Tungsten trioxide nano bowl electrochromic material and preparation method thereof

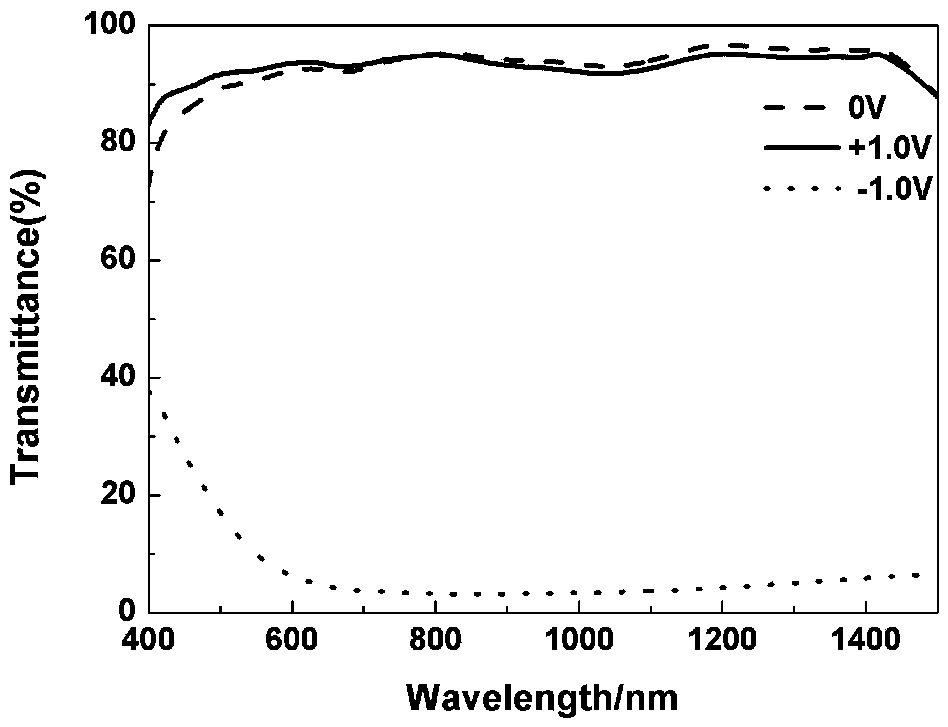

An electrochromic material, tungsten trioxide technology, applied in coatings and other directions, can solve the problems of optical contrast, response time cycle stability, unsatisfactory electrochromic performance indicators, chemical stability, poor cycle life, limited ion transmission capacity, etc. problems, to achieve the effect of improving electron transport speed and particle diffusion rate, excellent cycle stability, and improving electrochromic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a preparation method of the tungsten trioxide nanobowl electrochromic material described in the above technical solution, comprising the following steps:

[0036] Mixing the polystyrene microsphere dispersion, ethanol and acetone to obtain a suspension;

[0037] Put water and FTO conductive glass into a petri dish, drop the suspension and triton into the water surface in turn, then take out the FTO conductive glass, and dry it naturally to obtain FTO conductive glass wrapped by a single-layer PS sphere film;

[0038] Na 2 WO 4 Powder, H 2 o 2 After the solutions are mixed, the pH value is adjusted to 1.0-2.0 with perchloric acid to obtain an electrolyte solution;

[0039] The FTO conductive glass wrapped by the single-layer PS spherical film is used as the working electrode, the platinum wire is used as the counter electrode, and the Ag / AgCl electrode is used as the reference electrode, and the working electrode is pulse-deposited...

Embodiment 1

[0057] (1) Place the FTO conductive glass in acetone, ethanol, and deionized water for ultrasonic cleaning in sequence, and dry it in a vacuum oven after cleaning.

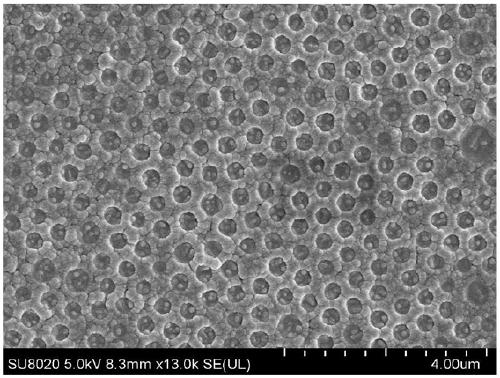

[0058] (2) Mix PS sphere dispersion with a diameter of 500nm (8% concentration, dispersed in deionized water) with ethanol and acetone at a ratio of 5:5:2, ultrasonically disperse to form a milky white suspension, take a clean culture Fill the dish with deionized water and cleaned FTO conductive glass, take a little of the above milky white suspension and drop it on the deionized surface under the guidance of the glass slide, and drop a few drops of Triton diluted 100 times on the deionized water On the surface, a single layer of dense PS sphere film is formed, and then the FTO conductive glass is pulled out, and after natural drying, a single layer of PS sphere film is formed.

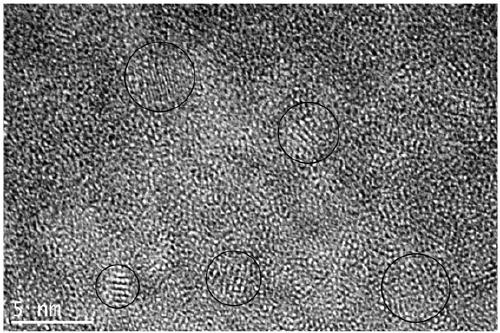

[0059] (3) Na under magnetic stirring 2 WO 4 Powder dissolved in 0.4wt% H 2 o 2 solution, forming 12.5mM H 2 WO 4 The solution was...

Embodiment 2

[0066] A preparation method of a tungsten trioxide nanobowl electrochromic material, the specific steps are as follows:

[0067] (1) Place the FTO conductive glass in acetone, ethanol, and deionized water for ultrasonic cleaning in sequence, and dry it in a vacuum oven after cleaning.

[0068] (2) Mix PS sphere dispersion with a diameter of 500nm (8% concentration, dispersed in deionized water) with ethanol and acetone at a ratio of 5:5:2, ultrasonically disperse to form a milky white suspension, take a clean culture Fill the dish with deionized water and cleaned FTO conductive glass, take a little of the above milky white suspension and drop it on the deionized surface under the guidance of the glass slide, and drop a few drops of Triton diluted 100 times on the deionized water On the surface, a single layer of dense PS sphere film is formed, and then the FTO conductive glass is pulled out, and naturally dried in the air to form a single layer of PS sphere film.

[0069] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| coloring efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com