Method for producing metal laminated composite tube

A composite pipe and metal layer technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., to achieve the effects of low production cost, high mold life, simple production process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

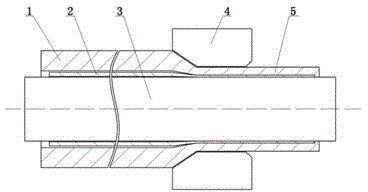

[0023] The invention discloses a method for preparing a metal laminated composite pipe, the specific steps are as follows:

[0024] (1) Select the metal tube: The laminated composite tube is prepared by combining two kinds of metal tubes, the inner and outer metal tubes have a wall thickness of 10-30mm, and The outer diameter of the outer metal tube is 100-300mm. After the package, the gap between the inner diameter of the outer metal tube and the outer diameter of the inner metal tube is 0.2-0.3mm; wherein, the inner metal tube is a stainless steel tube, a hot-dip galvanized steel tube or Aluminum tube; the outer tube is copper tube, titanium tube or aluminum alloy tube;

[0025] (2) Metal tube pretreatment: degreasing, derusting, grinding and drying the inner surface of the outer metal tube selected in step (1) and the inner and outer surfaces of the inner metal tube respectively; wherein, the degreasing method is Wash with an inorganic strong alkaline solution with a mass ...

Embodiment 1

[0031] (1) Select the metal tube: The laminated composite tube is prepared by combining the inner and outer metal tubes. The inner metal tube is a stainless steel tube. Copper pipe, its specification is that the wall thickness of the pipe is 30mm, and the outer diameter is 131mm;

[0032] (2) Metal tube pretreatment: the inner surface of the outer metal tube of the copper tube and the inner and outer surfaces of the stainless steel tube are washed and degreased with a sodium hydroxide solution with a mass concentration of 8%, and then hydrochloric acid with a mass concentration of 8% Wash and remove rust with the solution, then use a wire brush to polish the treated surface to a fresh metal surface, and finally dry the treated surface with hot air;

[0033] (3) Pipe fitting assembly: Set the treated stainless steel pipe in the copper pipe, and insert a mandrel coated with lubricating oil in the stainless steel pipe;

[0034] (4) Compression compounding: Put the pipe fittings ...

Embodiment 2

[0038] (1) Select the metal pipe: The laminated composite pipe is prepared by combining the inner and outer metal pipes. The inner metal pipe is a hot-dip galvanized steel pipe. The tube is an aluminum alloy tube with a wall thickness of 30mm and an outer diameter of 180.5mm;

[0039] (2) Metal pipe pretreatment: Wash and degrease the inner surface of the outer metal pipe of the aluminum alloy pipe and the inner and outer surfaces of the hot-dip galvanized steel pipe with a potassium hydroxide solution with a mass concentration of 8%, and then use a mass concentration of 8 % nitric acid solution to wash and remove rust, then use a wire brush to polish the treated surface to a fresh metal surface, and finally dry the treated surface with hot air;

[0040] (3) Pipe fitting combination: Set the treated hot-dip galvanized steel pipe in the aluminum alloy pipe, and insert a mandrel coated with lubricating oil in the hot-dip galvanized steel pipe;

[0041] (4) Compression compoundi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com