A kind of ozone elimination catalyst with porous substrate as carrier and preparation method thereof

A technology of porous substrates and catalysts, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of short life, high resistance and low load of ozone depletion catalysts and other problems, to achieve the effect of improving the catalytic effect of ozone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

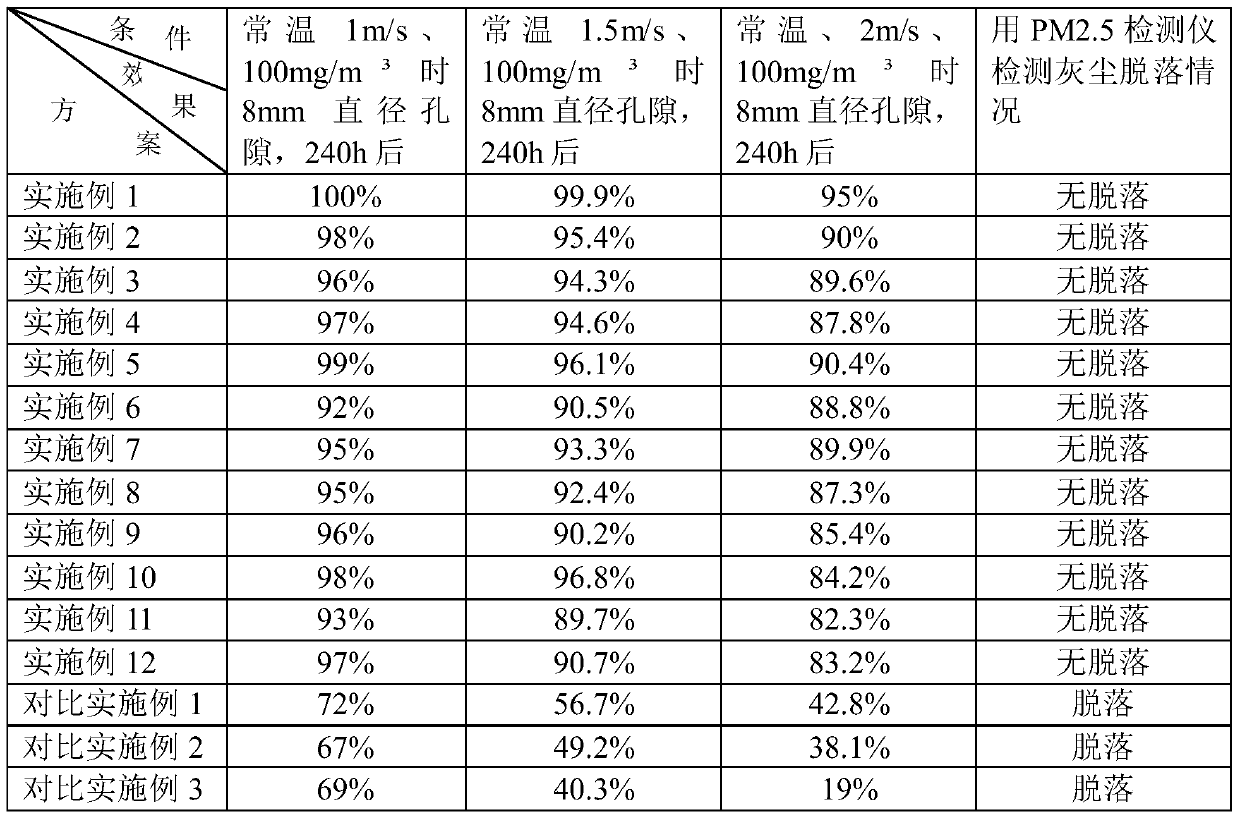

Examples

Embodiment 1

[0023] An ozone elimination catalyst with a porous substrate as a carrier, which is prepared by loading a coating liquid on a porous substrate, and the parts by weight of each active component in the coating liquid are: 1 part of sorbitol stearate Ester, 2 parts of OP-10, 5 parts of polyethylene glycol, 0.5 parts of sodium carboxycellulose, 1.5 parts of polyvinyl alcohol, 4 parts of vinyl acetate, 100 parts of water, nano-copper oxide and nano-ferrous oxide, nano-dioxide 18 parts of compound mixture composed of aluminum.

Embodiment 2

[0025] An ozone elimination catalyst with a porous substrate as a carrier, prepared by loading a coating liquid on a porous substrate, the weight ratio of each active component in the coating liquid is: 0.8 parts of sorbitol stearate Esters, 1.6 parts of OP-10, 4.2 parts of polyethylene glycol, 0.15 parts of sodium carboxycellulose, 1.1 parts of polyvinyl alcohol, 3.2 parts of vinyl acetate, 90 parts of water, a compound mixture of nano-iron oxide and nano-titanium dioxide 20 share.

Embodiment 3

[0027] An ozone elimination catalyst with a porous substrate as a carrier, prepared by loading a coating liquid on a porous substrate, the weight ratio of each active component in the coating liquid is: 0.85 parts of sorbitol stearate Ester, 1.7 parts of OP-10, 4.4 parts of polyethylene glycol, 0.2 parts of sodium carboxycellulose, 1.2 parts of polyvinyl alcohol, 3.4 parts of vinyl acetate, 105 parts of water, a compound composed of nano-zinc oxide and nano-manganese dioxide Mixture 6 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com