Magnesium hydride compound powder, preparation method thereof and hydrogen preparation and storage integrated device adopting magnesium hydride compound powder

A compound, magnesium hydride technology, applied in the field of hydrogen production and hydrogen storage, can solve problems such as affecting reaction efficiency, and achieve the effects of improving reaction efficiency, improving reaction kinetics and good control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

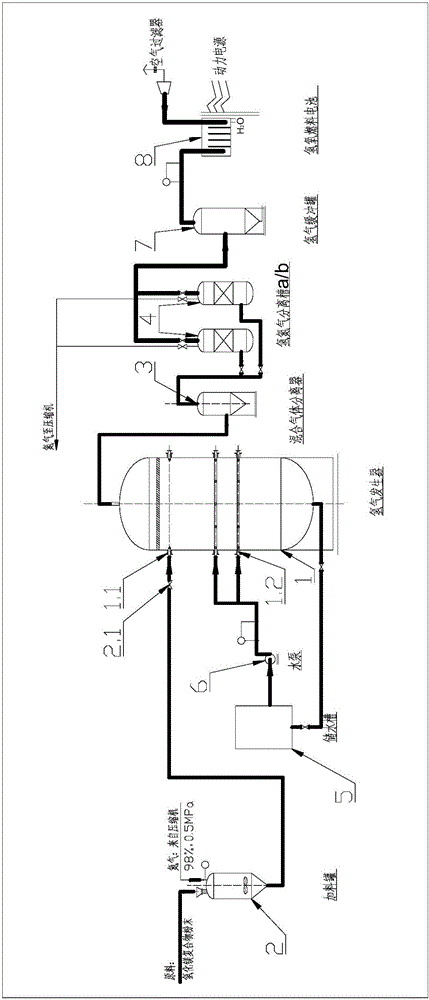

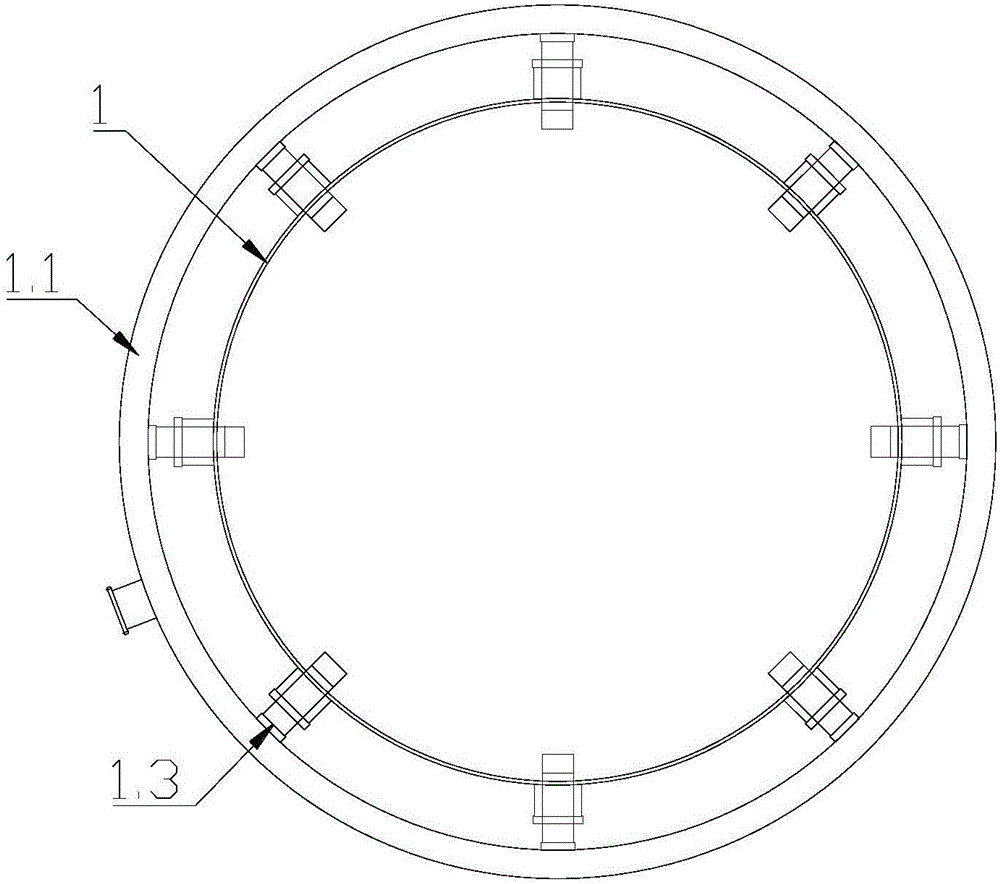

Method used

Image

Examples

Embodiment 1

[0049] As shown in Table 1, in a hydrogen atmosphere, 100g of magnesium powder, 8g of graphite, 1g of graphene, and 1g of Ti were placed in a vacuum ball mill and fully ball milled at 150°C for about 1.5h to obtain magnesium hydroxide composite powder. The magnesium hydroxide composite powder is sent to the aforementioned hydrogen production and hydrogen storage integrated device to produce hydrogen, and the raw materials and water are sprayed into the hydrogen generator 1, and the hydrogen production rates under different reaction times are shown in Table 2. .

Embodiment 2~6

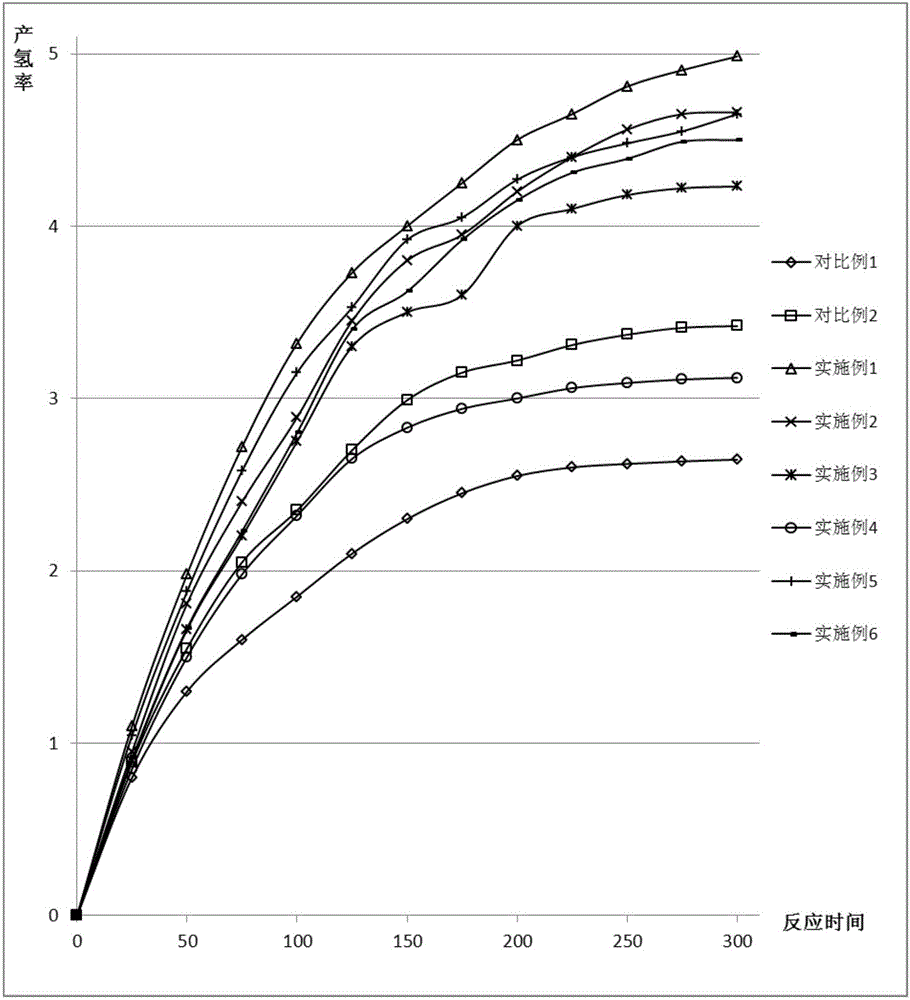

[0051] According to the raw materials and parameters of each embodiment listed in Table 1, the magnesium hydride composite powder is prepared with reference to the steps in Example 1, and the magnesium hydride composite powder is sent to the aforementioned hydrogen production and hydrogen storage integrated device to produce hydrogen. and water are all added in the hydrogen generator 1 in the form of spraying, without

[0052] The hydrogen production rate (referring to the cumulative hydrogen production rate) under the same reaction time is shown in Table 2.

[0053] Table 1 raw material ratio and reaction conditions

[0054]

[0055] Table 2 hydrogen production rate - reaction time

[0056]

[0057] In the above table, the hydrogen production rate=reaction time when the reaction time is t is the cumulative hydrogen production (in g) when the reaction time is 0~t ÷ the reaction whole process drops into the magnesium hydride composite powder (for embodiment 1 is magnesiu...

Embodiment 3

[0061] The magnesium hydride composite powder used in Example 3 is the same as that used in Comparative Example 2. The difference is that the aforementioned integrated hydrogen production and storage device is used in Example 3 to produce hydrogen, and the composite powder and water are added in the form of spray to generate hydrogen. device 1. It can be seen from Table 2 that when the reaction time is 300s, the hydrogen production rate of Example 3 is increased by 24% compared with Comparative Example 2. It can be seen that the hydrogen production rate can be significantly improved by adopting the hydrogen production and hydrogen storage integrated device provided by the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com