Grain-refined manganese-lithium alloy and method for manufacturing same

A magnesium-lithium alloy and grain refining technology, applied in the field of grain-refining magnesium-lithium alloy and its preparation, can solve the problems of high cost and low industrialization promotion value, reduce the probability and quantity, and reduce the phenomenon of over-aging , The effect of refining magnesium-lithium alloy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

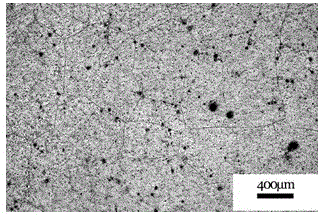

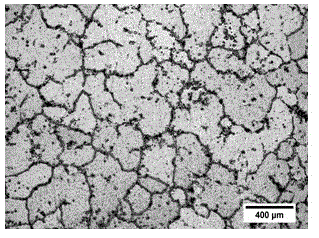

Image

Examples

Embodiment 1

[0030] The grain-refined magnesium-lithium alloy of this embodiment consists of the following components by mass percentage:

[0031] Li 14.0%;

[0032] Al 1.0%;

[0033] La 0.3%;

[0034] Impurities ≤0.3%;

[0035] Magnesium balance.

[0036] In the preparation method of the grain-refined magnesium-lithium alloy of this embodiment, the formulated amount of pure magnesium, pure lithium, pure aluminum and magnesium-lanthanum master alloy is heated to 720° C. under the condition of vacuuming and feeding inert gas, and waits for After the alloy is completely melted, it is kept at 700°C for 15 minutes, and then the melted alloy solution is poured into a mold to obtain a cast magnesium-lithium alloy; the mass percentage of each component in the magnesium-lanthanum master alloy is: La 30%; Magnesium 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com