High-toughness aluminum oxide ceramic, and preparation method and application thereof

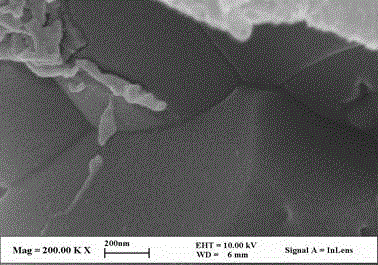

A technology of alumina ceramics and high toughness, which is applied in the field of high toughness alumina ceramics and its preparation, and can solve the problems of alumina ceramics, such as the decrease of hardness, strength and fracture toughness of comprehensive mechanical properties, uneven distribution of additives, and long heat preservation time at high temperature. , to achieve fine and uniform microstructure, inhibit the growth of grains, and shorten the high-temperature holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

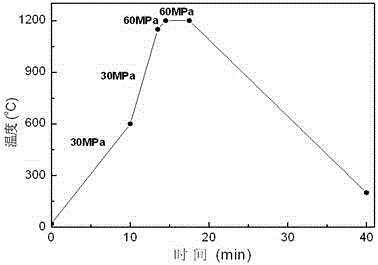

Examples

Embodiment 1

[0028] a) CNTs pretreatment

[0029]Prepare H at a volume ratio of 3:1 2 SO 4 / HNO 3 Mixed acid solution 100mL, put 1g of CNTs into the mixed acid solution, after ultrasonic treatment at 30°C for 24h, the CNTs in the mixed acid was viscous and black, after diluting the mixed acid solution, filter with suction, wash the CNTs with twice distilled water until pH= 7. After drying at 60°C, put it into polyvinyl alcohol with a mass percentage concentration of 5% for ultrasonic dispersion for 6 hours, then remove the solvent, and dry at 60°C to obtain 0.92 g of pretreated CNTs.

[0030] b) Preparation of nanopowders with "shell-core" composite structure

[0031] Al(OH) with an average particle size of 0.4μm and a purity of 99.98% is used 3 and Y(NO 3 ) 3 Powder. Weigh 12.5g Al(OH) 3 powder, 0.6gY (NO 3 ) 3 powder and 0.22g of pretreated CNTs were dissolved in 20mL of ethanol, and 0.05mL of n-butanol was added, and ultrasonically oscillated for 2h to make a uniformly dispers...

Embodiment 2

[0037] a) CNTs pretreatment

[0038] Prepare H at a volume ratio of 3:1 2 SO 4 / HNO 3 Mixed acid solution 100mL, put 1g of CNTs into the mixed acid solution, after ultrasonic treatment at 30°C for 24h, the CNTs in the mixed acid was viscous and black, after diluting the mixed acid solution, filter with suction, wash the CNTs with twice distilled water until pH= 7. After drying at 60°C, place it in polyvinyl alcohol with a mass percentage concentration of 8% for ultrasonic dispersion for 18 hours, then remove the solvent, and dry at 60°C to obtain 0.9 g of pretreated CNTs.

[0039] b) Preparation of nanopowders with "shell-core" composite structure

[0040] Al(OH) with an average particle size of 0.5μm and a purity of 99.96% is used 3 and Y(NO 3 ) 3 Powder. Weigh 15.6g Al(OH) 3 Powder, 0.55gY (NO 3 ) 3 powder and 0.24g of pretreated CNTs were dissolved in 20mL of ethanol, and 0.15 mL of PEG-400 dispersant was added, ultrasonically oscillated for 2 hours to make a unif...

Embodiment 3

[0046] a) CNTs pretreatment

[0047] Prepare H at a volume ratio of 3:1 2 SO 4 / HNO 3 Mixed acid solution 100mL, put 1g of CNTs into the mixed acid solution, after ultrasonic treatment at 30°C for 24h, the CNTs in the mixed acid was viscous and black, after diluting the mixed acid solution, filter with suction, wash the CNTs with twice distilled water until pH= 7. After drying at 60°C, put it into polyvinyl alcohol with a mass percentage concentration of 3% for ultrasonic dispersion for 24 hours, then remove the solvent and dry to obtain 0.91 g of pretreated CNTs;

[0048] b) Preparation of nanopowders with "shell-core" composite structure

[0049] Al(OH) with an average particle size of 0.8μm and a purity of 99.94% is used 3 and Y(NO 3 ) 3 Powder. Weigh 18.7g Al(OH) 3 powder, 0.5gY(NO 3 ) 3 powder and 0.26g of pretreated CNTs were dissolved in 20mL of ethanol, and 0.2mL of isopropanol was added, and ultrasonically oscillated for 2h to make a uniformly dispersed susp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com