System and method for preparing low-sulfur iron powder

A low-sulfur iron and metal iron technology, applied in the field of resource recycling, can solve problems such as poor product quality, high sulfur content in metal iron powder, and inability to sell products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

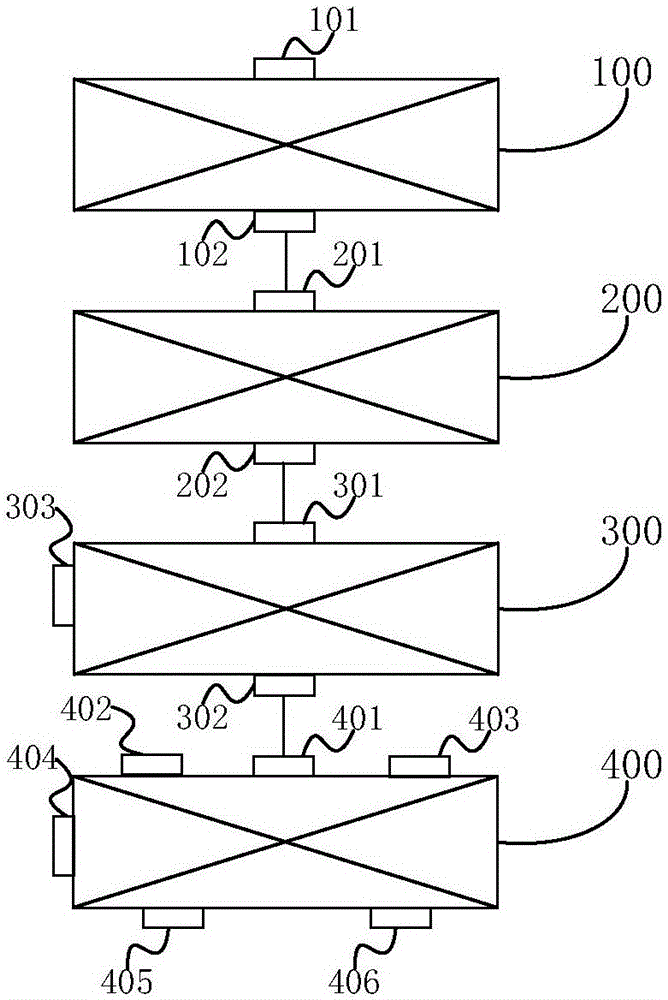

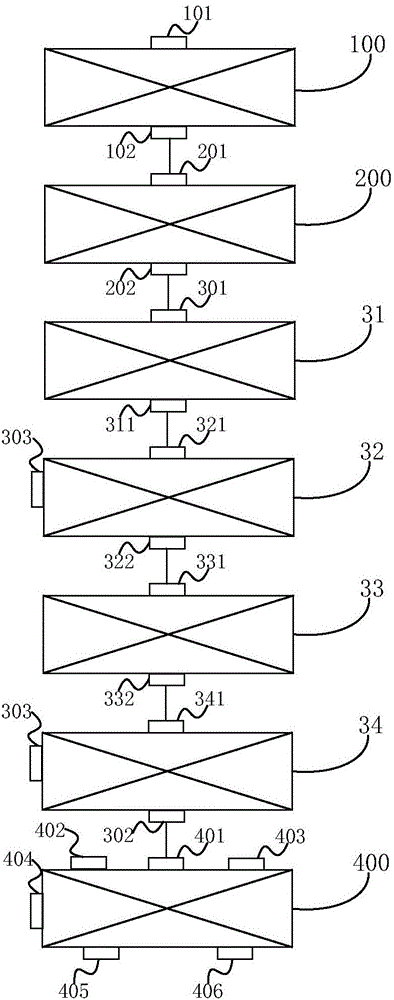

[0075] The system for preparing low-sulfur iron powder according to the embodiment of the present invention pretreats the metallized pellets by using a microwave pretreatment device. On the one hand, microwave irradiation of the metallized pellets can increase the temperature of the metallized pellets. The thermal conductivity of iron and other gangue minerals in pellets is different, resulting in different thermal shock damage caused by thermal stress caused by temperature gradients, so that metallized pellets can be selectively broken; on the other hand, microwave radiation The energy can make the Fe—S bond in the sulfur-containing minerals gain energy, thereby enhancing the reactivity of the sulfur-containing minerals, which is conducive to the subsequent flotation process. Pretreatment not only promotes the dissociation of mineral monomers, thereby improving the subsequent grinding efficiency, but also improves the buoyancy of sulfur-containing minerals, making it unnecessa...

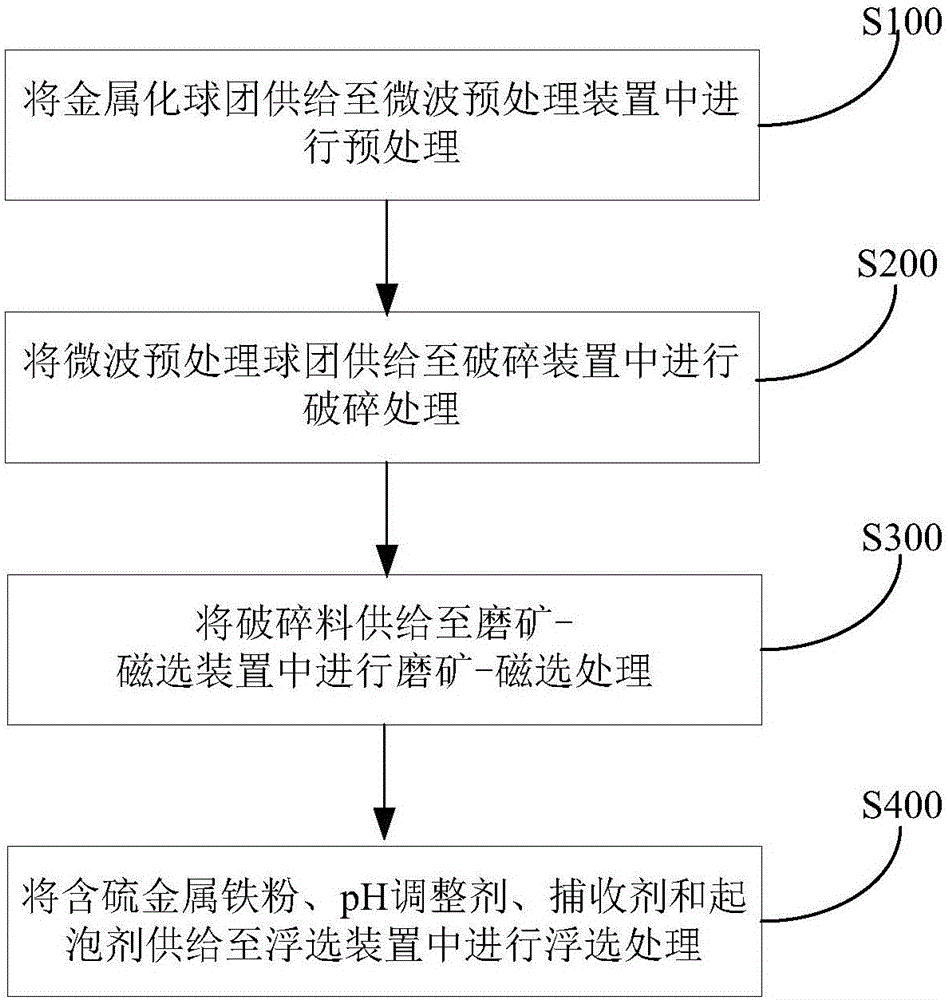

Embodiment 1

[0118] The composition of copper slag metallized pellets is: the mass fraction of total iron is 25.91%, the mass fraction of metallic iron is 22.51%, the metallization rate is 90.37%, Al 2 o 3 The mass fraction is 20.11%, SiO 2 The mass fraction is 26.73%, the CaO mass fraction is 6.63%, and the S mass fraction is 2%. refer to Figure 5 , the specific operation steps are as follows:

[0119] (1) Supply the copper slag metallized pellets to a microwave pretreatment device for pretreatment to obtain microwave pretreated pellets, wherein the microwave frequency in the pretreatment process is 2.0GHz, the microwave power is 500W, and the processing time is 20min;

[0120] (2) supplying the microwave pretreated pellets to the crushing device for crushing so as to obtain crushed material, wherein the particle size of the crushed material is not higher than 2mm;

[0121] (3) Supply the crushed material obtained above to a first-stage grinding device for a first-stage grinding trea...

Embodiment 2

[0124] The composition of red mud metallized pellets is: the mass fraction of total iron is 28.22%, the mass fraction of metallic iron is 25.75%, the metallization rate is 91.26%, Al 2 o 3 The mass fraction is 20.71%, SiO 2 The mass fraction is 26.34%, the CaO mass fraction is 7.45%, and the S mass fraction is 3%. refer to Figure 5 , the specific operation steps are as follows:

[0125] (1) Supply the red mud metallized pellets to a microwave pretreatment device for pretreatment to obtain microwave pretreated pellets, wherein the microwave frequency during the pretreatment process is 2.5GHz, the microwave power is 500W, and the processing time is 20min;

[0126] (2) supplying the microwave pretreated pellets to the crushing device for crushing so as to obtain crushed material, wherein the particle size of the crushed material is not higher than 2mm;

[0127] (3) Supply the crushed material obtained above to a first-stage grinding device for a first-stage grinding treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com