Pressure-sensitive adhesive composite with repulping property and double-sided pressure-sensitive adhesive tape

A technology of pressure-sensitive adhesives and compositions, applied in the direction of adhesives, film/sheet adhesives, adhesive types, etc. The problem of easy separation of plasticizers, etc., achieves the effects of improved wettability, good repulpability, and high 180° peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0048] The acrylate copolymer in the pressure-sensitive adhesive composition is prepared by free radical solution polymerization, and the preparation process is as follows: add monomer, AIBN and ethyl acetate to a multi-necked flask equipped with nitrogen inlet, stirrer, condenser and thermometer, Keep the temperature at 65° C. for 5 hours, raise the temperature to 80° C., and continue polymerization for 2 hours to obtain an acrylate copolymer solution. The amounts of monomers, initiators and other components in the acrylate copolymers of Examples 1-10 are shown in Table 1.

[0049] Table 1 - Acrylate Copolymer Composition

[0050]

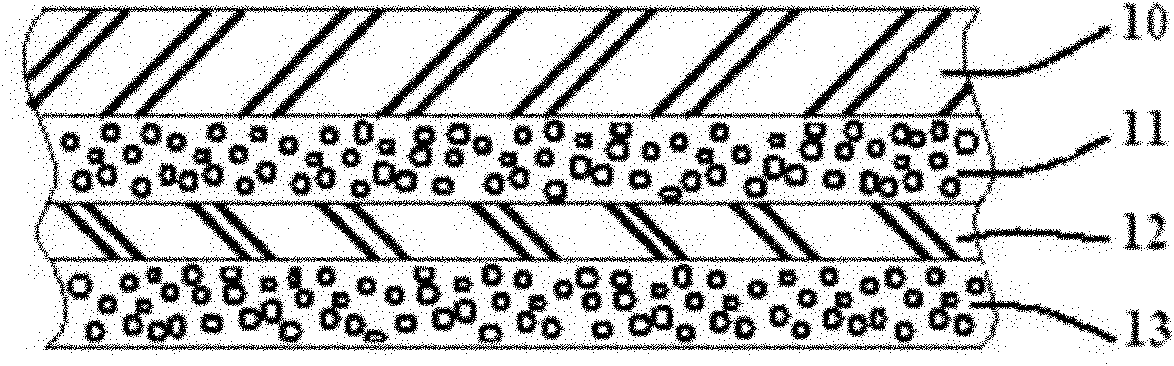

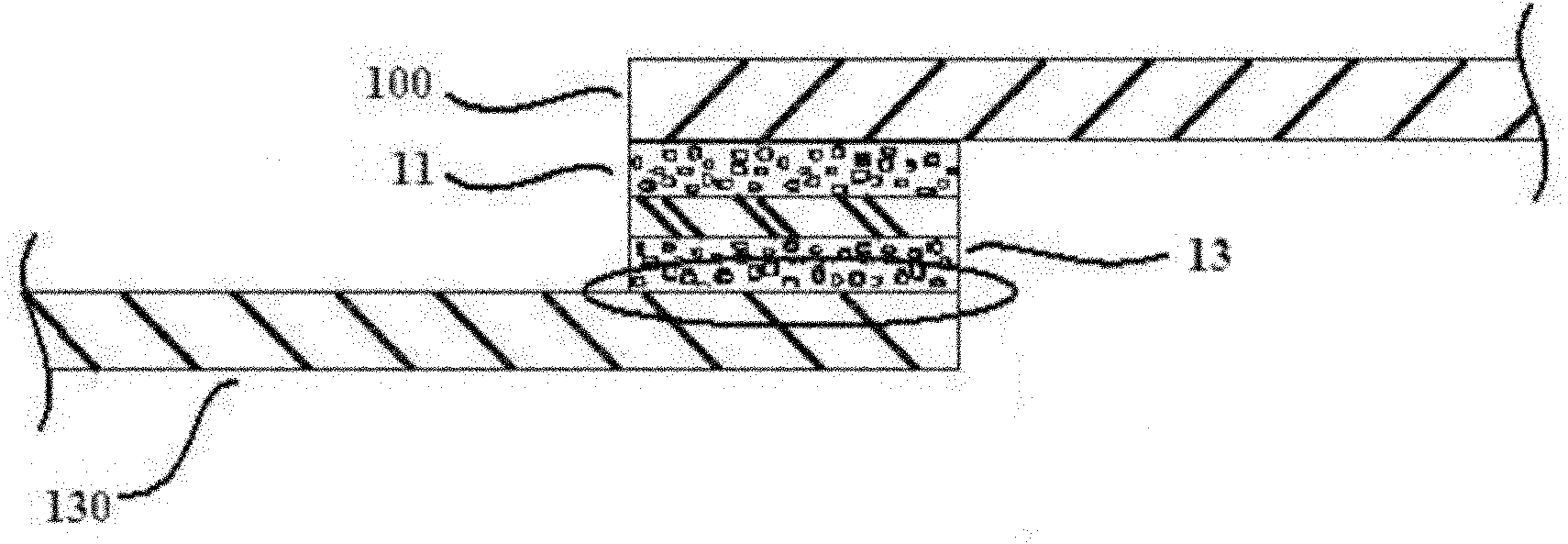

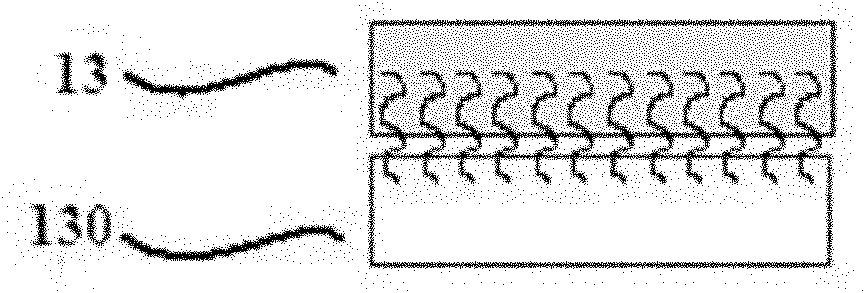

[0051] The pressure-sensitive adhesive composition is prepared according to the following method: at room temperature, add a KOH aqueous solution with a mass percent concentration of 45% to the above-mentioned acrylate copolymer solution, stir for 10 minutes, add plasticizer, TGIC, IR1076, RL, etc., stir After uniform coating, the pressure-sen...

Embodiment 5~7

[0054] Table 3 - Components in the pressure-sensitive adhesive composition of Examples 5-7

[0055]

Embodiment 8~10

[0056] Table 4 - Components in the pressure-sensitive adhesive composition of Examples 8-10

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com