Nanometer material reaction kettle capable for preventing agglomeration

A nanomaterial and reactor technology, applied in chemical/physical/physical-chemical stationary reactors, feeding devices, mixers with rotary stirring devices, etc., can solve uneven stirring, affect the quality of nanomaterials, and material mixing. Inhomogeneous and other problems, to avoid agglomeration, improve dispersion, change the effect of surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

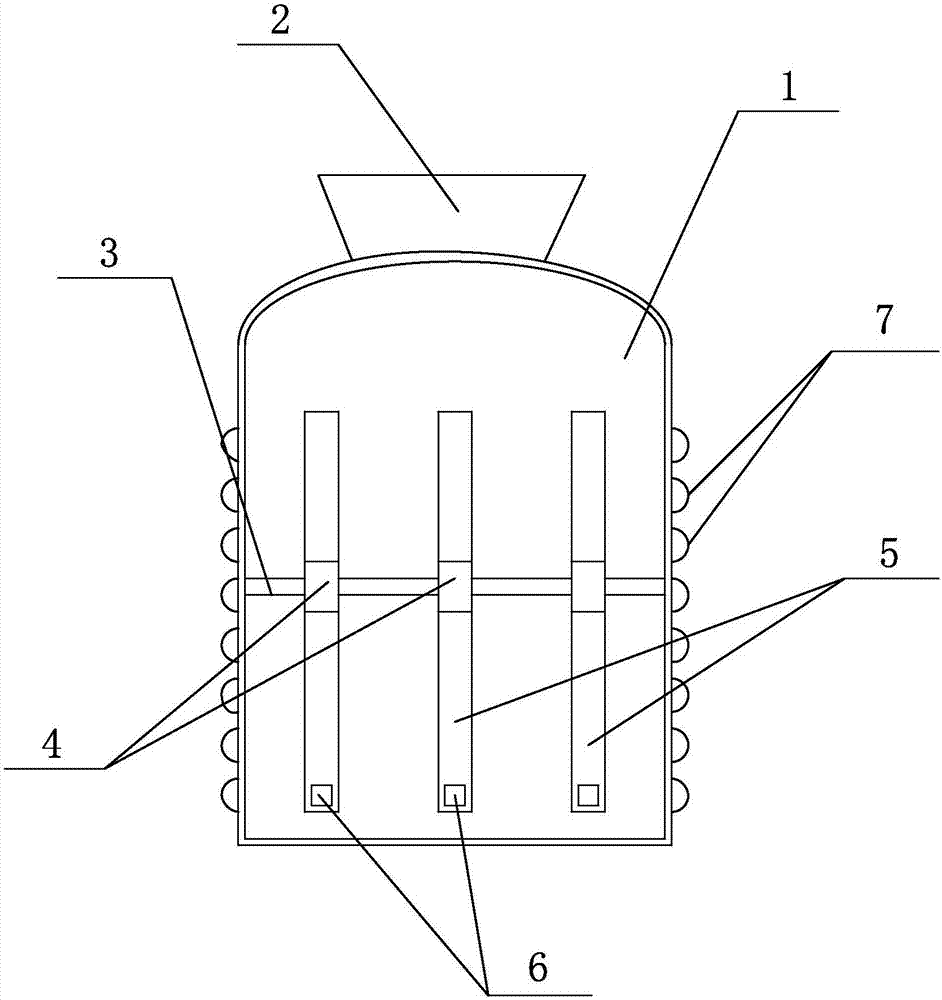

[0023] Such as figure 1 As shown, the nano-material reactor for preventing agglomeration of the present invention includes a reactor body 1, the top of the reactor body 1 is provided with a feed port, and an atomization device 2 is arranged above the reactor body 1, and the atomization device 2 is connected with the reactor body 1 through the feed port; the reactor body 1 is covered with a magnetic induction coil 7, and the magnetic induction coil 7 is connected with the circuit; the reactor body 1 is provided with a horizontally arranged rotating shaft 3, so The rotating shaft 3 rotates around its own axis. The rotating shaft 3 is provided with multiple groups of stirring groups 4 arranged in sequence. The stirring group 4 includes a plurality of stirring rods 5 vertically connected to the rotating shaft 3. The adjacent two Two stirring rods 5 form an included angle of 20-30°, and a groove 6 is provided on the side of the stirring rod 5 away from the end of the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com