Patents

Literature

44results about How to "Change in surface activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

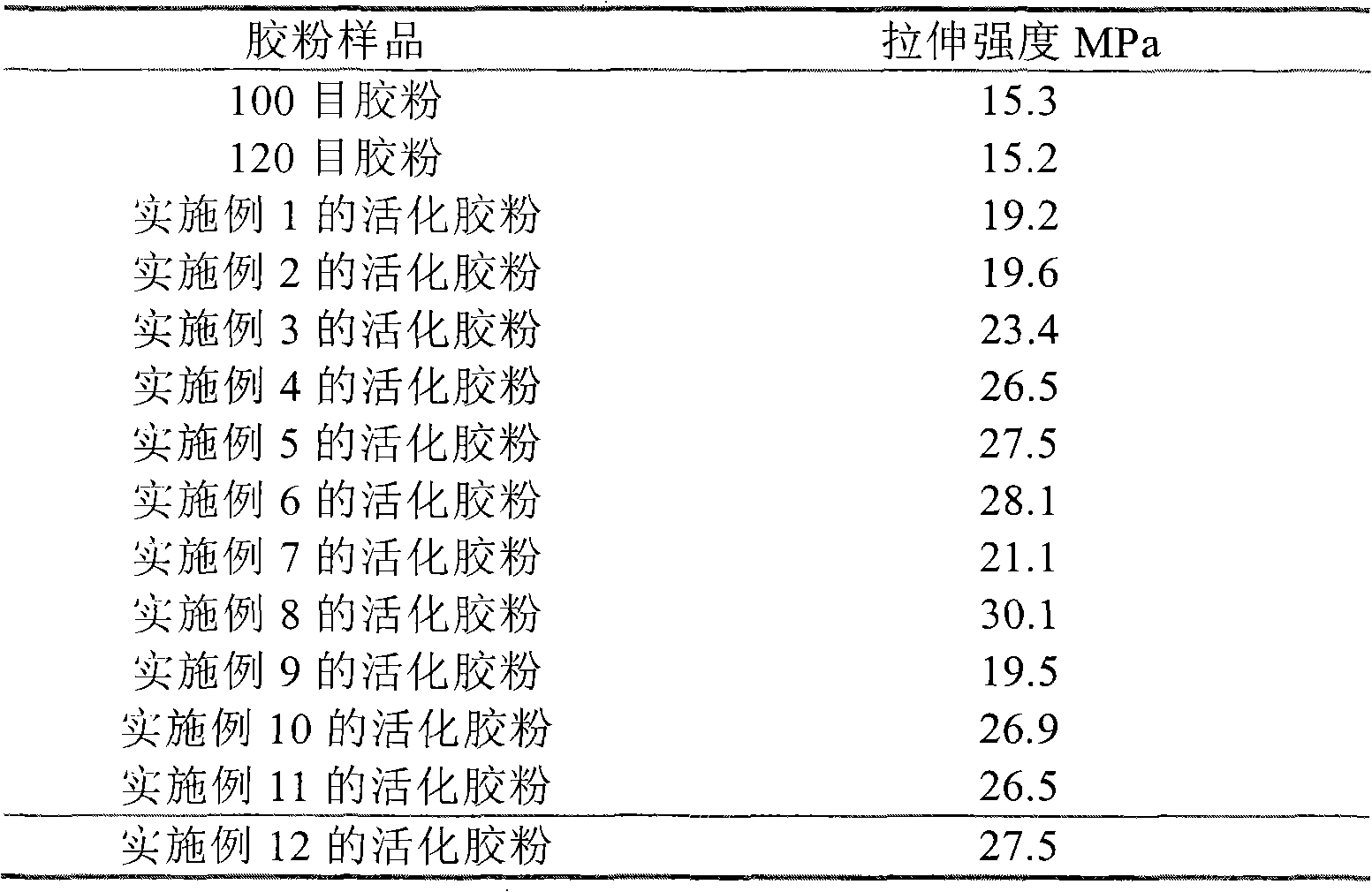

Activated waste rubber powder and preparation thereof

InactiveCN101440145AChange in surface activityReasonable usePlastic recyclingPolymer scienceWaste rubber

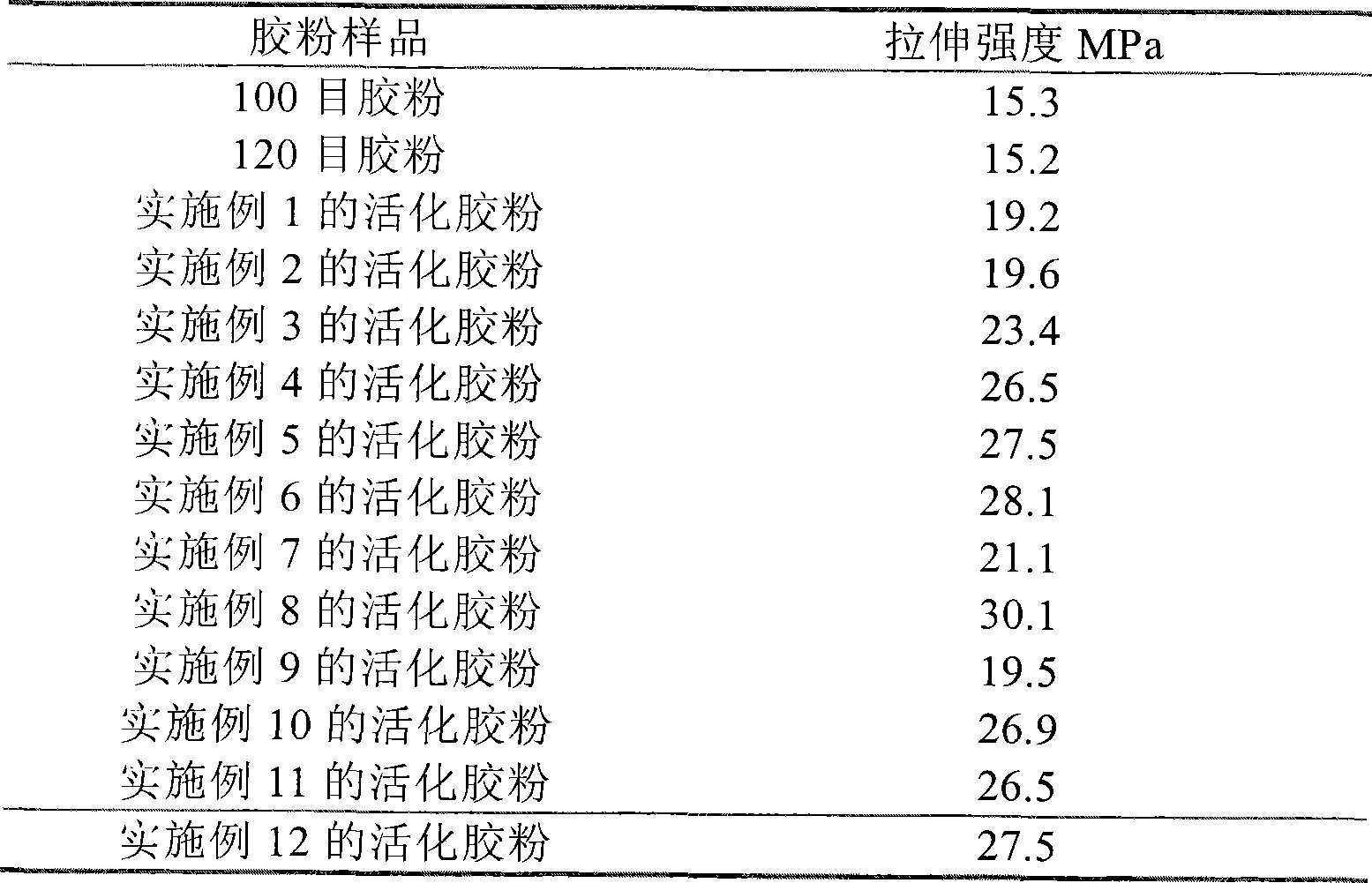

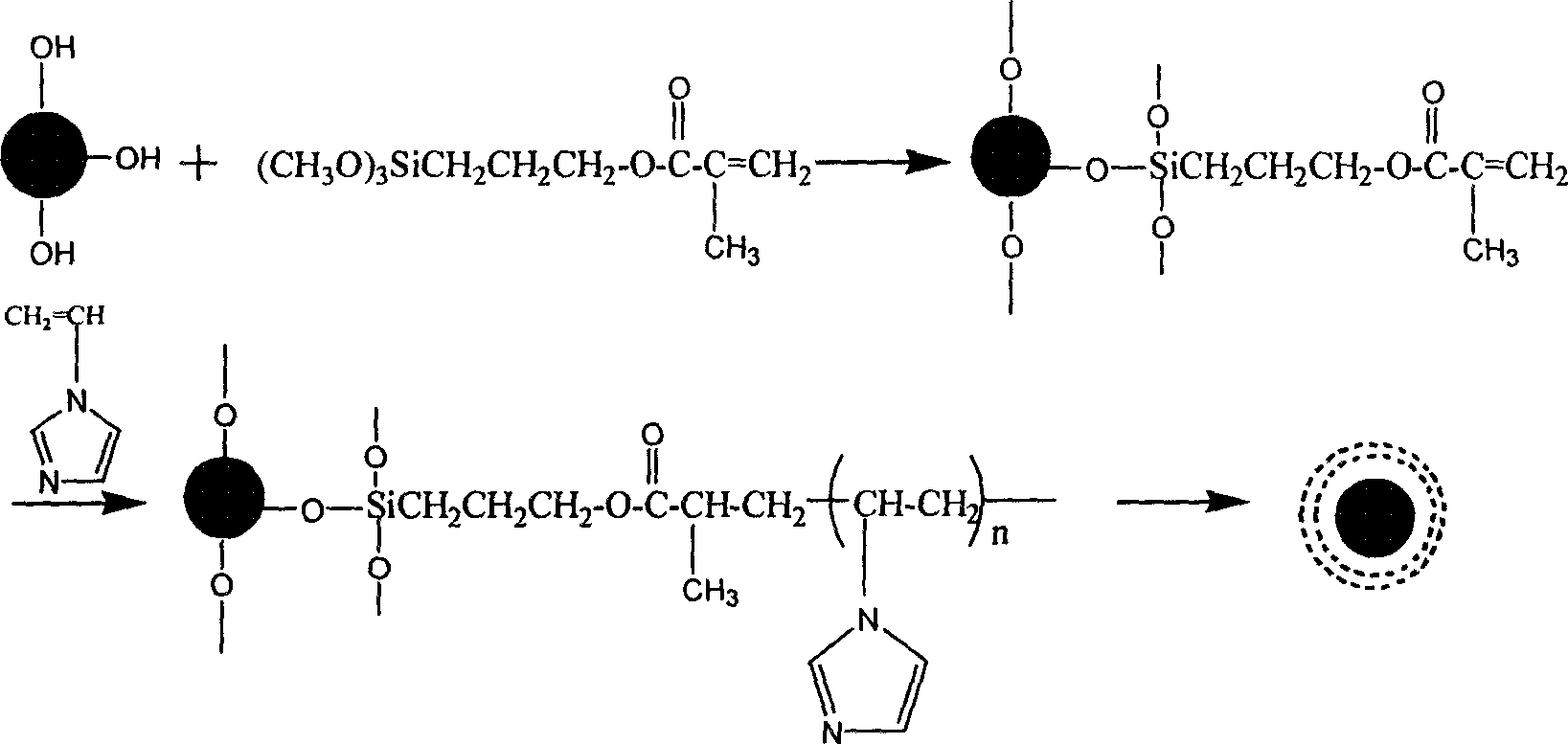

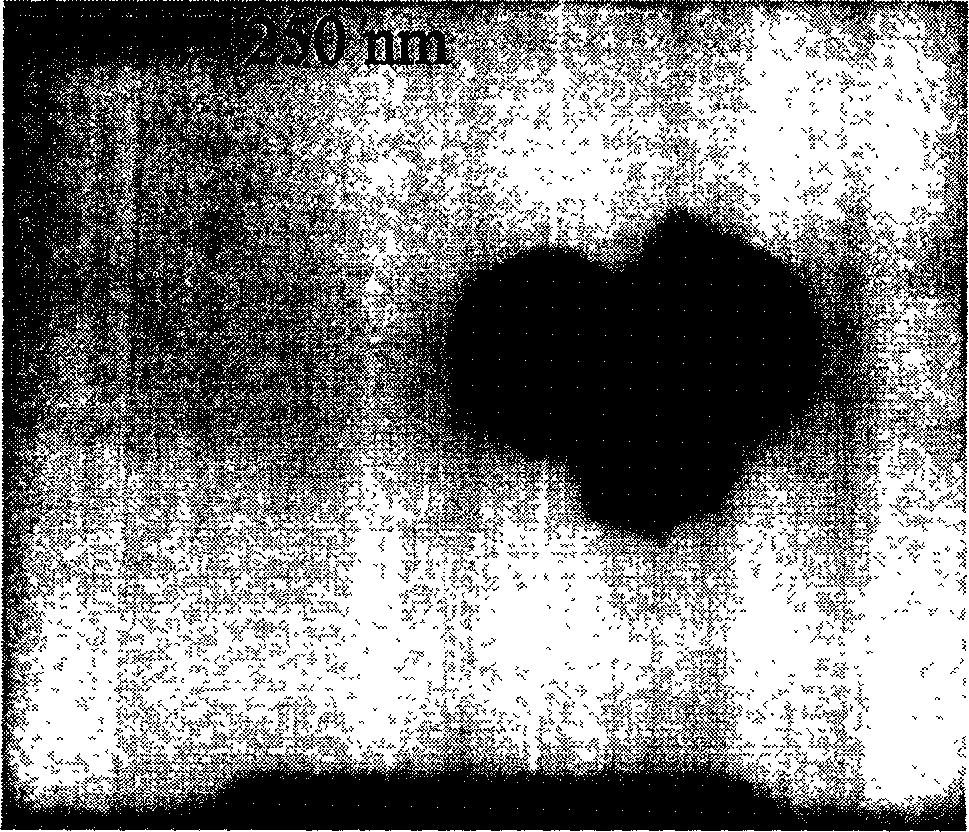

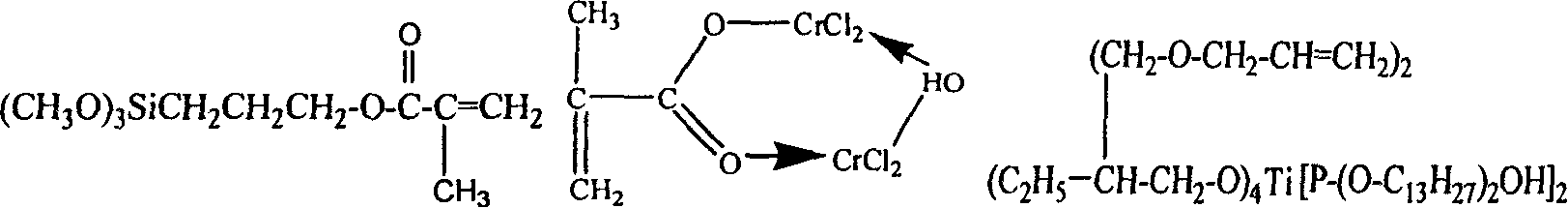

The invention provides activated waste rubber powder and a preparation method thereof. The components by weight of the activated waste rubber powder are: waste rubber powder accounts for 40 to 60 percent; activator accounts for 60 to 40 percent; and initiator accounts for 0.005 to 0.015 percent of the total weight of a composition, wherein the sum of the weight percentages of all the components is 100 percent. The preparation method is characterized in that fine rubber powder of waste tires and the activator form graft copolymer, interpenetrating polymer networks or wrapping-winding structures under the action of the initiator, so as to change the surface activity of the rubber powder and improve the compatibility between the rubber powder and polymer materials, particularly the polymer materials of the same type with the activator. The rubber powder can be used for the blending modification or copolymerization with polystyrene, polyvinyl chloride, polyethylene or polymethyl methacrylate and other materials, thereby improving the shock resistance of the materials, reasonably utilizing the waste tires, saving energy and reducing emission.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Tungsten trioxide/polymer nano core-shell microsphere and preparing process thereof

InactiveCN1634647AChange optical propertiesChange thermal propertiesMicroballoon preparationMicrocapsule preparationOrganic solventMicrosphere

This invention relates to a tungsten trioxide and polymer nanometer shell micro ball and the process method, which belongs to organic and inorganic, compound materials technique field and are processed by emulsion polymerization on the surface of tungsten trioxide particles. It covers macromolecule materials on the tungsten trioxide nanometer particles to avoid the reaction between outer environments with the particles and to alter the particles optics properties and it together with other organic semi-conductor makes effective compound to improve its photoelectricity property or process property.

Owner:ZHEJIANG CHANGE ORGANIC SILICON MATERIAL

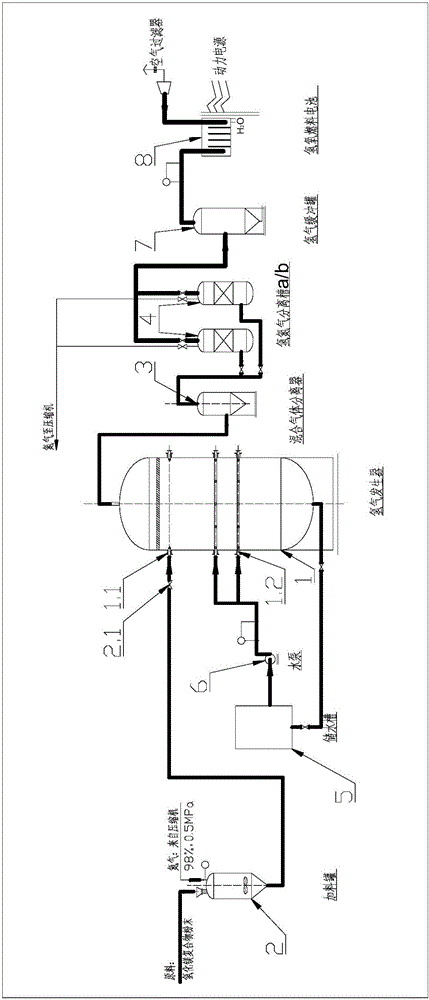

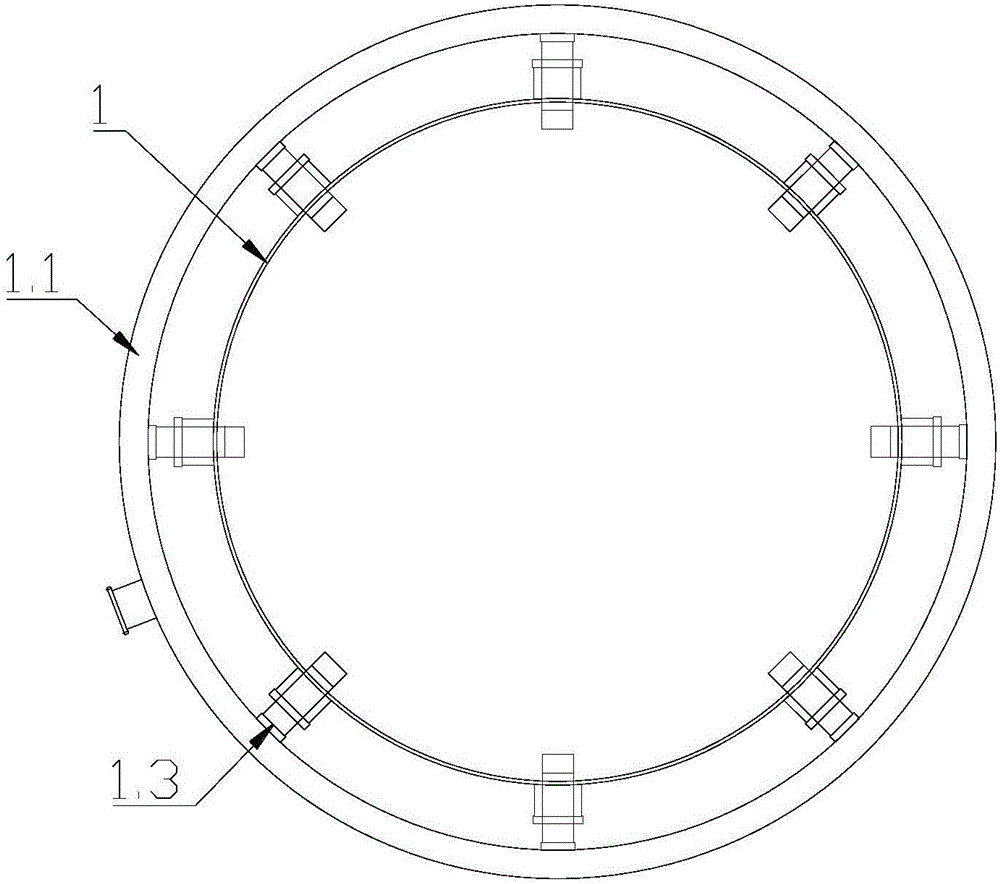

Magnesium hydride compound powder, preparation method thereof and hydrogen preparation and storage integrated device adopting magnesium hydride compound powder

ActiveCN106006552AImprove reaction kineticsChange in surface activityHydrogen productionHydrogen/synthetic gas productionMagnesium hydrideMagnesium

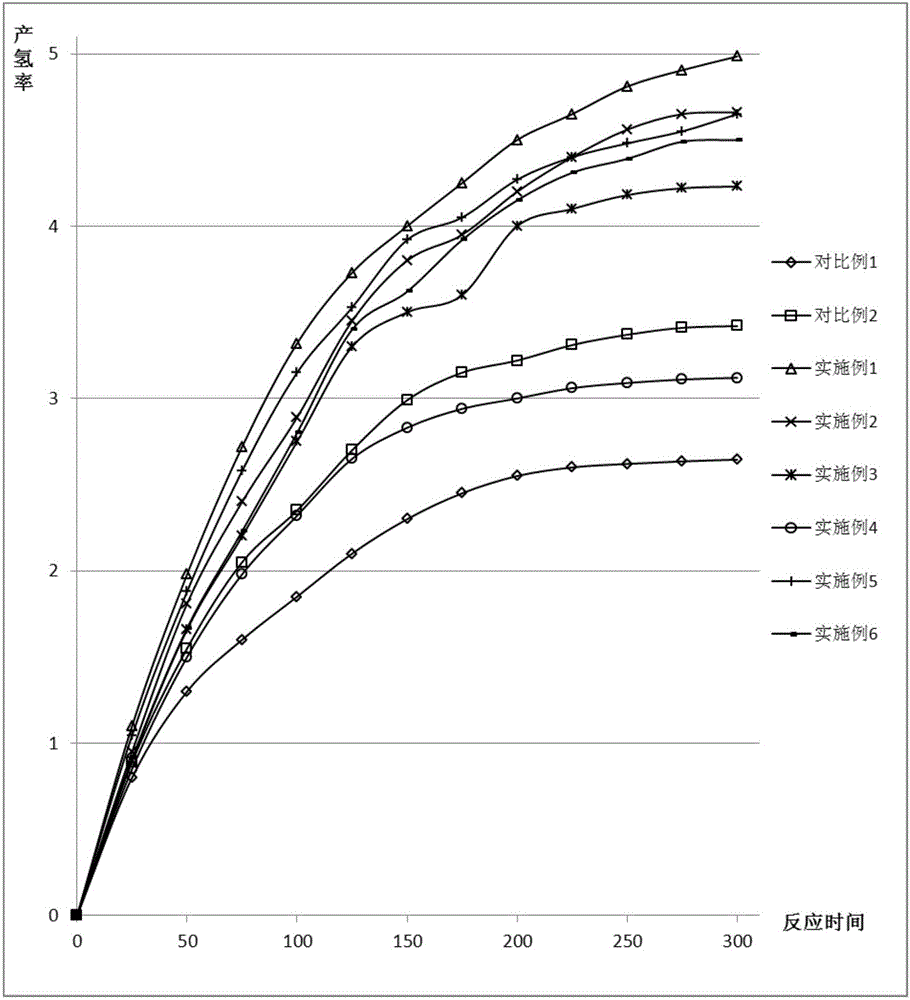

The invention discloses magnesium hydride compound powder. The magnesium hydride compound powder is mainly prepared from raw materials in parts by weight as follows: 100 parts of magnesium powder, 5.3-11.4 parts of graphite, 0.5-2.3 parts of graphene and 0-1.7 parts of an antioxidant, the raw materials are subjected to ball milling for 1-2.5 h at the temperature of 150-200 DEG C under the hydrogen atmosphere, and the magnesium hydride compound powder with the particle size of 15-25 nm is prepared. The invention further discloses a hydrogen preparation and storage integrated device adopting the magnesium hydride compound powder. The hydrogen preparation and storage integrated device comprises a feeding device, a water supply device, a hydrogen generator and a hydrogen separation device, wherein a powder spraying device and a water spraying device are arranged on the hydrogen generator; a powder output port of the feeding device is connected with a powder input port of the powder spraying device; a water outlet of the water supply device is connected with a water inlet of the water spraying device; a mixed gas input port of the hydrogen separation device is connected with a mixed gas output port of the hydrogen generator. A small amount of graphite and graphene is added to magnesium hydride, and reaction kinetics of magnesium hydride is improved; the raw materials and water are added to the hydrogen generator in a spraying manner, so that the reaction efficiency is improved.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Low-temperature cashmere dyeing method adopting ethanolamine for pretreatment

The invention discloses a low-temperature cashmere dyeing method adopting ethanolamine for pretreatment. The method is characterized by pretreating cashmere with ethanolamine at a concentration of 6-10g / l at 30 DEG C in a bath ratio of 1:50, carrying out water bathing for 10-20 minutes, carrying out steaming for 5-10 minutes at 100 DEG C, after pretreatment, using a dye with volume concentration of 5-10%, adding 6g / l anhydrous sodium sulfate and 8g / l peregal 0, regulating the pH value to 4-5, carrying out water bathing and adding a low-temperature aid for dyeing at 80 DEG C, wherein the dye is an acid dye or a reactive dye; the bath ratio of water bathing in the dyeing step is 1:50 and the time is 60-80 minutes; the low-temperature aid is JL-D or ZJ-W; and the volume concentration of the low-temperature aid is 0.5-2%. The method has the obvious advantages that the strength of the yarns after dyeing is 15% higher than that after normal dehaired wool dyeing; the yarn spinnability can be greatly improved; and the damages of dyeing to fibers can be reduced.

Owner:TAICANG SHARTEX SHENTAI SWEATER

Cleaning technology for changing metal surface activity

InactiveCN105970242AChange in surface activityGood subsequent processing performanceRadio frequencyIon

Owner:SHENZHEN XINCHENGNUO ENVIRONMENTAL PROTECTION IND CO LTD

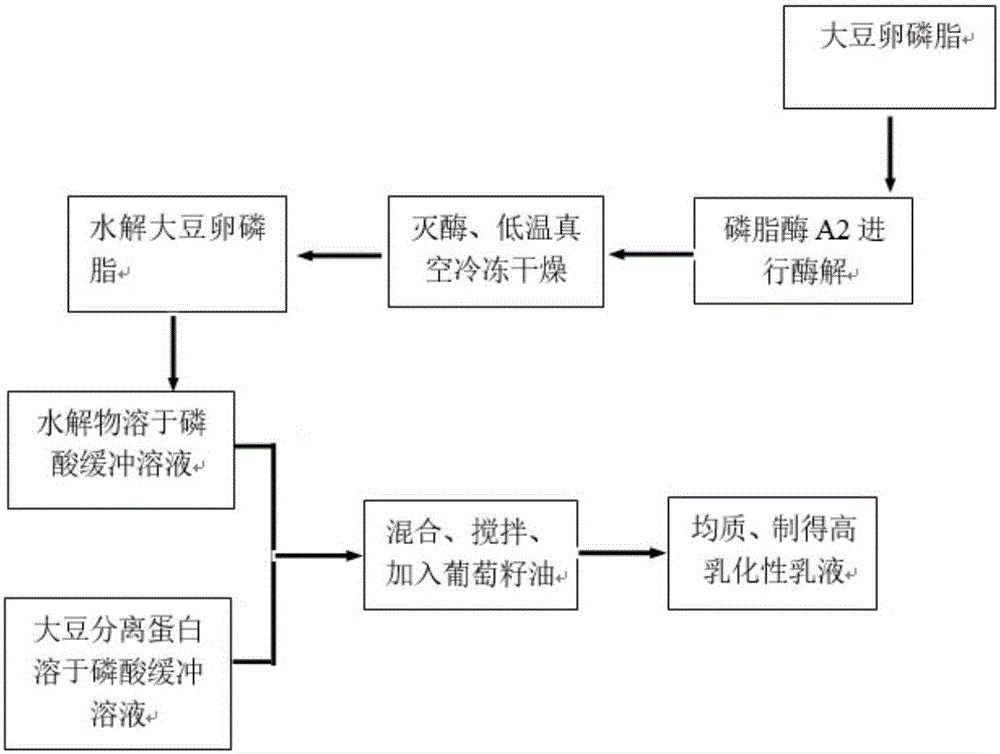

Preparation method of soybean protein emulsion with high emulsibility

InactiveCN105076669ANon-polar group reductionImprove hydrophilicityVegetable proteins working-upFreeze-dryingPhosphoric acid

The invention relates to a preparation method of a soybean protein emulsion with high emulsibility, and belongs to the field of deep processing of soybean protein. The method comprises the following steps: dissolving soybean lecithin to obtain a soybean lecithin solution, then adding phospholipase A2 for enzymolysis, and after enzymolysis, freeze-drying the soybean lecithin solution so as to obtain hydrolyzed soybean lecithin powder; dissolving the hydrolyzed soybean lecithin powder into a phosphoric acid buffer solution, and magnetically stirring the hydrolyzed soybean lecithin powder and the phosphoric acid buffer solution until the hydrolyzed soybean lecithin powder is completely dissolved to obtain a hydrolyzed soybean lecithin solution; dissolving soy protein isolate into the phosphoric acid buffer solution, and magnetically stirring the soy protein isolate and the phosphoric acid buffer solution until the soy protein isolate is completely dissolved to obtain a soybean protein solution; and mixing the hydrolyzed soybean lecithin solution and the soybean protein solution to obtain mixed liquor, adding grape seed oil to the mixed liquor, and performing homogenizing treatment so as to obtain the soybean protein emulsion with high emulsibility. The composite emulsion obtained by the method is high in emulsifying activity, high in emulsifying stability, safe and harmless, and is suitable for food trade and the like. In addition, the method also has the characteristics of being simple in technology, mild in reaction conditions, safe to operate and the like.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

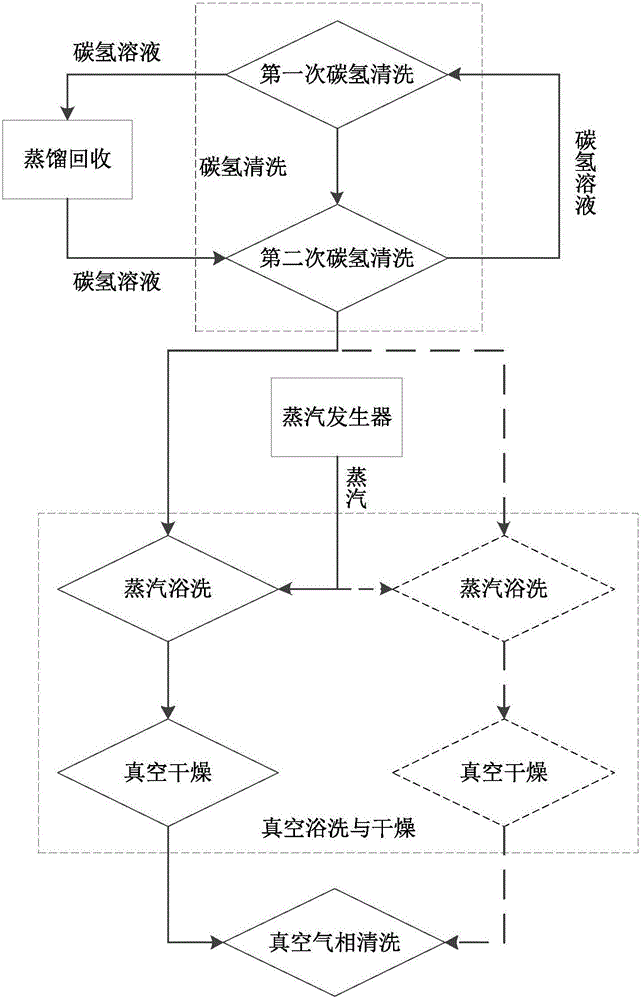

Method for removing flux from surface of substrate and chip on substrate

InactiveCN107611008AChange in surface activityImprove surface bonding stateSemiconductor/solid-state device manufacturingWater basedBonding process

The invention discloses a method for removing flux from the surface of a substrate and a chip on the substrate. The method comprises the following steps of 1, cleaning flux on the substrate and the chip on the substrate by a water-based cleaning reagent firstly; 2, performing cleaning on the substrate and the chip on the substrate after being cleaned in the step 1 by adopting a bromopropane gaseous phase cleaning technology; and 3, performing argon plasma cleaning on the substrate and the chip on the substrate after being cleaned in the step 2 by adopting a plasma cleaning system. By adoptionof the method, the flux and pollutants on an electronic assembly can be removed, and the residual flux in the tiny gaps also can be completely taken away; in addition, the surface activity on the electronic assembly also can be changed, and the surface bonding state between a transmission line and a gold wire bonding pad also can be improved, thereby improving the bonding adhesive property and improving the bonding process reliability; by virtue of the method, the cleaning efficiency is improved, the yield is high and the process is simple; and low toxicity can be realized as far as possible on the basis that the cleaning capability can be satisfied, and strong respiratory tract irritation can be avoided.

Owner:SUZHOU HUIHUA ELECTRONICS TECH

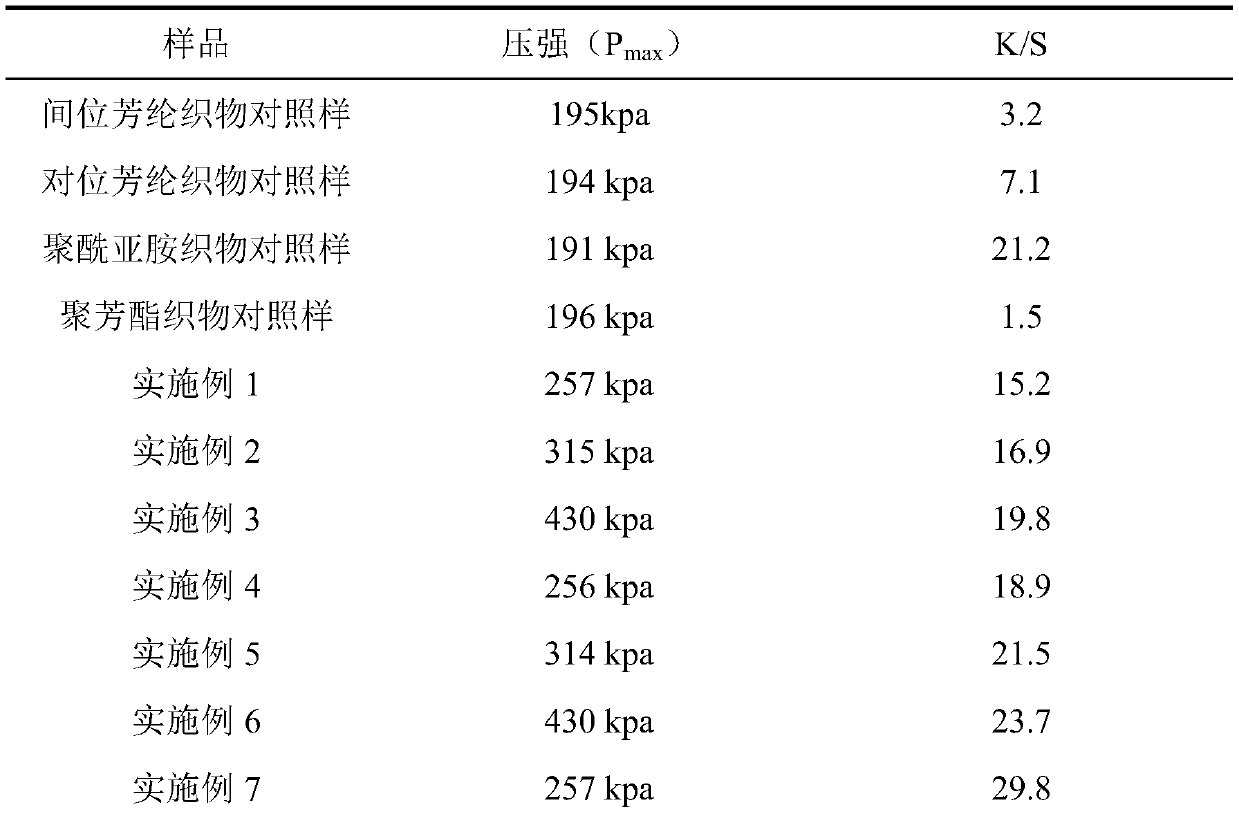

High-performance fabric self-pressurization carrier dyeing method

The invention relates to a high-performance fabric self-pressurization carrier dyeing method and belongs to the technical field of textile printing and dyeing. According to the method, carbon dioxideand ammonia gas generated by thermal decomposition of ammonium bicarbonate are utilized in the dyeing process of a high-performance fabric, the carbon dioxide enables the pressure intensity in a closed space of a dyeing cup to be increased, the solubility of the ammonia gas to rise and the amount of formed ammonia water to be increased, the polarity of the ammonia water is strong, the surface activity of fiber can be changed, and it is facilitated that the active chlorine generated by the complexation effect of N,N-dimethylacetamide and sodium chloride acts on the high-performance fiber, the hydrogen bonding force among macromolecular chains of the fiber is weakened, and the porosity of the fiber is improved. The N,N-dimethylacetamide has strong polarity under the low temperature dyeing condition of 70-90 DEG C, the dissolving concentration of dye can be effectively improved, the micelle concentration of the dye is reduced, the dye molecules are easy to adsorb and dye the high-performance fabric, and the dyeing efficiency of the high-performance fabric is effectively improved. In addition, the method can achieve a better dyeing effect at a relatively low dyeing temperature, and theproduction cost and the energy consumption are reduced.

Owner:WUHAN TEXTILE UNIV

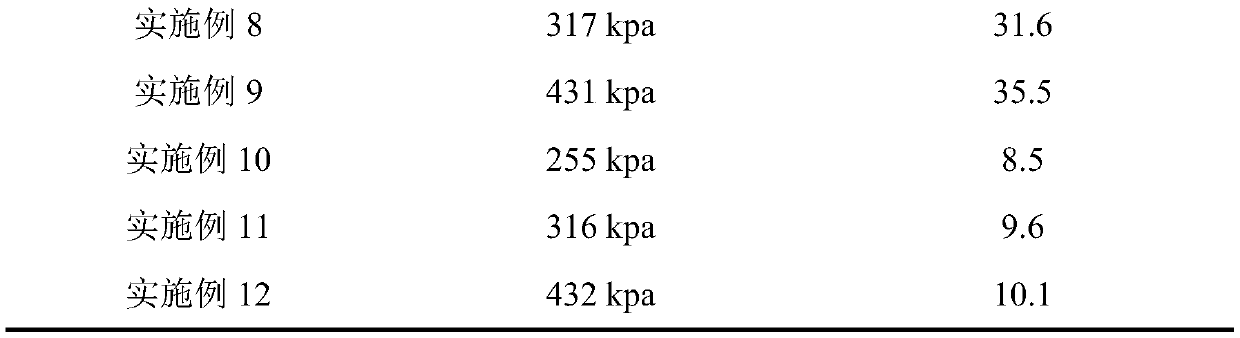

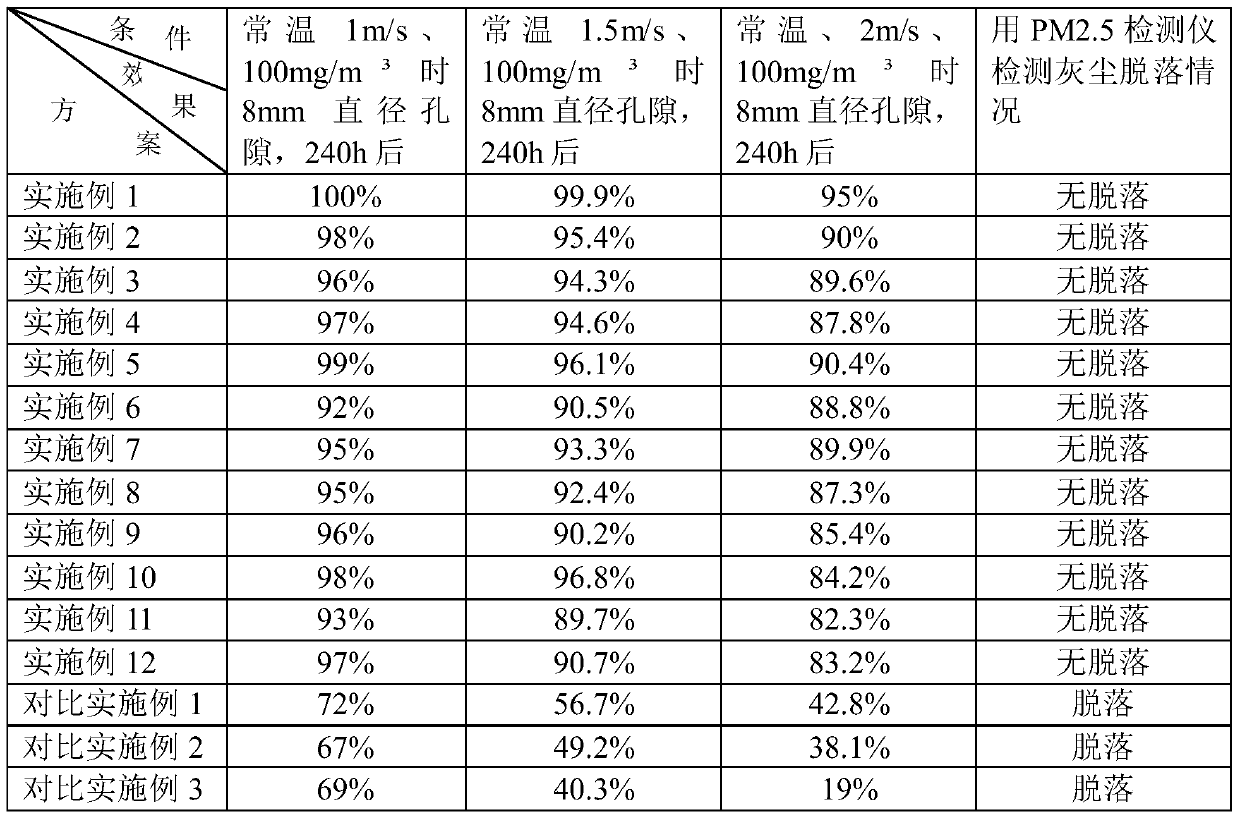

Ozone elimination catalyst with porous substrate as carrier and preparation method thereof

ActiveCN105056948ANo secondary dust pollution will occurImprove wind resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPorous substratePolyvinyl alcohol

The invention relates to an ozone elimination catalyst with a porous substrate as the carrier. The ozone elimination catalyst is prepared by loading a coating solution on the porous substrate. The coating solution comprises the following active ingredients by weight: 0.8-1.2 parts of stearic acid sorbitol ester, 1.6-2.4 parts of OP-10, 4.2-5.8 part of polyethylene glycol, 0.15-0.85 part of carboxymethyl cellulose sodium, 1.1-1.9 parts of polyvinyl alcohol, 3.2-4.8 parts of vinyl acetate, 90-110 parts of water, and 2-50 parts of a nano-metal oxide. The invention also provides a preparation method of the ozone elimination catalyst with the porous substrate as the carrier. The prepared catalyst has the advantages of long service life, low cost, small wind resistance, and no secondary dust.

Owner:THE JUYE HAILIN ENVIRONMENTAL EQUIP ENG

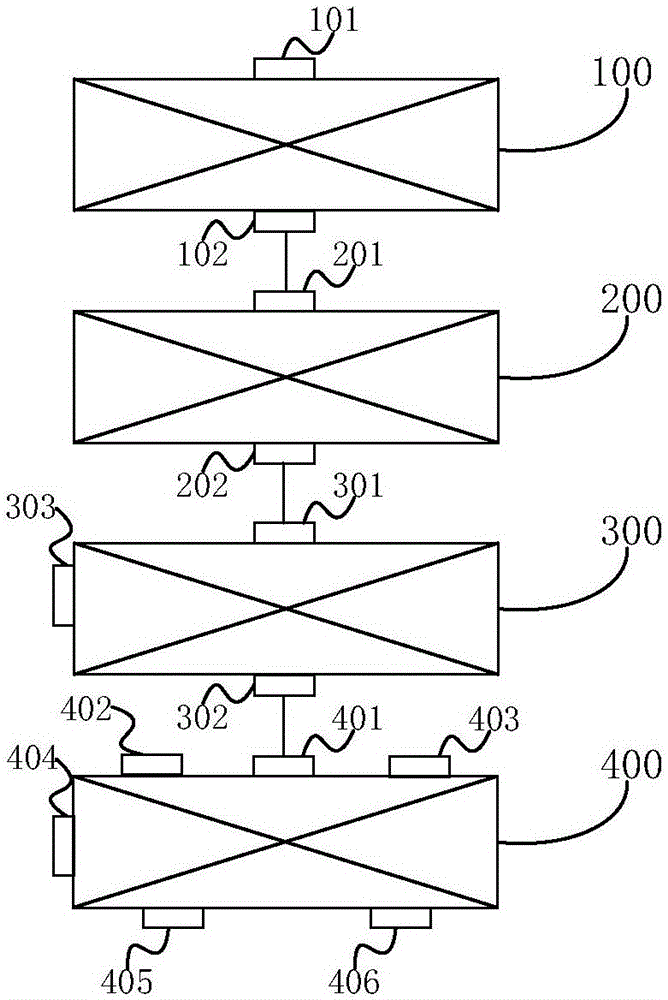

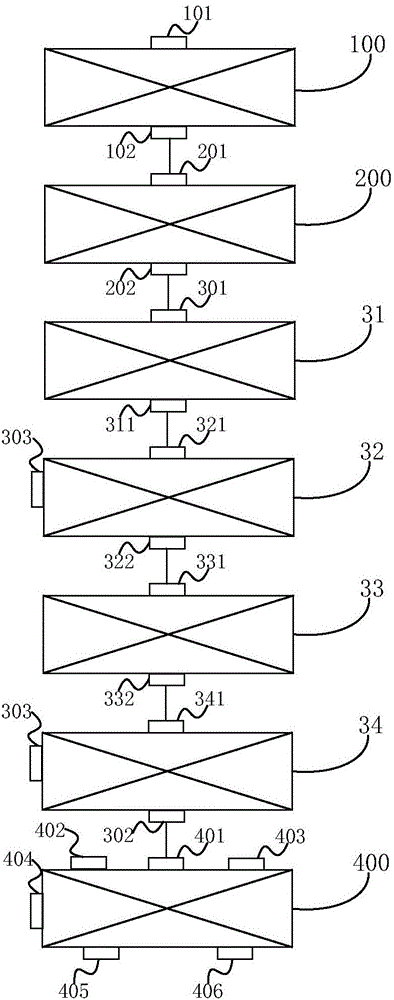

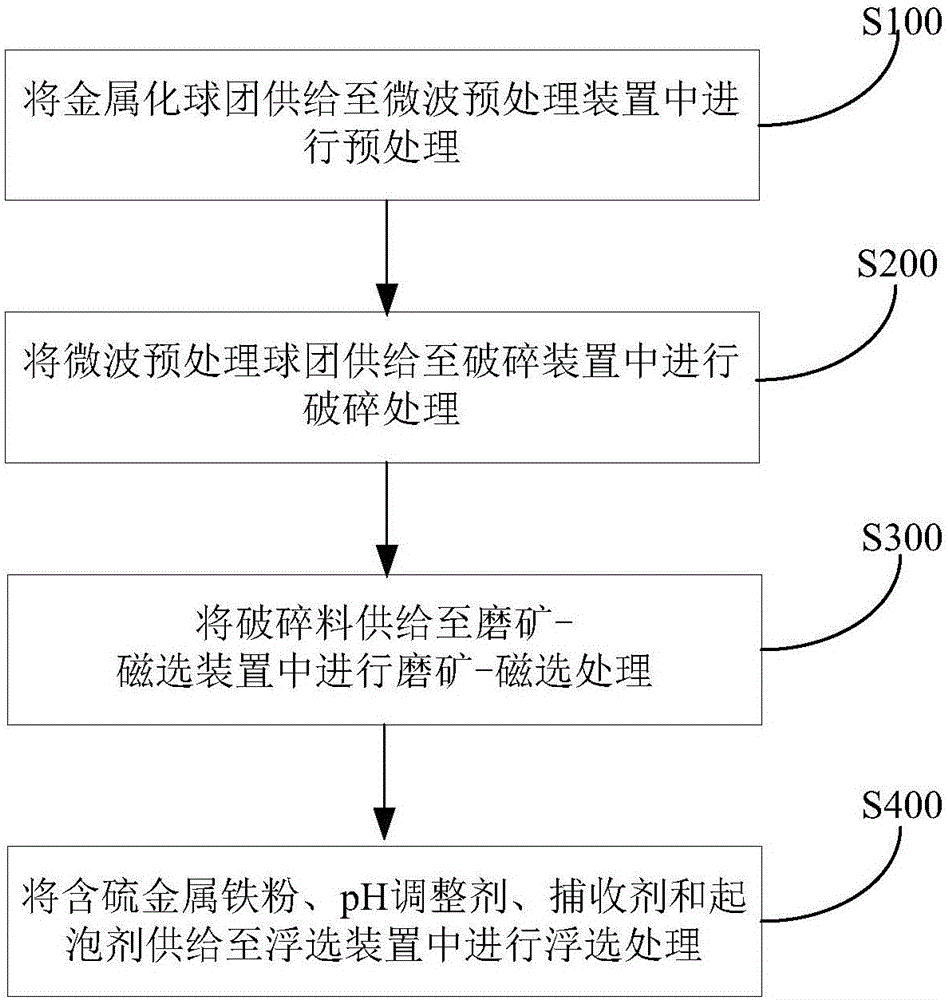

System and method for preparing low-sulfur iron powder

The invention discloses a system and a method for preparing low-sulfur iron powder. The system comprises a microwave pretreatment unit, a crushing device, an ore grinding and magnetic separating unit and a flotation unit, wherein the microwave pretreatment unit is provided with a metalized pellet inlet and microwave pretreated pellet outlet; the crushing device is provided with a microwave pretreated pellet inlet and a crushed material outlet; the ore grinding and magnetic separating unit is provided with a crushed material inlet, a sulfur-containing metal iron powder outlet and a tailings outlet; the flotation unit is provided with a sulfur-containing metal iron powder inlet, a pH regulating agent inlet, a collecting agent inlet, a foaming agent inlet, a low-sulfur iron powder outlet and a ferrous sulfide outlet. The system can be used for treating a metalized pellet to obtain low-sulfur iron powder (the sulfur content can be reduced to about 0.1%), and the product quality is improved, so full utilization of iron-containing resources is widened, and full recycle (the grade and recovery rate of iron can be as high as 90%) of iron element and sulfur element is realized as well.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

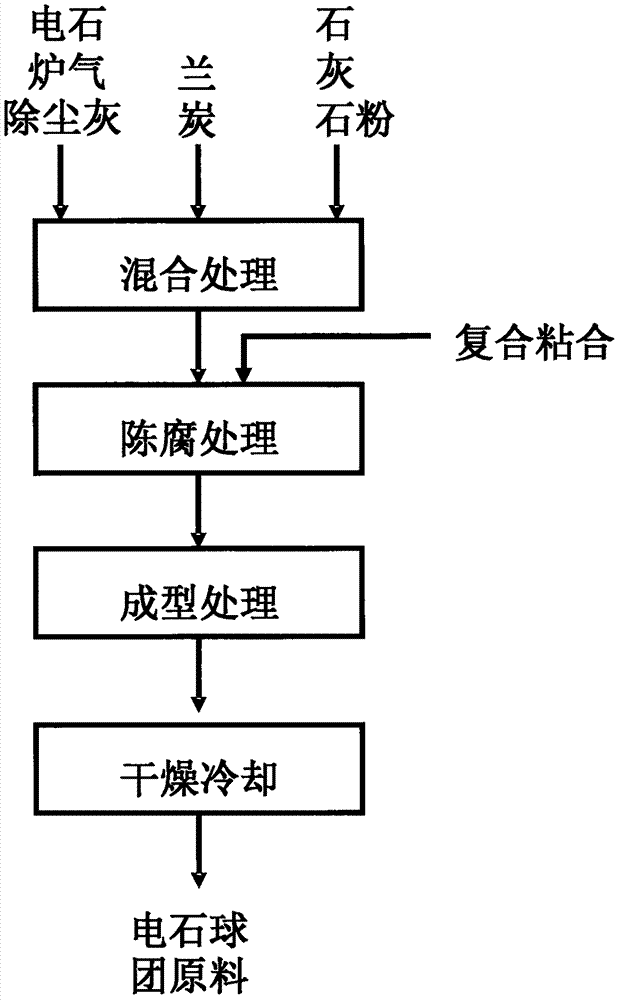

Method for producing calcium carbide pellet raw material by recycling calcium carbide furnace gas fly ash, semi-coke powder and lime powder

The invention relates to a method for producing calcium carbide pellet raw material by recycling calcium carbide furnace gas fly ash, semi-coke powder and lime powder. The method comprises the following steps: (1) uniformly mixing the calcium carbide furnace gas fly ash, semi-coke powder and lime powder in a proper ratio according to composition of the raw material, so that a mixture is obtained; (2) adding water into the mixture and humidifying, adding composite adhesive at the same time, uniformly stirring by adopting a stirring machine and then carrying out ageing and homogenizing treatment; (3) feeding the aged powdery product into a roll-type forming machine to be formed, so that solid pellets in a certain shape are obtained; and (4) drying the solid pellets by utilizing hot flue gas generated in combustion of a hot air furnace. The method provided by the invention utilizes solid waste produced in calcium carbide production, and environmental pollution is avoided; and the composite adhesive is added, so that heat intensity of the pellets is improved, and organic adhesive improves cold intensity of the pellets.

Owner:北京柯林斯达科技发展有限公司

Copper-iron intermediate alloy and preparing method thereof

The invention discloses copper-iron intermediate alloy and a preparing method thereof. The copper-iron intermediate alloy is prepared from, by mass percentage, 20-50% of Fe, 0.01-1.0% of Ni, 0.01-1.0%of Cr, 0.01-0.5% of Mg, 0.01-0.5% of Y, 0.01-0.05% of S, 0.005-0.03% of P and the balance copper and other inevitable trace impurities. The invention further provides a preparing method of the copper-iron intermediate alloy. Ni, Cr, Mg, Y, S, P and other various metal elements are added, and a technology of combining smelting with compressed air blowing and quick cooling is adopted under a non-vacuum condition. According to the copper-iron intermediate alloy prepared by means of the method, segregation and beneficiation of iron in ingot casting are avoided, the component homogeneity is greatly improved, and can reach the range of + / -2%, and the average size of the iron-rich phase is smaller than or equal to 50 micrometers.

Owner:JINTIAN COPPER GROUP CORP NINGBO

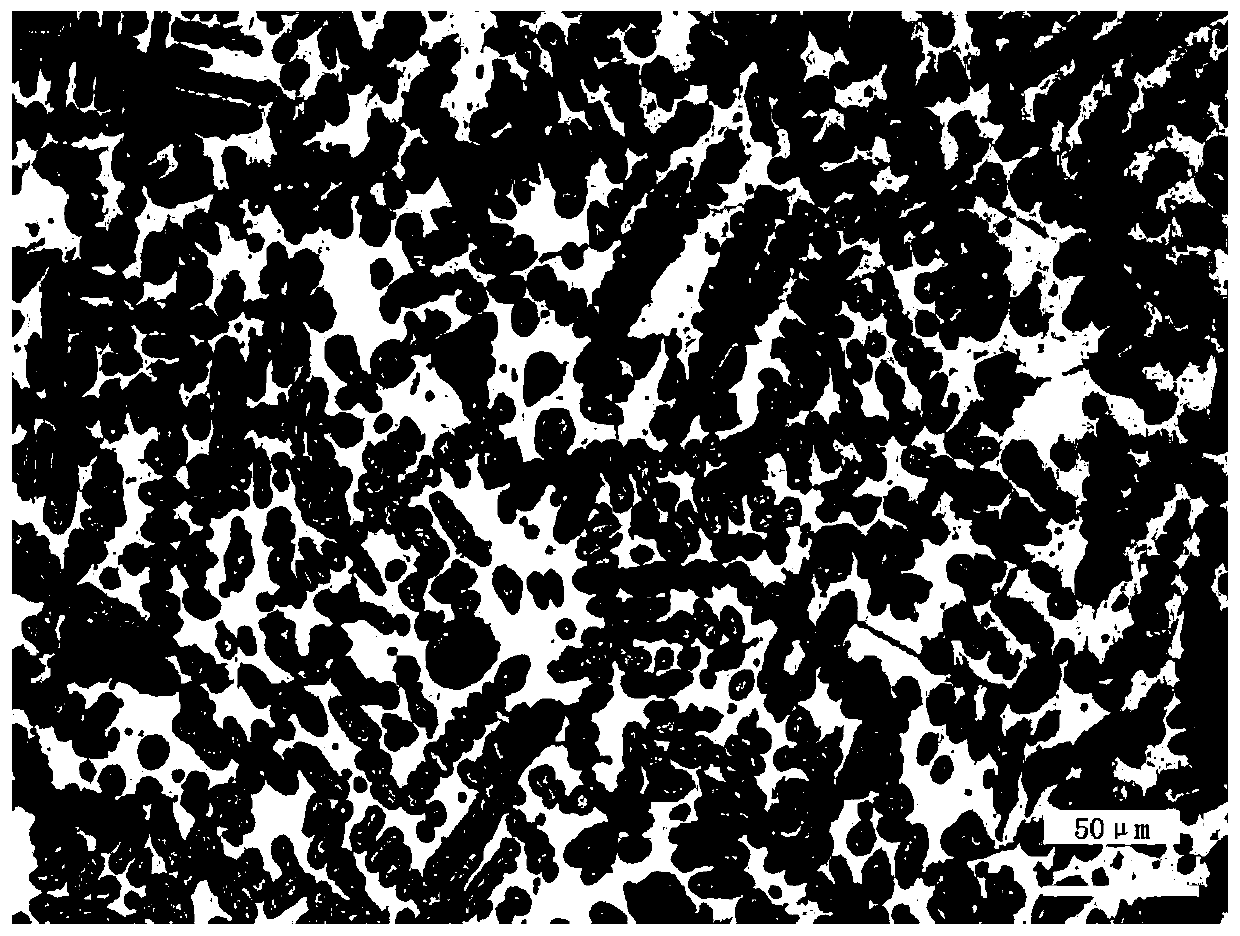

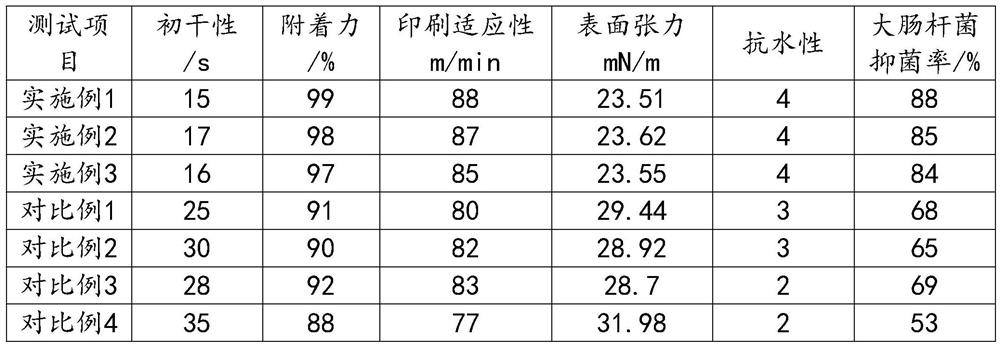

Environment-friendly printing ink and preparation method thereof

The invention discloses environment-friendly printing ink. The environment-friendly printing ink contains the following raw materials in parts by weight: 40-60 parts of modified water-based acrylic resin, 5-10 parts of nano-composite fillers, 3-5 parts of a functional aid, 10-20 parts of soybean oil fatty acid ethyl ester, 3-5 parts of an anti-skinning agent, 25-30 parts of a coupling agent, 1-3 parts of a defoamer and 5-10 parts of a slipping agent. The invention further discloses a preparation method of the printing ink. The modified water-based acrylic resin, the soybean oil fatty acid ethyl ester and the coupling agent are taken as the main materials, and the nano-composite fillers, the functional aid, the anti-skinning agent, the defoamer and the slipping agent are added to prepare the printing ink, and the prepared printing ink does not contain heavy metal additive and harmful organic additive and has the characteristics of environmental friendliness, no pollution, high heat resistance, good adsorbability and high antibacterial performance.

Owner:付正谋

Environment-friendly bentonite adsorbent and preparation method thereof

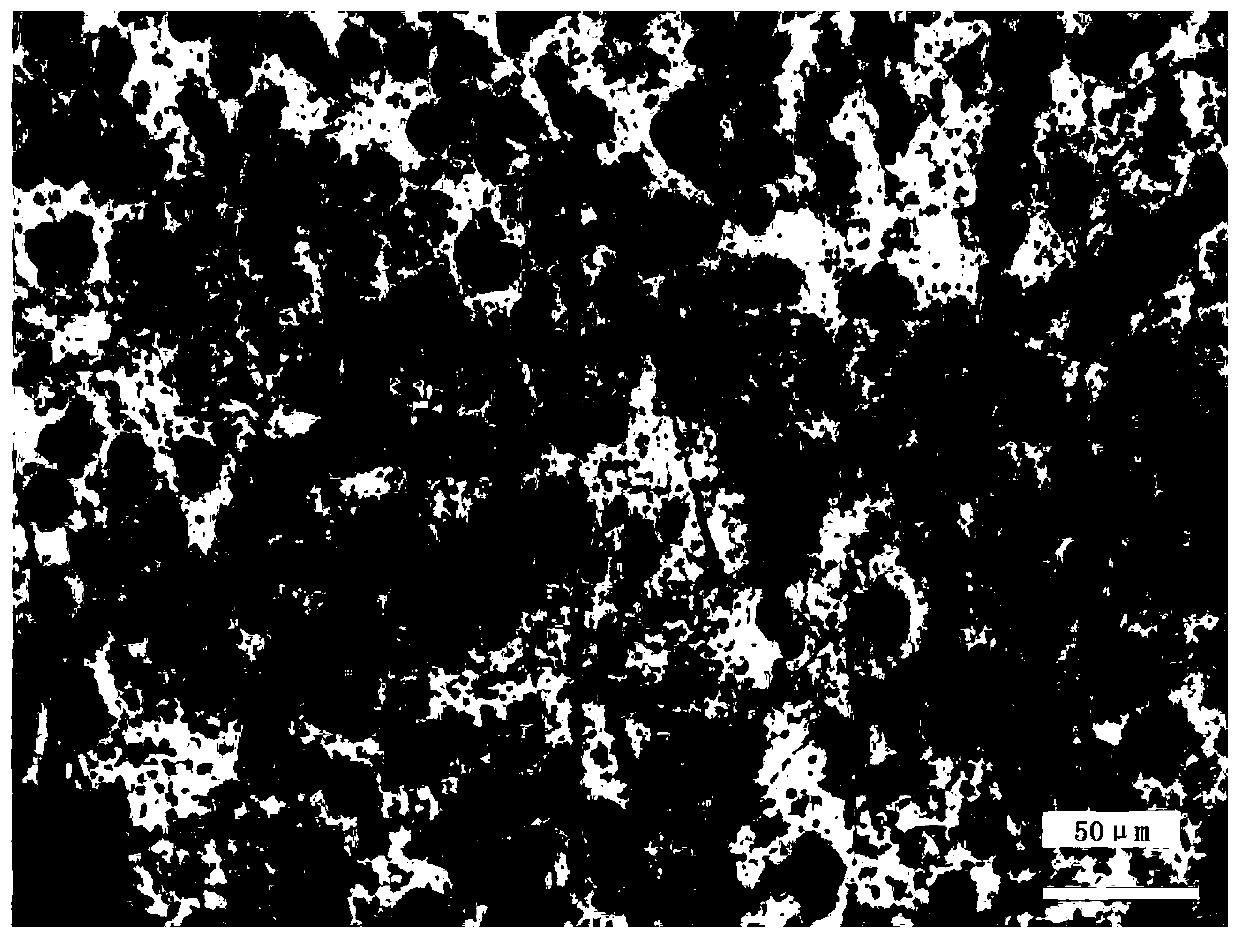

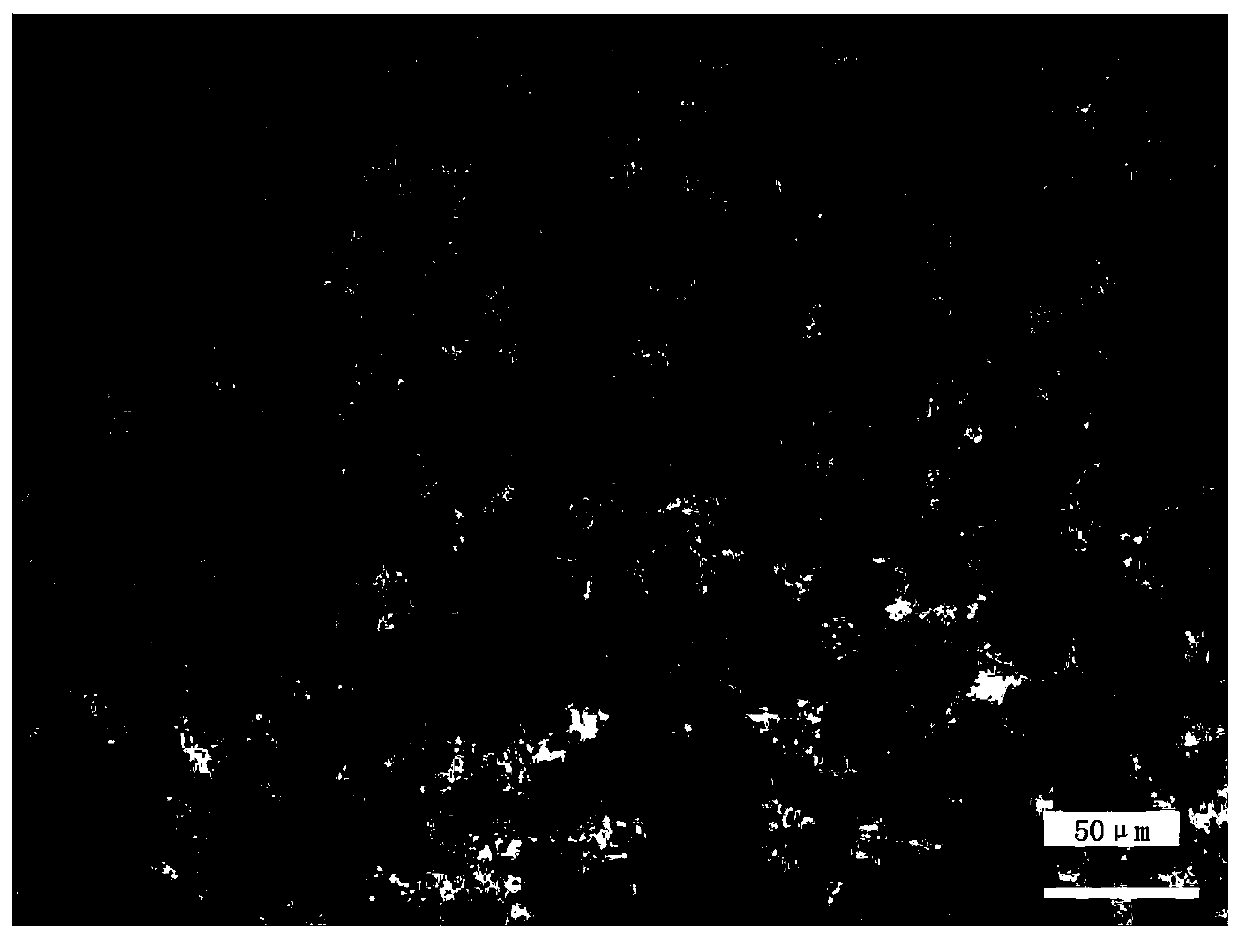

InactiveCN107321332AImprove adsorption capacityHigh grafting rateOther chemical processesMicro structureSodium Bentonite

The invention relates to the field of materials, in particular to an environment-friendly bentonite adsorbent and a preparation method thereof. The environment-friendly bentonite adsorbent is prepared from, by weight, 60-75 parts of bentonite, 7-13 parts of chitosan, 4-5 parts of starch, 4-5 parts of partially hydrolyzed polyacrylamide, 0.7-1.5 parts of cetyl trimethyl ammonium bromide and 11-15 parts of microbead particles with the particle size of 0.1-5 microns. Through the modification of the micro-bead particles and the bentonite by various organic substances, the adsorbent with a good adsorption property is finally prepared. The partially hydrolyzed polyacrylamide can be effectively grafted onto the starch to increase the grafting rate of nonionic groups on the starch. The microbead particles are filled among bentonite particles. Through the modification of the outer surfaces of the micro-bead particles and bentonite by the organic substances, the surface activity and micro-structures of interlayers are changed to improved the adsorption property of the adsorbent.

Owner:重庆卡美伦科技有限公司合川分公司

Graphene water-borne heating film conductive slurry

InactiveCN110769528AAdhesiveThe overall thickness is thinHeating element materialsEpoxyConductive paste

The invention discloses a graphene water-borne heating film conductive slurry. The graphene water-borne heating film conductive paste is characterized by being prepared by mixing three different slurry which are slurry A, slurry B and slurry C; the slurry A is prepared from carbon nanotubes, a first dispersant and deionized water; the slurry B is prepared from spherical conductive carbon black, asecond dispersant and deionized water; the slurry C is prepared from graphene, a third dispersant, a binder and deionized water; and a water-borne binder is selected, and the three slurry are subjected to compound preparation to finally obtain the graphene water-borne heating film conductive slurry. First, graphene is modified, and epoxy resin monomer is added for emulsification to enable the modified grapheme to be more cohesive; and according to the characteristics of the carbon nanotubes, the carbon nanotube dispersant is added to change the surface activity, so that the carbon nanotubes are connected with other groups more conveniently, and finally different water-borne binders are choosed according to the type of coating so as to obtain the conductive slurry with high-conductivity, thinner coating thickness, more water-borne and environment protection.

Owner:深圳天元羲王材料科技有限公司

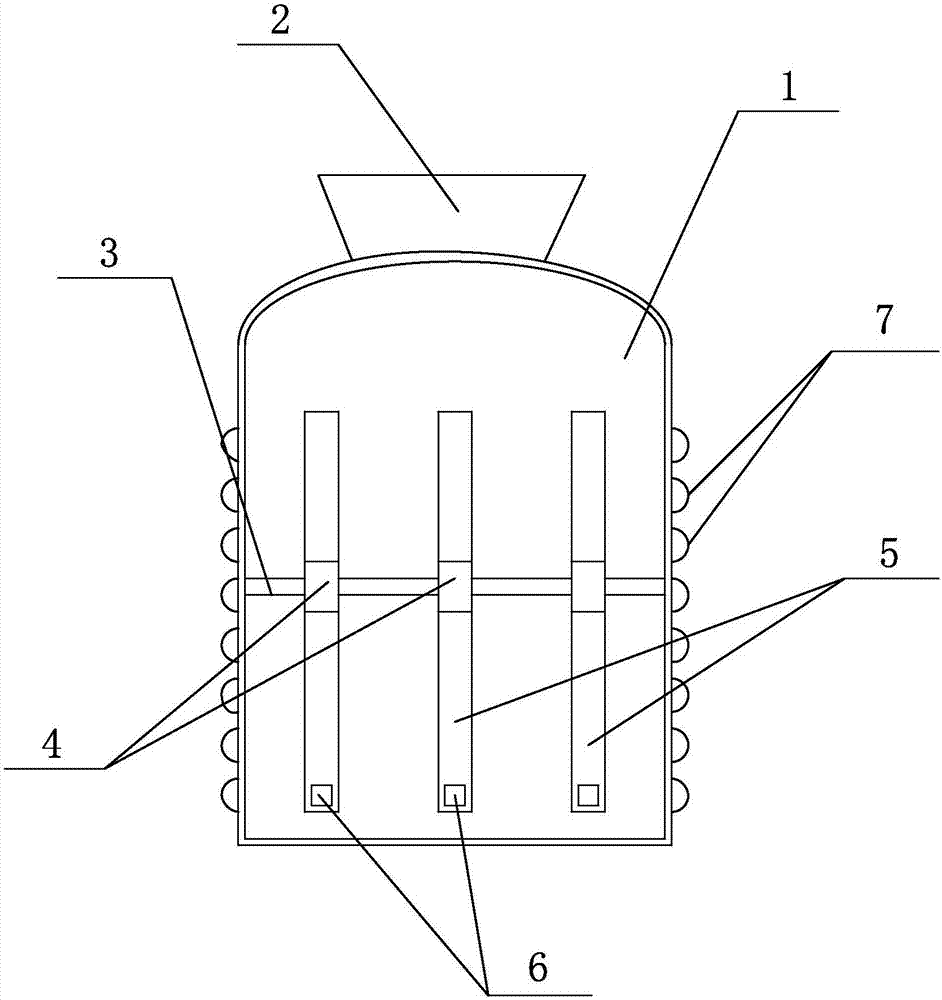

Nanometer material reaction kettle capable for preventing agglomeration

InactiveCN106955656AGood dispersionAvoid reunionShaking/oscillating/vibrating mixersRotary stirring mixersNanoparticleEngineering

The invention discloses a nanometer material reaction kettle capable for preventing agglomeration, which comprises a reaction kettle body, the top of the reaction kettle body is provided with a feed inlet, an atomizer is arranged on the top of the reaction kettle body, and the atomizer is connected to the reaction kettle body through the feed inlet; a magnetic induction coil jackets the reaction kettle body, and the magnetic induction coil is connected to a circuit; a horizontally arranged rotary shaft is arranged in the reaction kettle body, a plurality of agitating groups which are sequentially arranged are arranged on the rotary shaft, each agitating group comprises a plurality of agitator arms which are perpendicularly connected to the rotary shaft, and the side of one end, which is far from the rotary shaft, of each agitator arm is provided with a recess. By atomizing fed material, the reaction kettle disclosed by the invention first increases the dispersivity of the raw material, so that the raw material can be sufficiently stirred, and thereby the production quality is increased; moreover, the magnetic induction coil is utilized to generate a magnetic field to change the surface activity between nanoparticles, consequently, the dispersivity of the material is increased, and the agglomeration between the particles is prevented.

Owner:四川纳诺科技有限公司

Salt-free dyeing technology adopting ethyl alcohol

The invention relates to the technical field of dyeing of textiles, in particular to a salt-free dyeing technology adopting ethyl alcohol. The dyeing technology is used for dyeing wool fabrics, the salt-free dyeing technology under the ethyl alcohol system is adopted, and a dye dissolution agent accounting for 5%-10% of a to-be-dyed fabric by weight is mixed with an ethyl alcohol solution accounting for 90%-95% of the to-be-dyed fabric by weight; the ethyl alcohol is taken as a dyeing carrier and used for dye conveying and energy transmission, the dye dissolution agent is used for dissolving dye, and the dissolved dye and the ethyl alcohol jointly form a dyeing solution; during dyeing, salt does not need to be added, ultraviolet radiation treatment is adopted, quick dyeing can be achieved,and 5% of water can be used as the dye dissolution agent. By means of the method, the application amount of the water and the salt can be significantly reduced, compared with a traditional technology, the application amount of water for dyeing is reduced by 90%-95%, the ethyl alcohol is recycled, and zero-discharge of dyeing is basically achieved; the dyeing time is shortened by 50%, the dyeing temperature is reduced by 10-20 DEG C, the energy is saved by 30% or above, and the sewage problem of the textile industry is solved by adopting the zero-discharge scheme.

Owner:SHANDONG JINING RUYI WOOLEN TEXTILE CO LTD

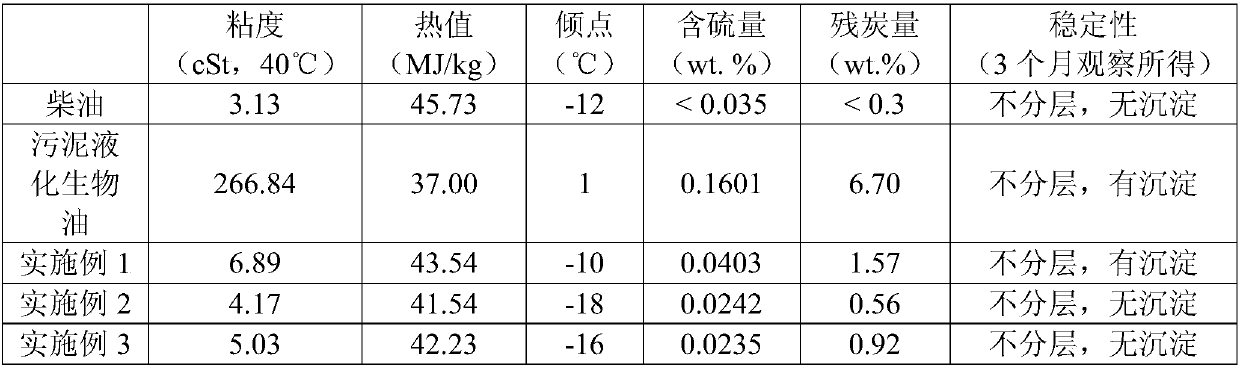

Reversed micelle micro-emulsion and preparation method thereof, and reversed micelle biological oil micro-emulsion and preparation method thereof

InactiveCN107674718AReduce the limitations of application to diesel enginesSmall limitationsLiquid carbonaceous fuelsEmulsionDiesel engine

The invention discloses a reversed micelle micro-emulsion and a preparation method thereof, and a reversed micelle biological oil micro-emulsion and a preparation method thereof, wherein the reversedmicelle micro-emulsion comprises diesel oil, a surfactant, a co-surfactant and ethanol, the co-surfactant content in the reversed micelle micro-emulsion is 0.07-0.15 mL / mL, the ethanol content in thereversed micelle micro-emulsion is 0-0.16 mL / mL, a molar volume ratio of the surfactant to the diesel oil is 0.15-0.50 mol:1 L, and the reversed micelle biological oil micro-emulsion is prepared fromthe reversed micelle micro-emulsion and biological oil. According to the present invention, the biological oil is subjected to solubilization and quality upgrading through the reversed micelle micro-emulsion using the diesel oil as the continuous phase, such that the limitation of the biological oil in the diesel engine is reduced through the constructed reversed micelle biological oil micro-emulsion, and the potential of the biological oil as the transportation fuel is improved.

Owner:HUNAN UNIV

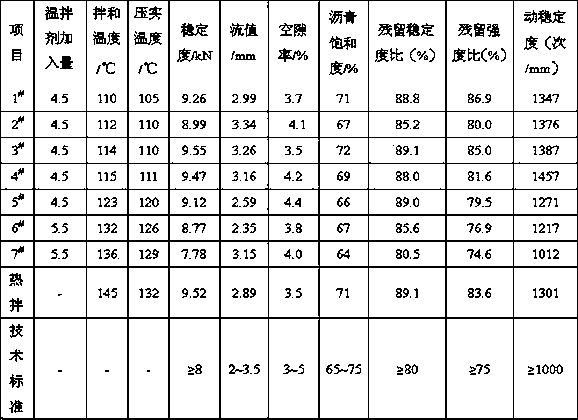

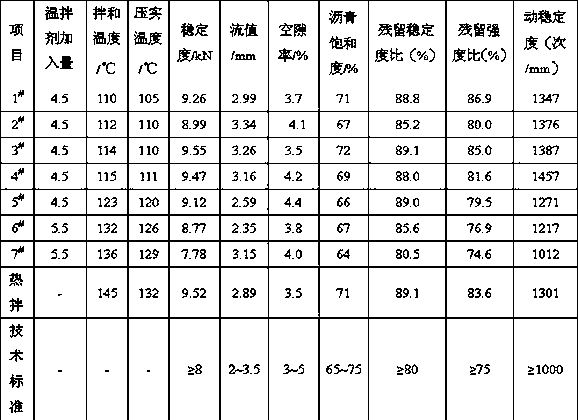

Anionic liquid-crystal-form asphalt warm-mixing agent and preparation method therefor

ActiveCN105623283ASimple ingredientsEasy to prepareClimate change adaptationBuilding insulationsSulfonateFatty alcohol

The invention discloses an anionic liquid-crystal-form asphalt warm-mixing agent and a preparation method therefor. The asphalt warm-mixing agent contains the raw materials in parts by weight: 5.5-40.6 parts of sulfosuccinate, 0.1-20 parts of fatty alcohol and 39.4-94.4 parts of water. The preparation method comprises the following steps: (1) uniformly mixing the water and the sulfosuccinate in a vessel according to a proportioning ratio; and (2) adding the fatty alcohol into a material obtained in the step (1), carrying out uniform mixing, and carrying out standing for a period of time, thereby obtaining the anionic liquid-crystal-form asphalt warm-mixing agent. The asphalt warm-mixing agent disclosed by the invention can be used for effectively lowering the high-temperature viscosity of asphalt and has the advantages that the performance is stable, the raw materials are easily acquired, the preparation method is simple and convenient, the range of application is wide, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Liquid nano combustion material and preparation method thereof

InactiveCN111732978AImprove stabilityImprove durabilityLiquid carbonaceous fuelsCyclohexylaminesSalicylic acid

The invention discloses a liquid nano combustion material and a preparation method thereof. The liquid nano-combustion material is prepared from the following raw materials in parts by weight: 20.0 to 40.0 parts of gasoline, 40.0 to 80.0 parts of methanol, 0.5 to 2.5 parts of modified nano nickel powder, 0.3 to 1.0 part of calcium alkyl salicylate, 5.0 to 8.0 parts of di-tert-butyl peroxide, 1.0to 2.0 parts of tert-butyl dimethyl chlorosilane, 0.05 to 0.10 part of diethylene glycol monoethyl ether, 0.01 to 0.04 part of dibenzoyl peroxide, 2.0 to 4.0 parts of cyclohexylamine and 1.5 to 4.5 parts of catalytic combustion improver. According to the liquid nanometer combustion material prepared by the invention, the compatibility of all the components is good, the components are synergistic,the combustion heat value of the liquid nanometer combustion material can be increased, energy waste is reduced, environmental pollution is reduced, and resources are saved.

Owner:保蓝行福建环保技术研究院有限责任公司

Method for manufacturing recycled propene polymer (PP) and recycled poly ethylene (PE) wood-plastic greenhouse framework material

The invention provides a method for manufacturing a recycled propene polymer (PP) and recycled poly ethylene (PE) wood-plastic greenhouse framework material. The method comprises the steps of mixing wood meal, recycled PP plastics, recycled PE plastics, an antioxidant, filler, a lubricant, a coupling agent and toner, heating the raw materials to 80-90 DEG C, performing heat preservation for 5-10 min, and performing cold mixing for 5-10 min. According to the method, the shortcomings that an existing greenhouse framework material is insufficient in rigidity and toughness are overcome, the prepared greenhouse framework material has the advantages of high rigidity and high toughness and is good in outdoor weather resistance and excellent in deformation resistance, and resources are recycled.

Owner:中山市易高达环保科技有限公司

Low-concentration flue gas desulfurization method for hydroelectric silicon smelting

ActiveCN109482048AReduce emission concentrationReduce generationDispersed particle separationParticulatesSorbent

The invention discloses a low-concentration flue gas desulfurization method for hydroelectric silicon smelting. The method comprises the following steps: 1) preparing absorption slurry, namely fully uniformly mixing a desulfurization adsorbent ground to the granularity of 325-400 meshes and water so as to obtain the absorption slurry; 2) absorbing acid gas, namely enabling the absorption slurry and flue gas to be fully contacted in a desulfurizing tower when flue gas during hydroelectric silicon smelting enters a desulfurization system, so that acid gas and particles in the flue gas are absorbed by the absorption slurry; and 3) discharging the flue gas, namely detecting the emission concentration of SO2 at the outlet, discharging the SO2 while meeting requirements, if not, returning to thedesulfurization system to treat, filtering the absorption slurry after absorption, and returning the filtrate to the step (2) to serve as absorption liquid, and taking the filter residues as by-products for sales, thereby obtaining the product. According to the method disclosed by the invention, limestone and other desulfurization adsorbents are mixed with water to prepare the absorption slurry,the flue gas enters the desulfurization system to be fully contacted with the slurry, and the acid gas and particles are removed, so that the emission concentration of sulfur dioxide in the flue gas is reduced to 80mg / Nm3, and green and environmental-friendly production is effectively realized.

Owner:云南永昌硅业股份有限公司

Activated waste rubber powder and preparation thereof

InactiveCN101440145BChange in surface activityReasonable usePlastic recyclingPolymer scienceWaste rubber

The invention provides activated waste rubber powder and a preparation method thereof. The components by weight of the activated waste rubber powder are: waste rubber powder accounts for 40 to 60 percent; activator accounts for 60 to 40 percent; and initiator accounts for 0.005 to 0.015 percent of the total weight of a composition, wherein the sum of the weight percentages of all the components is 100 percent. The preparation method is characterized in that fine rubber powder of waste tires and the activator form graft copolymer, interpenetrating polymer networks or wrapping-winding structures under the action of the initiator, so as to change the surface activity of the rubber powder and improve the compatibility between the rubber powder and polymer materials, particularly the polymer materials of the same type with the activator. The rubber powder can be used for the blending modification or copolymerization with polystyrene, polyvinyl chloride, polyethylene or polymethyl methacrylate and other materials, thereby improving the shock resistance of the materials, reasonably utilizing the waste tires, saving energy and reducing emission.

Owner:CHINA NAT OFFSHORE OIL CORP +1

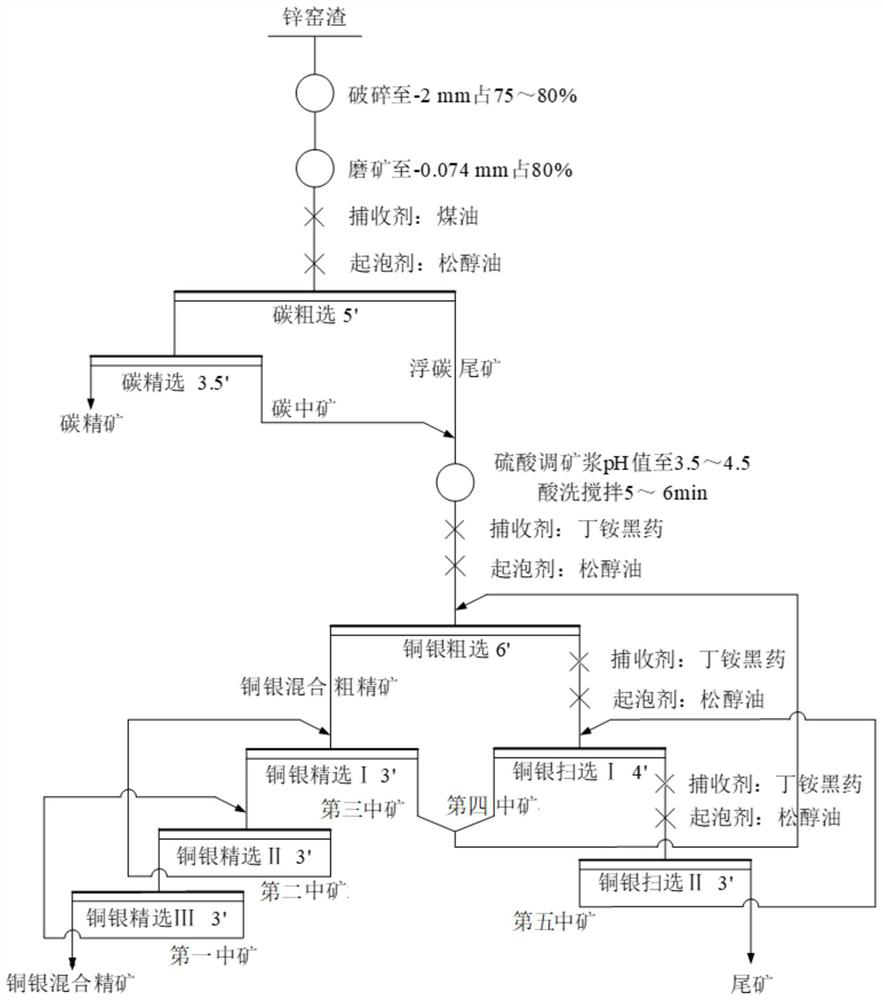

A method for recovering carbon, copper and silver in zinc kiln slag

ActiveCN110743900BChange in surface activityEffective dissociationSolid waste disposalFlotationSlagCopper

The invention discloses a method for recovering carbon, copper and silver in zinc kiln slag, which comprises: crushing zinc kiln slag and performing wet grinding to obtain flotation raw materials; Carry out carbon floatation in advance in a flotation machine to obtain carbon concentrate and pickling raw materials; carry out pickling treatment on the pickling raw materials to obtain copper-silver flotation raw ore pulp; place the copper-silver flotation raw ore pulp Copper-silver mixed flotation is carried out in the flotation machine to obtain copper-silver mixed concentrate and tailings. The present invention adopts crushing, pickling and flotation processes to comprehensively recover carbon concentrate and copper-silver mixed concentrate from zinc kiln slag, and achieves The purpose is to effectively dissociate mineral elements, change the surface activity of minerals, reduce the consumption of chemicals, and simplify the process flow.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

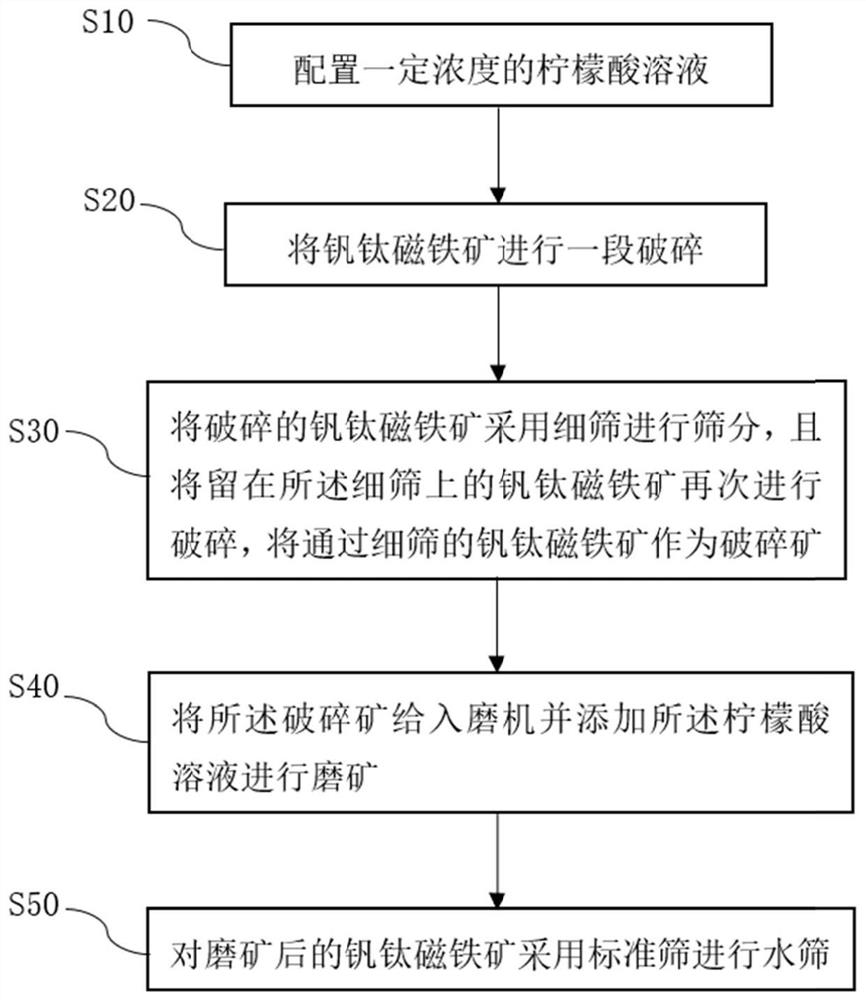

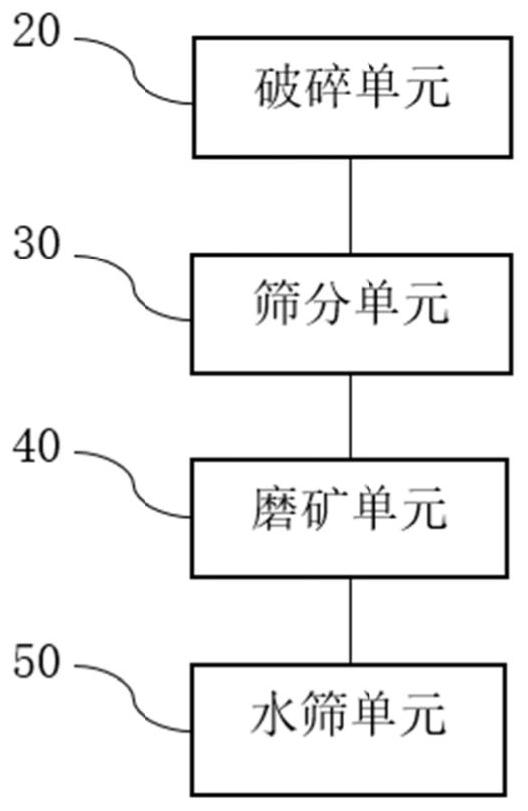

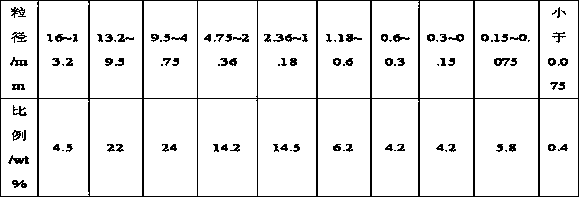

Vanadium titano-magnetite grinding aiding method and system

InactiveCN112387409AChange in surface activityReduce the cost of beneficiationGrain treatmentsCitric acidEnvironmental geology

The invention provides a vanadium titano-magnetite grinding aiding method and system. The method comprises the following steps: preparing a citric acid solution with a certain concentration; carryingout primary crushing on the vanadium titano-magnetite; screening the crushed vanadium titano-magnetite through a fine screen, crushing the vanadium titano-magnetite left on the fine screen again, andenabling the vanadium titano-magnetite passing through the fine screen to serve as crushed ore; feeding the crushed ore into a mill, and adding a citric acid solution for ore grinding; and carrying out water screening on the vanadium titano-magnetite obtained after ore grinding through a standard screen. According to the method, the prepared citric acid solution is added in the ore grinding process to assist in grinding, so that the surface activity of minerals is changed, the ore grinding efficiency is effectively improved, the ore grinding energy consumption is reduced, and the ore dressingcost of the vanadium titano-magnetite is reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of environment-friendly water-soluble cathode electron emission slurry and preparation method thereof

InactiveCN102856154BHigh densityExhaust decomposition is goodGas discharge lampsSlurryDefoaming Agents

The invention relates to environment-friendly water-soluble cathode electron emission slurry, and also simultaneously relates to a preparation method of the environment-friendly water-soluble cathode electron emission slurry. The environment-friendly water-soluble cathode electron emission slurry is prepared from the materials by weight: 50-60% of electronic powders; 20-30% of water, 5-8% of water-soluble binder, 1-2% of hydrophilc agent, 1-2% of defoamer, 3-5% of activating agent, 0-2% of wetting agent, 0-2% of dispersing agent and 0-2% of curing agent. The environment-friendly water-soluble cathode electron emission slurry has the beneficial effects that the environment-friendly water-soluble cathode electron emission slurry is good in stability performance, economical and environment-friendly, excellent in performance, less in impurity and suitable for large-scale production and use; and the emission property of electron and the quality of a lamp tube are improved, and the service life of the lamp tube is prolonged.

Owner:南京双鹿电光源材料有限公司

A low-concentration flue gas desulfurization method for hydropower silicon smelting

ActiveCN109482048BReduce emission concentrationReduce generationDispersed particle separationParticulatesSorbent

Owner:云南永昌硅业股份有限公司

A kind of anionic liquid crystal type asphalt warm mix agent and preparation method thereof

ActiveCN105623283BSimple ingredientsEasy to prepareClimate change adaptationBuilding insulationsSulfonateFatty alcohol

The invention discloses an anionic liquid-crystal-form asphalt warm-mixing agent and a preparation method therefor. The asphalt warm-mixing agent contains the raw materials in parts by weight: 5.5-40.6 parts of sulfosuccinate, 0.1-20 parts of fatty alcohol and 39.4-94.4 parts of water. The preparation method comprises the following steps: (1) uniformly mixing the water and the sulfosuccinate in a vessel according to a proportioning ratio; and (2) adding the fatty alcohol into a material obtained in the step (1), carrying out uniform mixing, and carrying out standing for a period of time, thereby obtaining the anionic liquid-crystal-form asphalt warm-mixing agent. The asphalt warm-mixing agent disclosed by the invention can be used for effectively lowering the high-temperature viscosity of asphalt and has the advantages that the performance is stable, the raw materials are easily acquired, the preparation method is simple and convenient, the range of application is wide, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Efficient waterproof material for tunnels and preparation method thereof

ActiveCN113321860AChange the organizational structureChange in surface activityActive agentPolyvinyl chloride

The invention relates to the technical field of waterproof materials, and provides an efficient waterproof material for tunnels and a preparation method thereof in order to solve the problem that an existing waterproof material is poor in fracture resistance and tensile property during construction. The efficient waterproof material for tunnels is prepared from the following components: filler, modified paraffin, modified rubber, polyvinyl chloride, an antioxidant, a tackifier, coupling modified bamboo charcoal fibers and polyacrylonitrile fibers. Modified rubber is further added into the filler, the modified rubber is firstly put into a sodium hydroxide solution to be soaked and passivated, then the passivated rubber reacts with an anionic surfactant, the surface of the rubber is modified through the anionic surfactant, the rubber can be in full contact with graphene oxide and a silicon-hydrogen compound, and the graphene oxide and the silicon-hydrogen compound are grafted on the surface of the rubber, so that the ductility and the strength of the rubber are improved.

Owner:CHINA FIRST HIGHWAY ENG

A kind of ozone elimination catalyst with porous substrate as carrier and preparation method thereof

ActiveCN105056948BNo secondary dust pollution will occurImprove wind resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPorous substratePolyvinyl alcohol

The invention relates to an ozone elimination catalyst with a porous substrate as the carrier. The ozone elimination catalyst is prepared by loading a coating solution on the porous substrate. The coating solution comprises the following active ingredients by weight: 0.8-1.2 parts of stearic acid sorbitol ester, 1.6-2.4 parts of OP-10, 4.2-5.8 part of polyethylene glycol, 0.15-0.85 part of carboxymethyl cellulose sodium, 1.1-1.9 parts of polyvinyl alcohol, 3.2-4.8 parts of vinyl acetate, 90-110 parts of water, and 2-50 parts of a nano-metal oxide. The invention also provides a preparation method of the ozone elimination catalyst with the porous substrate as the carrier. The prepared catalyst has the advantages of long service life, low cost, small wind resistance, and no secondary dust.

Owner:THE JUYE HAILIN ENVIRONMENTAL EQUIP ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com