Reversed micelle micro-emulsion and preparation method thereof, and reversed micelle biological oil micro-emulsion and preparation method thereof

A technology of microemulsion and reverse micelles, which is applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of high viscosity and poor low-temperature fluidity, and limit the application of bio-oil, so as to improve low-temperature fluidity, increase potential, The effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

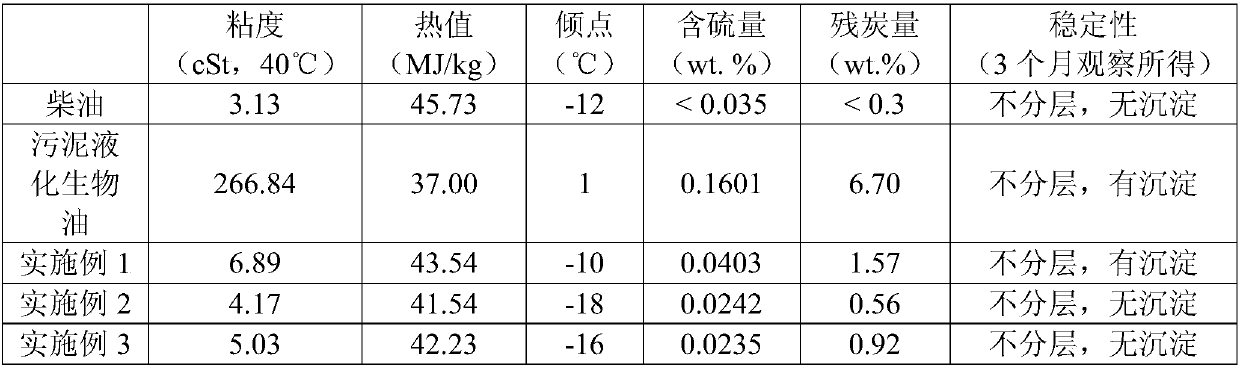

Embodiment 1

[0029] A reverse micelle microemulsion of the present invention, the reverse micelle microemulsion comprises diesel oil, surfactant Span 80 and co-surfactant n-octanol, wherein diesel oil is used as the continuous phase. In the reverse micellar microemulsion of this example, the molar volume ratio of the surfactant Span 80 to diesel oil was 0.15mol:1L, and the content of the cosurfactant n-octanol in the reverse micellar microemulsion was 0.116mL / mL.

[0030] A preparation method of the above-mentioned reverse micellar microemulsion of the present embodiment, comprising the following steps: dissolving 3.2g of surfactant Span 80 and 7mL of n-octanol in 50mL of diesel oil, mixing and shaking to obtain a clear and transparent reverse glue bundle of microemulsions. The prepared reverse micellar microemulsion is left to stand at room temperature for a period of time until the reverse micellar microemulsion is stable and ready for use.

[0031] A method for preparing the reverse mi...

Embodiment 2

[0034] A reverse micelle microemulsion of the present invention, the reverse micelle microemulsion comprises diesel oil, surfactant Span 80, co-surfactant n-octanol and ethanol, wherein diesel oil is used as the continuous phase. In the reverse micellar microemulsion of the present embodiment, the molar volume ratio of surfactant Span 80 to diesel oil is 0.30mol: 1L, and the content of co-surfactant n-octanol in the reverse micellar microemulsion is 0.095mL / mL, The content of ethanol in the reverse micellar microemulsion was 0.136mL / mL.

[0035] A preparation method of the reverse micellar microemulsion of the above-mentioned present embodiment, comprising the following steps: dissolving 6.4g of surfactant Span 80, 7mL of n-octanol and 10mL of ethanol in 50mL of diesel oil, mixing and shaking to obtain a clear and transparent Inverse micellar microemulsion. The prepared reverse micellar microemulsion is left to stand at room temperature for a period of time until the reverse ...

Embodiment 3

[0039] A reverse micelle microemulsion of the present invention, the reverse micelle microemulsion comprises diesel oil, surfactant Span 80, co-surfactant n-octanol and ethanol, wherein diesel oil is used as the continuous phase. In the reverse micellar microemulsion of the present embodiment, the molar volume ratio of surfactant Span 80 to diesel oil is 0.50mol: 1L, and the content of co-surfactant n-octanol in the reverse micellar microemulsion is 0.09mL / mL, The content of ethanol in the reverse micellar microemulsion was 0.129mL / mL.

[0040] A preparation method of the reverse micellar microemulsion of the above-mentioned present embodiment, comprising the following steps: dissolving 10.7g of surfactant Span 80, 7mL of n-octanol and 10mL of ethanol in 50mL of diesel oil, mixing and shaking to obtain a clear and transparent Inverse micellar microemulsion. The prepared reverse micellar microemulsion is left to stand at room temperature for a period of time until the reverse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com