Vanadium titano-magnetite grinding aiding method and system

A vanadium-titanium magnetite and ore grinding technology, which is applied in the field of vanadium-titanium magnetite grinding aid method and system, can solve the problems of high energy consumption in the grinding process, improve grinding efficiency, reduce grinding energy consumption, The effect of changing the surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

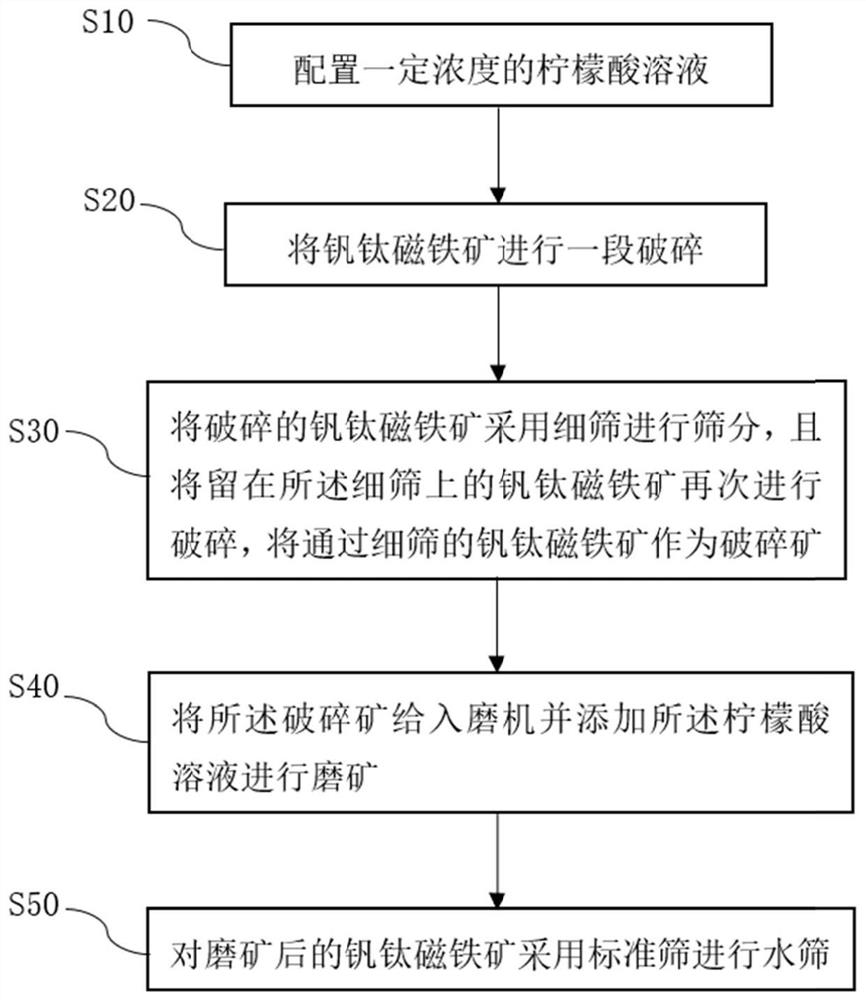

[0039] The 10mm vanadium-titanium magnetite raw ore is crushed to less than 3mm by a closed circuit, and 500g of the crushed ore is fed into the ball mill and added with 10ml of citric acid solution to grind for 10min, wherein the filling rate of the ball mill medium is 30% and the grinding mass concentration 60%, and then use 200-mesh standard sieve to water-screen the grinding product, and the -200-mesh content is 68.3%.

Embodiment 2

[0041] The 10mm vanadium-titanium-magnetite raw ore is crushed to less than 3mm in a closed circuit, and 500g of the crushed ore is fed into the ball mill and added with 15ml of citric acid solution to grind for 10min, wherein the filling rate of the ball mill medium is 30% and the grinding mass concentration 60%, and then use 200-mesh standard sieve to water-screen the grinding product, and the -200-mesh content is 69.4%.

Embodiment 3

[0043] The 10mm vanadium-titanium-magnetite raw ore is crushed to less than 3mm in a closed circuit, and 500g of the crushed ore is fed into the ball mill and added with 20ml of citric acid solution to grind for 10min, wherein the filling rate of the ball mill medium is 30% and the grinding mass concentration 60%, and then use 200-mesh standard sieve to water-screen the grinding product, and the -200-mesh content is 70.3%.

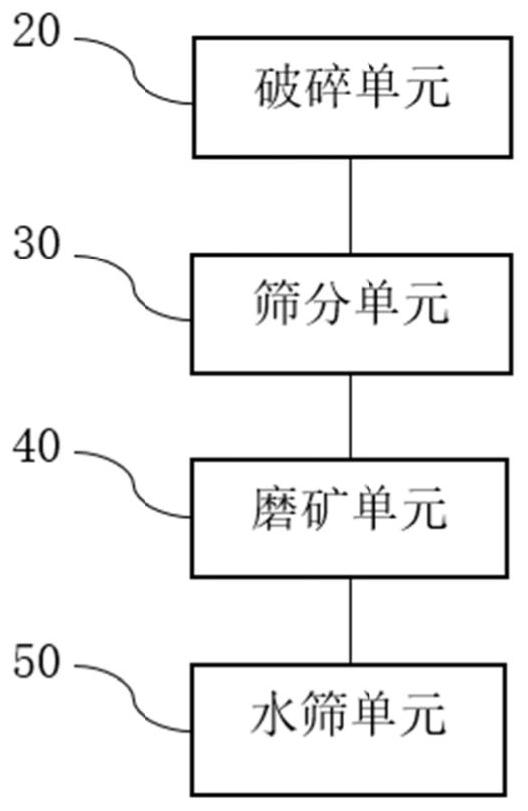

[0044] The second aspect of the embodiment of the present invention also provides a vanadium-titanium-magnetite grinding aid system. figure 2 What is shown is a schematic diagram of an embodiment of the vanadium-titanium-magnetite grinding aid system provided by the present invention. A vanadium-titanium-magnetite grinding aid system includes: a crushing unit 20, which is used to crush the vanadium-titanium-magnetite in one stage; a screening unit 30, which is used to screen the broken vanadium-titanium-magnetite with a fine sieve, And the vanadium-titan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com