A kind of sintered silver-containing cerium-rich yttrium neodymium-iron-boron permanent magnet and its preparation method

A permanent magnet, NdFeB technology, applied in the direction of magnetic objects, inductors/transformers/magnet manufacturing, magnetic materials, etc., can solve the problems of performance degradation, achieve the effect of improving microstructure, improving comprehensive magnetic properties, and meeting market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 A kind of sintered silver-containing cerium-rich yttrium neodymium-iron-boron permanent magnet, its mass percent chemical formula general formula is: (Ce 20 Y 1 Nd 79 ) 30.8 [Fe 98 (Co 0.2 Ag 0.1 Cu 0.1 al 0.5 Nb 0.1 ) 2 ] 68.2 B 1 , and Ag accounts for 10% of the Mc content.

[0024] The preparation method of the above-mentioned sintered silver-containing cerium-rich yttrium neodymium-iron-boron permanent magnet is carried out as follows:

[0025] (1) Raw material preparation: prepare raw materials according to the design composition.

[0026] (2) Quick-setting cast sheet: under argon filling pressure ≤3×10 4 The slabs were cast in the quick-setting casting furnace of Pa, the casting temperature was 1420°C, the speed of the quick-setting copper roll was 41r / min, and the slabs with a thickness of 0.15-0.3mm were obtained.

[0027] (3) Hydrogen crushing and jet milling: adopting hydrogen crushing and jet milling anaerobic process to make the ca...

Embodiment 2

[0033] Embodiment 2 A kind of sintered silver-containing cerium-rich yttrium neodymium-iron-boron permanent magnet, its mass percent chemical formula general formula is: (Ce 30 Y 0.5 Nd 69.5 ) 30.8 [Fe 98 (Co 0.2 Ag 0.1 Cu 0.1 al 0.5 Nb 0.1 ) 2 ] 68.2 B 1 , and Ag accounts for 10% of the Mc content.

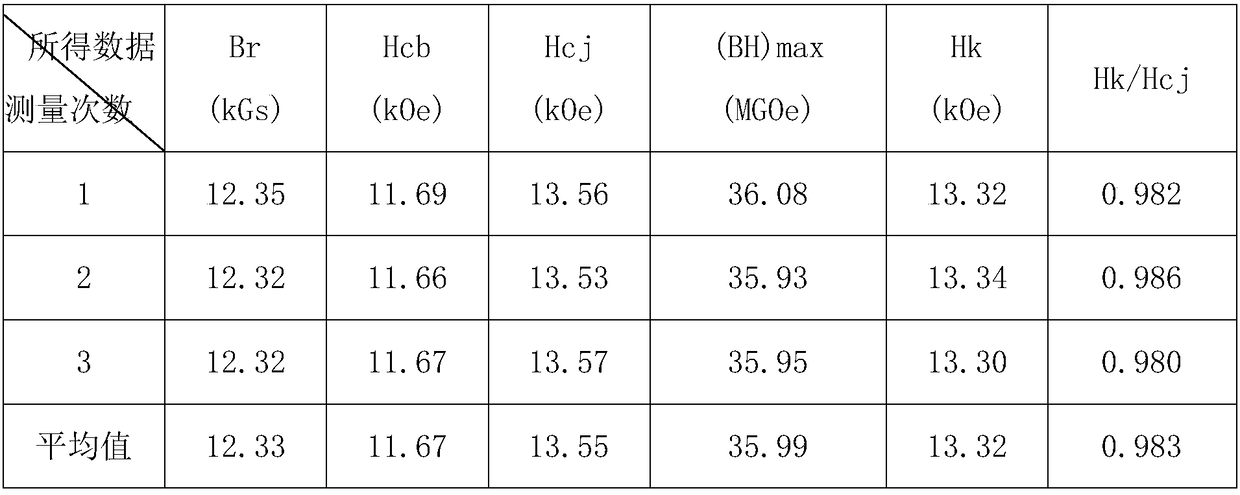

[0034] The preparation method of the above-mentioned sintered silver-containing cerium-rich yttrium-iron-boron permanent magnet is exactly the same as that of Example 1. To obtain a permanent magnet, proceed at 20 °C Cylindrical test, measuring remanence (Br), coercive force (Hcb), intrinsic coercive force (Hcj), magnetic energy product ((BH)max), J on the demagnetization curve of the magnet = 0.9J r When the reverse magnetic field (Hk) and squareness (Hk / Hcj) are obtained, the data shown in the following table are obtained:

[0035]

[0036] 2

Embodiment 3

[0037] Embodiment 3 A kind of sintered silver-containing cerium-rich yttrium neodymium-iron-boron permanent magnet, its mass percent chemical formula general formula is: (Ce 20 Nd 80 ) 30.8 [Fe 98 (Co 0.2 Ag 0.1 Cu 0.1 al 0.5 Nb 0.1 ) 2 ] 68.2 B 1 , and Ag accounts for 10% of the Mc content.

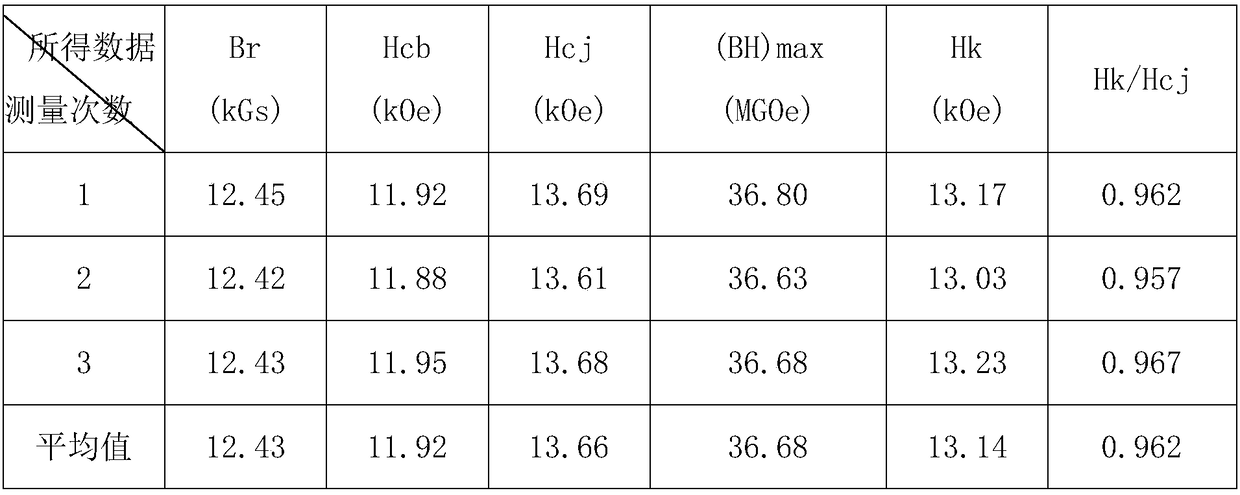

[0038] The preparation method of the above-mentioned sintered silver-containing cerium-rich yttrium-iron-boron permanent magnet is exactly the same as that of Example 1. To obtain a permanent magnet, proceed at 20 °C Cylindrical test, measuring remanence (Br), coercive force (Hcb), intrinsic coercive force (Hcj), magnetic energy product ((BH)max), J on the demagnetization curve of the magnet = 0.9J r When the reverse magnetic field (Hk) and squareness (Hk / Hcj) are obtained, the data shown in the following table are obtained:

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com