Sn-containing fine-grained magnesium-lithium tin alloy

A magnesium-lithium alloy and tin alloy technology is applied in the field of new magnesium alloy materials, which can solve the problems of poor plasticity and over-aging of the alloy, and achieve the effects of low production cost, increased strength and plasticity, and avoiding the problem of over-aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Using the following formula (mass percentage): Mg: 82.20%; Li: 14.0%; Sn: 3.5%; the total of Mn, Fe, Si, Ni, Cu and Na is less than 0.30%, and the melting is carried out in a vacuum induction melting furnace. The two components are put into the stainless steel crucible together according to the corresponding addition amount. Before smelting, first pump the furnace to a vacuum state, then introduce argon gas, and then start smelting. After the alloy is completely melted, keep it warm for 20 minutes, then cut off the power of the induction melting furnace, and take out the crucible after the alloy is completely solidified. , to obtain cast alloys. It should be pointed out that the whole melting process is under the protection of argon.

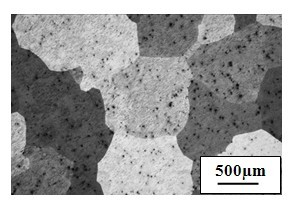

[0021] The grain size of the obtained magnesium-lithium alloy was measured by the intercept method, and the average grain size was 700??m. The novel magnesium lithium tin alloy that adopts this method to make, its as-cast g...

Embodiment 2

[0022] Example 2: Adopt the following formula (mass percentage): Mg: 86.70%; Li: 12.0%; Sn: 1.0%; Mn, Fe, Si, Ni, Cu, Na are less than 0.30%. The components are put into the stainless steel crucible together according to the corresponding addition amount. Before smelting, evacuate the furnace to a vacuum state, then introduce argon gas, and then start smelting. After the alloy is completely melted, keep it for 20 minutes to make the added raw materials fully alloyed, and then cut off the power supply of the induction melting furnace until The alloy is completely solidified, and the crucible is taken out to obtain the cast alloy. It should be pointed out that the whole melting process is under the protection of argon.

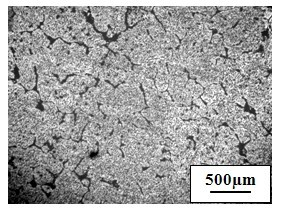

[0023] The grain size of the obtained magnesium-lithium alloy was measured by the intercept method, and the average grain size was 750??m.

Embodiment 3

[0024] Example 3: Adopt the following formula (mass percentage): Mg: 86.70%; Li: 10.0%; Sn: 3.0%; Mn, Fe, Si, Ni, Cu, Na are less than 0.30%. The components are put into the stainless steel crucible together according to the corresponding addition amount. Before smelting, first pump the furnace to a vacuum state, then introduce argon gas, and then start smelting. After the alloy is completely melted, keep it warm for 20 minutes, then cut off the power of the induction melting furnace, and take out the crucible after the alloy is completely solidified. , to obtain cast alloys. It should be pointed out that the whole melting process is under the protection of argon.

[0025] The grain size of the obtained magnesium-lithium alloy was measured by the intercept method, and the average grain size was 800??m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com