ratio of chitosan and ferrous sulfide is 1:10, ) preparation method, said method comprising the following steps:

[0038] (1) Preparation of zirconia sol: configure 65mL of ethanol and water as a 5:3 (v / v) mixed solution, and then weigh 3.223g of ZrOCl 2 ·8H 2 O was added to the mixed solution to dissolve, so that the concentration was 0.154mol / L, transferred to a jar, sealed in a water bath, and heated to 70°C for 2 hours. The obtained clear and transparent zirconia sol was sealed and cooled to normal temperature for later use.

[0039] (2) preparation of chitosan solution: first prepare 1% glacial acetic acid with high-purity water, take by weighing 0.176g chitosan and add 1% glacial acetic acid solution to make it fully dissolve, prepare the chitosan solution of 5.275g / L, then tra...

Embodiment 2

[0042] This embodiment provides a chitosan-stabilized zirconium-modified nano-ferrous sulfide composite material (the molar ratio of zirconia to ferrous sulfide is 1:2, and the mass ratio of chitosan to ferrous sulfide is 3:10) The preparation method, described method comprises the following steps:

[0043] (1) The pretreatment of zirconia sol is described in step 1 in example 1.

[0044] (2) Chitosan solution was prepared as described in step 2 in Example 1, except that 0.528g chitosan was weighed.

[0045] (3) Prepare the chitosan-stabilized zirconium-modified nano-ferrous sulfide composite material as described in step 3 in Example 1. (Theoretical CS / ZrO 2 -FeS=0.3).

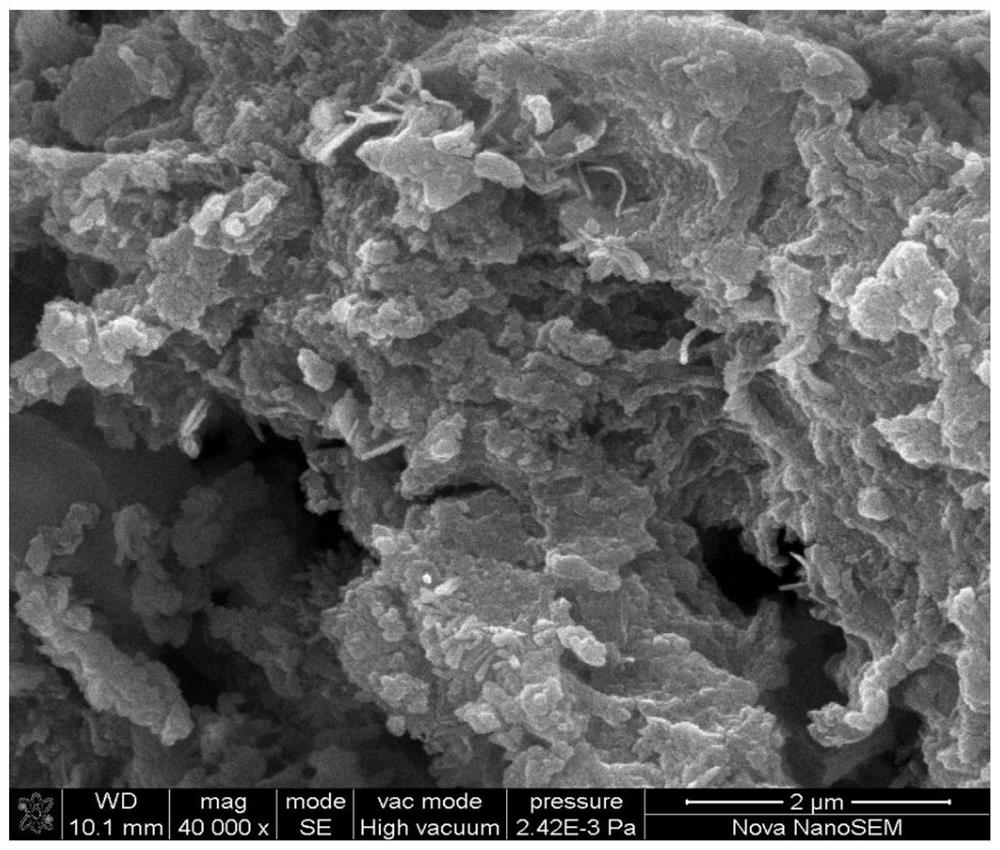

[0046] The composite material obtained in this example is rough and porous, and the rich zirconia component mainly exists in an amorphous state, and has a strong adsorption capacity for metal ions. (like figure 1 shown).

Embodiment 3

[0048] This embodiment provides a chitosan-stabilized zirconium-modified nano-ferrous sulfide composite material (the molar ratio of zirconia to ferrous sulfide is 1:2, and the mass ratio of chitosan to ferrous sulfide is 5:10) The preparation method, described method comprises the following steps:

[0049] (1) The pretreatment of zirconia sol is described in step 1 in example 1.

[0050] (2) Chitosan solution was prepared as described in step 2 in Example 1, except that 0.88 g of chitosan was weighed.

[0051] (3) Preparation of chitosan zirconium modified nano-ferrous sulfide composite material is the same as described in step 3 in Example 1. (Theoretical CS / ZrO 2 -FeS=0.5).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com