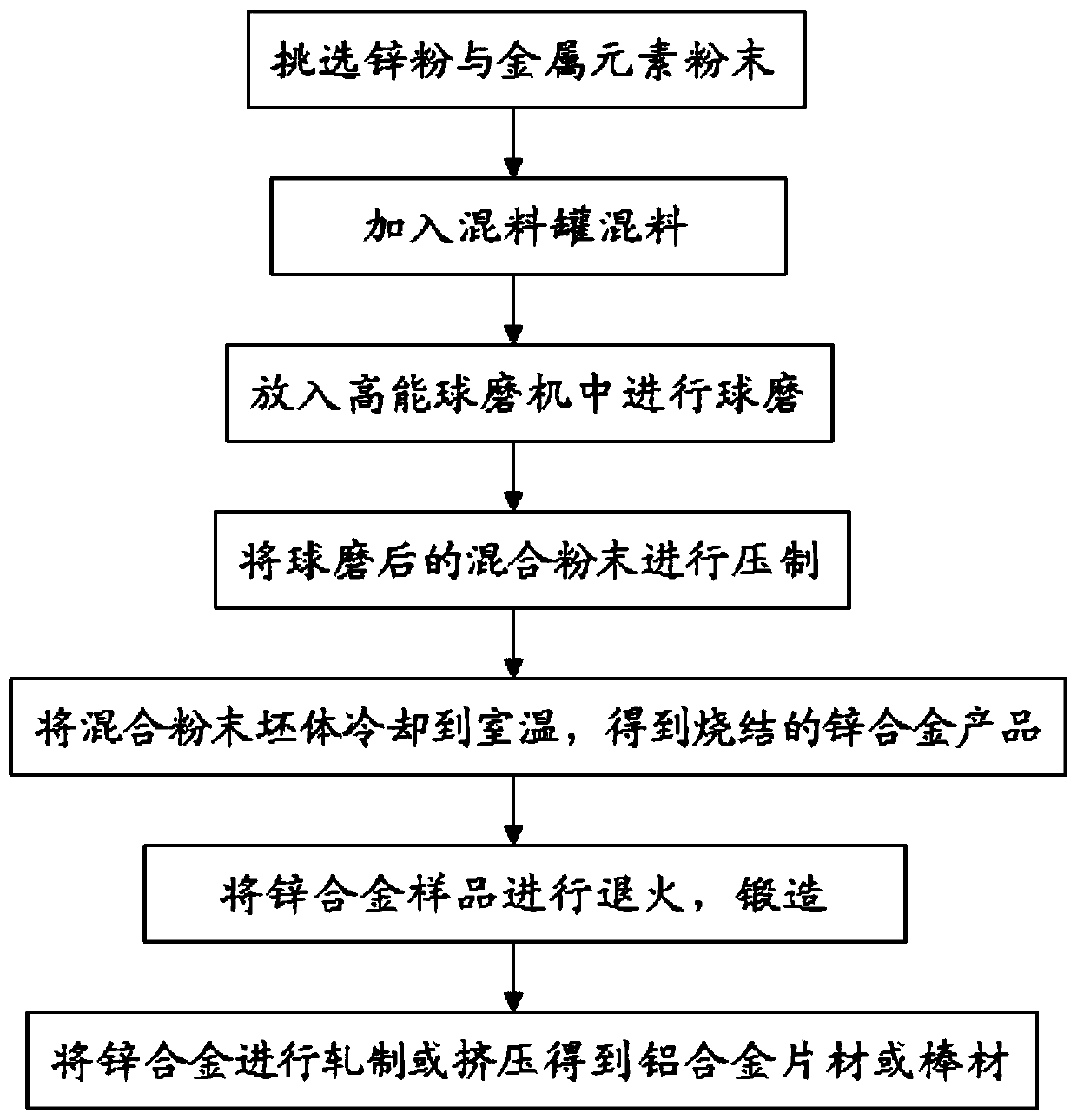

Method for preparing degradable zinc alloy material by metal powder sintering

A technology for degrading materials and metal powders, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of inaccurate element ratio, large difference in melting point of alloy elements, etc., and achieve short process flow, low production cost, and hinder oxidation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1. Select zinc powder and iron powder with appropriate particle size. The particle size of zinc powder is between 10μm and 20μm, the particle size of iron powder is between 20μm and 50μm, and the purity of the powder is above 99.9%;

[0041] Step 2. The zinc powder and iron powder are weighed on an electronic balance according to the mass ratio of Zn-0.5% Fe alloy composition, put into a sealing mixing tank filled with argon, and mixed on a three-dimensional mixer , 40min of mixing;

[0042] Step 3. Put the mixed metal powder into a planetary high-energy ball mill for ball milling, the ball-to-material ratio is 10:1, and the milling time is 4h;

[0043] Step 4. Place the ball-milled zinc powder and iron powder in a mold and compact tightly under a cold press with a pressing pressure of 10 MPa; place the pressed metal powder in a vacuum hot pressing sintering furnace protected by argon Medium sintering, heat up from room temperature to 360°C, hold for 10min, then heat up ...

Embodiment 2

[0048] Step 1. Select zinc powder and magnesium powder with appropriate particle size, the particle size of zinc powder is between 40-50μm, the particle size of magnesium powder is between 40-50μm, and the purity of the powder is above 99.9%;

[0049] Step 2. Mix the zinc powder and magnesium powder, weigh them on an electronic balance according to the Zn-0.5% Mg alloy composition, put them into a sealing mixing tank filled with argon, and mix them on a three-dimensional mixer. Feed 60min;

[0050] Step 3. Put the mixed metal powder into a planetary high-energy ball mill for ball milling with a ball-to-material ratio of 10:1 and a milling time of 12h;

[0051] Step 4. Place the ball-milled metal powder in a mold and compact it tightly under a cold press with a pressing pressure of 50MPa; place the metal powder after being pressed into a vacuum hot-pressing sintering furnace protected by argon. Raise the room temperature to 360°C, hold for 20min, then heat up to the sintering tempera...

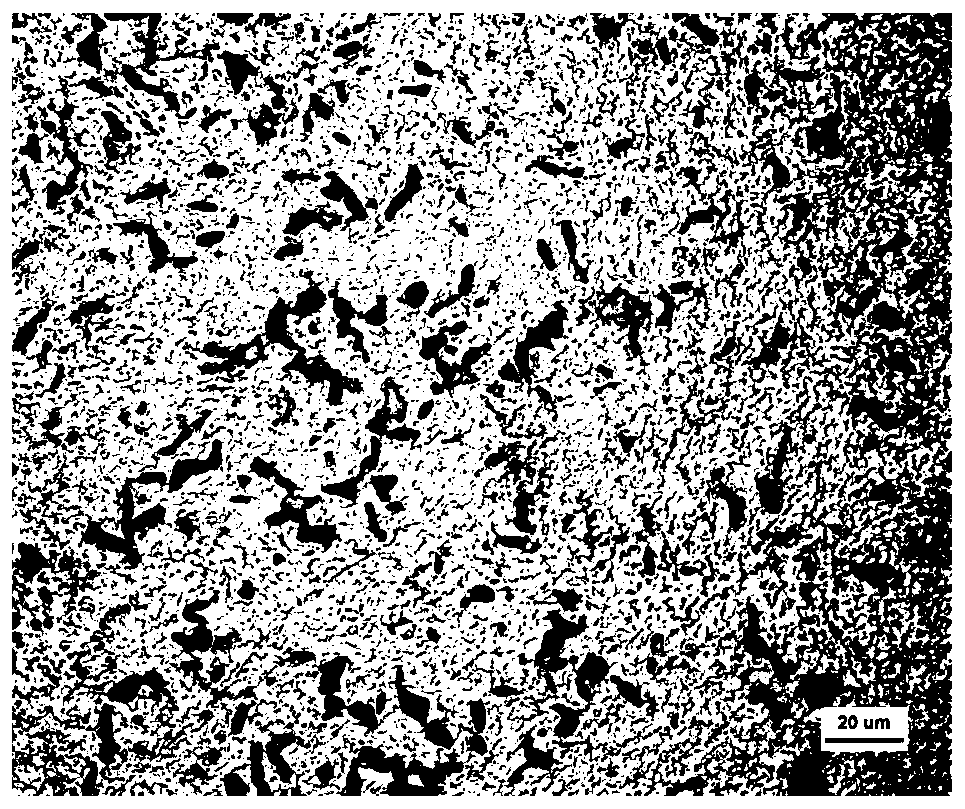

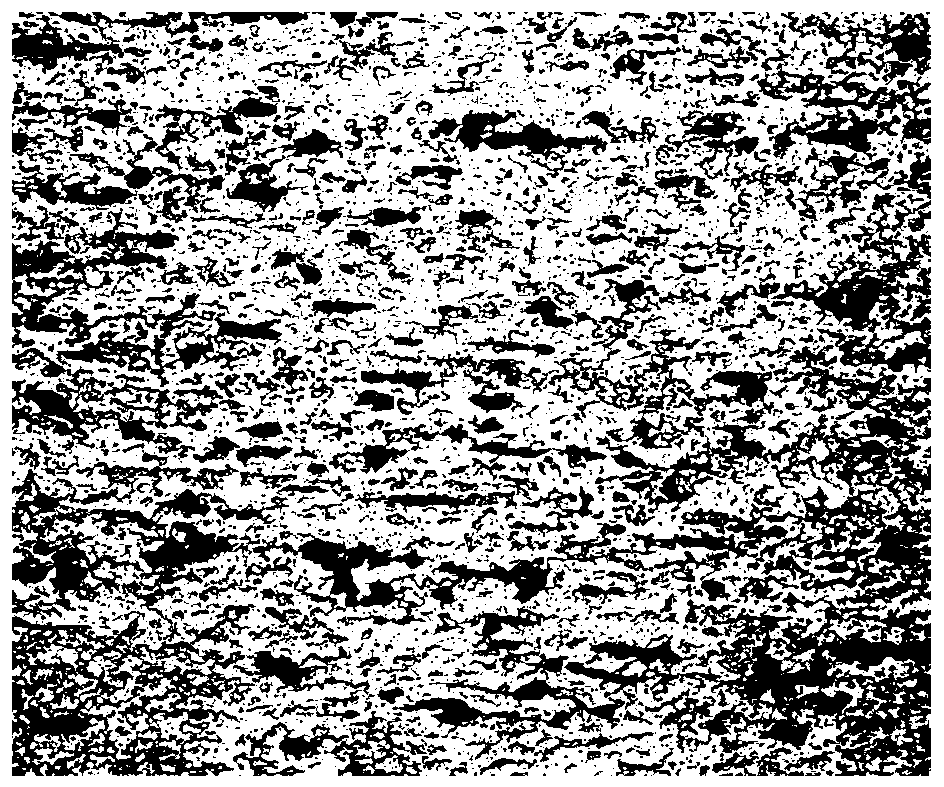

Embodiment 3

[0056] Step 1. Select zinc powder, iron powder, and magnesium powder with appropriate particle size, the particle size of the powder is between 20μm and 30μm, and the purity of the powder is above 99.9%;

[0057] Step 2. Weigh the zinc powder, iron powder, and magnesium powder according to the designed alloy composition Zn-1% Fe-1% Mg on an electronic balance, and put them into a sealing mixing tank filled with argon. Mixing on the three-dimensional mixer, mixing for 60 minutes;

[0058] Step 3. The mixed metal powder is put into a planetary high-energy ball mill for ball milling. The ratio of ball to material is generally 10:1, and the milling time is 24h;

[0059] Step 4. Place the ball-milled metal powder in a mold and compact it tightly under a cold press with a pressing pressure of 40MPa. The metal powder after compression is heated from room temperature to 360°C for 15 minutes, and then heated to the sintering temperature 1000℃, the sintering time is 30min, the heating rate is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com