Method and device for quickly and nondestructively judging processing precision grade of rice

A rice processing and precision grade technology, applied in measuring devices, instruments, color/spectral characteristic measurement, etc., can solve problems such as limited application, cumbersome operation, low efficiency, etc., to improve accuracy and applicability, improve accuracy recognition, good The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

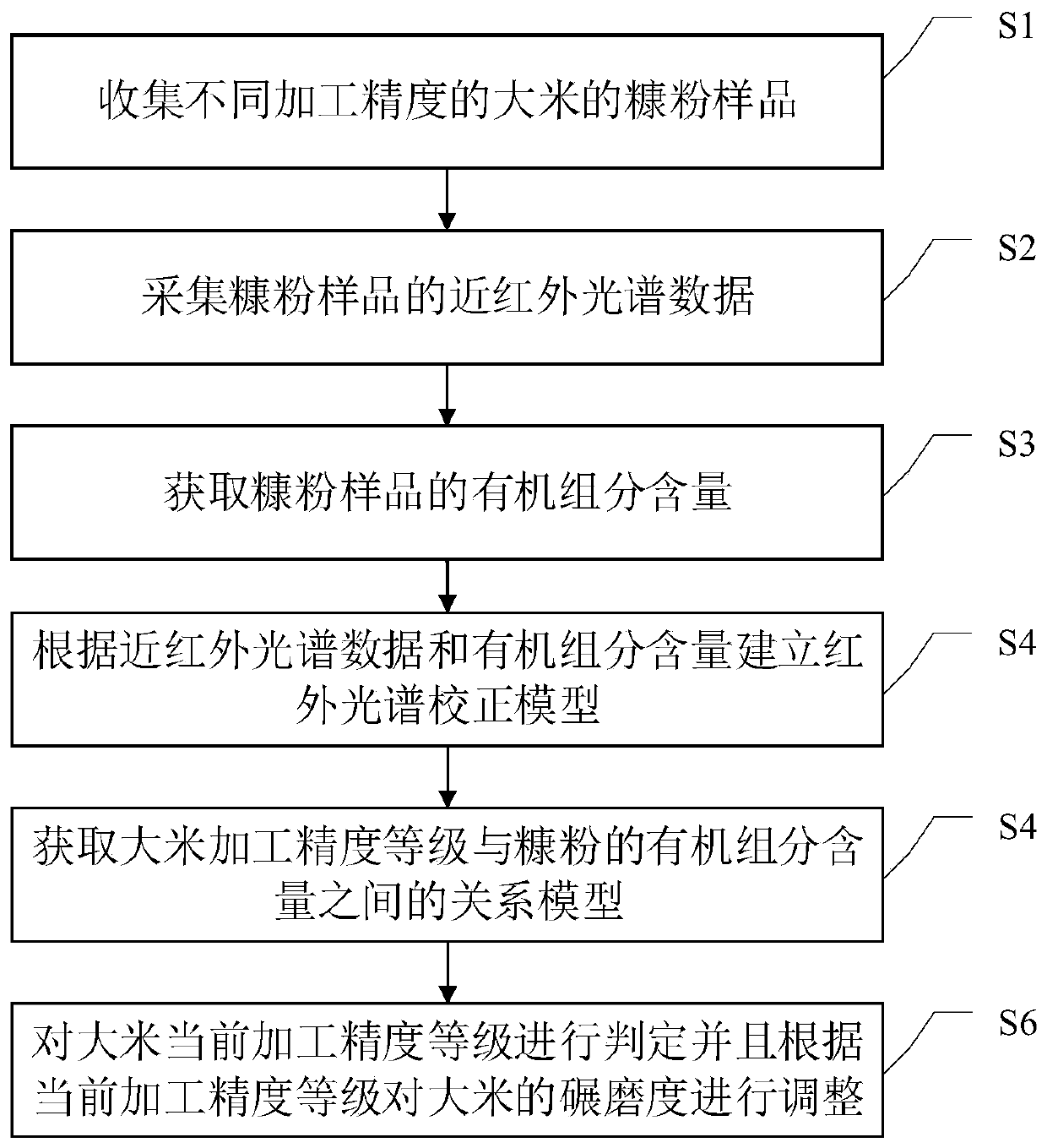

[0042] Such as figure 1 As shown, a method for quickly and non-destructively determining the precision level of rice processing includes:

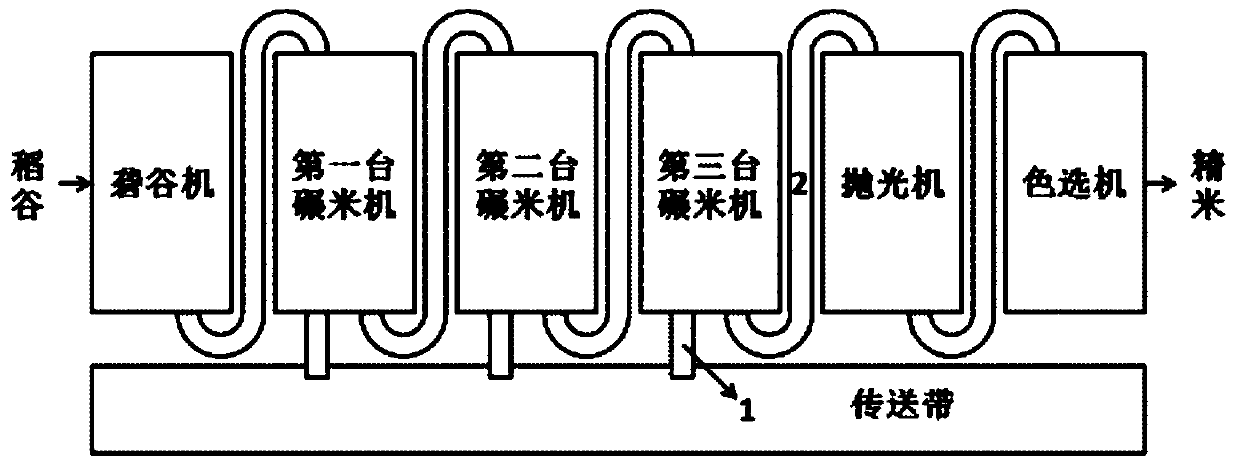

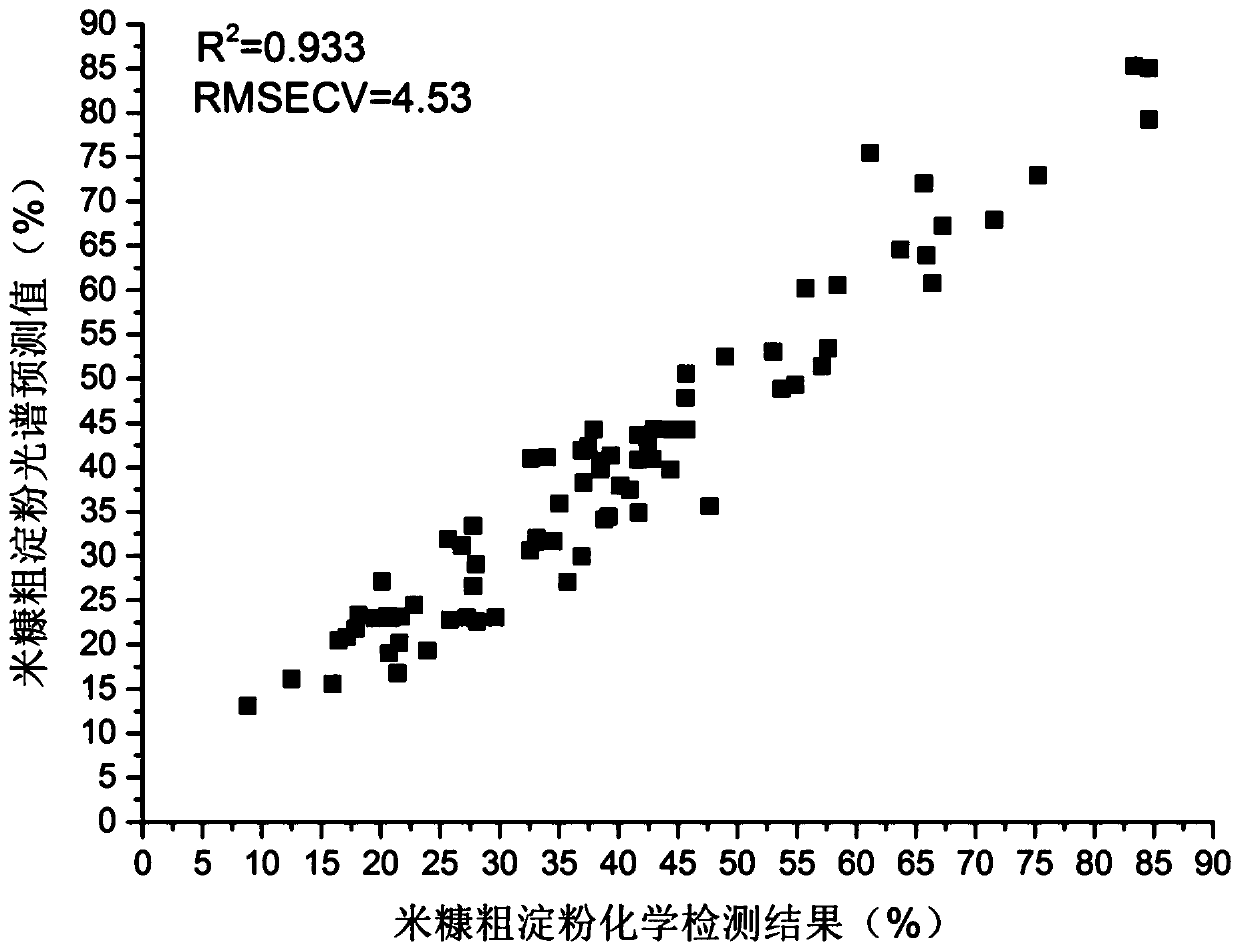

[0043] Step S1: Collect rice bran powder samples with different processing precisions; in this embodiment, a total of 77 bran powder samples are collected. Among them, 47 samples of bran powder with different grinding degrees were collected in the rice processing line of Shuanghu Grain and Oil Company in Shou County, Anhui Province, which has three rice milling procedures. The remaining 30 bran meal samples came from 30 rice varieties with different genetic backgrounds. These rice varieties are harvested, hulled, and milled in a laboratory using rice polishing machines on Science Island in Hefei, Anhui Province, China. The schematic diagram of rice production and processing and the collection position of rice and bran powder are as follows figure 2 Shown. The rice processing process includes successively connected rice hulling machines, se...

Embodiment 2

[0053] Corresponding to Embodiment 1 of the present invention, Embodiment 2 of the present invention also provides a device for quickly and non-destructively judging the precision level of rice processing, and the device includes:

[0054] The sample collection module is used to collect rice bran powder samples with different processing precisions;

[0055] Near-infrared spectrum data acquisition module, used to collect near-infrared spectrum data of bran powder samples;

[0056] The organic component content acquisition module is used to acquire the organic component content of the bran powder sample;

[0057] The calibration model establishment module is used to establish an infrared spectrum calibration model based on the near-infrared spectrum data and the content of organic components;

[0058] The relationship model acquisition module is used to acquire the relationship model between the rice processing accuracy level and the organic component content of the bran powder;

[0059] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com