Heavy oil processing process

A processing technology and heavy oil technology, which is applied in the direction of refining and cracking process only in multi-stage series, can solve the problems of high investment and energy consumption, low liquid yield, etc., and achieve the effect of less investment, simple processing flow and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

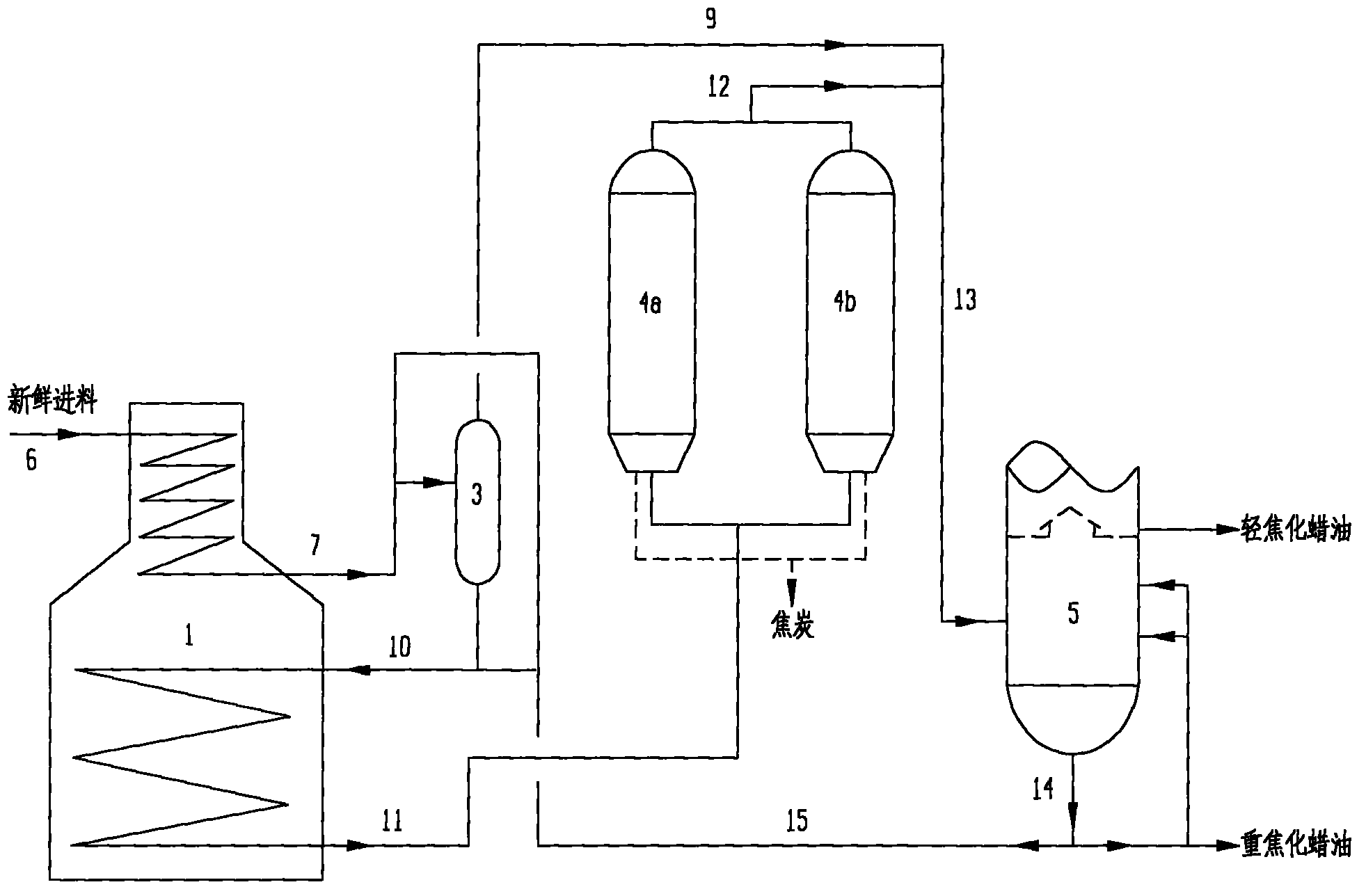

Method used

Image

Examples

Embodiment 1

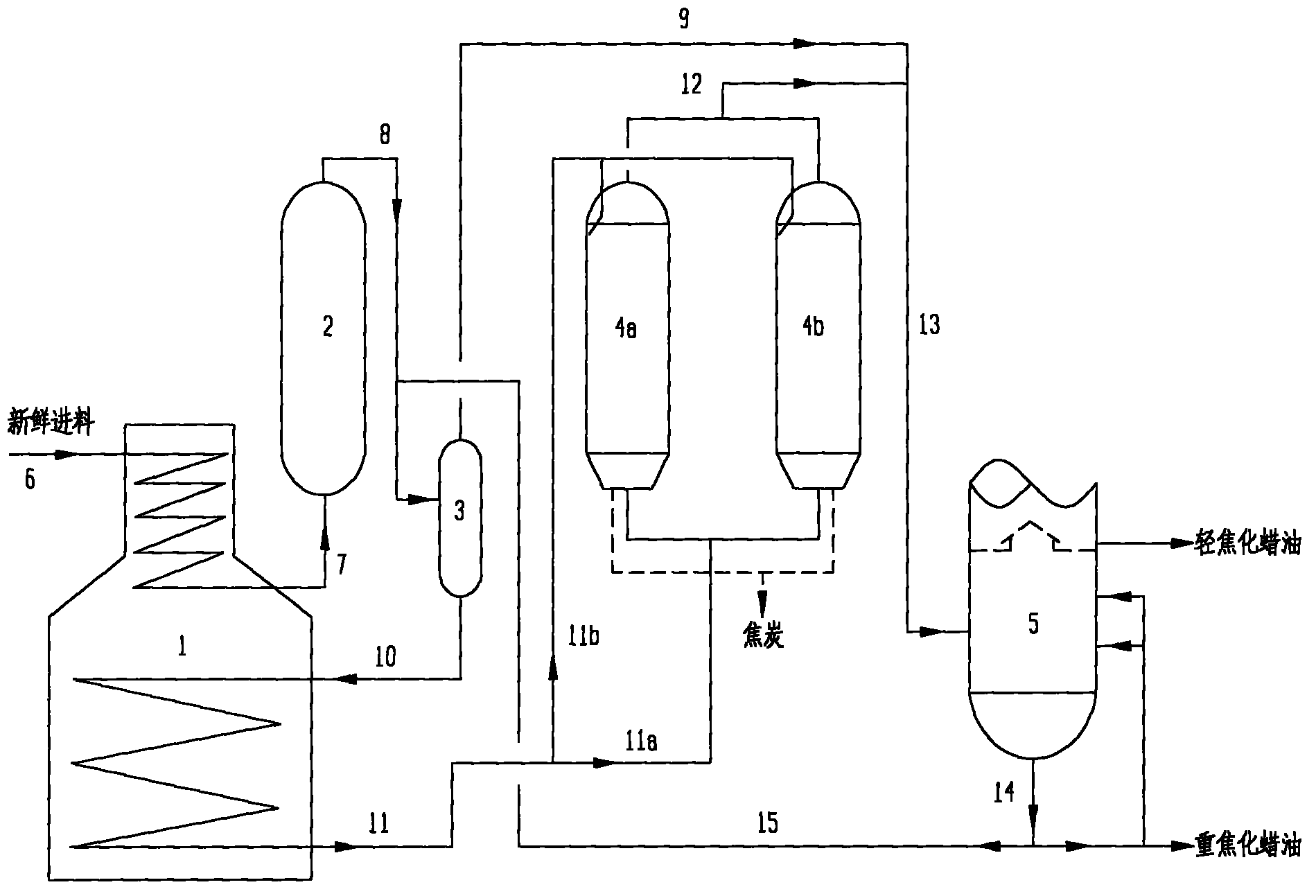

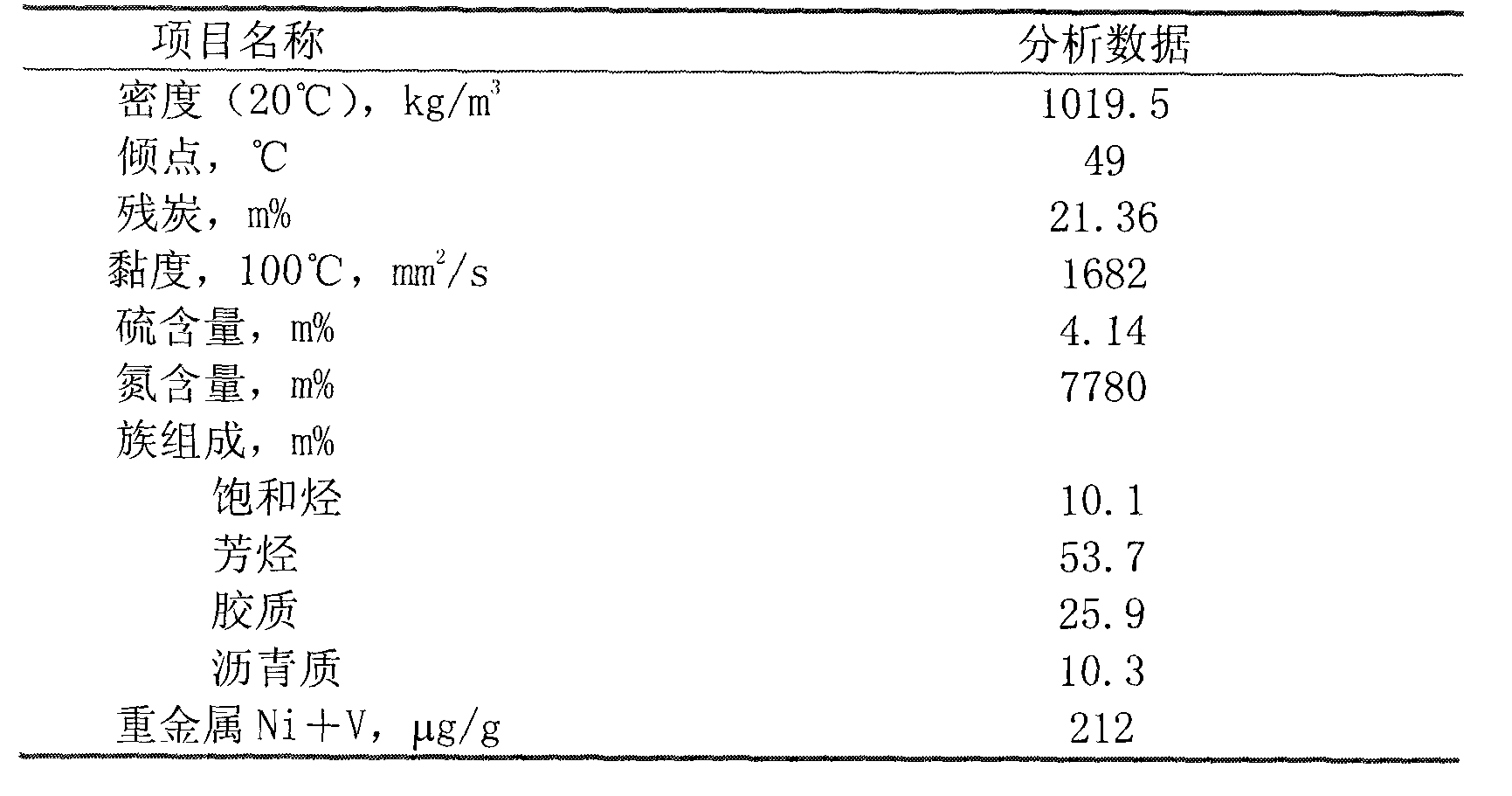

[0045] according to figure 2 As shown in the process flow, heavy oil I (listed in Table 1) at 320°C is pressurized by a pump and enters the coking heating furnace 1 convection section for heating. same), control the temperature of the material at the outlet of the furnace tube in the convection section to be 410°C, and then enter the shallow thermal cracking reactor 2 and stay for 40.2min under the gauge pressure of 0.35MPa to carry out the shallow thermal cracking reaction.

[0046] The mixed material from the shallow thermal cracking reactor 2 is mixed with the circulating oil from the coking fractionation tower 5 and then enters the gas-liquid separation tank 3 for gas-liquid separation, and the oil gas is decoked and fractionated in the fractionation tower 5 for fractionation. The liquid phase returns to the radiant section of the coking heating furnace 1 to continue heating, injects 1.95% water vapor into the furnace tube of the radiant section, controls the furnace outl...

Embodiment 2

[0059] This example mainly investigates the change of properties of heavy oil I before and after shallow thermal cracking.

[0060] The shallow thermal cracking conditions are the same as in Example 1. The mixture of heavy oil I after shallow thermal cracking is cooled, separated and analyzed. The product distribution and main properties of the shallow thermal cracked heavy oil are listed in Table 4.

[0061] Comparing Table 1 and Table 4, it can be seen that the viscosity of shallow thermally cracked heavy oil is significantly reduced, the viscosity reduction rate at 100°C is 74.13%, the distillation range becomes lighter, and the yields of gas and gasoline fractions below 180°C respectively account for 1.56% and 3.92%, improving the feed properties of the radiant section of the heating furnace.

[0062] Table 4 Distribution of shallow thermal cracking products of heavy oil I and main properties of shallow thermal cracking heavy oil

[0063]

Embodiment 3

[0065] Investigation on coking tendency of heavy oil and its shallow thermal cracking in heating furnace tube.

[0066] Test principle: The traditional thermal scaling method (temperature difference method) is used to evaluate the coking tendency of heavy oil in the heating furnace tube. After the fluid passes through the coke scale test tube, the temperature decreases accordingly to investigate the coking tendency of heavy oil.

[0067] Test method: At the beginning of the test, the raw material oil is drawn out from the raw material tank with a pump, and input into the coke scale test tube. Control the temperature of the heating furnace to be constant, and keep the flow rate of the raw oil and the temperature of the raw oil at the inlet of the test tube constant throughout the test. At the beginning of the test, there is no fouling in the coke scale test tube, the total thermal resistance is the smallest, and the heat transferred to the fluid by the heating furnace is the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com