A kind of low-resistivity copper indium gallium selenide quaternary alloy sputtering target material and preparation method thereof

A quaternary alloy, sputtering target technology, applied in the field of powder metallurgy, can solve the problem of not considering the conductive properties of the target, and achieve the effects of fine and uniform microstructure, low resistivity, and improved film thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

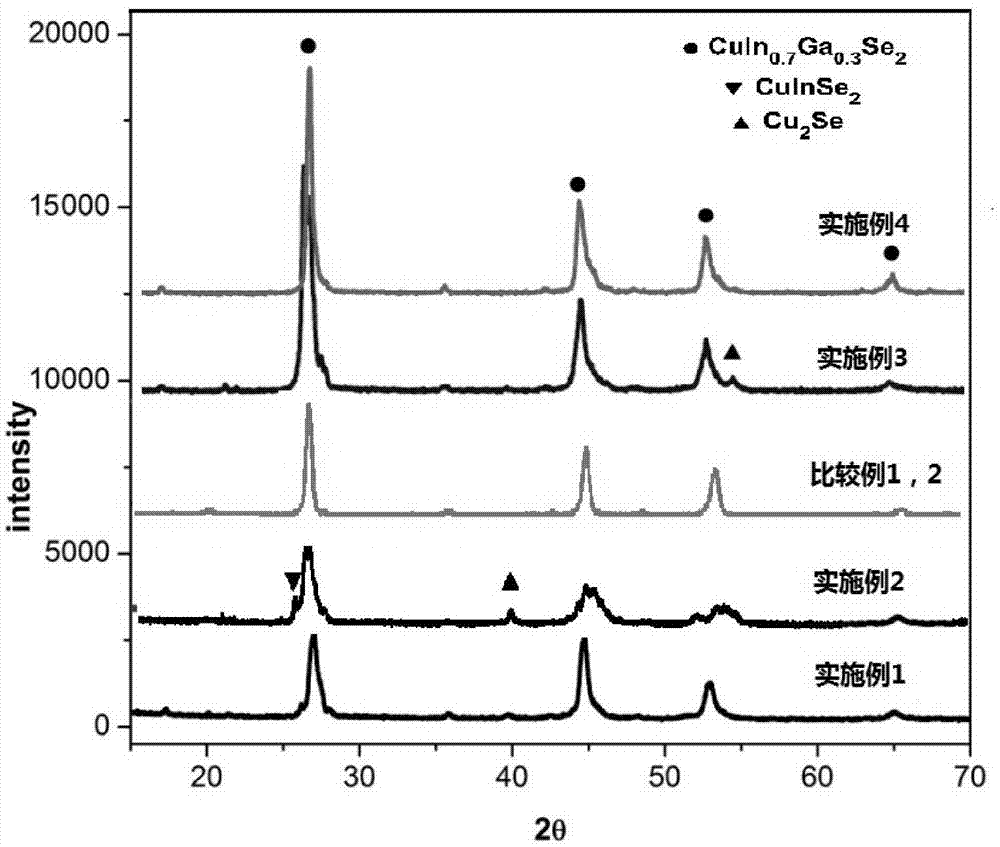

[0025] The present invention prepares the above-mentioned copper indium gallium selenide alloy target with low resistivity through the following preparation method. The preparation method includes: powder preparation, powder mixing, powder metallurgy sintering and other processes, and the powder preparation includes CuIn0.7 Ga 0.3 Se 2 Preparation of single-phase alloy powders, the CuIn 0.7 Ga 0.3 Se 2 Single-phase alloy powder is prepared by vacuum reaction synthesis method, vacuum degree ≥ 10 -1 Pa, the reaction temperature is 500-700°C, and the heating rate is not greater than 5°C / min.

[0026] The powder preparation also includes In 2 Se 3 , Ga 2 Se 3 and Cu 2 Se single-phase alloy powder and In 0.7 Ga 0.3 Se 2 Preparation of ternary alloy powder, the In 2 Se 3 , Ga 2 Se 3 and Cu 2 Se single-phase phase alloy powder is prepared by vacuum reaction synthesis method, vacuum degree ≥ 10 -1 Pa, the reaction temperature is 400-600°C, the heating rate is not more...

Embodiment 1

[0031] Embodiment 1: The copper indium gallium selenide quaternary alloy target material of the present invention is prepared according to the following steps:

[0032] (1) Raw material powder preparation: select 5N and above high-purity raw material powder to prepare CuIn according to the stoichiometric ratio 0.7 Ga 0.3 Se 2 500 grams of quaternary mixed powder, the mixed powder is sealed in a quartz vessel and vacuumized to 10 -1 Pa, and then place the sealed quartz vessel in a muffle furnace and heat it to 650°C for 3 to 5 hours at a heating rate of 1°C / min, and the cooling method is furnace cooling. The obtained single-phase CuIn 0.7 Ga 0.3 Se 2 The quaternary alloy powder is mechanically crushed to prepare alloy powder below 300 mesh; the preparation of the raw material powder also includes In 2 Se 3 , Ga 2 Se 3 and Cu 2 Preparation of three binary single-phase alloy powders of Se, specifically In 2 Se 3 The sintering temperature of the alloy powder is 400-500...

Embodiment 2

[0034] Embodiment 2: difference with embodiment 1 is:

[0035] (1) The preparation of the raw material powder also includes In 2 Se 3 , Ga 2 Se 3 and Cu 2 Preparation of three binary single-phase alloy powders of Se, specifically In 2 Se 3 The sintering temperature of the alloy powder is 400-500°C, the heating rate is 1°C / min, and the heat preservation is 3-5 hours; Ga 2 Se 3 The sintering temperature of the alloy powder is 500-700°C, the heating rate is 1°C / min, and the heat preservation is 3-5 hours; Cu 2 The sintering temperature of Se alloy powder is 500-600°C, the heating rate is 1°C / min, and the heat preservation is 3-5 hours;

[0036] (2) Mixing of raw material powder: CuIn 0.7 Ga 0.3 Se 2 Quaternary alloy powders and the above three binary single-phase alloy powders according to CuIn 0.7 Ga 0.3 Se 2 The stoichiometric ratio is mixed, and the weight ratio of the quaternary alloy powder to the sum of the above three binary alloy powders is 4:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com