Patents

Literature

83results about How to "Good subsequent processing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

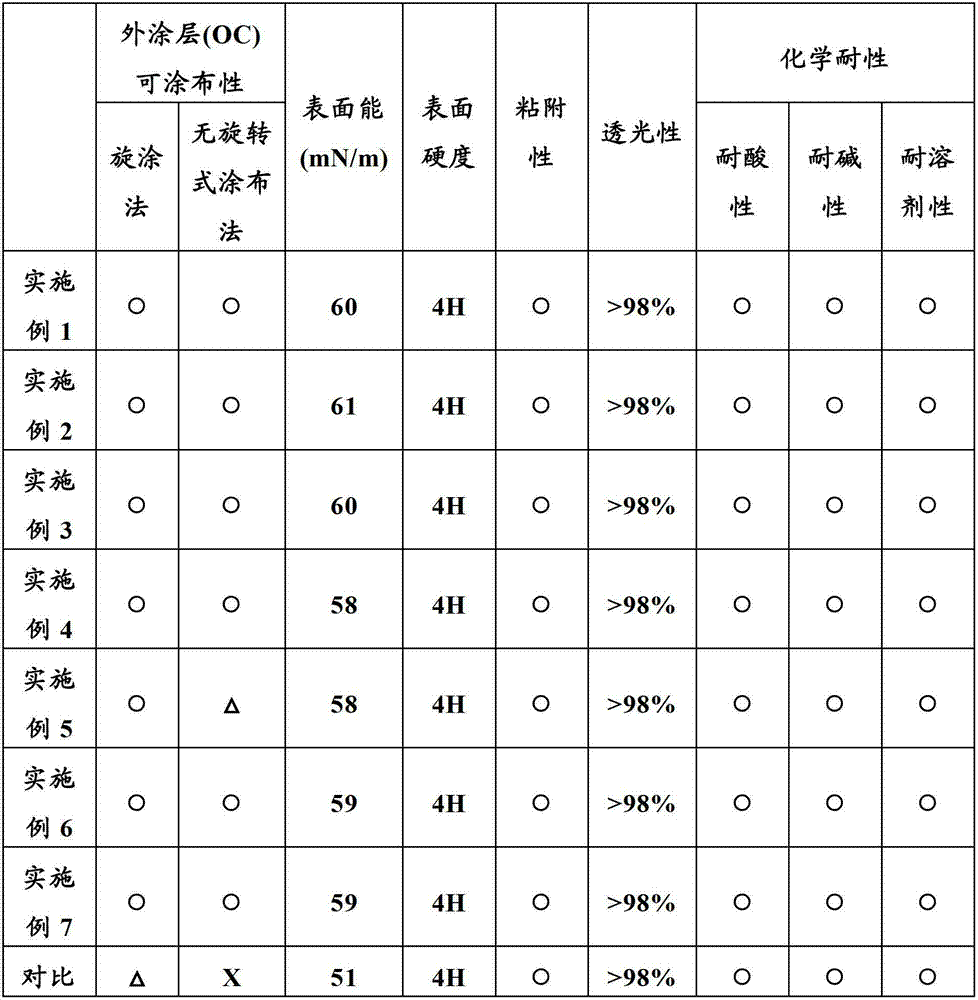

Thermosetting resin composition having good coatability and re-coatability

ActiveCN103025827AProtect coatabilityGood subsequent processing performanceOptical filtersCoatingsLiquid-crystal displayEthylene oxide

Owner:LG CHEM LTD

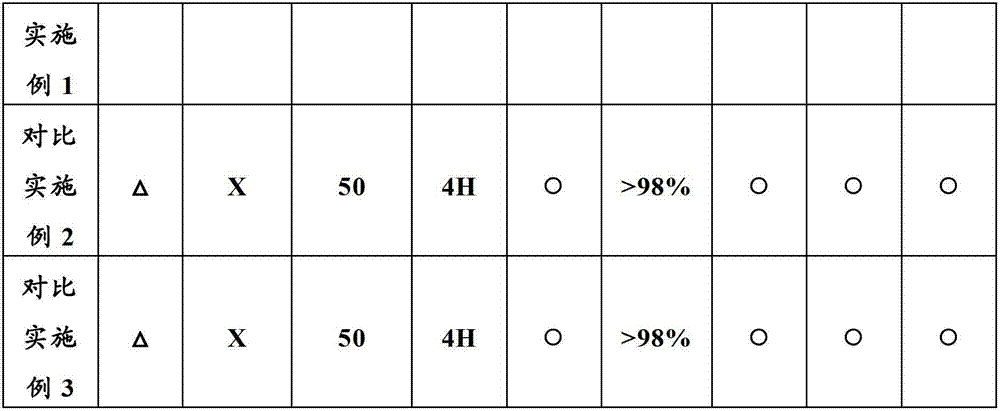

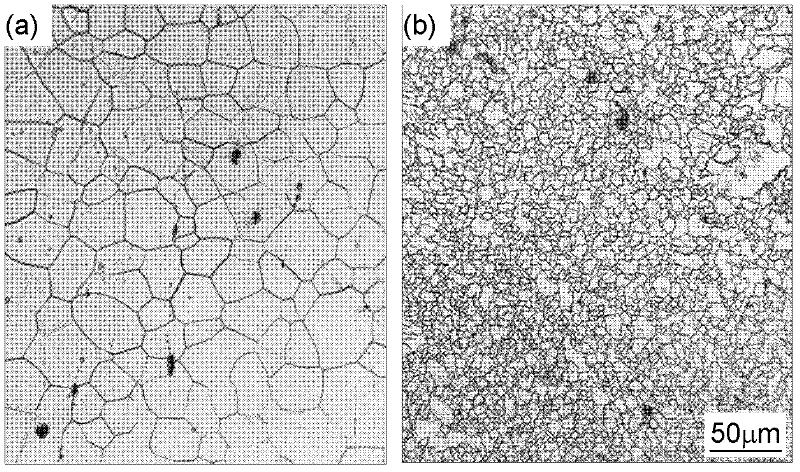

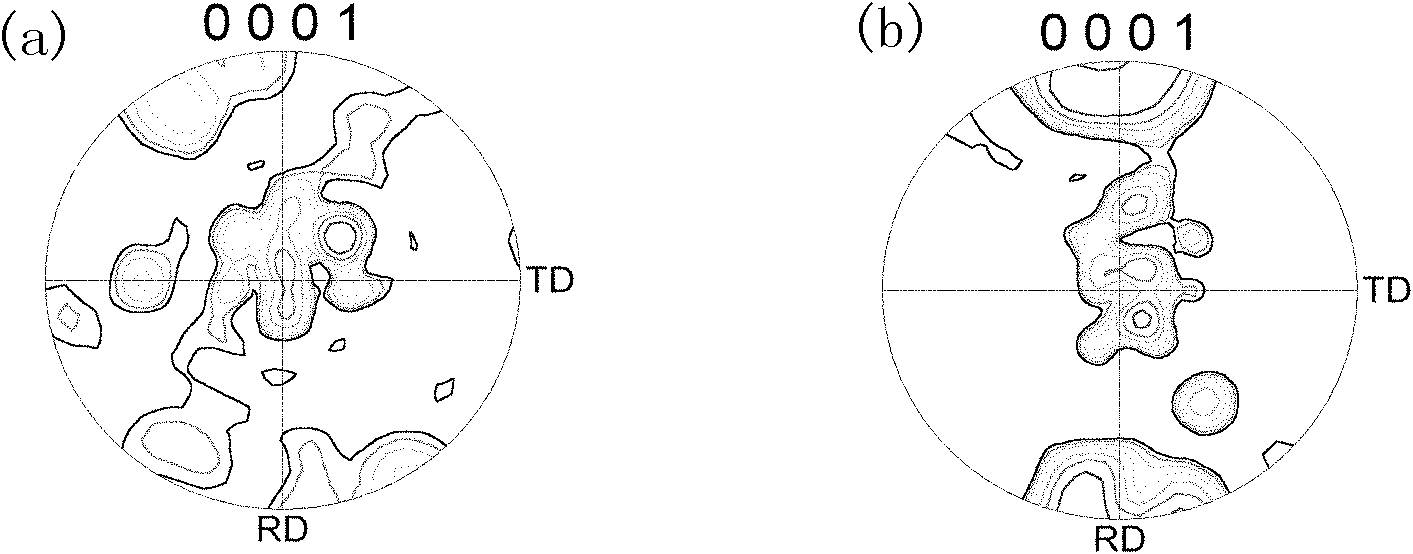

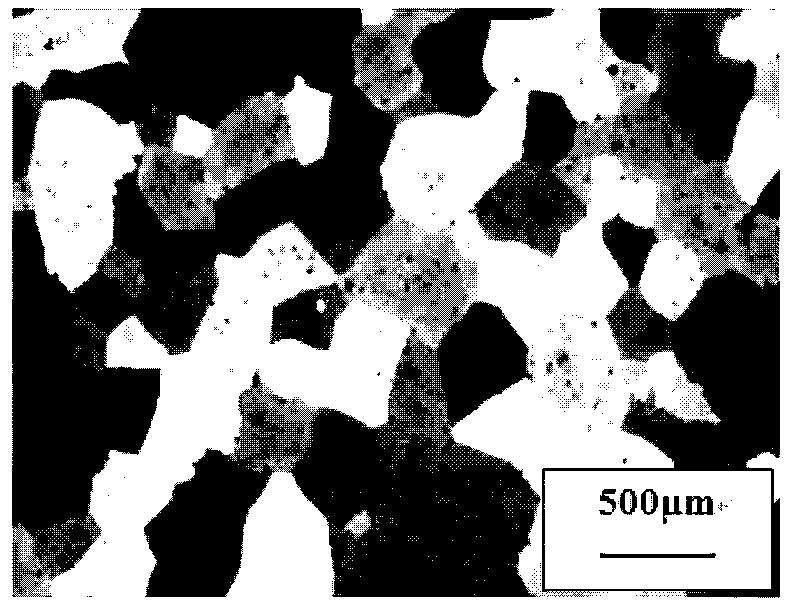

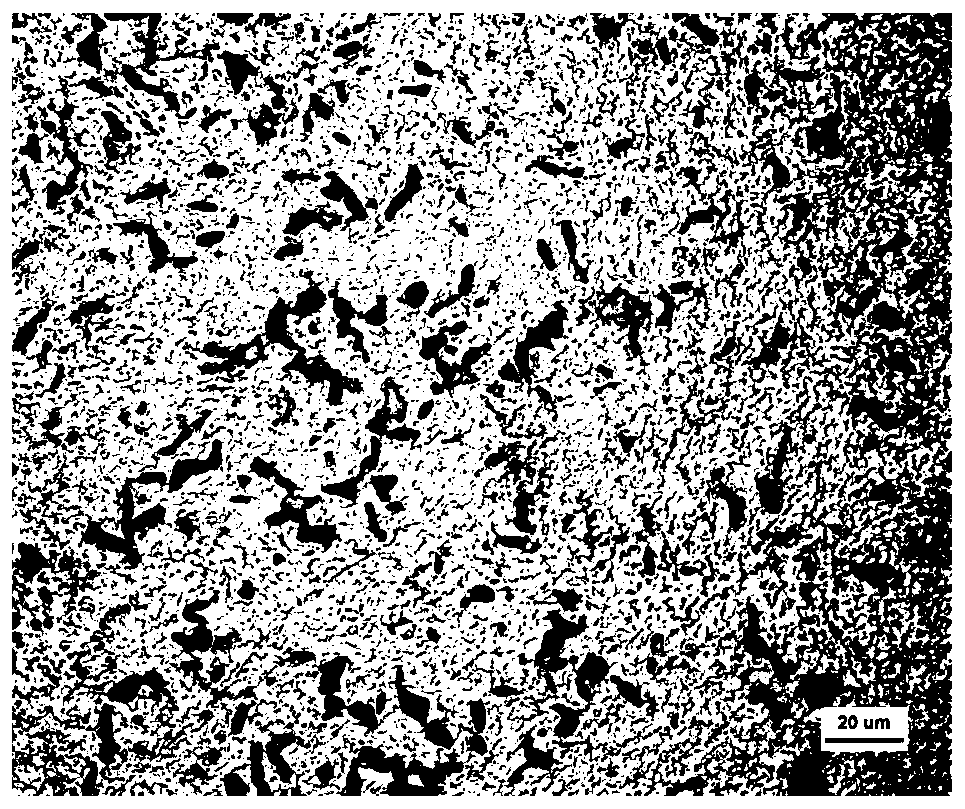

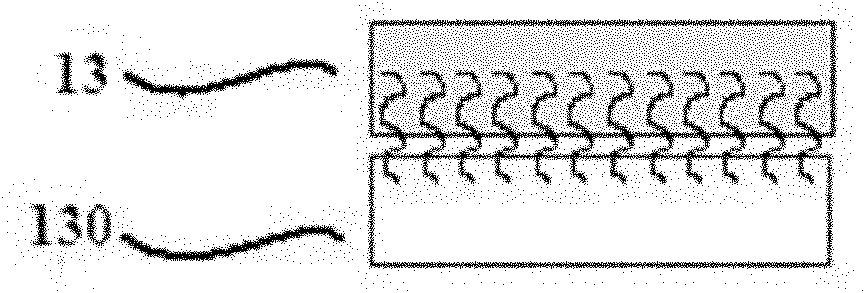

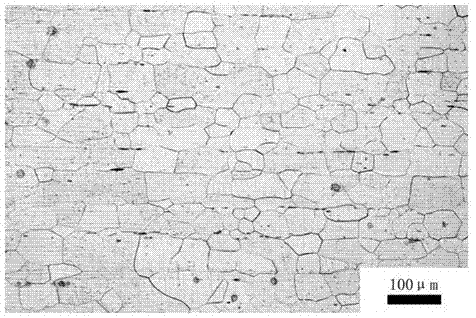

Method for weakening cardinal plane texture of magnesium alloy plate strip

InactiveCN102409273AImprove ductilityGood subsequent processing performanceCrystal twinningUltimate tensile strength

The invention relates to a method for weakening the cardinal plane texture of a magnesium alloy plate strip, which comprises the following steps of: placing the magnesium alloy plate strip between corrugated rollers, carrying out alternative rolling for many times under the temperature of 300-550 DEG C, straightening, and water quenching, or carrying out multi-channel one-way or alternative rolling for many times under the temperature of 150-300 DEG C, straightening, carrying out static recrystallization, and annealing; carrying out corrugated rolling at the temperature of over 300 DEG C, andincreasing along with the channel, wherein each flat surface which is vertical to normal direction of the plate strip is respectively applied with shearing force in different directions; inducing dynamic recrystallization, so that the orientation distribution of grains in the plate strip is randomized, and the strength of the cardinal plane texture is reduced; and carrying out corrugated rolling under the temperature of below 300 DEG C, wherein at the position in the plate strip, especially, the position where the repeated wave bending deformation is the most serious, a large amount of twin crystals are produced to enable the grain orientation to deflect, and further, the initial texture is weakened. The invention has the advantages that the process design is reasonable, the equipment is easy to manufacture, the operation process is easy to realize, the defects of the normal plastic deformation and difficulty in weakening of the texture in annealing of the magnesium alloy are overcome, and the efficiency is high. The method is suitable for the large scale of industrial production.

Owner:CENT SOUTH UNIV

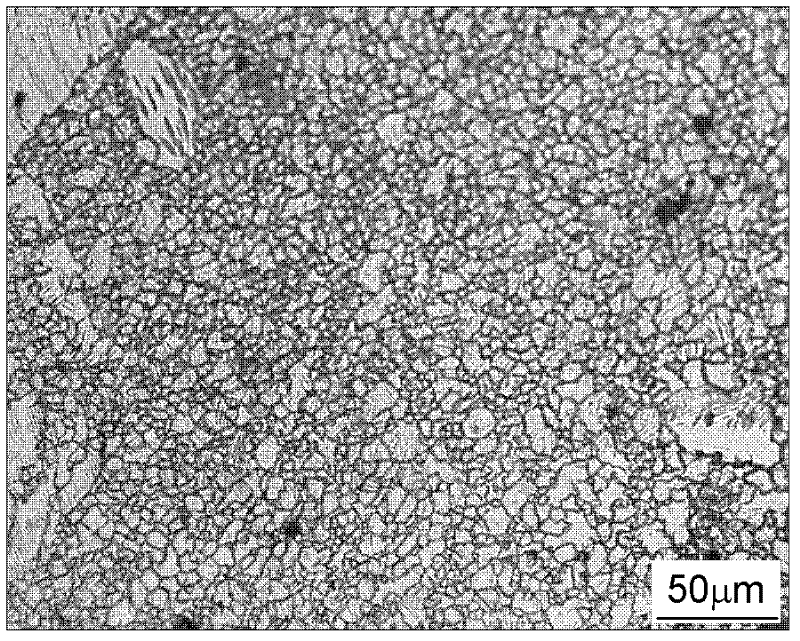

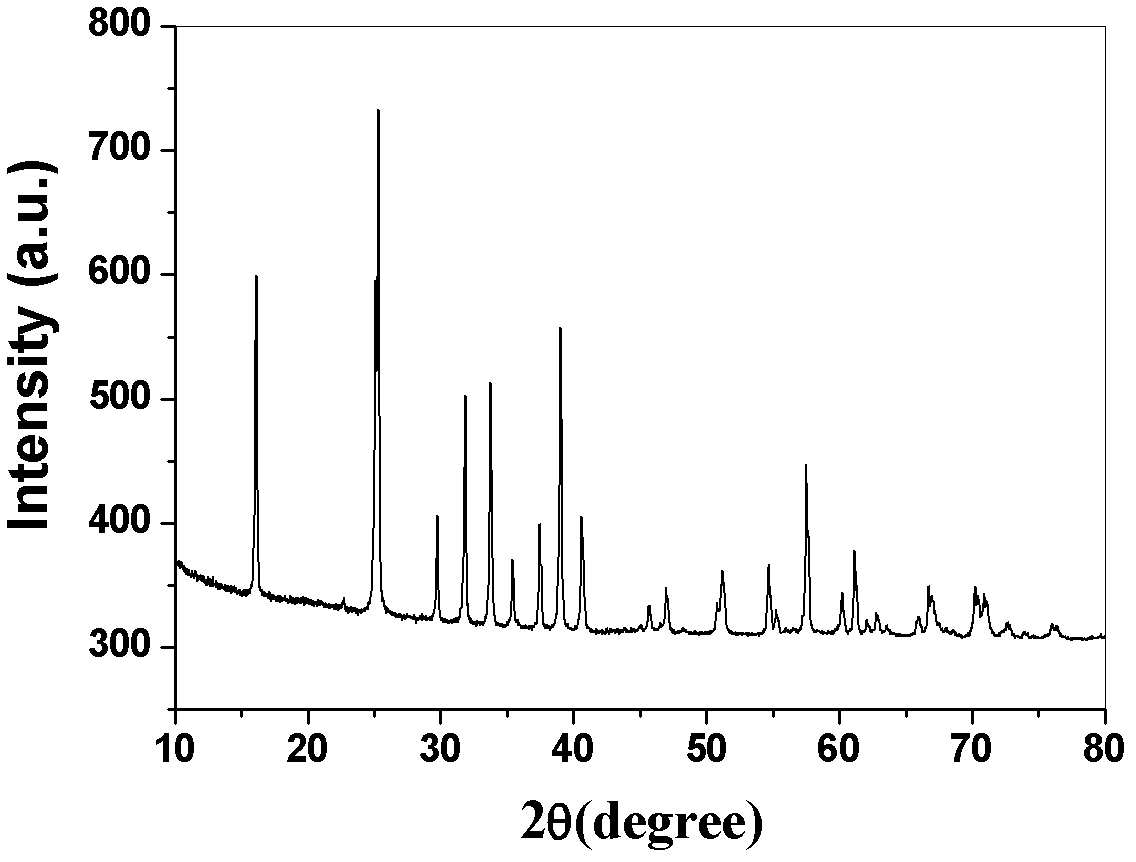

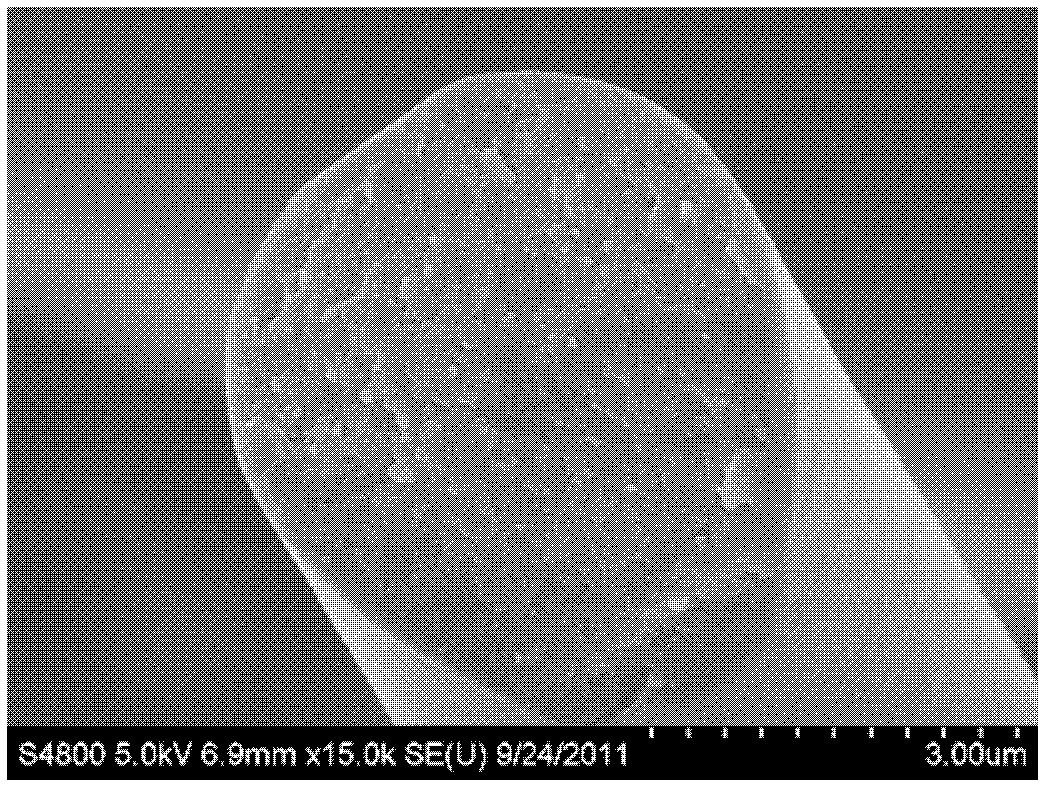

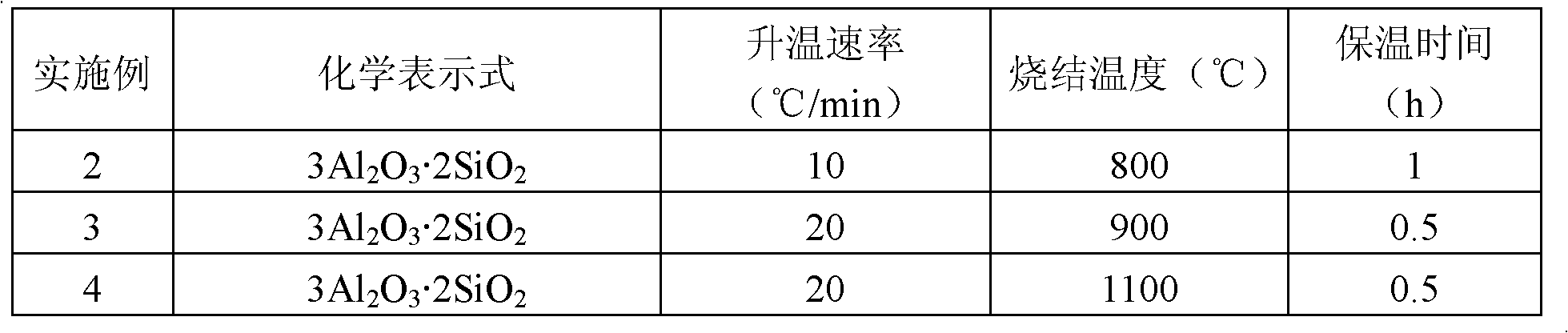

Mullite fiber preparation method

The invention discloses a mullite fiber preparation method which is efficient, rapid, environment-friendly and low in cost. The method includes: taking raw materials according to stoichiometric ratio of elements in the mullite fiber chemical formula, preparing colloid, performing fiber forming and drying for colloid discharging to obtain mullite non-crystal fiber, adding the fiber into a sagger made of wave permeable materials, placing the sagger in a special microwave oven, controlling heating rate by adjusting the microwave power under the air or oxygen atmosphere, heating to a heat treatment temperature, and cooling to the room temperature to obtain the mullite fiber. The mullite fiber prepared by the method is high in impurity and low in porosity, the grain size is about 30nm, and the fiber diameter ranges from 6 micrometers to 10 micrometers. Further, the mullite fiber is excellent in uniformity, brittle fracture and chalking of the fiber are greatly reduced, yield is increased, heat treatment temperature is lowered, heat insulation time is shortened, and production efficiency is greatly improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Clean ecological cattle vamp leather water field production technology

ActiveCN107641668AReduce pollutionReduce water consumptionTanning treatmentPre-tanning chemical treatmentIonChemistry

The invention relates to the technical field of tanning chemistry and engineering, and provides a clean ecological cattle vamp leather water field production technology. During implementation of the clean ecological cattle vamp leather water field production technology, lime, sulfide, ammonium salt, industrial salt and a heavy metal chromium-containing material are not used, so that main tanning pollutants such as sulfide, heavy metal chromium, ammonia nitrogen, chloride ions and the like are eliminated from sources, the environment pollution is relieved, and thus good cleanness, environment friendliness and ecology are achieved; furthermore, a whole process is simple and easy to implement, the operation is convenient and simple, and the practicality is high, so that the clean ecological cattle vamp leather water field production technology is a tannery cleaner production technology suitable for popularization and industrialization; in addition, chrome-free tanned crust leather produced by the clean ecological cattle vamp leather water field production technology is detailed, compact, soft, plump and elastic, has the shrinkage temperature of above 90 DEG C, has good follow-up processing performance, and has other physical and chemical properties meeting vamp leather requirements.

Owner:XINGYE LEATHER TECH CO LTD

Homogenization heat treatment process of large-size magnesium alloy ingot

The invention relates to a homogenization heat treatment process of a large-size magnesium alloy ingot, belonging to the technical field of magnesium alloy material preparation. The process is characterized by heating a large-size magnesium alloy ingot to 320-350 DEG C at a heating rate of 10-30 DEG C / min and then heating the large-size magnesium alloy ingot to 410-430 DEG C at a heating rate of 12-27 DEG C / h, insulating the large-size magnesium alloy ingot and then cooling the large-size magnesium alloy ingot to the room temperature at a cooling speed of 2-10 DEG C / min, thus obtaining the finished product, wherein the diameter phi of the large-size magnesium alloy ingot is not less than 220mm. The process has the beneficial effects that quick heating is carried out at the early stage of homogenization to release the casting stress to prevent growth of grains in the homogenization process; later, slow heating is carried out till the homogenization temperature to ensure that all the parts are heated uniformly to prevent overburning; then cooling is carried out at a cooling speed of 2-10 DEG C / min till the room temperature is reached, thus preventing cracking due to too quick cooling and also avoiding precipitation strengthening, which is unfavourable for subsequent deformation, due to too slow cooling; dendritic segregation of the large-size magnesium alloy ingot treated by the process is basically eliminated and the components in various parts of the large-size magnesium alloy ingot are uniform; besides, the equipment used in the process is a conventional resistance furnace, is mature in process and is safe and reliable.

Owner:CENT SOUTH UNIV

Water-based coating and preparation method thereof

ActiveCN101942256AReduce pollutionPollution meetsAnti-corrosive paintsPotassium persulfateSodium acetate

The invention relates to a water-based coating. The water-based coating is prepared form the following raw materials in percentage by weight: 52 to 55 percent of water, 0.5 to 0.7 percent of sodium dodecyl sulfate, 20 to 25 percent of methyl methacrylate, 3 to 4.5 percent of butyl acrylate, 0 to 2 percent of ethyl hexyl acrylate, 1 to 1.5 percent of acrylic acid, 10 to 15 percent of butyl methacrylate, 1 to 2 percent of butyl maleate, 0.6 to 1 percent of ethyl acrylate, 0.4 to 1 percent of itaconic acid, 0.8 to 1 percent of ammonia water, 0.1 to 0.2 percent of antifoaming agent, 0.05 to 0.1 percent of sodium acetate, 0.1 to 0.2 percent of preservative and 0.1 to 0.2 percent of potassium persulfate. The invention also provides a method for preparing the water-based coating. The water-based coating of the invention is innoxious and has a small amount of environmental pollution; and a coating layer formed by coating has the advantages of high brightness, toughness, excellent anti-explosion performance, excellent subsequent processing performance, capability of stamping gold rapidly and efficiently and good gold stamping effect.

Owner:SHANTOU XINYUAN CHEM TECH CO LTD

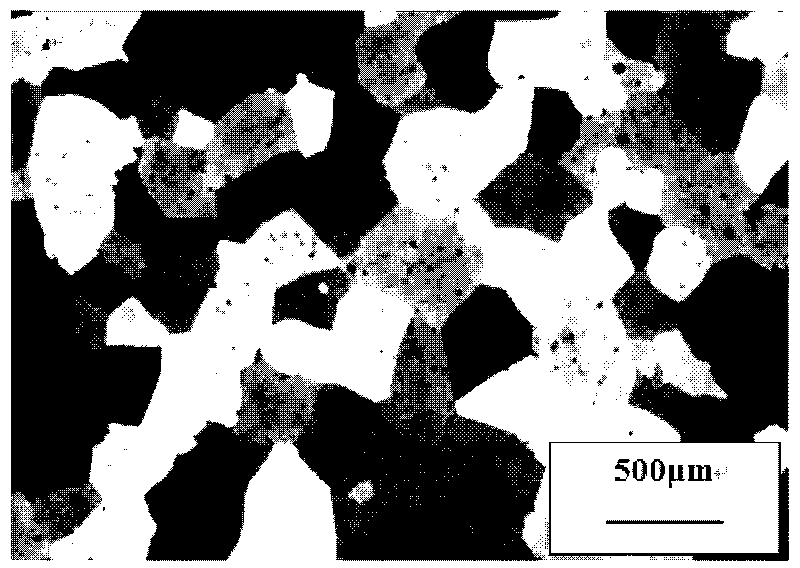

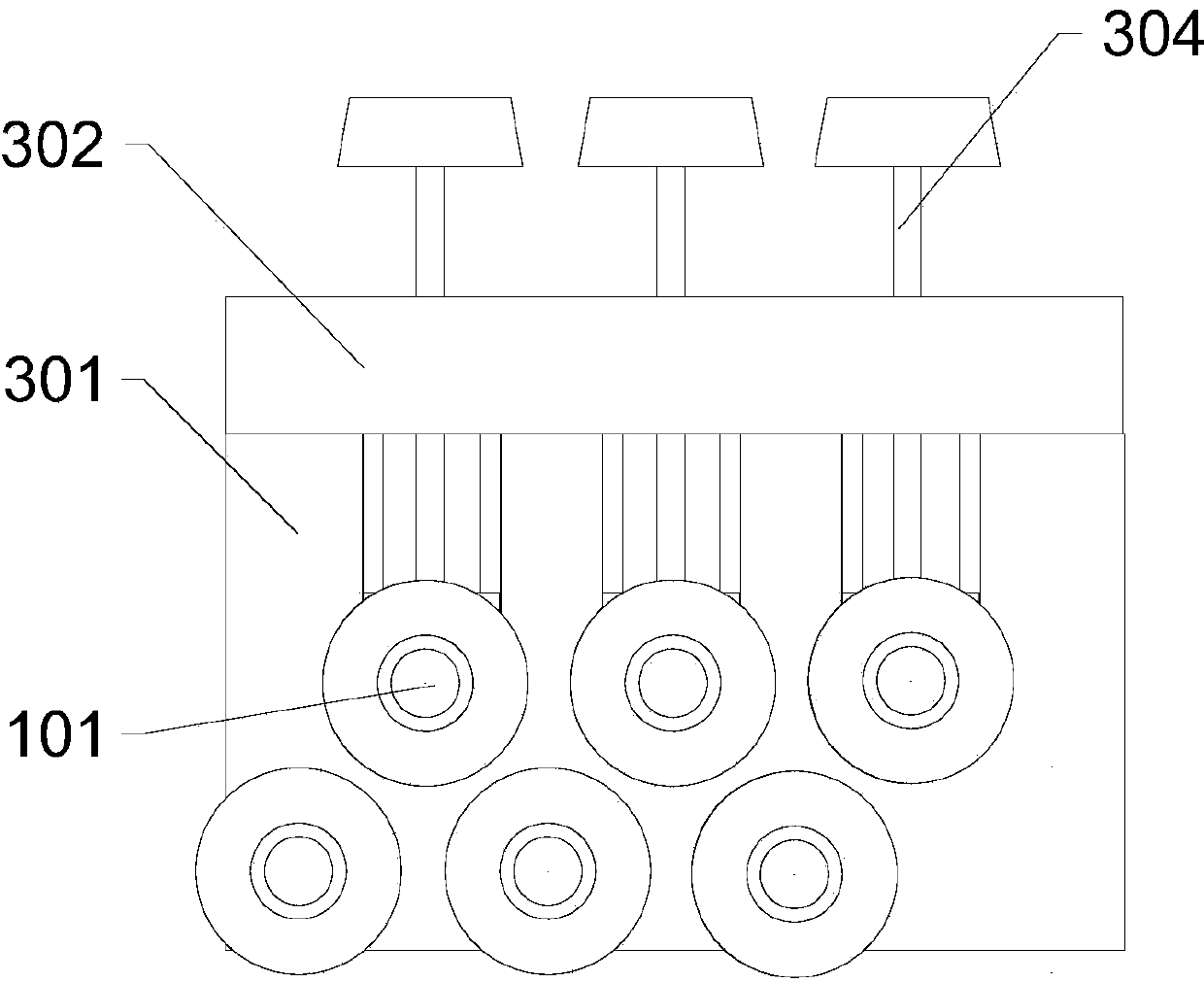

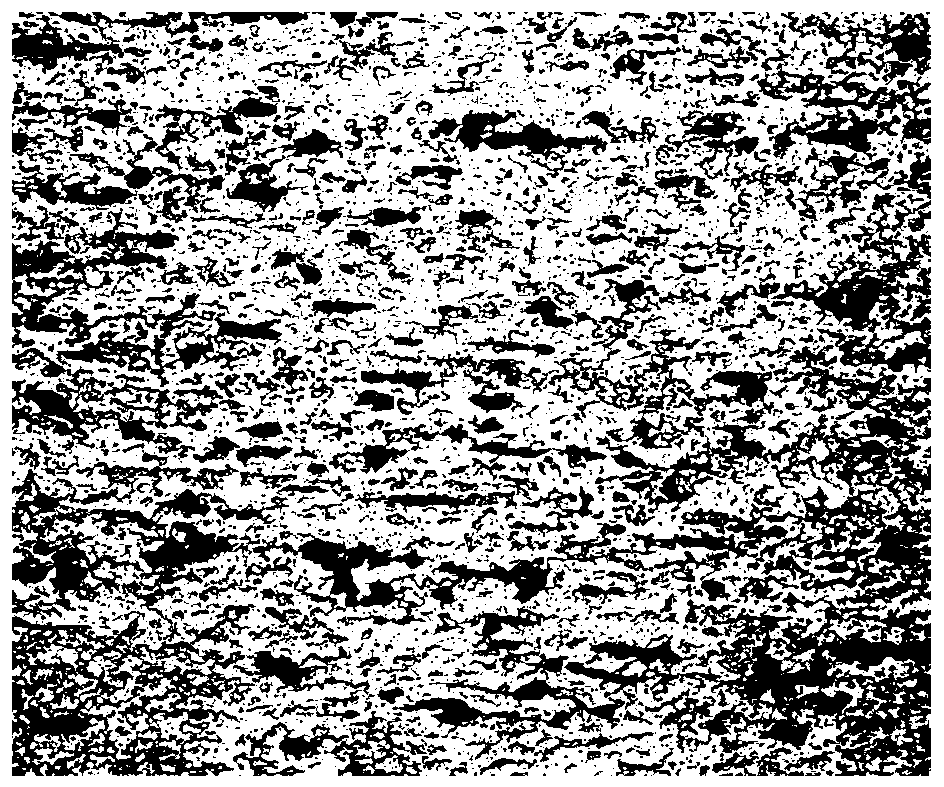

Processing method for refining crystal grains and improving texture of double surface layers of magnesium alloy plate strip

The invention relates to a processing method for refining crystal grains and improving texture of double surface layers of a magnesium alloy plate strip. In the method, the magnesium alloy plate strip is arranged between at least two groups of bending rolls which are stacked up and down and staggered mutually at the temperature of between 250 and 400 DEG C; the magnesium alloy plate strip is driven to move towards one direction for at least one pass, and when passing through the bending rolls, the magnesium alloy plate strip are bent and deformed, so the magnesium alloy plate strip of which the crystal grains of the double surface layers are refined and the texture is improved is prepared. In the deformation process, large strain is accumulated on the upper and lower surface layers of the plate strip due to repeated stretching and compression, and dynamic recrystallization is induced at middle and high temperature, so that the crystal grains of the double surface layers of the plate strip are refined; and the surface layers are subjected to shear stress, so that a basal plane deflects to improve the original texture. In the method, a process design is reasonable, and equipment is simple and convenient to operate, can be matched with the conventional processing equipment for magnesium alloy, has high processing efficiency and can improve the rigidity and ductility of the double surface layers of the magnesium alloy plate strip effectively and improve the subsequent processing performance of the magnesium alloy plate strip; and large-scale industrial production is easy to realize.

Owner:CENT SOUTH UNIV

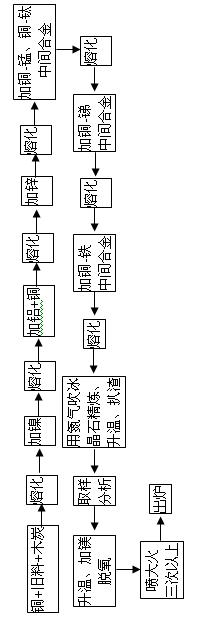

Cupronickel alloy and manufacturing method thereof for coinage

The invention discloses a cupronickel alloy for coinage. The cupronickel alloy comprises elements of, by mass, 8,0 to 10.0 percents of Ni, 16.0 to 19.0 percents of Zn, 3.0 to 5.0 percents of Mn, 1.8 to 2.5 percents of Ti, and 0.5 to 0.9 percent of Fe; and 0.3 to 0.7 percent of Al, 0.2 to 0.5 percent of Sb, no more than 0.9 percent of impurities, and the balance copper. According to the cupronickel alloy and the manufacturing method thereof, low price metal Zn, Mn, Al are used to replace precious metal Ni, thereby production and manufacture cost of the copper-based metal circulation currency can be greatly reduced; subsequent processing performance of production and manufacture of the metal circulation currency is improved by adding trace amounts of Sb; abrasion resistance performance of the metal circulation currency is improved by adding trace amounts of Fe; and abrasion resistance performance of the metal circulation currency is improved, and attractiveness and silver luster sensation of the metal currency are enhanced by adding alloy elements such as Al, Ti and the like.

Owner:甘肃和宏新材料有限公司

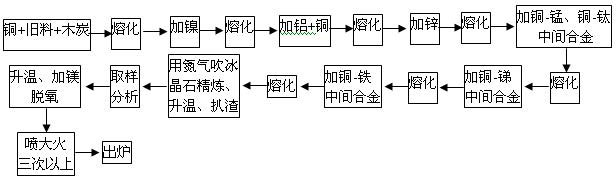

Cleaning technology for changing metal surface activity

InactiveCN105970242AChange in surface activityGood subsequent processing performanceRadio frequencyIon

Owner:SHENZHEN XINCHENGNUO ENVIRONMENTAL PROTECTION IND CO LTD

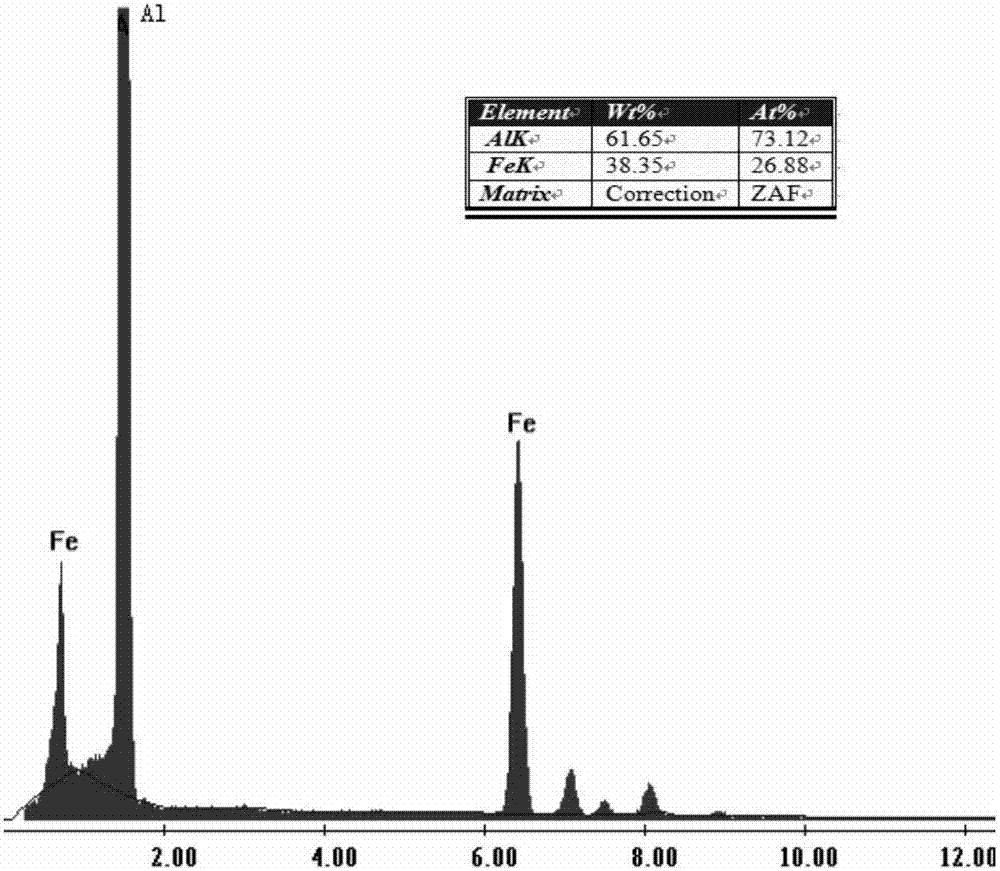

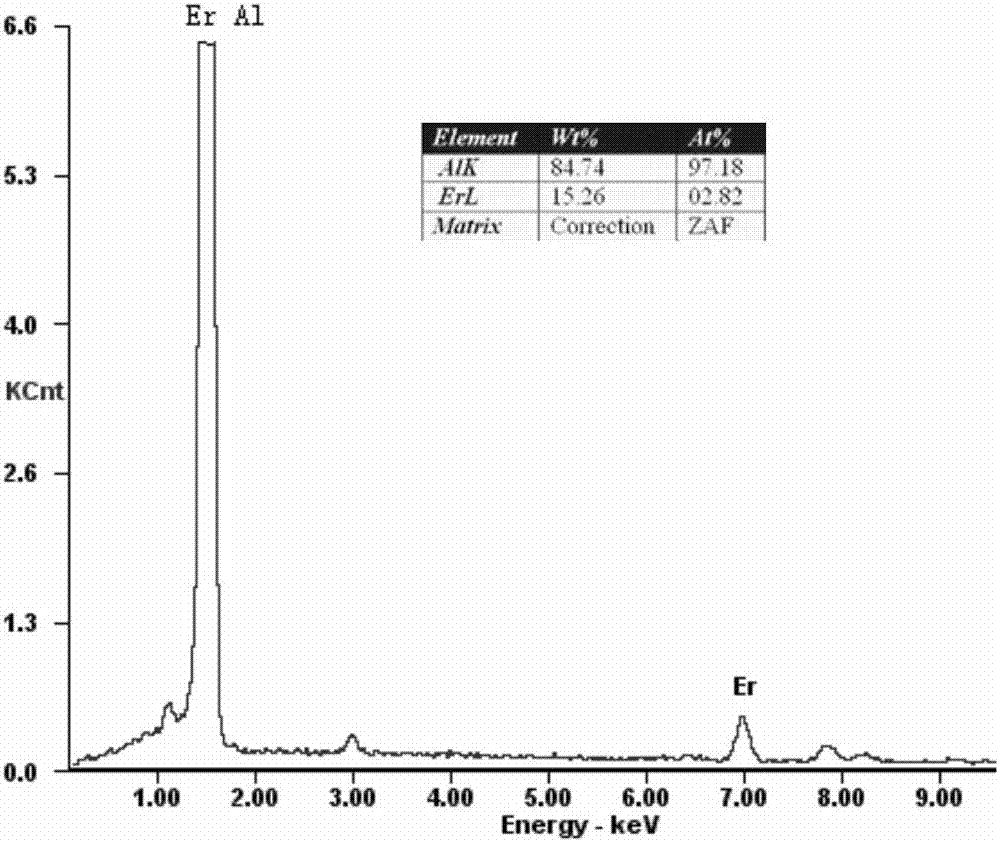

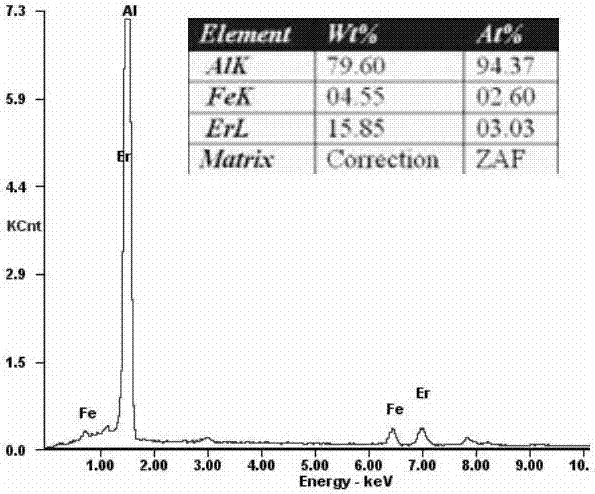

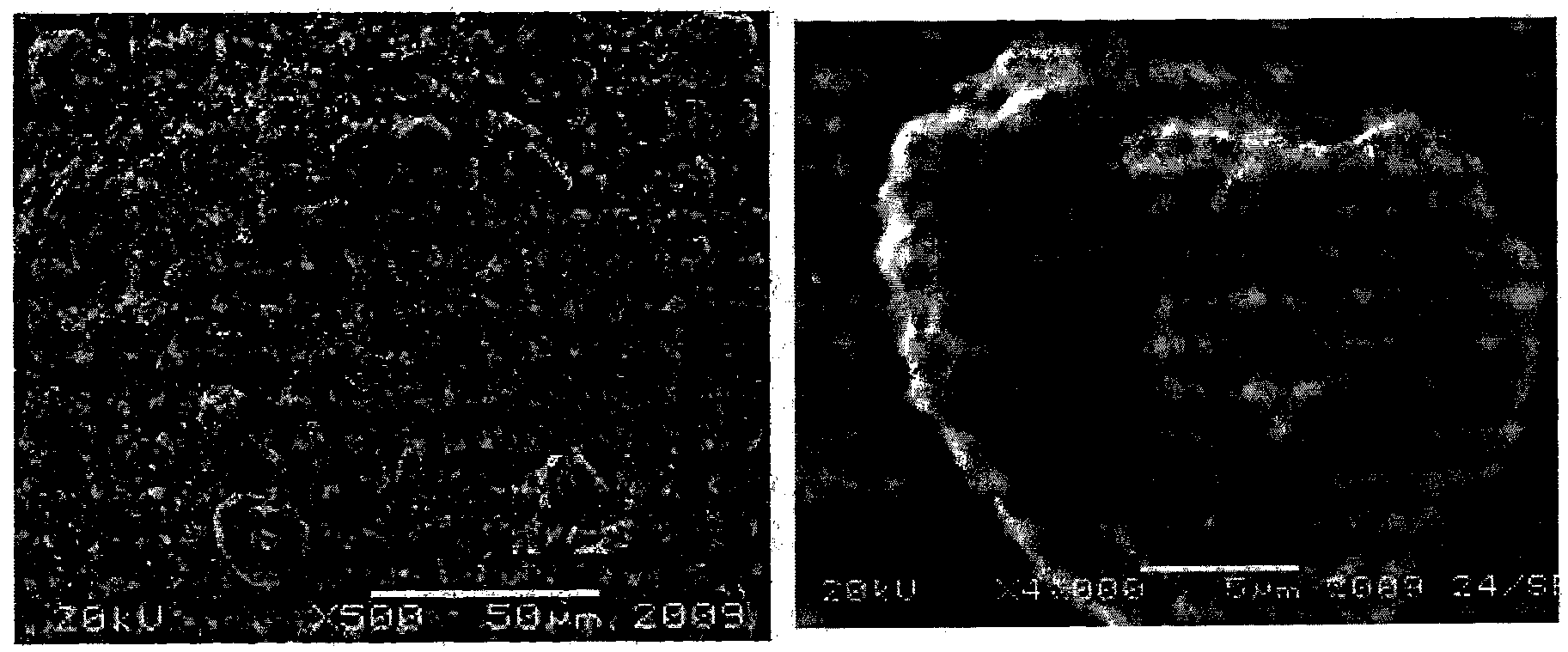

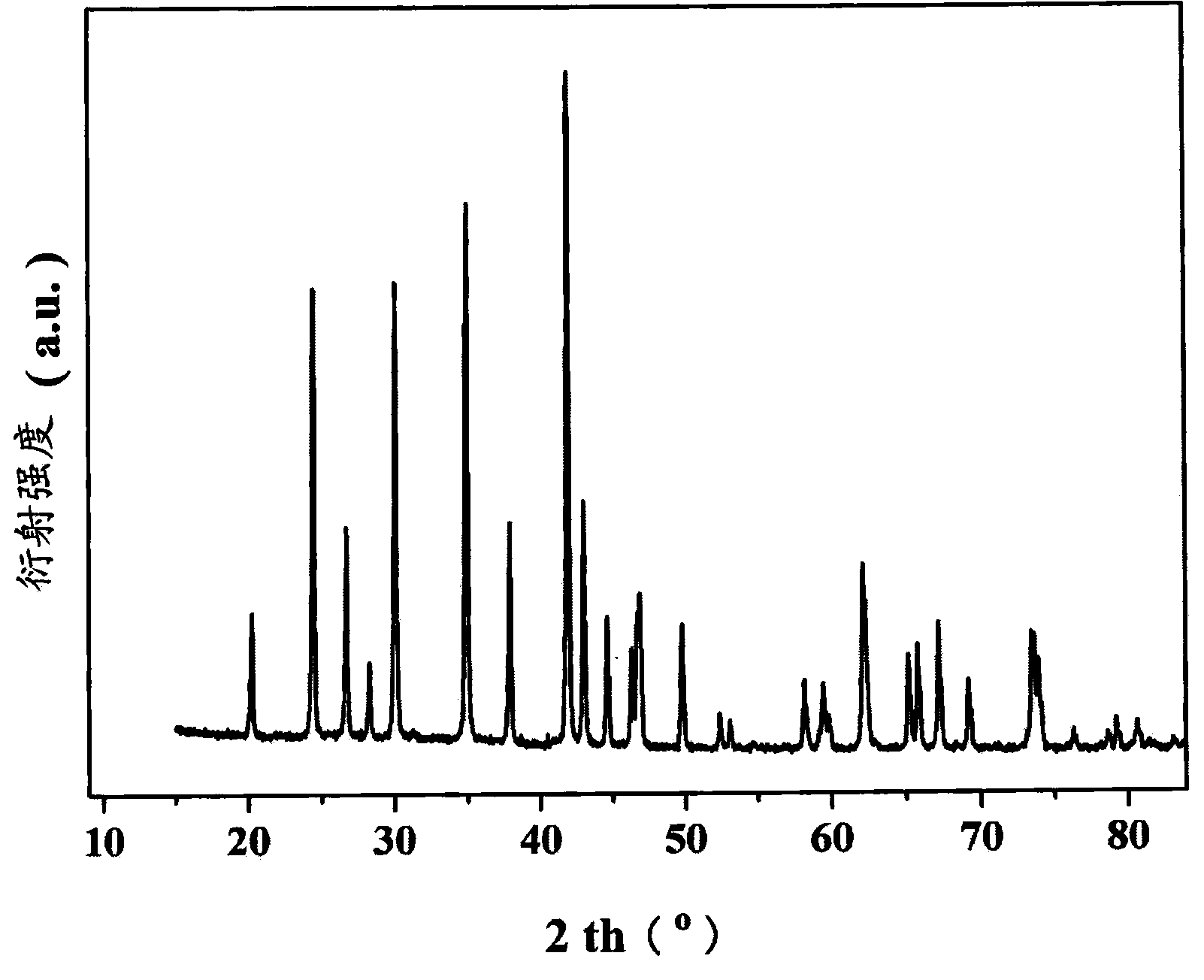

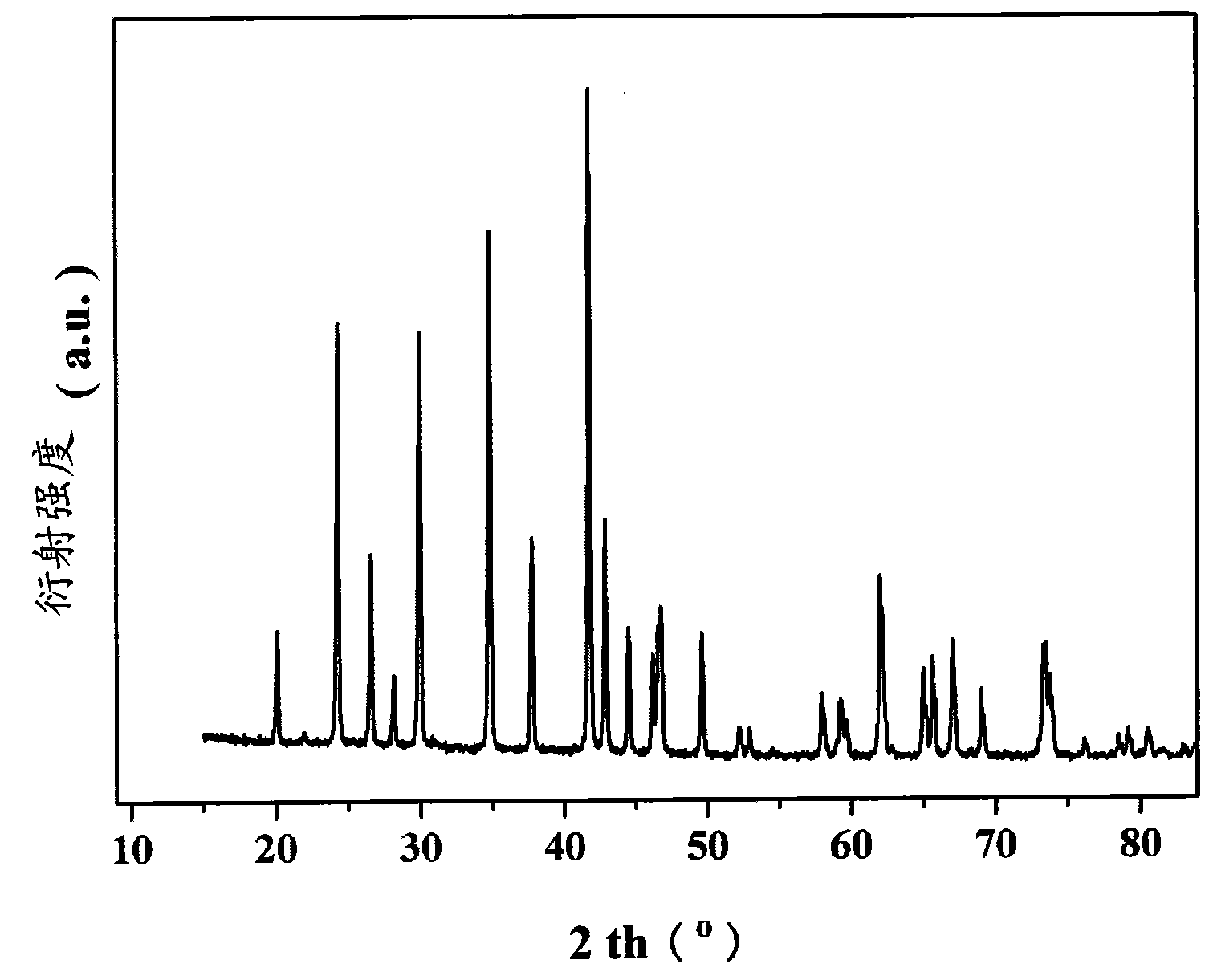

Light high-conductivity and heat-resistant aluminum conductor and preparation method thereof

ActiveCN105734353AImprove conductivityOo fullConductive materialMetal/alloy conductorsElectricityHeat resistance

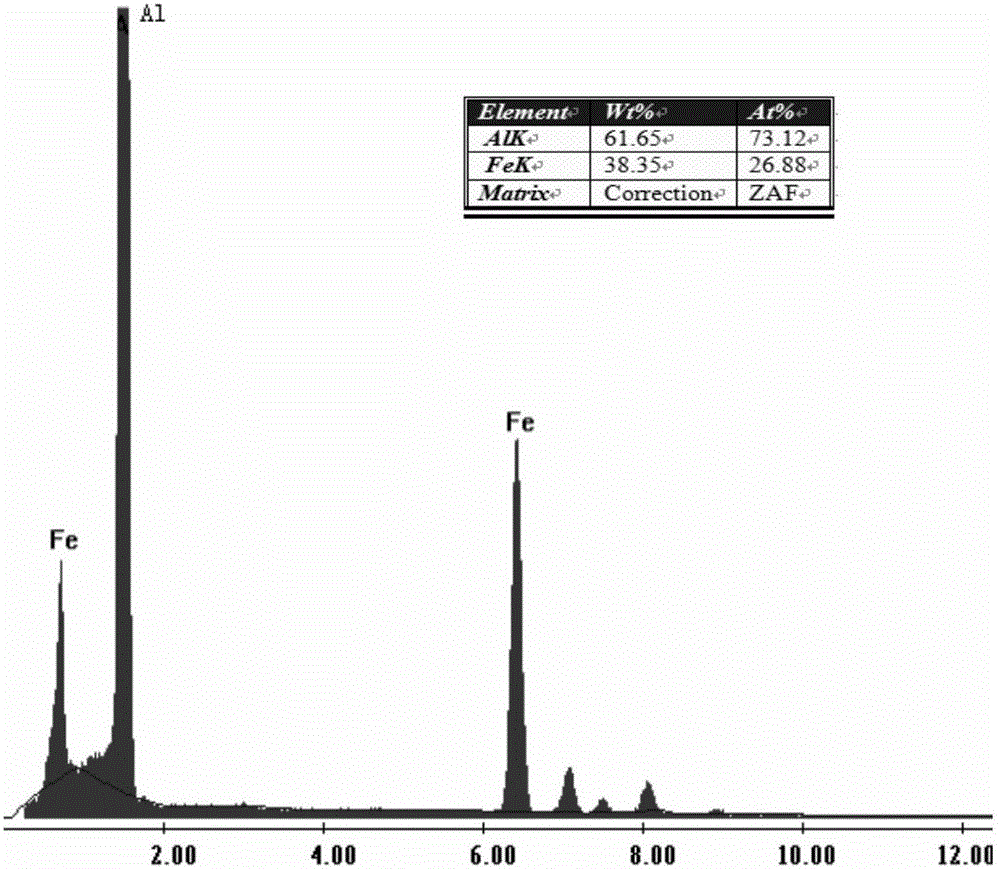

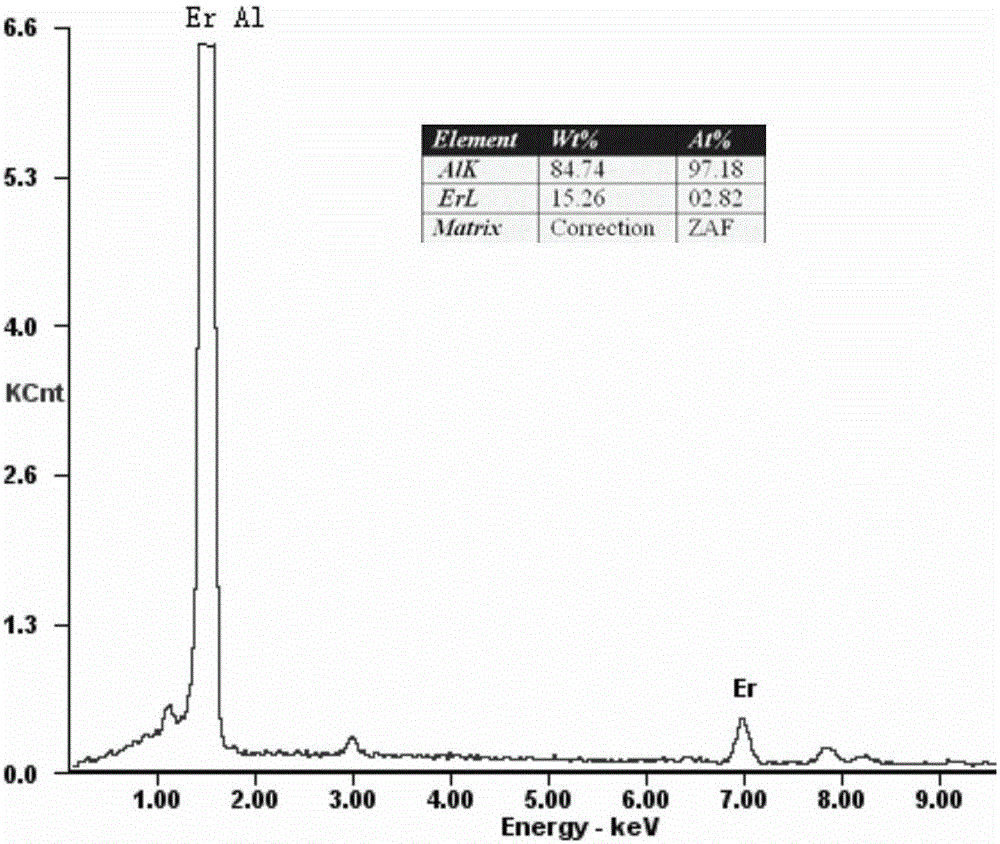

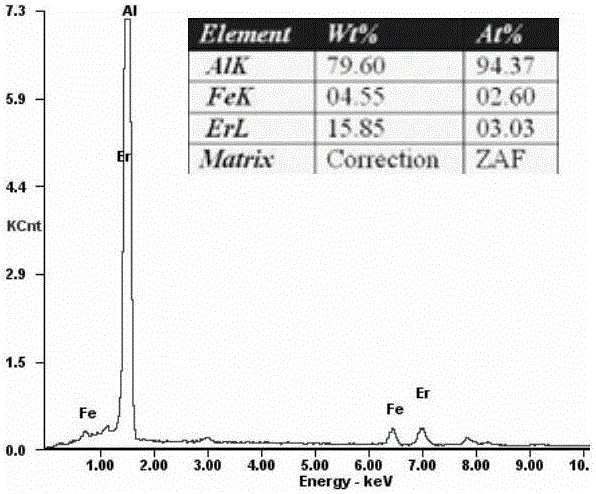

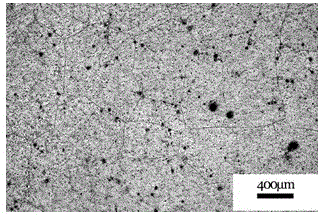

The invention discloses a light high-conductivity and heat-resistant aluminum conductor and a preparation method thereof. The aluminum conductor is composed of, by weight, 0.035-0.06% of B, 0.1-0.2% of Zr, 0.1-0.3% of Er, inevitable impurities and the balance Al. The technological process comprises the steps of smelting, on-the-spot fast component analyzing, refining, rapid cooling casting, blank annealing, extruding and drawing. The added B element has the refining and modifying effects and mainly has the effect of promoting supersaturated solid solutions containing Zr and Er to separate out Al3(Er and Zr) ternary composite phases; the Al3(Er and Zr) composite phases are nano particles which are coherent with a matrix and have shell-core structures, are dispersed in the aluminum matrix and can greatly improve the electricity conductivity and the heat resistance of the aluminum conductor; the density of obtained monofilaments is smaller than or equal to 2.71 g / cm<3>, the electricity conductivity of the monofilaments is greater than or equal to 62%IACS, the short-time heat-resistance temperature of the monofilaments reaches 230 DEG C, the long-term heat-resistance temperature of the monofilaments reaches 210 DEG C, and the tensile strength of the monofilaments is greater than or equal to 165 MPa; the economic benefits are remarkable, the energy is greatly saved, and the environmental friendliness is high.

Owner:CENT SOUTH UNIV

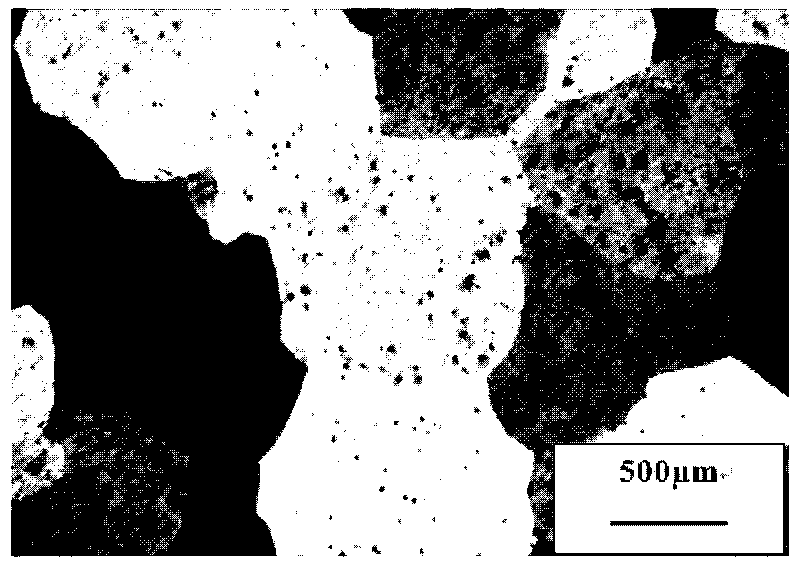

Grain-refined manganese-lithium alloy and method for manufacturing same

The invention discloses grain-refined manganese-lithium alloy and a method for manufacturing the same. The manganese-lithium alloy comprises, by mass, from 11.0% to 15.0% of Li, form 1.0% to 3.0% of Al, from 0.1% to 0.5% of La, lower than or equal to 0.3% of impurities and the balance manganese. The method for manufacturing the grain-refined manganese-lithium alloy includes heating a formula amount of the pure manganese, a formula amount of the pure lithium, a formula amount of the pure aluminum and a formula amount of manganese-lanthanum master alloy under conditions of vacuumizing and feeding of inert gas until the temperature reaches 720 DEG C to obtain alloy; preserving heat at the temperature of 700 DEG C after the alloy is completely melted, and allowing the alloy to stand for 15 minutes; and pouring melted alloy liquid in molds to obtain as-cast manganese-lithium alloy. The grain-refine manganese-lithium alloy contains rare earth La, structures of grains of the grain-refine manganese-lithium alloy are fine and uniform, the strength and the plasticity are improved, and the grain-refine manganese-lithium alloy is excellent in follow-up processing property, low in production cost and suitable for industrial large-scale production.

Owner:CHONGQING UNIV

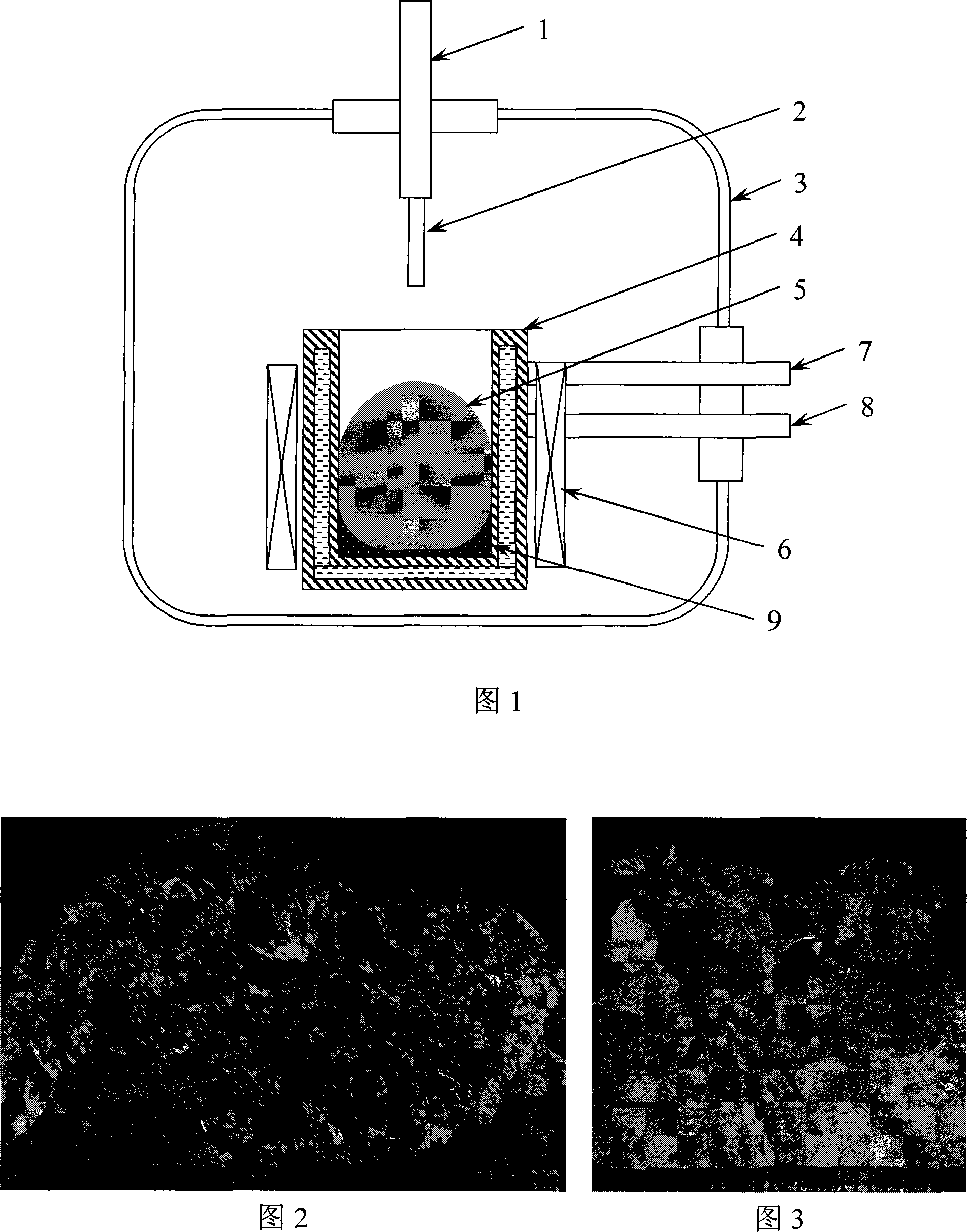

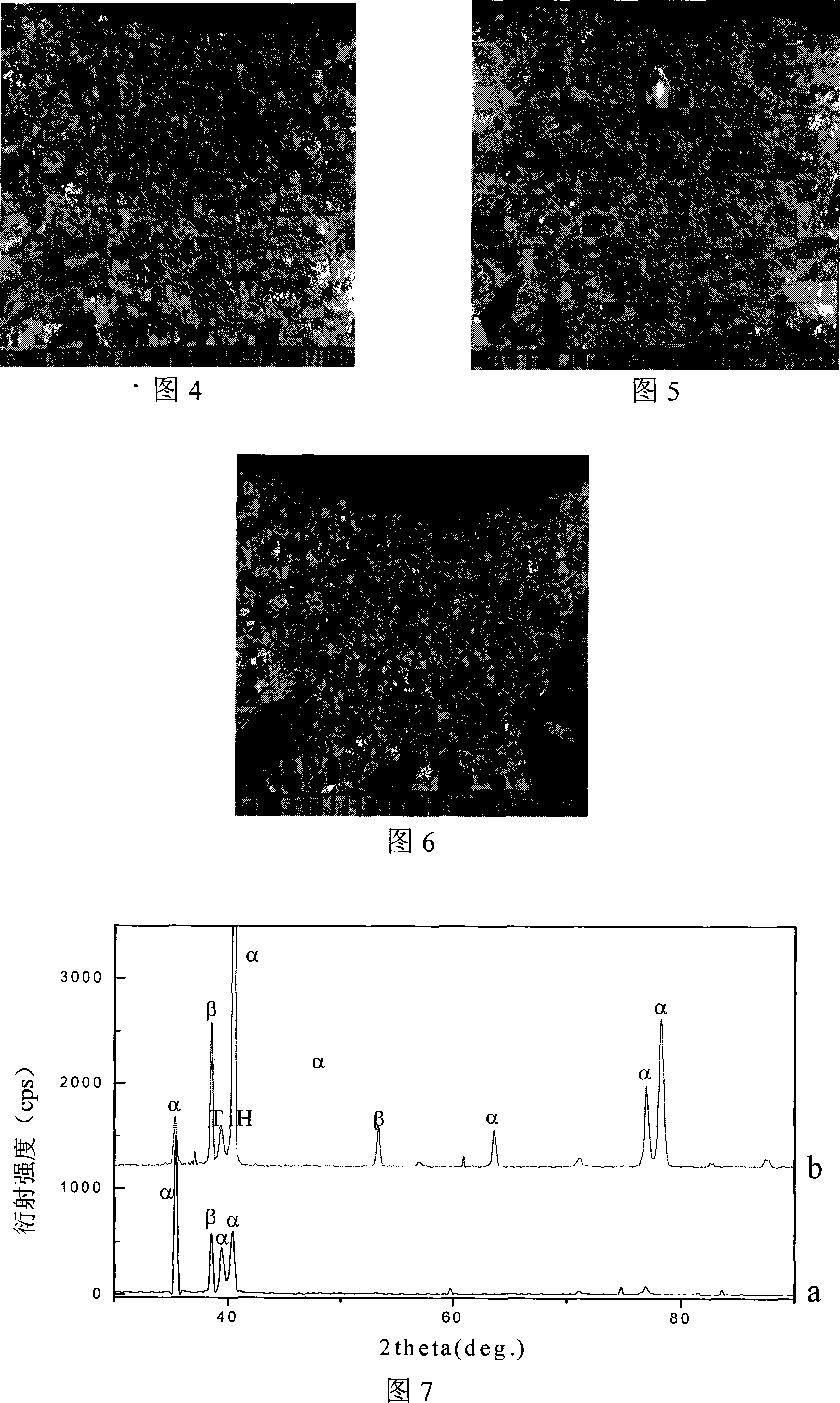

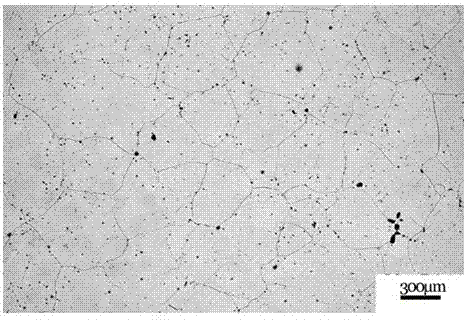

Liquid state hydrogen-replacing thinning solidifying tissue method in Ti-6Al-4V alloy induction shell smelting process

InactiveCN101121969AImprove mechanical propertiesGood subsequent processing performanceTi 6al 4vTemperature drop

A method for liquid hydrogenation refinement of solidification structure in the process of Ti-6Al-4V alloy induction skull melting relates to a liquid hydrogenation technology in the process of titanium alloy induction skull melting. The method solves the problem of slow speed of hydrogen permeation under titanium alloy atmosphere which is only applicable to the preparation of small specimen or thin specimen, but not to wide production. The detailed procedures of the method are as follows: the charging material of Ti-6Al-4V alloy is put into the crucible of an induction skull melter, heated and melted under the environment of high-purity argon and 400-700Pa pressure; pre-coated bars with the TiH2 of the weight accounting for 0.09 to 0.2 percent of the charging material are added in; when the hydrogen-contained titanium alloy in the crucible cools and the temperature drops below 300 DEG C, the charging material is vented off and cooled until the temperature equal to room temperature. The size of the Ti-6Al-4V alloy crystallization grain after the treatment of liquid hydrogenation with the method is smaller than 800 Mu m. The method is widely applicable in preparation of titanium alloys.

Owner:HARBIN INST OF TECH

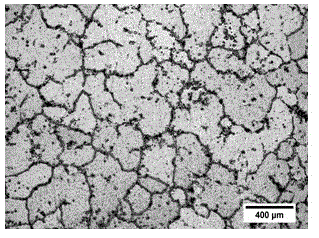

Method for refining LA141 magnesium-lithium alloy grains

The invention relates to a method for refining LA141 magnesium-lithium alloy grains. In the process of smelting, Al-5Ti-1B master alloy is added to refine the LA141 magnesium-lithium alloy grains. A cast structure of the obtained LA141 magnesium-lithium alloy is fine, and simultaneously has excellent intensity and plasticity and excellent subsequent machining performance.

Owner:CHONGQING UNIV

Low-density high-strength magnesium lithium alloy and preparing method thereof

The invention provides a low-density high-strength magnesium-lithium alloy and a preparation method thereof. The components and mass percentages of the magnesium-lithium alloy are: 11-15% Li, 0.5-4% Al, 0.05-0.5% Zr, 0.2~1.2%La, 0.1~0.6%Ce, the total amount of impurity elements Fe, Ni, Cu, Si≤0.2%, and the balance is Mg. The preparation method of the magnesium-lithium alloy involved in the present invention includes vacuum induction melting and plastic deformation treatment. The magnesium-lithium alloy processed by means of alloying, crystal grain refinement and deformation treatment in the present invention has high strength and plasticity under the premise of ensuring low density, and at the same time has excellent machining performance.

Owner:江苏立美航材科技有限公司

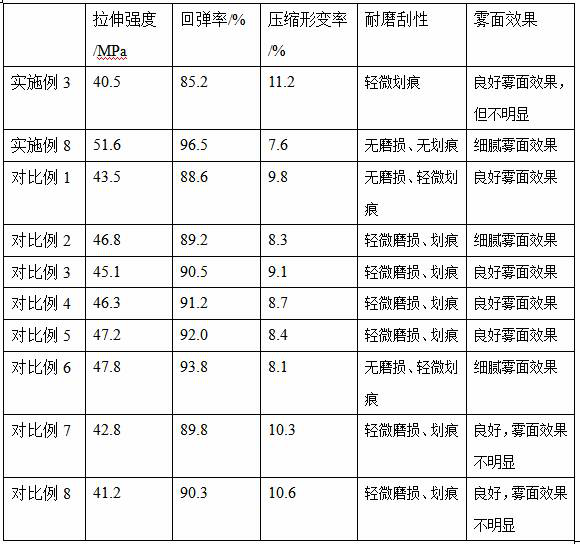

Polyester elastomer-based neck hanging line shaping material as well as preparation method and application thereof

The invention relates to the field of polymer materials, in particular to a polyester elastomer-based neck hanging line shaping material as well as a preparation method and application thereof. The material is prepared from the following raw materials in parts by weight: 50-70 parts of polyester elastomer, 15-25 parts of TPU, 10-25 parts of polyolefin elastomer, 3-5 parts of a compatilizer, 1-3 parts of a lubricant and 3-4 parts of an assistant. According to the material, the TPU and the polyolefin elastomer are introduced for polymerization, the compatibility of the materials is improved under the action of the compatilizer, the flexibility and toughness of the shaping material are improved by introducing the TPU, and the resilience and impact resistance of the shaping material are improved by combining the polyolefin elastomer; and the shaping material prepared after polymerization can be prepared and molded in a low-temperature environment, so that the preparation difficulty and theenergy consumption cost are reduced, and the product is good in rebound resilience, not liable to deform, high in breaking strength, high in impact strength and not liable to break.

Owner:东莞市鼎誉新材料有限公司

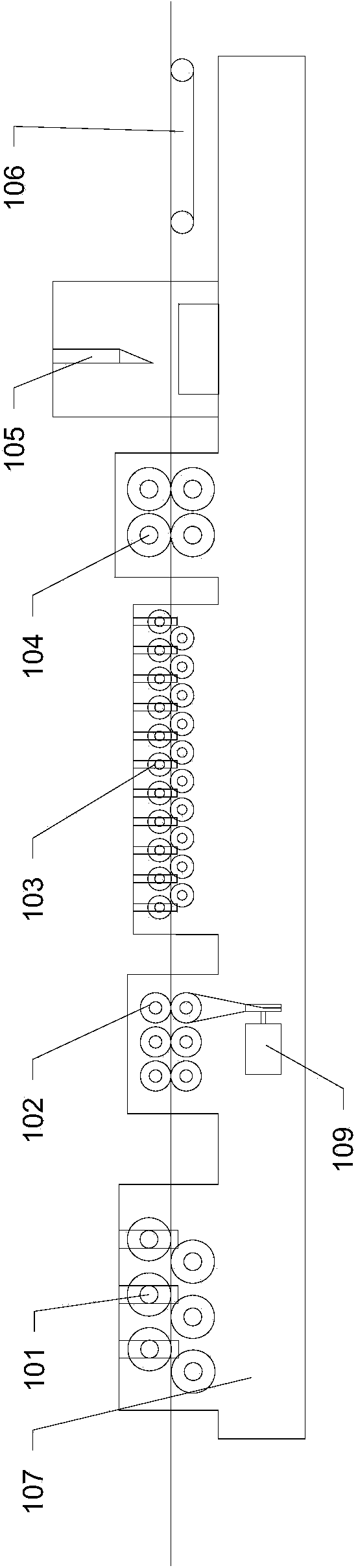

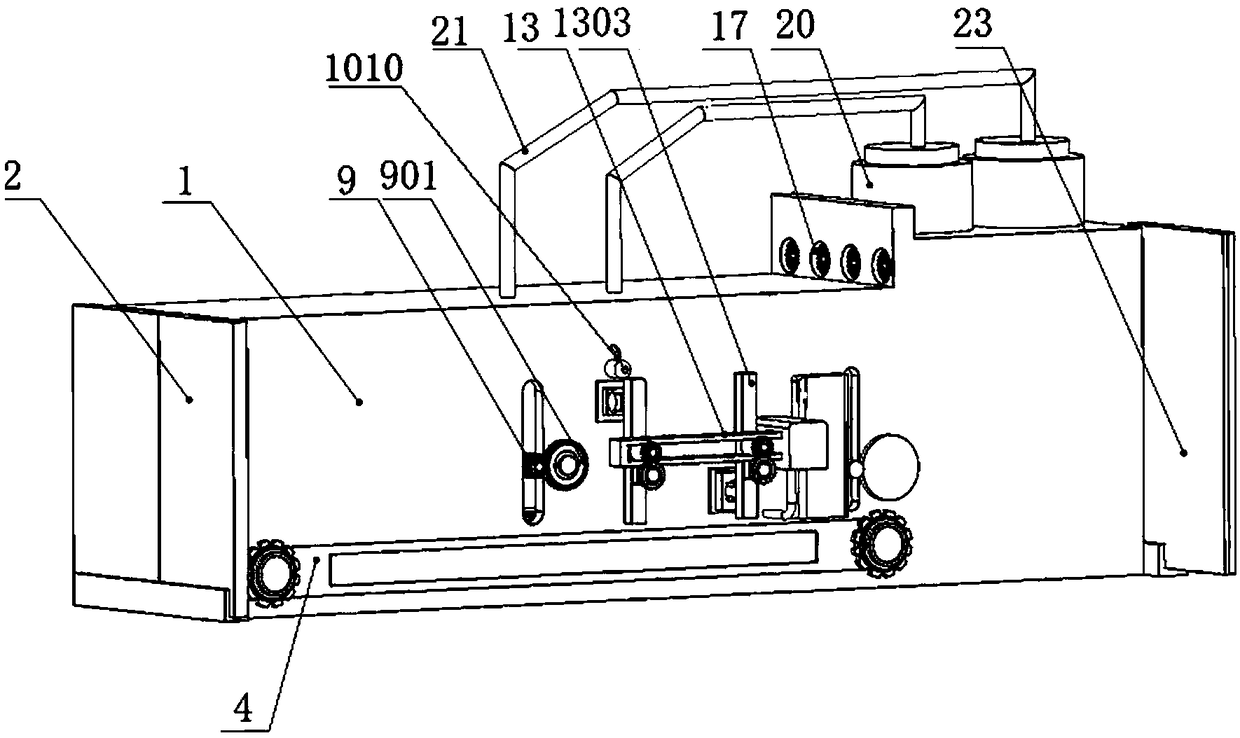

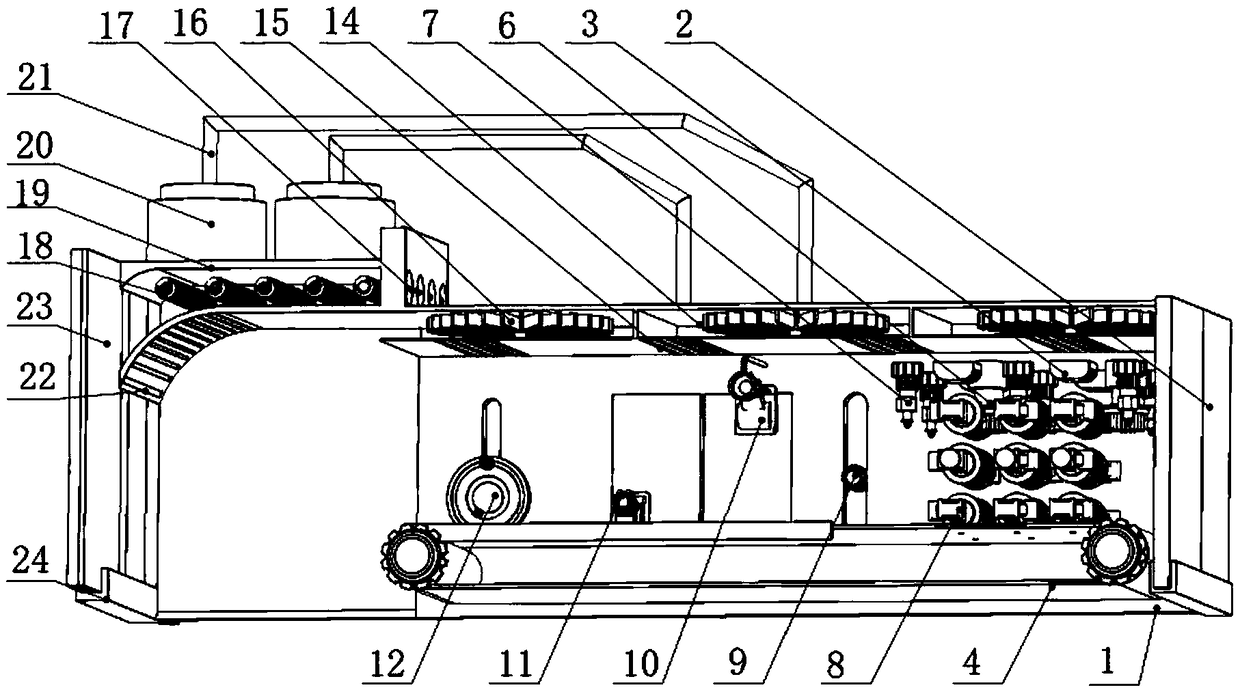

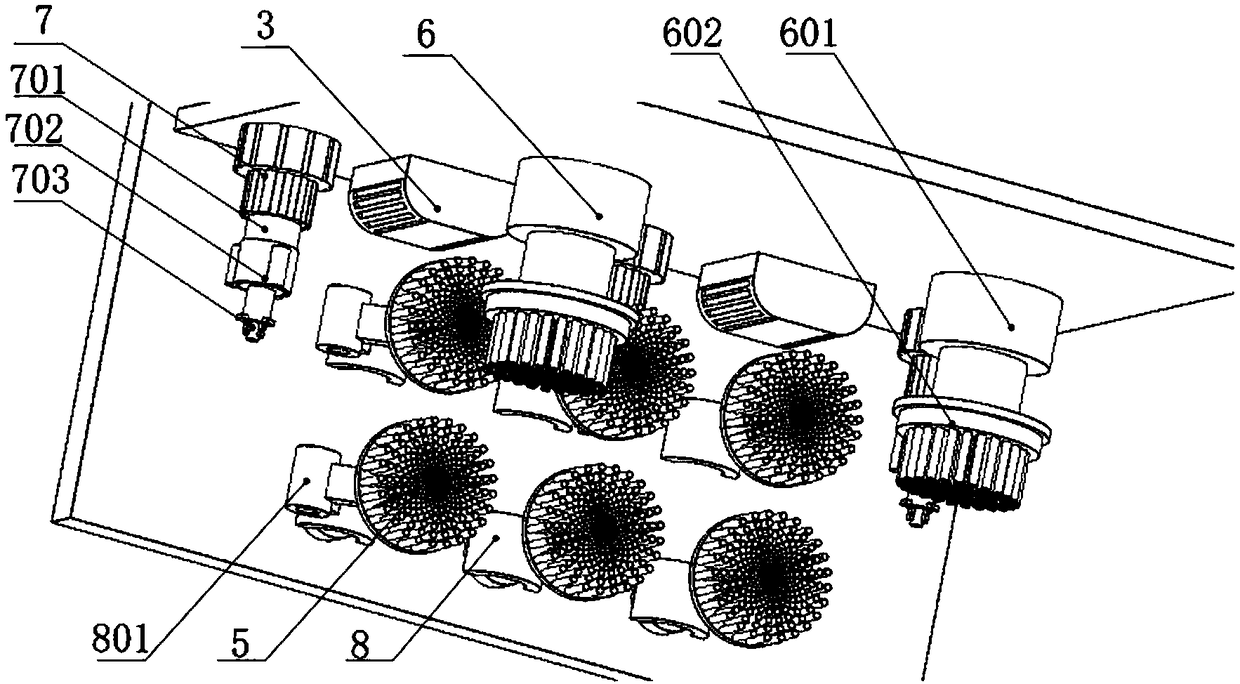

Metal wire straightening and cutting machine

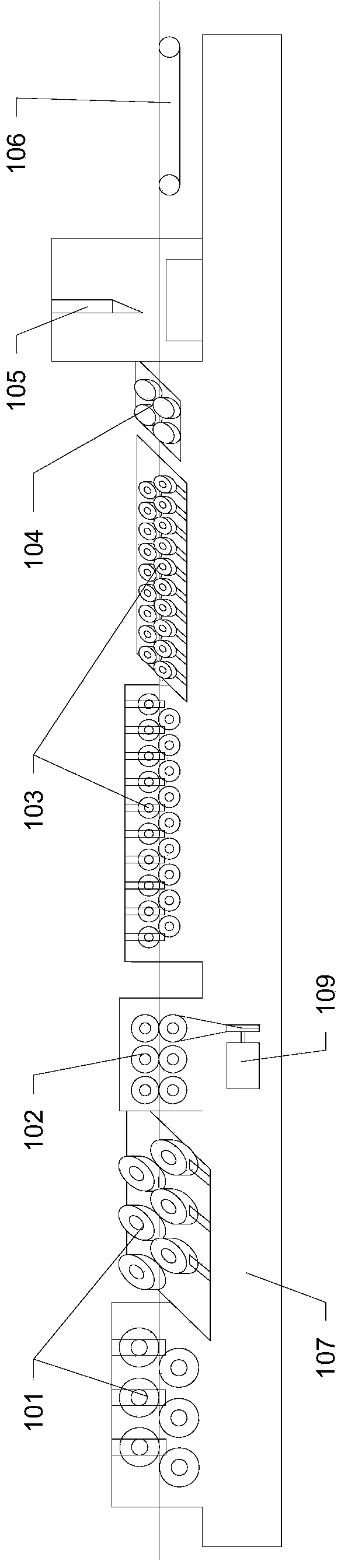

ActiveCN103801636AQuick straightening and cuttingImprove roughness accuracyDrive wheelMetal machining

The invention provides a metal wire straightening and cutting machine and relates to the field of metal machining equipment. The metal wire straightening and cutting machine comprises a roller train, a driving wheel set, a straightening wheel set, a milling wheel set, a cutting mechanism, a delivery mechanism, a power source and a machine tool, wherein the delivery mechanism is arranged at one end of the machine tool; the cutting mechanism is adjacent to the delivery mechanism and is arranged on the machine tool; at one side of the cutting mechanism, which is far away from the delivery mechanism, the milling wheel set, the straightening wheel set, the driving wheel set and the roller train are sequentially and adjacently arranged on the machine tool; the power source is connected with the driving wheel set. The metal wire straightening and cutting machine has the benefits that the metal wire straightening and cutting machine is provided, can straighten a metal wire when eliminating stress of the metal wire and also can ensure that the straightened and cut metal wire has small wear and scratches to appearance, high roughness accuracy, small residual stress and excellent subsequent machinability.

Owner:陆国华

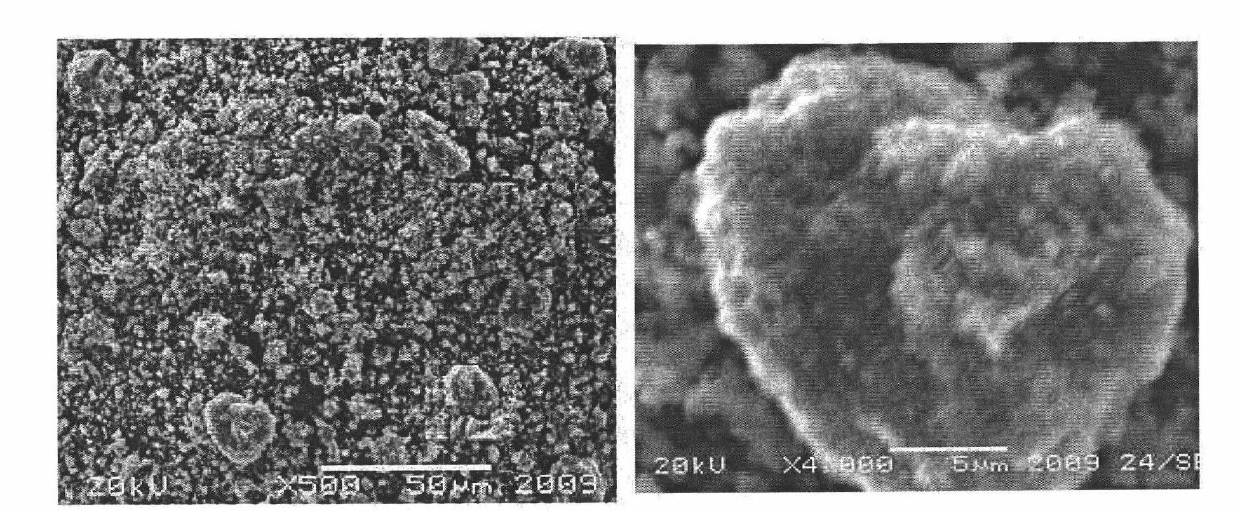

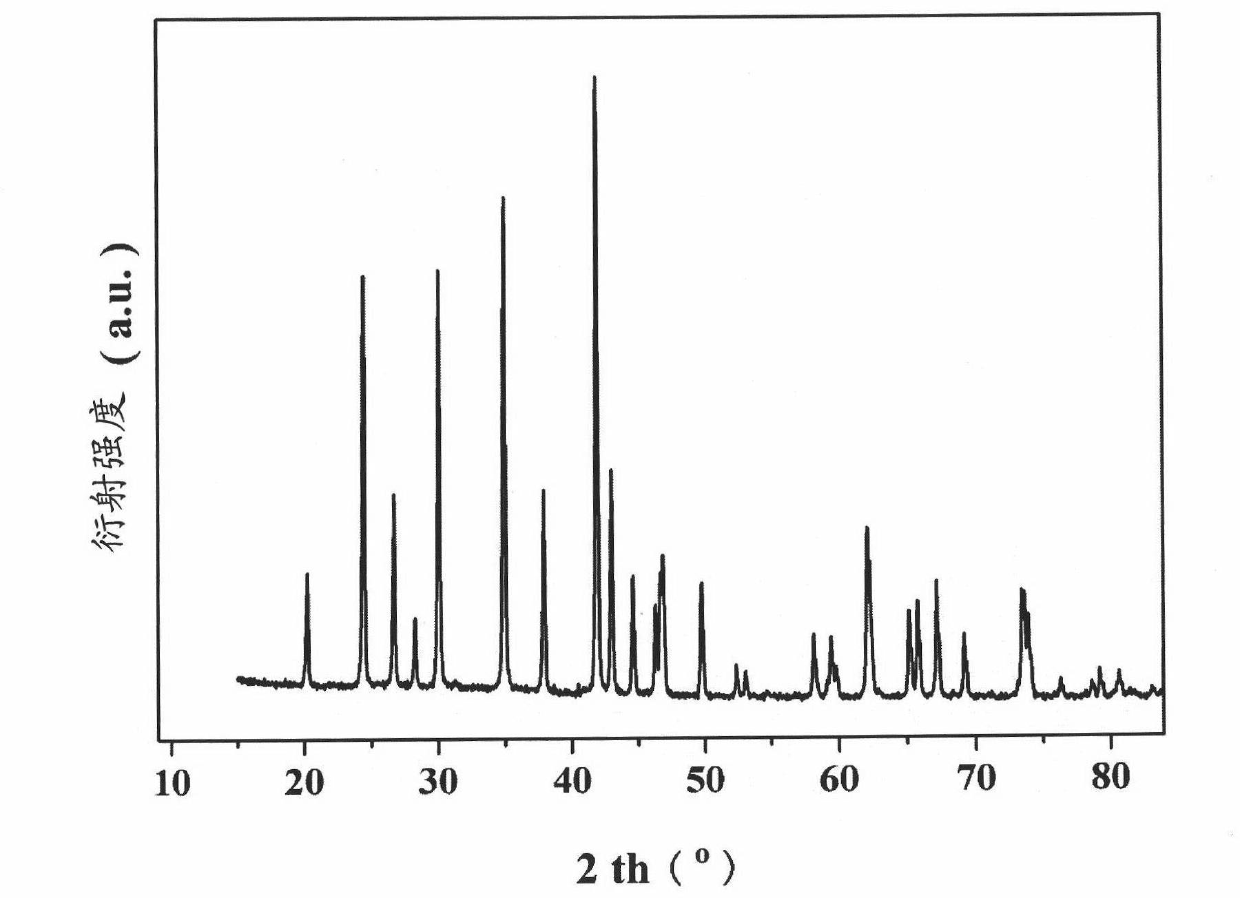

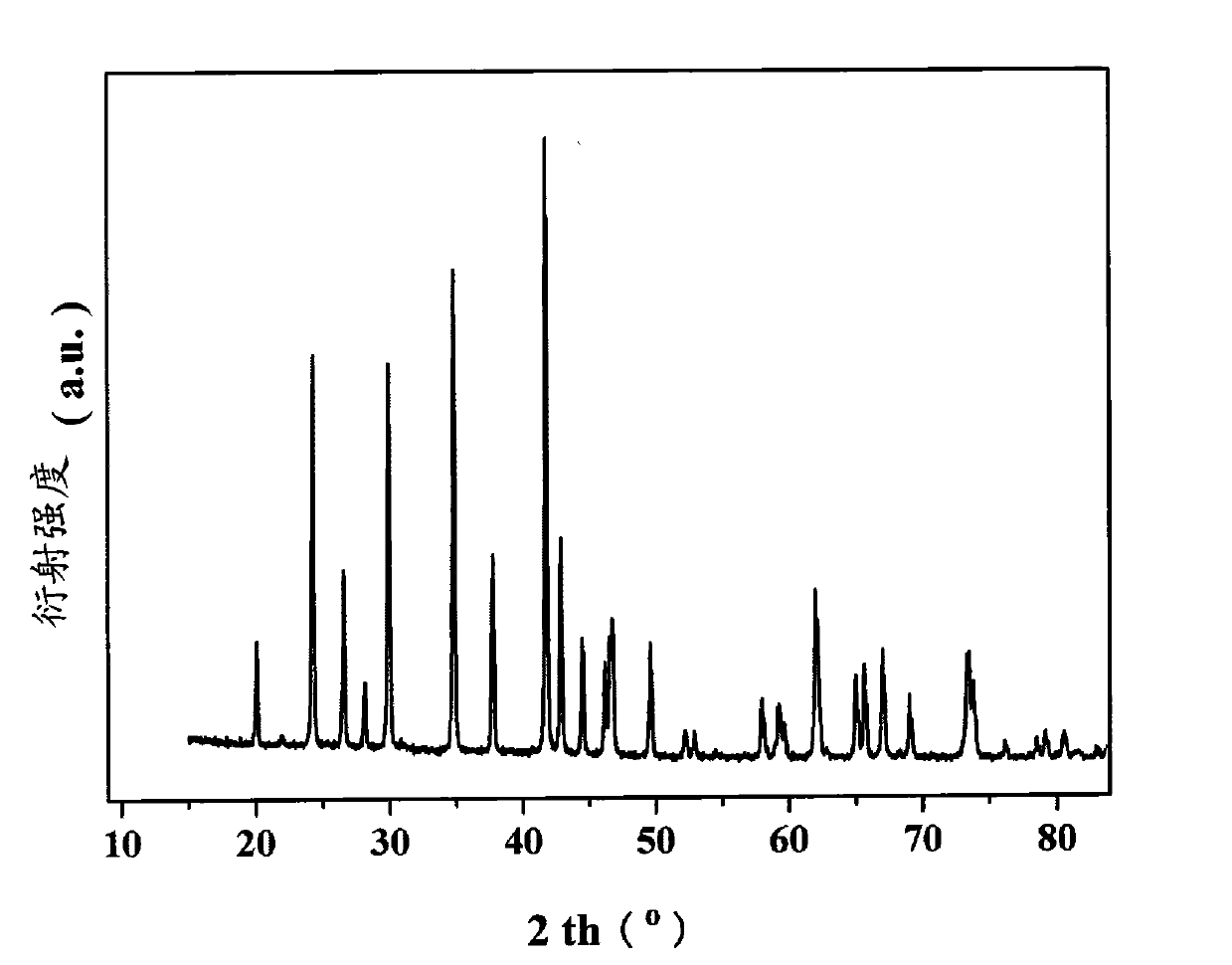

Preparation method and application of micro/nano structured LiFePO4 compound

InactiveCN102086032AImprove featuresGood subsequent processing performanceCell electrodesPhosphorus compoundsNano structuringPhosphate

The invention discloses a preparation method of micro / nano structured LiFePO4 compound and the method comprises: mixing Li source, divalent iron source, phosphate, and compound(s) with molten salt effects and calcinating the mixture in an inert atmosphere at a temperature of 550 to 850 DEG C, wherein the compound(s) with molten salt effects can change into molten compound(s) at a calcination temperature. The invention also discloses the applications of the LiFePO4 compound prepared by the above preparation method and the applications of the LiFePO4 compound as lithium ion battery cathode materials. The preparation method of the present invention is simple in operation and can be used to produce products with good electrochemical performance; and moreover the materials required are of low price, therefore the method is convenient for large scale production.

Owner:ZHENGZHOU BAK BATTERY CO LTD

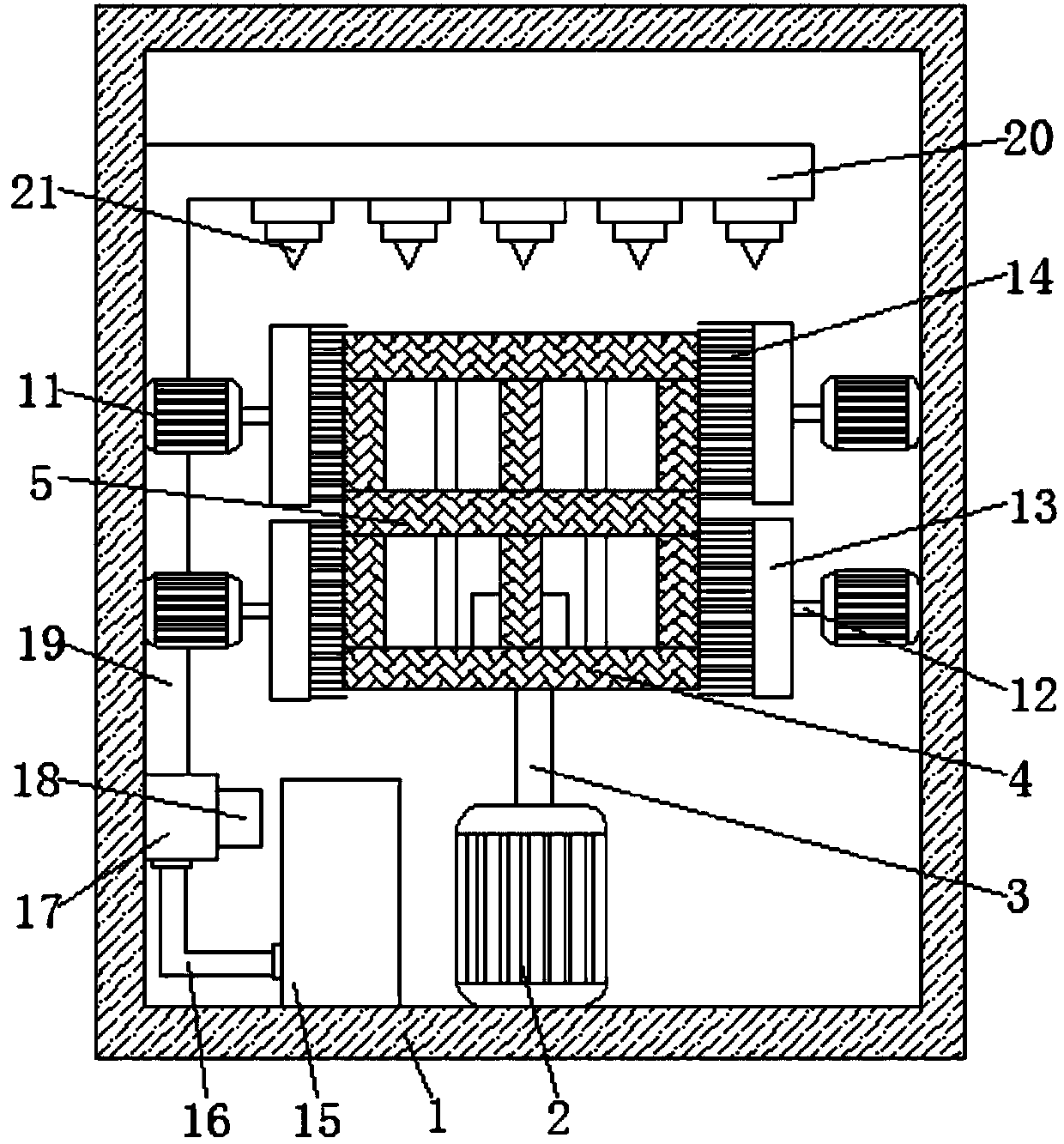

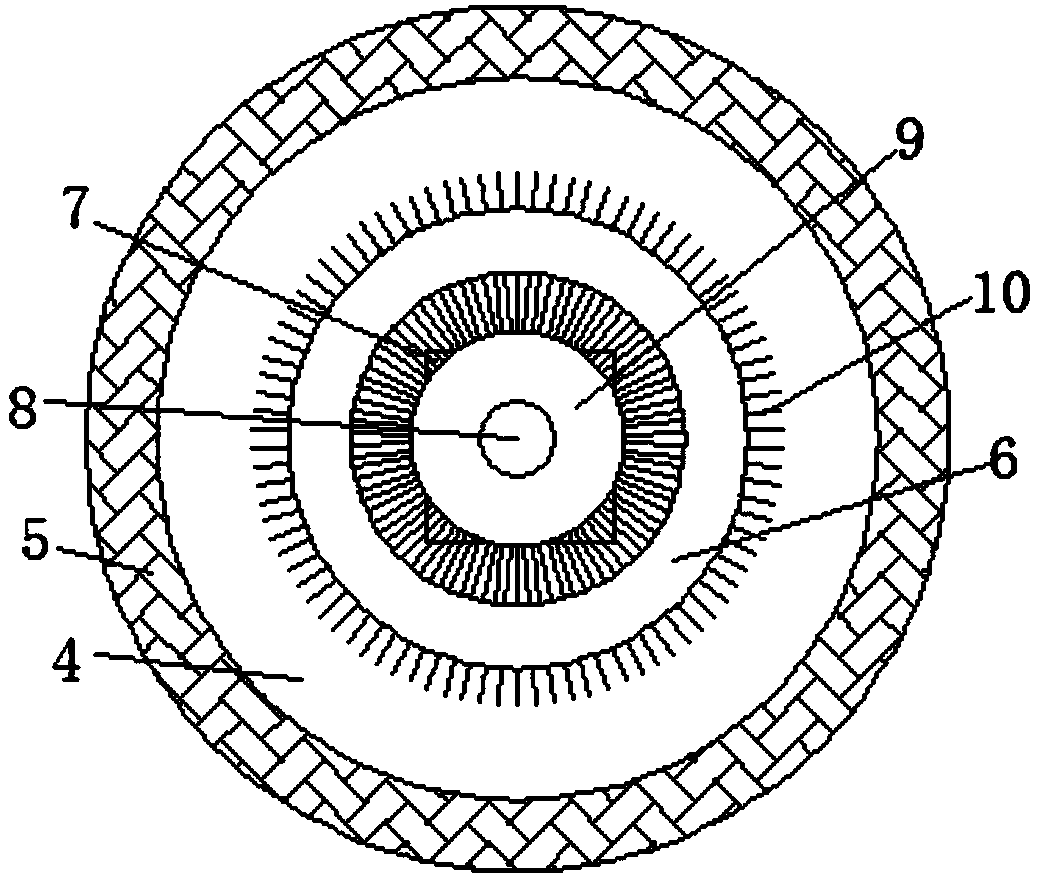

Vehicle paint surface spraying and repairing device

InactiveCN108906459AImprove repair effectRestore the effect of car paintPretreated surfacesCoatingsElectrophoresisEngineering

The invention discloses a vehicle paint surface spraying and repairing device, and belongs to the technical field of vehicle paint repairing technologies. The vehicle paint surface spraying and repairing device comprises a shell and sealing doors, and the sealing doors are arranged at the two ends of the shell to form a closed shell with a mounting space inside. A conveying device used for conveying a vehicle is arranged at the bottom of the inner side of the shell, and the inner part of the shell is sequentially provided with a grinding area, a phosphorization area, an electrophoresis area, aspraying area and a drying area in the conveying direction of the conveying device. The grinding area is provided with a grinding mechanism, the phosphorization area is provided with a phosphorization mechanism, an electrophoresis part is arranged in the electrophoresis area, a spraying part is arranged in the spraying area, and a drying mechanism is arranged in the drying area. By arranging multiple repairing mechanisms, car paint repairing can be carried out in a sealed dust-free environment, and the paint spraying and repairing effects of a vehicle paint surface are enhanced so that the vehicle can recover the paint spraying effect obtained when the vehicle leaves a factory. The conveying device and the like are arranged, so that the repairing work is more intelligent, and the work efficiency is improved.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

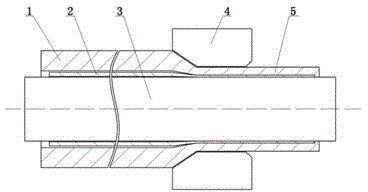

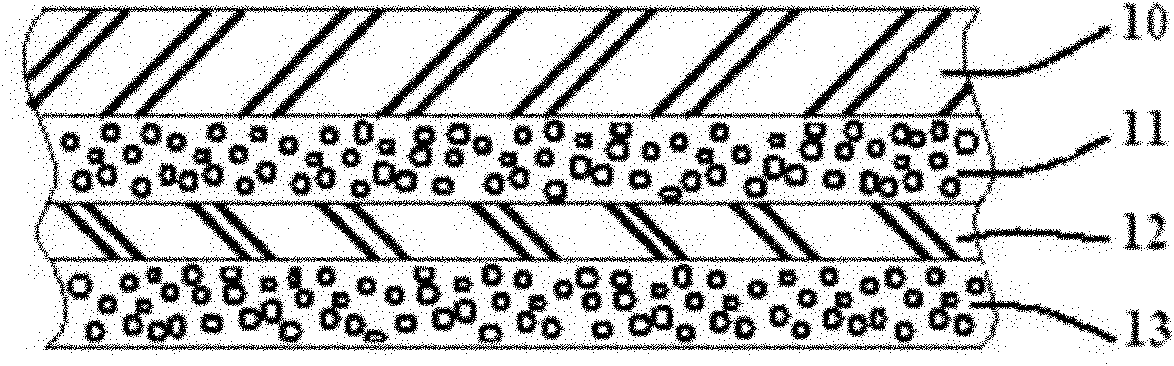

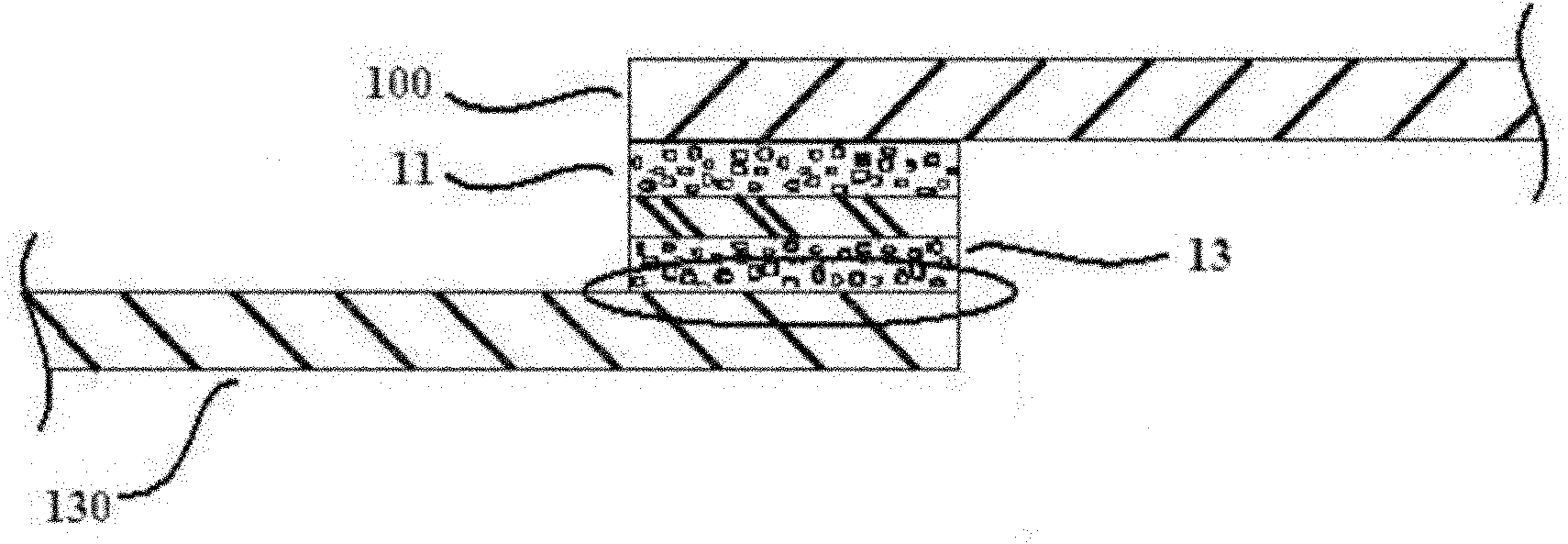

Method for producing metal laminated composite tube

InactiveCN104525615AExtend your lifeReduce manufacturing costRigid pipesPipe fittingUltimate tensile strength

The invention discloses a method for producing a metal laminated composite tube, which comprises the following steps: 1)selecting a metal tube; 2)pretreating the metal tube; 3)combining a pipe fitting; 4)compacting and compositing; 5)performing plastic processing; and 6)performing post-treatment. The method has the advantages of simple production technology and equipment, high die life and low production cost, core rod size and plastic processing condition can be changed according to the practical requirement, so that the bimetallic laminated composite tube with different specification can be produced; the prepared bimetallic laminated composite tube contains a metal transition layer, metallurgy combination of bimetallic tubes can be realized, no brittle intermetallic compounds can be generated on an interface, interface combination strength and subsequent processing performance of the laminated composite tube can be increased, and the application prospect is wide.

Owner:CHANGSHU DONGTAO METAL COMPOSITE MATERIAL

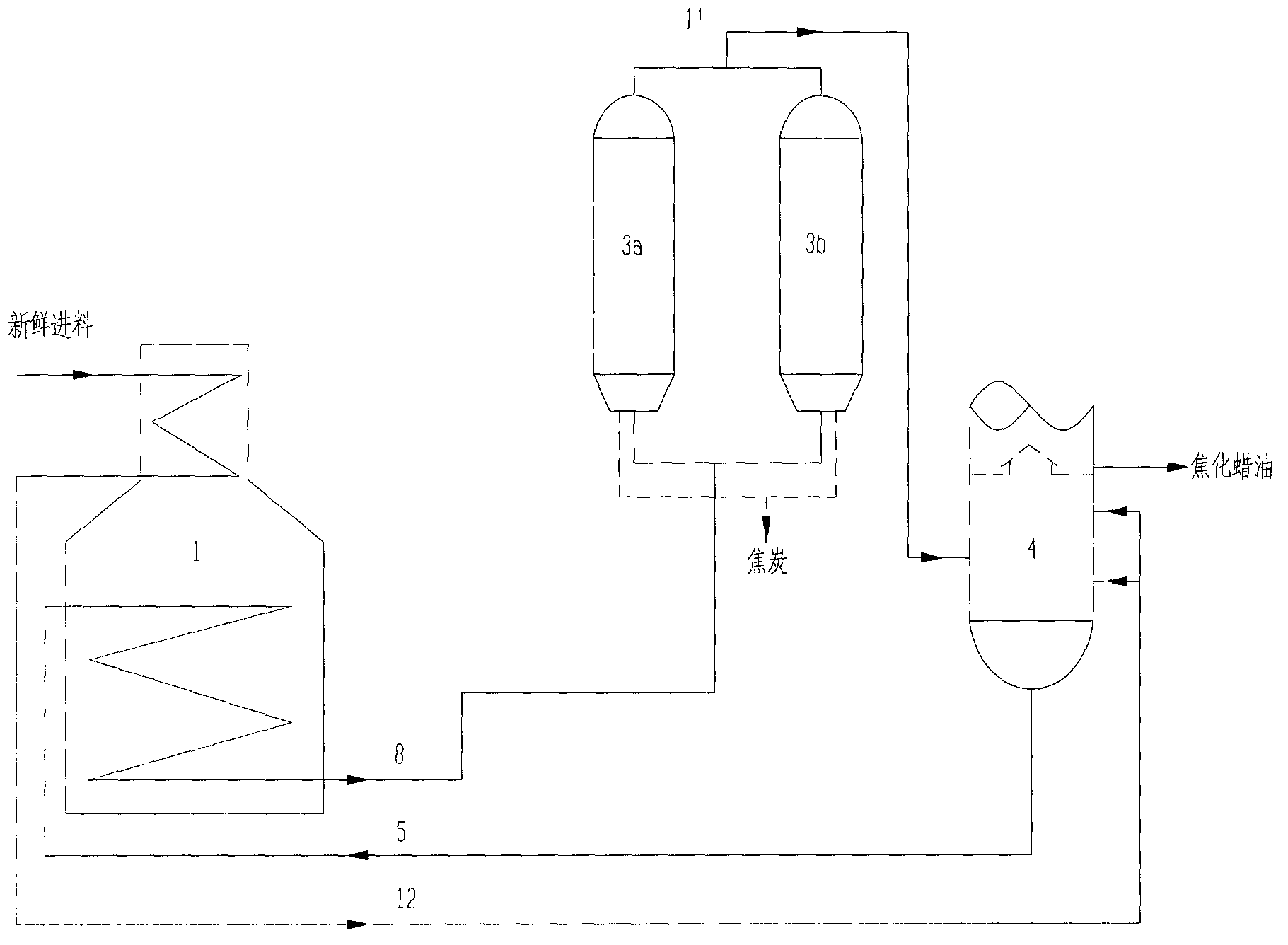

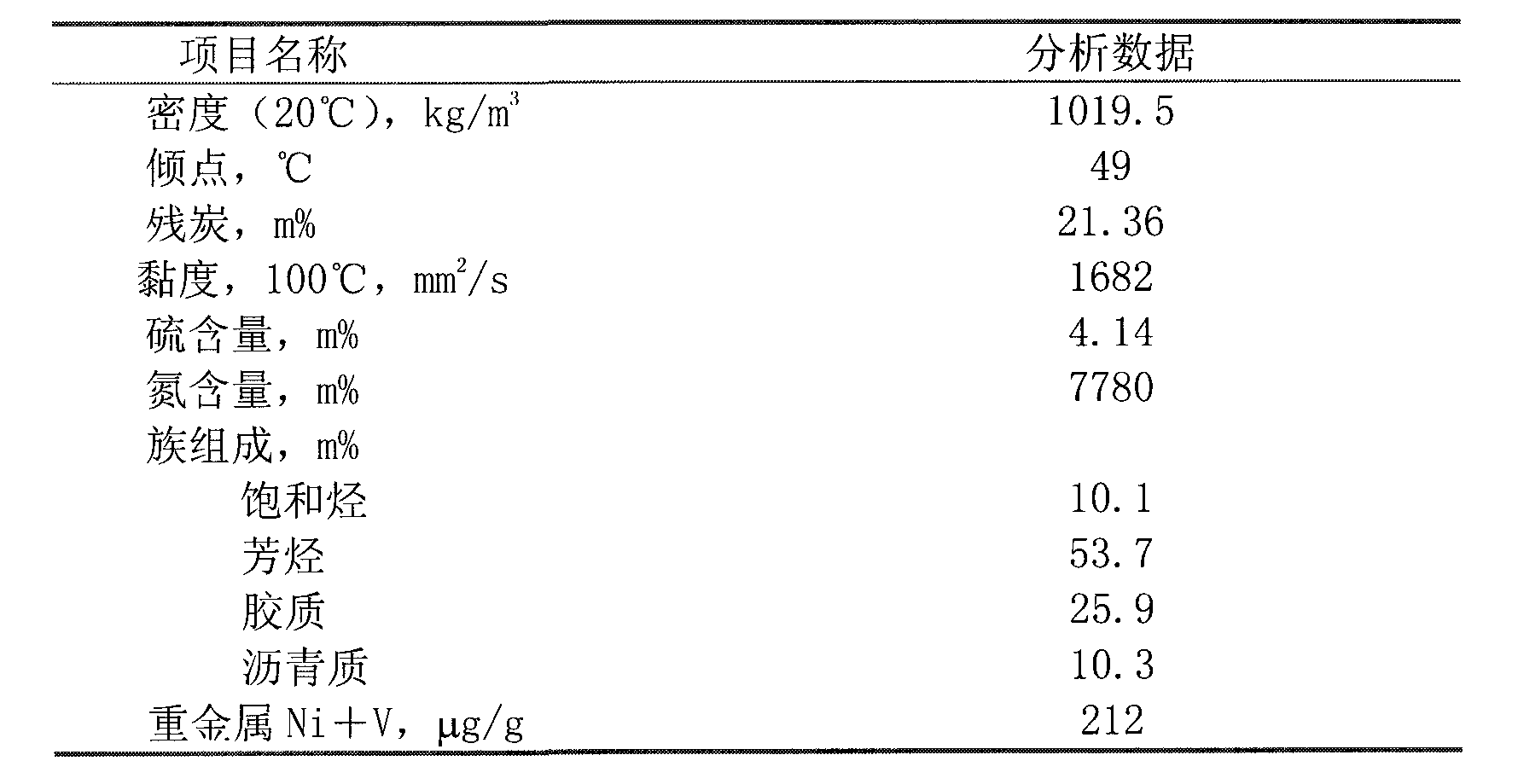

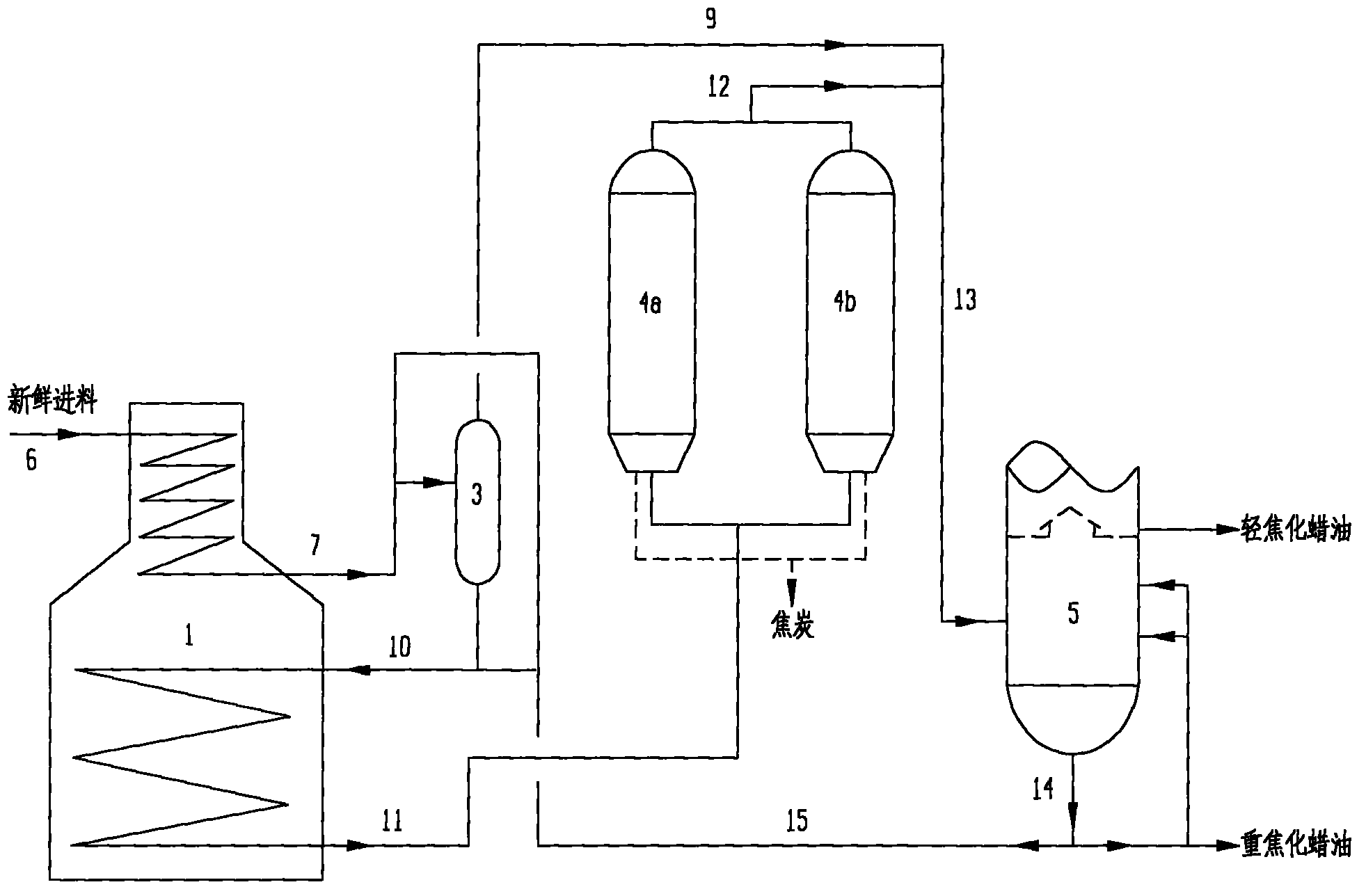

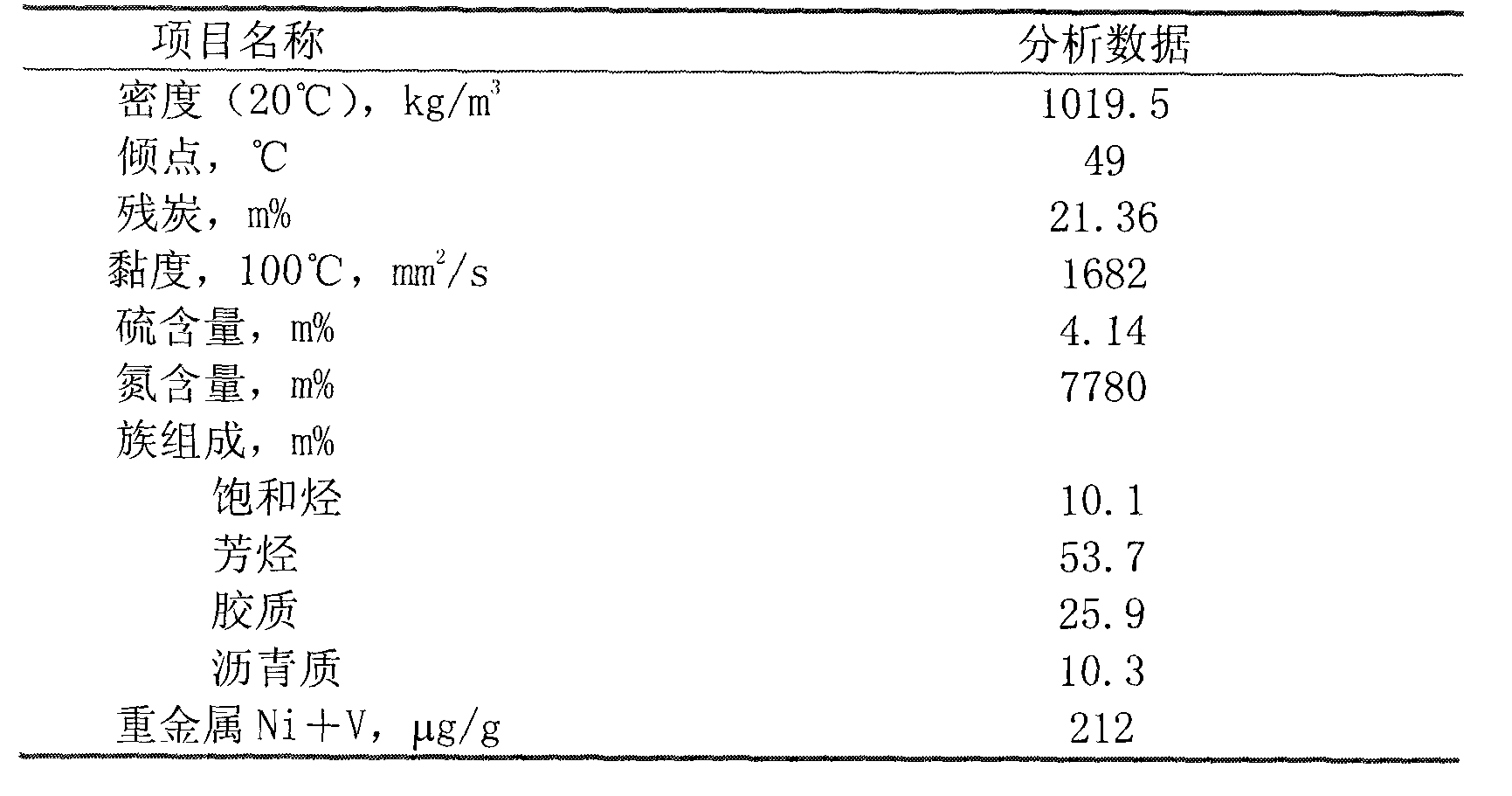

Heavy oil processing method

InactiveCN104164253AHigh yieldGood for heat transferTreatment with plural serial stages onlyCycle oilDry gas

The present invention provides a heavy oil processing method. According to the method, a fresh feed material and coking heavy oil are mixed in a fractionation tower, then enter a convection section of a heating furnace from the bottom of the fractionation tower so as to be heated, and then enter a slight thermal cracking reactor for reaction; the material discharged from the reactor returns back to a radiation section of a coking heating furnace; the material heated by the radiation section of the heating furnace is divided into two paths which enter a coke tower respectively from the upper portion (including the top portion) and the bottom portion of the coke tower for deep thermal reaction; oil gas generated from the reaction leaves from the top portion of the coke tower and enters a coking fractionation tower for fractionation; the coking heavy oil after fractionation is adopted as circulation oil and is mixed with the fresh feed material; and the obtained mixed material is discharged out of the coke tower and enters the heating furnace for continuous reaction. With such a method, the yields of dry gas and coke can be reduced; the liquid product yield can be improved; the coking of a heating furnace pipe can be slowed down; and the operation period of a coking device can be prolonged and delayed.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

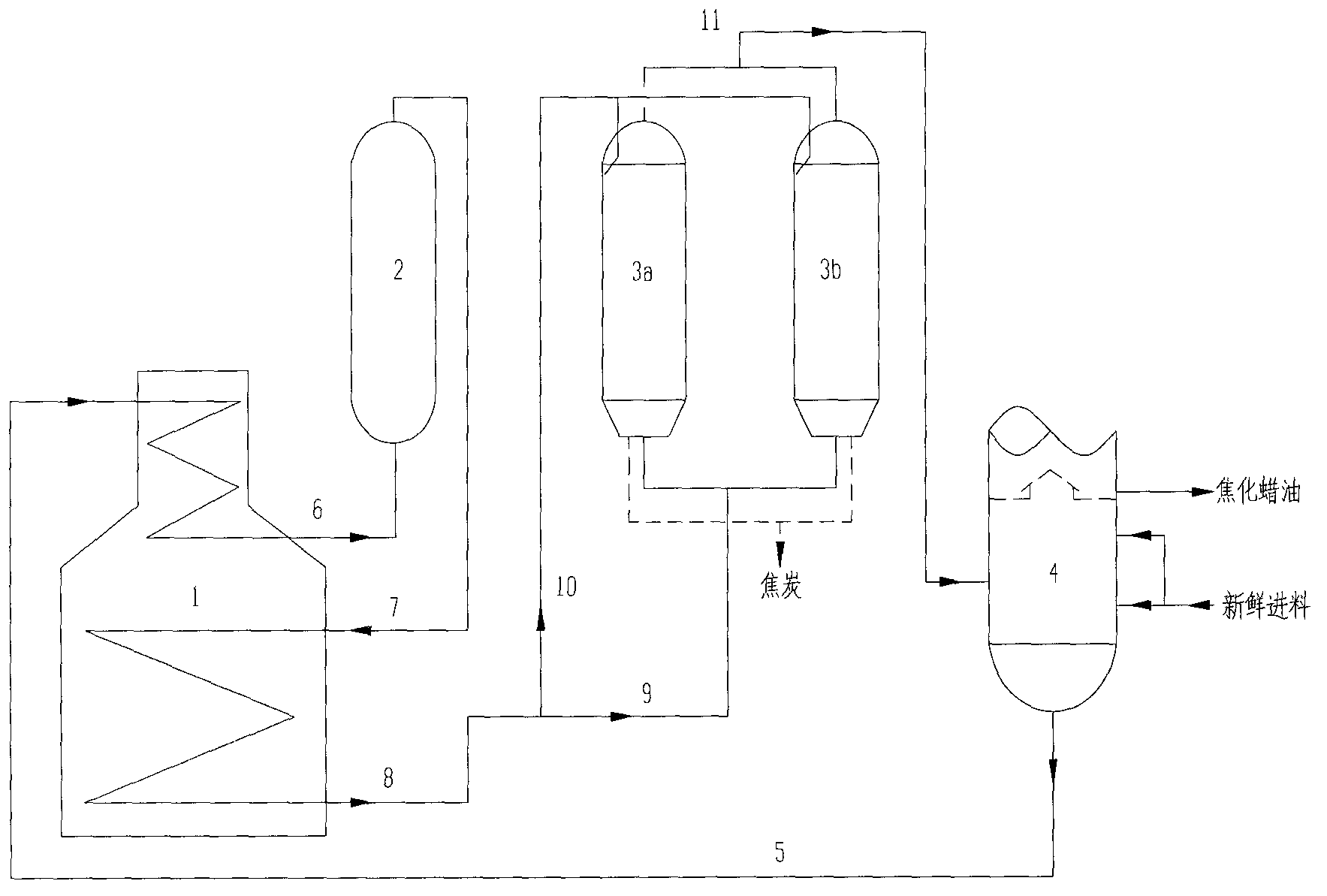

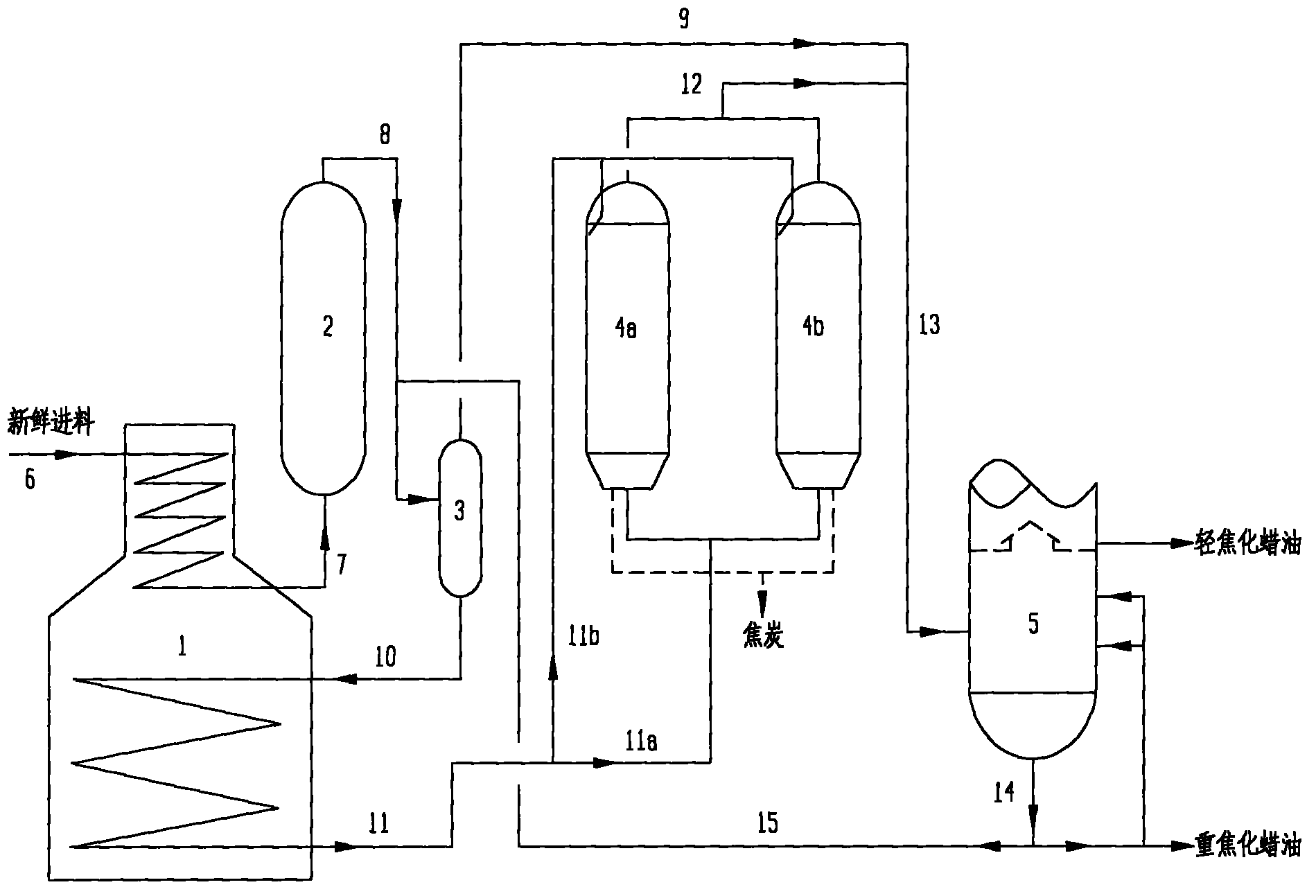

Heavy oil processing process

InactiveCN104164254AReduce yieldHigh yieldTreatment with plural serial stages onlyLiquid productOil processing

The invention provides a heavy oil processing process. According to the process, a fresh fed material is heated in a convection section of a heating furnace, and is subjected to a reaction in a shallow thermal cracking reactor; a material delivered from the reactor is subjected to gas-liquid separation; separated liquid-phase material is returned to a coking heating furnace and is heated; the heated liquid-phase material is divided into two parts which enter a coke tower respectively from the upper part (including the top part) and from the bottom part of the coke tower, and is subjected to deep thermal reaction; produced oil gas leaves from the top of the coke tower, and is fractionated in a coking fractionation tower; and after fractionation, a part of coking heavy oil is returned as circulation oil and is subjected to the reaction again. With the process, yields of dry gas and coke can be reduced, liquid product yield can be improved, heating furnace coking can be retarded, and coking device operation period can be prolonged.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

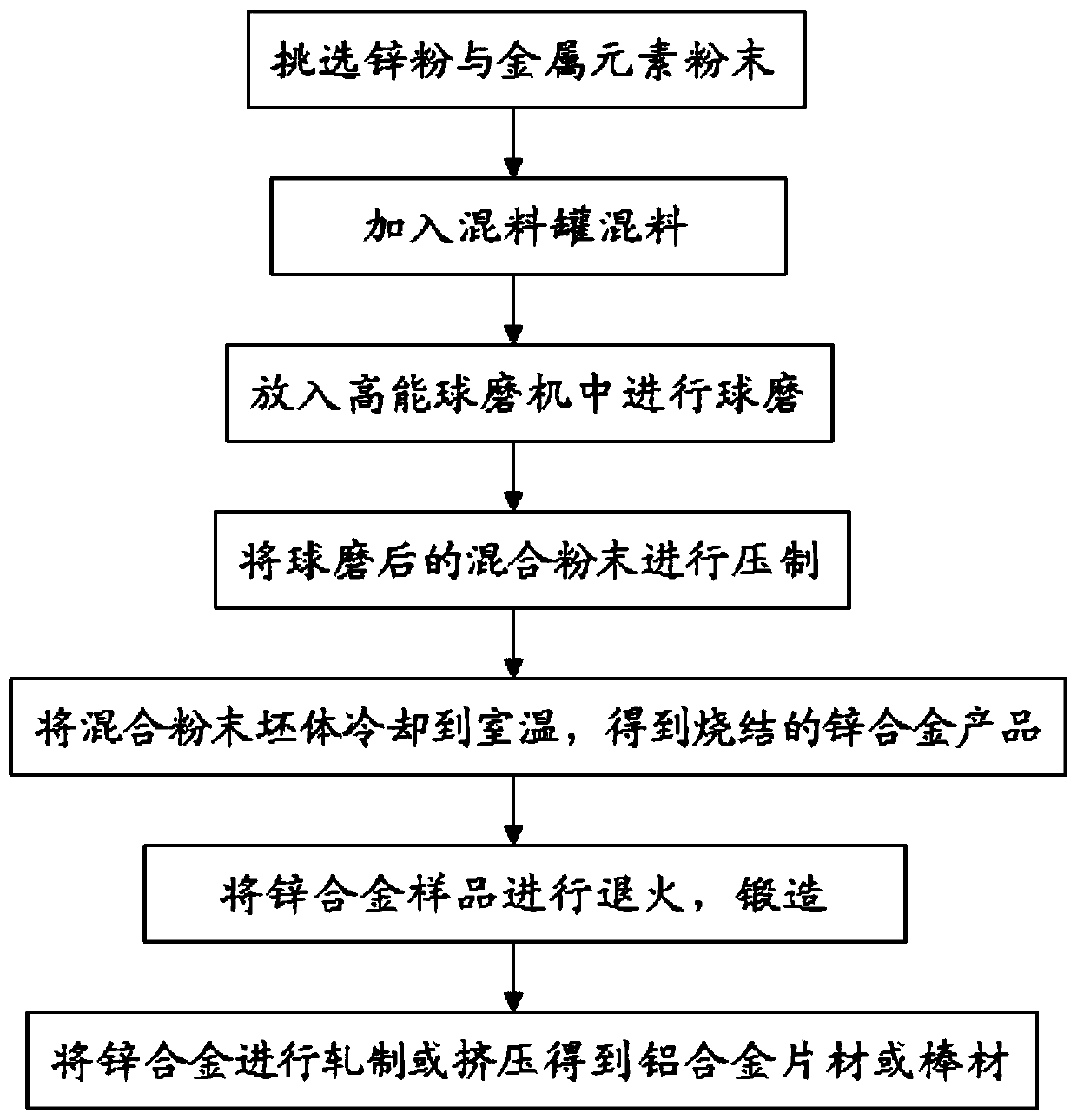

Method for preparing degradable zinc alloy material by metal powder sintering

InactiveCN111331128AImplement addAdd accurateTransportation and packagingMetal-working apparatusZinc alloysMetal powder

The invention provides a method for preparing a degradable zinc alloy material by metal powder sintering. The method includes the following steps that zinc powder and metal element powder are selected; the zinc powder and the metal element powder are put into a mixing tank to be mixed on a mixing machine; mixed powder obtained after mixing is put into a planetary high-energy ball mill to be subjected to ball milling; the ball-milled mixed powder is pressed and sintered; after sintering is completed, a mixed powder blank is cooled to the room temperature, the pressure is removed, and the vacuumstate and argon protection are broken to obtain a sintered zinc alloy product; the zinc alloy sample is annealed and forged; and the forged zinc alloy is rolled or extruded to obtain the zinc alloy sheet or bar. According to the method, by adopting a powder metallurgy preparation technology, the problem of difference of melting points of alloy elements can be effectively solved, and the proportion of the elements in the alloy can be accurately controlled, so that the obtained zinc alloy material is low in oxygen content and good in quality; and besides, the preparation method is stable and can realize batch production.

Owner:长沙镁捷新材料科技有限公司

Pressure-sensitive adhesive composite with repulping property and double-sided pressure-sensitive adhesive tape

InactiveCN101914356AIncrease stickinessGood water solubilityFilm/foil adhesivesEster polymer adhesivesAdhesive beltAntioxidant

The invention discloses a pressure-sensitive adhesive composite with the repulping property, which mainly comprises the following components in parts by weight: 70-89 parts of acrylic ester polymer and alkali, 9-28 parts of polyethylene glycol monomethyl ether plasticizer, 0.5-1 part of cross-linking agent, 0.2-0.5 part of antioxidant and 0-0.5 part of colorant, wherein the amount of the alkali is measured based on the molar ratio of carboxyl to be neutralized by the alkali, which accounts for 30-70 percent of the total molar ratio of the carboxyl in the acrylic ester polymer. The invention also discloses a double-sided pressure-sensitive adhesive tape prepared from the pressure-sensitive adhesive composite with the repulping property, which comprises two pressure-sensitive adhesive layers, can be used as an adhesive material, has the advantages of very strong initial stickiness and continuous stickiness, 180-degree peel strength and excellent repulping property, cannot pollute equipment in the waste paper recycling process and accords with the current requirements on environmental protection and sustainable development.

Owner:ZHEJIANG HEXIN TECH

Extruded acryl composite cloudy-color plate and manufacturing method thereof

InactiveCN101670745ALow densityHigh surface finishSynthetic resin layered productsSpecial ornamental structuresSurface finishPliability

The invention discloses an extruded acryl composite cloudy-color plate and a manufacturing method thereof. A color layer of the extruded acryl composite cloudy-color plate is formed by the coextrusion of a cloudy-color layer and a cloud background layer, the cloudy-color layer and the cloud background layer are both made of ABS, UV and titanium dioxide-color master batches, a base layer of the plate is made of ABS and titanium dioxide-color master batches, and an acryl layer is made of UV and PMMA. The raw materials are dried, simultaneously extruded into a dispatcher by four plastic extruders, extruded out by a T-shaped die head, and rolled to form the extruded acryl composite cloudy-color plate. The thickness of the extruded acryl composite cloudy-color plate can be controlled within 0.8-10 mm. The extruded acryl composite cloudy-color plate has the characteristics of wide application, low density, good surface finish, high flexibility, favorable subsequent processability, stable color and pattern and the like. Compared with production by the traditional secondary casting method, the production efficiency and the mechanization degree of products are improved.

Owner:CHANGZHOU BOSHUANG PLASTICS

Wet state dyeing and finishing one-bath technology for cattle instep leather

ActiveCN106834556AImprove permeabilityImprove bindingLeather manufacturingTanning treatmentSocial benefitsEconomic benefits

The invention relates to the technical field of tanning chemical and engineering, and provides a wet state dyeing and finishing one-bath technology for cattle instep leather. In the wet state dyeing and finishing process, the procedures of chromium retanning, neutralizing, filling retanning, dyeing, stuffing and the like are conducted in a one-bath manner, different materials act in a one-bath manner and can mutually promote seepage and diffusion, the technology process is simple, and operation is convenient and easy to achieve. Crust leather manufactured through the wet state dyeing and finishing one-bath technology for the cattle instep leather is soft and full in body and rich in elasticity, a grain surface is smooth, delicate, compact and free of a loose side, and various physical and chemical properties meet the industry requirement. Meanwhile, the wet state dyeing and finishing one-bath technology for the cattle instep leather has obvious energy saving and emission reducing benefits, waste water pollution can be greatly relieved, and the material usage amount and the water usage amount are reduced. The production time is shortened, the production cost is reduced, the production efficiency is improved, and good economic benefits and social benefits are achieved.

Owner:XINGYE LEATHER TECH CO LTD

Wood cleaning device for papermaking

InactiveCN107649424AAchieve cleaning effectLess impuritiesCleaning using toolsBristleInduction motor

The invention discloses a wood cleaning device for papermaking. The wood cleaning device comprises a machine body. A driving motor is fixedly connected to the inner wall of the bottom of the machine body. A rotary shaft is fixedly connected to the output end of the side, away from the inner wall of the bottom of the machine body, of the driving motor. A bottom plate is fixedly connected to the end, away from the output end of the driving motor, of the rotary shaft. The wood cleaning device is provided with a stepping motor, a rotary rod, first bristles, an asynchronous motor, a cleaning disc and second bristles, thus the cleaning effect on wood in a frame is achieved, the inner surface of the wood is cleaned with the first bristles, the outer surface of the wood is cleaned with the secondbristles, an overall cleaning effect on the wood is further achieved, a better cleaning effect is ensured, the effect of better subsequent processing is further achieved, and the effect of less impurities of produced paper is achieved.

Owner:江门市新会区崖门镇众力经济发展有限公司

Special-shaped titanium alloy capillary tube processing method

The invention discloses a special-shaped titanium alloy capillary tube processing method which comprises the following steps: coiling a titanium alloy capillary tube which is drawn to be a certain specifications on a reel; rotating the reel to release the capillary tube coiled on the reel; after the capillary tube is treated through a heating mechanism, feeding the capillary tube into a mold with a circular pore, reducing the diameter, and feeding the capillary tube into a cooling device; performing cold-drawing processing continuously by using molds of different pore shapes; selecting molds with different pore shape series according to the shape of a finished product special-shaped material to draw special-shaped materials with cross sections of a certain shapes. A product produced by using the method is high in quality stability, high in finished product rate, good in quality, excellent in mechanical property and elasticity, and good in subsequent processing property, and the processing method can be widely applied to the field of production and processing of intravascular stents and catheters for minimally invasive surgery.

Owner:QINGDAO MATE RUIOU NEW MATERIAL TECH CO LTD

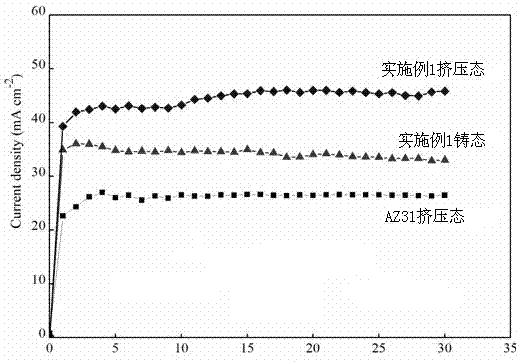

Magnesium alloy plate serving as battery cathode and preparation method thereof

The invention discloses a magnesium alloy plate serving as a battery cathode and a preparation method thereof. The magnesium alloy plate consists of the following components in percentage by mass: 4.0-6.0% of Li, 0.8-1.2% of Al, less than or equal to 0.3% of impurity and the balance of magnesium. The preparation method of the magnesium alloy plate comprises the following steps of: heating pure magnesium, pure lithium and pure aluminum of the formula amount to 720 DEG C under the conditions of vacuumizing and introducing an inert gas; after the alloy is completely molten, keeping the temperature at 700 DEG C and standing for 15 minutes; then pouring the molten alloy liquid into a die to obtain a cast-state magnesium alloy; and keeping the temperature of the cast-state magnesium alloy at 380 DEG C for 3 hours, and extruding to obtain the magnesium alloy plate. The magnesium alloy plate disclosed by the invention has relatively high activity, good discharge performance, corrosion resistance and good mechanical performance, and is a magnesium cathode material with excellent performance.

Owner:CHONGQING UNIV

A light-weight high-conductivity heat-resistant aluminum wire and its preparation method

ActiveCN105734353BGreat influence on conductivityImprove conductivityConductive materialMetal/alloy conductorsAdditive ingredientVolumetric Mass Density

A light-weight high-conductivity and heat-resistant aluminum wire and its preparation method, the material components include B: 0.035-0.06wt.%, 0.1-0.2wt.% Zr, 0.1-0.3wt.% Er, unavoidable impurities and the balance Al , The technological process is smelting, rapid component analysis before the furnace, refining, rapid cooling casting, billet annealing, extrusion, and drawing. In addition to refining and modifying, the B element added in the invention mainly plays the role of promoting the precipitation of Al3(Er, Zr) ternary composite phase in the supersaturated solid solution containing Zr and Er. The Al3(Er, Zr) composite phase is nanoparticles coherent with the matrix and having a core-shell structure, dispersed in the aluminum matrix, and can greatly improve the electrical conductivity and heat resistance of the aluminum wire. The monofilament density obtained is less than or equal to 2.71g / cm3, the electrical conductivity at 20°C is greater than or equal to 62% IACS, the short-term heat-resistant temperature is as high as 230°C, the long-term heat-resistant temperature is as high as 210°C, and the tensile strength is greater than or equal to 165MPa. The economic benefits and the significance of energy saving and environmental protection.

Owner:CENT SOUTH UNIV

Preparation method and application of micro/nano structured LiFePO4 compound

InactiveCN102086032BImprove featuresGood subsequent processing performanceCell electrodesPhosphorus compoundsNano structuringPhosphate

The invention discloses a preparation method of micro / nano structured LiFePO4 compound and the method comprises: mixing Li source, divalent iron source, phosphate, and compound(s) with molten salt effects and calcinating the mixture in an inert atmosphere at a temperature of 550 to 850 DEG C, wherein the compound(s) with molten salt effects can change into molten compound(s) at a calcination temperature. The invention also discloses the applications of the LiFePO4 compound prepared by the above preparation method and the applications of the LiFePO4 compound as lithium ion battery cathode materials. The preparation method of the present invention is simple in operation and can be used to produce products with good electrochemical performance; and moreover the materials required are of low price, therefore the method is convenient for large scale production.

Owner:ZHENGZHOU BAK BATTERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com