Patents

Literature

84results about How to "Improve sputtering efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

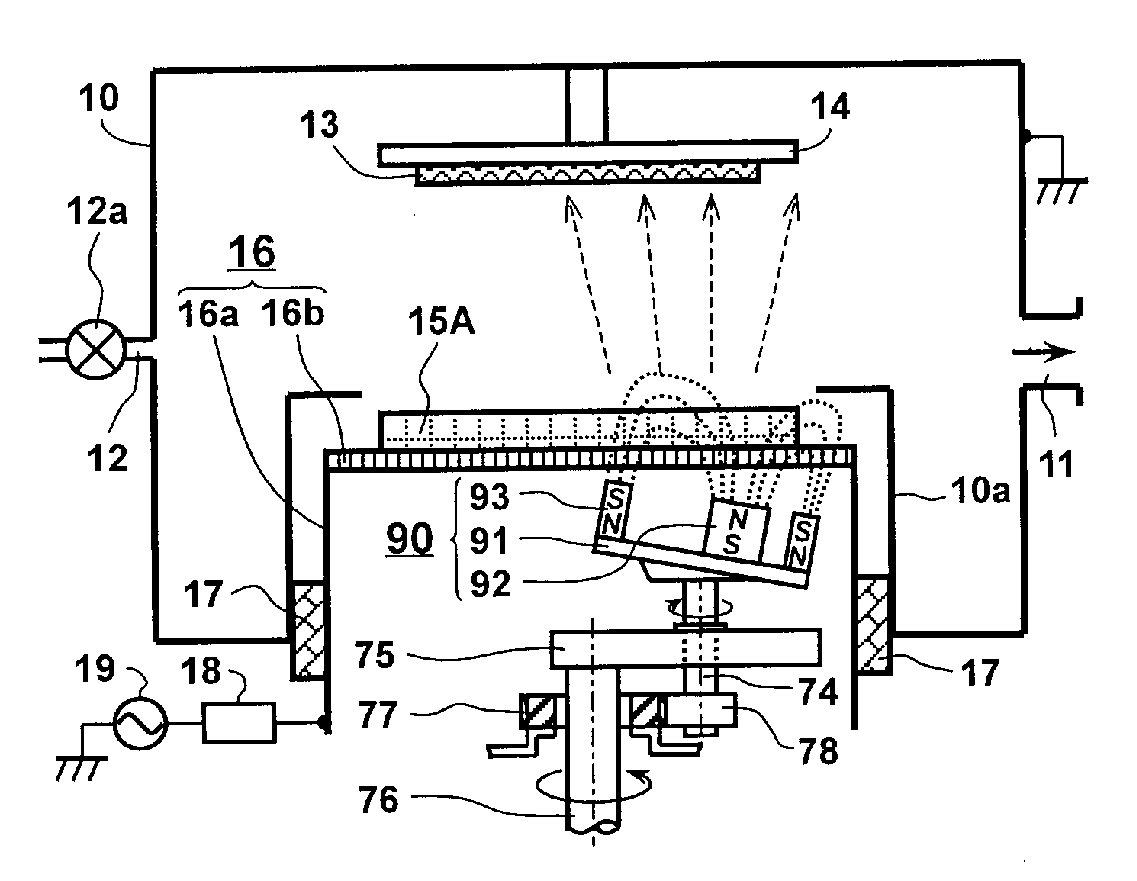

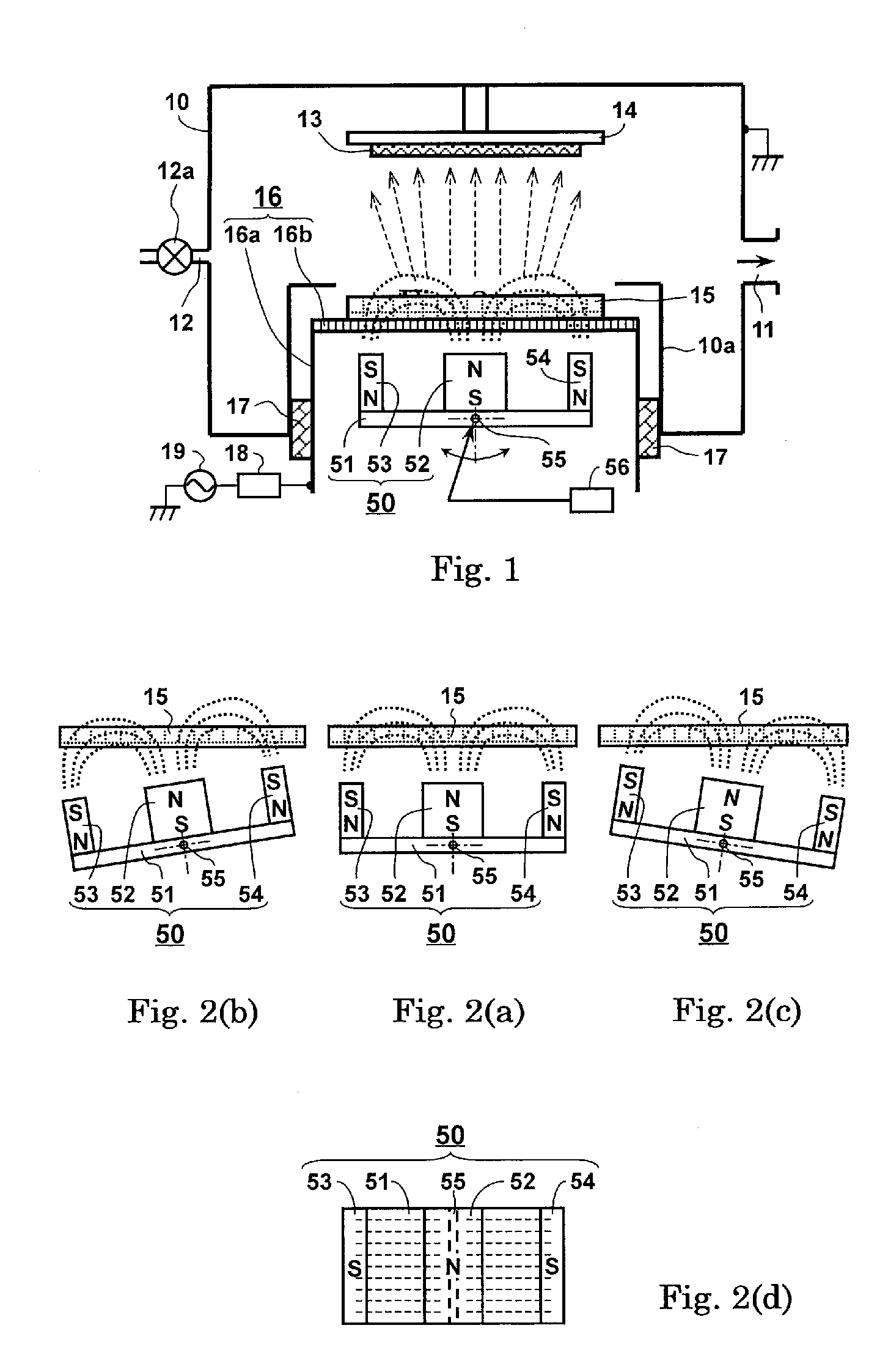

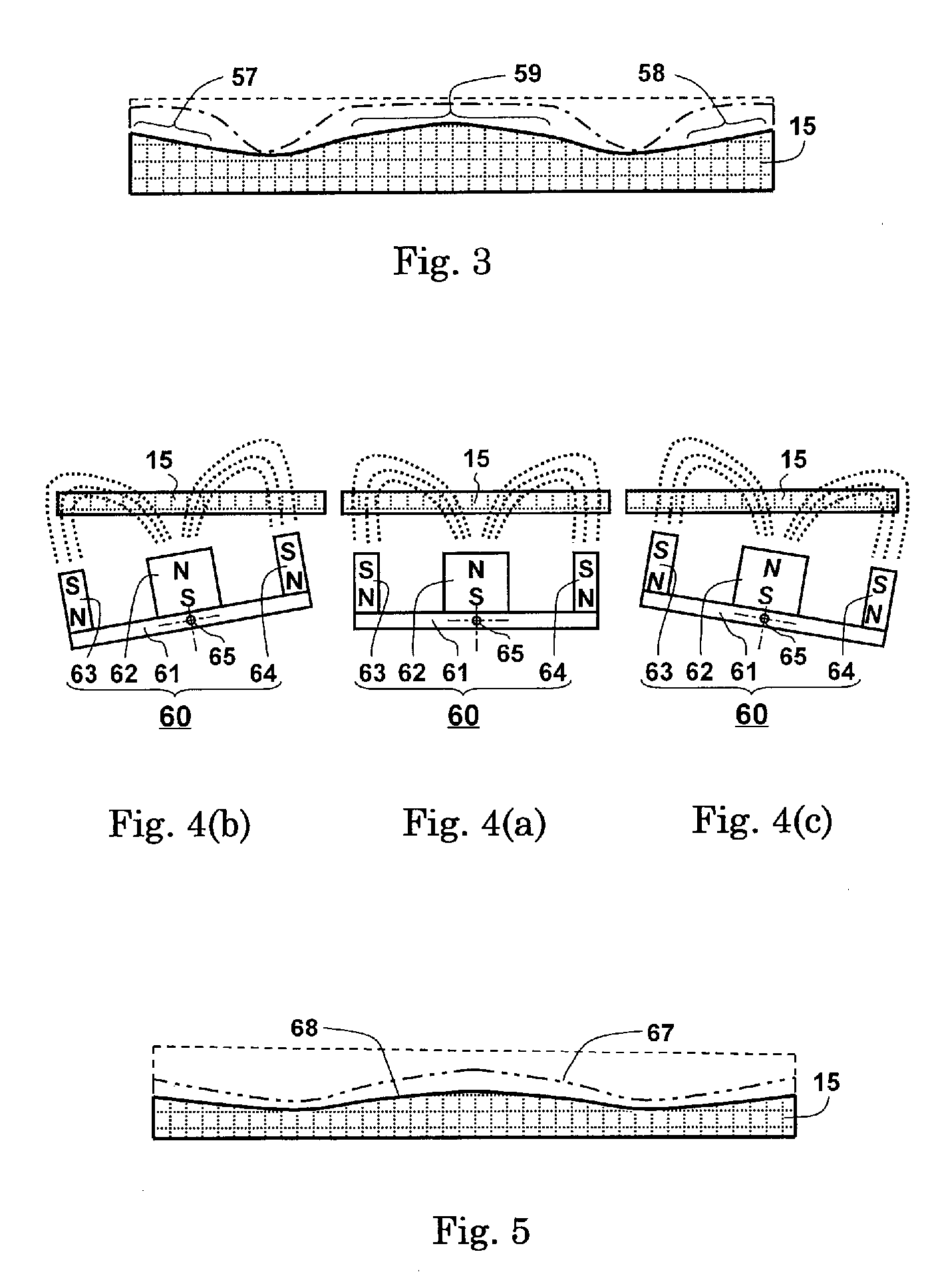

Magnetron sputtering apparatus

InactiveUS20050274610A1Improve sputtering efficiencyImprove targeting efficiencyCellsElectric discharge tubesSputteringVacuum chamber

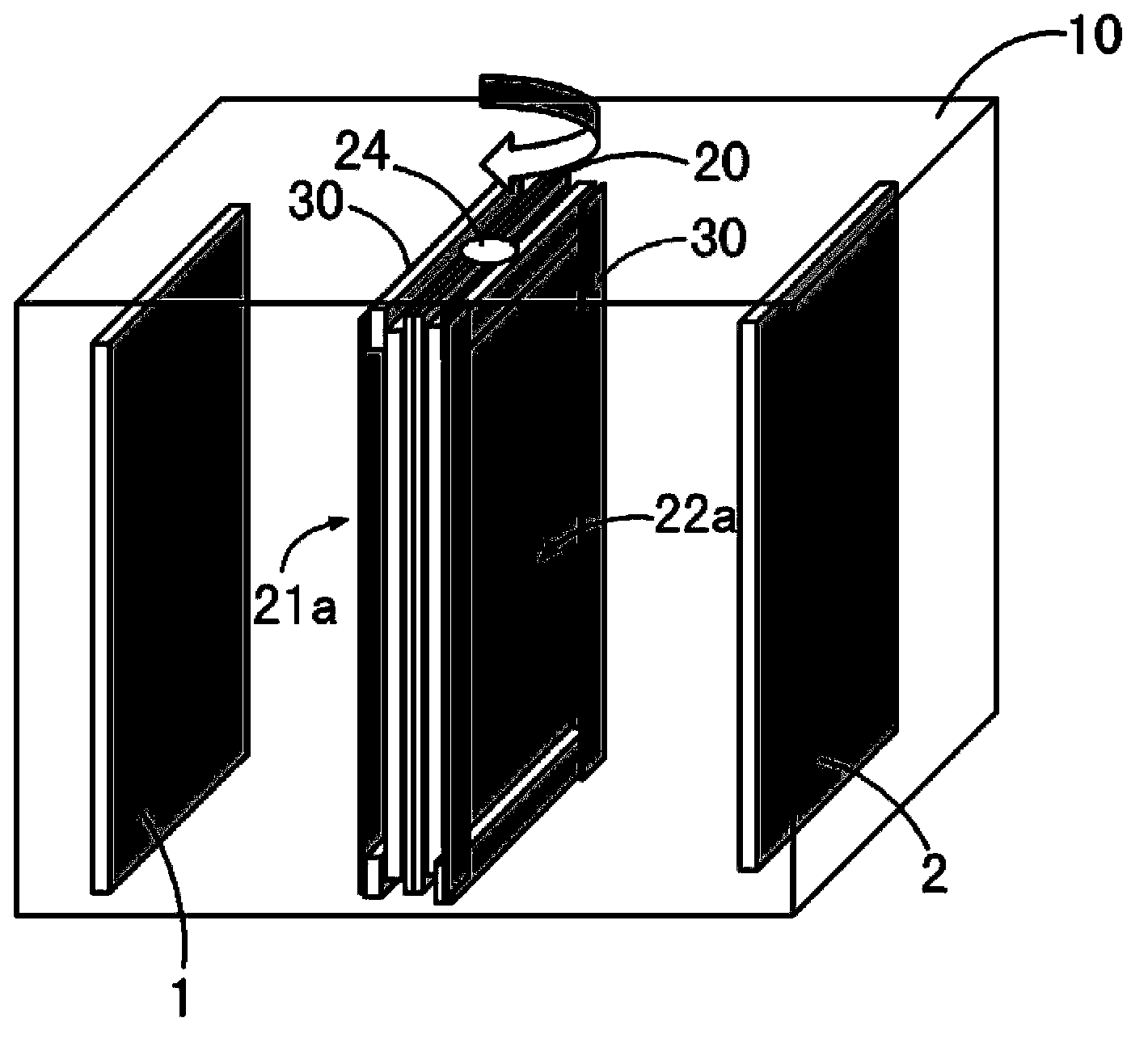

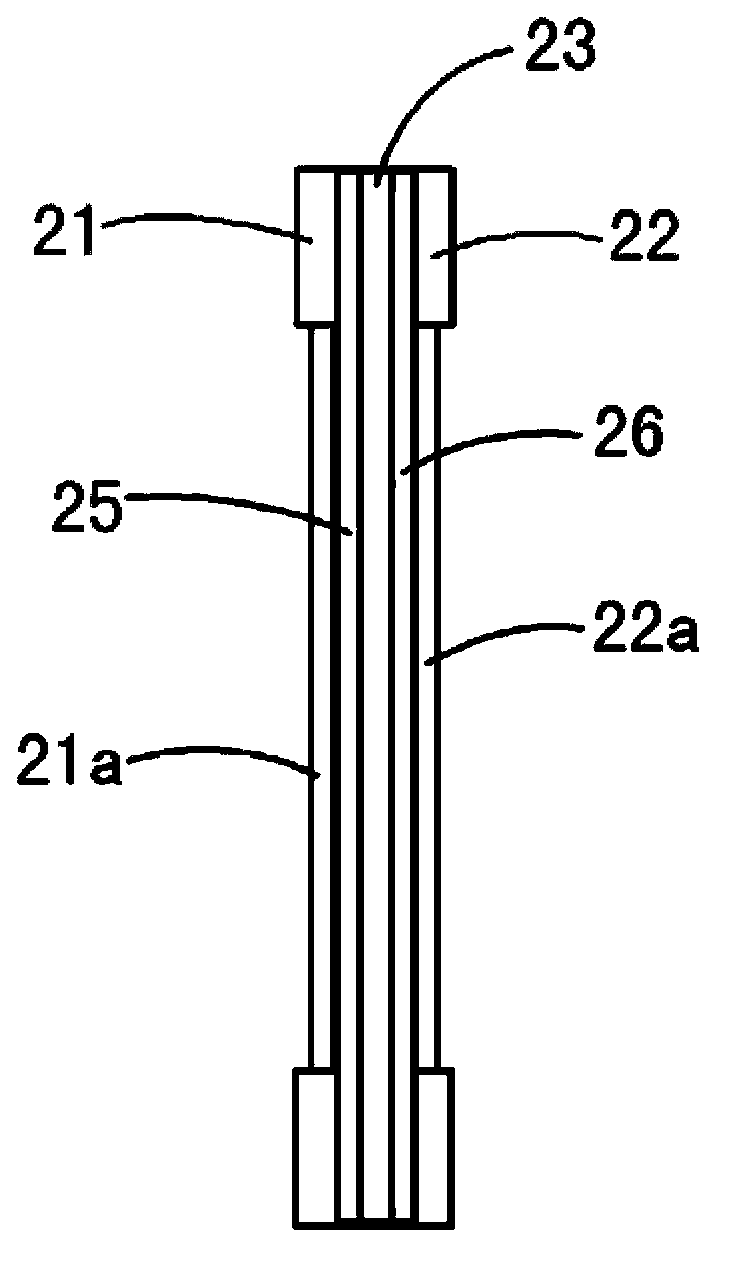

A magnetron sputtering apparatus is composed of a vacuum chamber (10), a target (15), a substrate (13), an anode (14) for supporting the substrate (13) that is disposed in the vacuum chamber, a cathodic body (16) for supporting the target (15) that is allocated so as to confront with the anode (14) and a magnetic field generating section (50) for generating a magnetic field on a surface of the target (15) that is allocated in neighborhood of one side of the cathodic body (16) opposite to the target (15). The target (15) is in a shape of square flat plate. The magnetic field generating section (50) is further composed of a yoke (51) in flat plate corresponding to the target (15), a first permanent magnet (52) in rectangular parallelepiped that is disposed in the middle of the yoke (51) and second and third permanent magnets (53, 54) in rectangular parallelepiped that are disposed in both end portions of the yoke (51) respectively. The magnetron sputtering apparatus is further composed of a driving unit (56) for swinging the magnetic field generating section (50) within a prescribed angle with centering a line as an axis of rotation, wherein the line passes through an approximate center (56) of the yoke (51) and is perpendicular to magnetic flux lines of the magnetic field and in parallel with the target (15).

Owner:VICTOR CO OF JAPAN LTD

Indium oxide-tin oxide powders and method for producing the same

InactiveUS6051166ADecrease productivityImprove sputtering efficiencyAluminium compoundsGallium/indium/thallium compoundsSaline waterIndium

A method for producing an indium oxide-tin oxide powder, which comprises supplying to react an aqueous solution of an indium salt, an aqueous solution of a tin salt and an aqueous alkaline solution into water at 40 DEG C. or more and less than 100 DEG C. so that the pH during the reaction is maintained within the range from 4 to 6, forming a precipitate, washing the formed precipitate after solid-liquid separation, and calcining the precipitate at 600 DEG C. or more and 1300 DEG C. or less.

Owner:SUMITOMO CHEM CO LTD

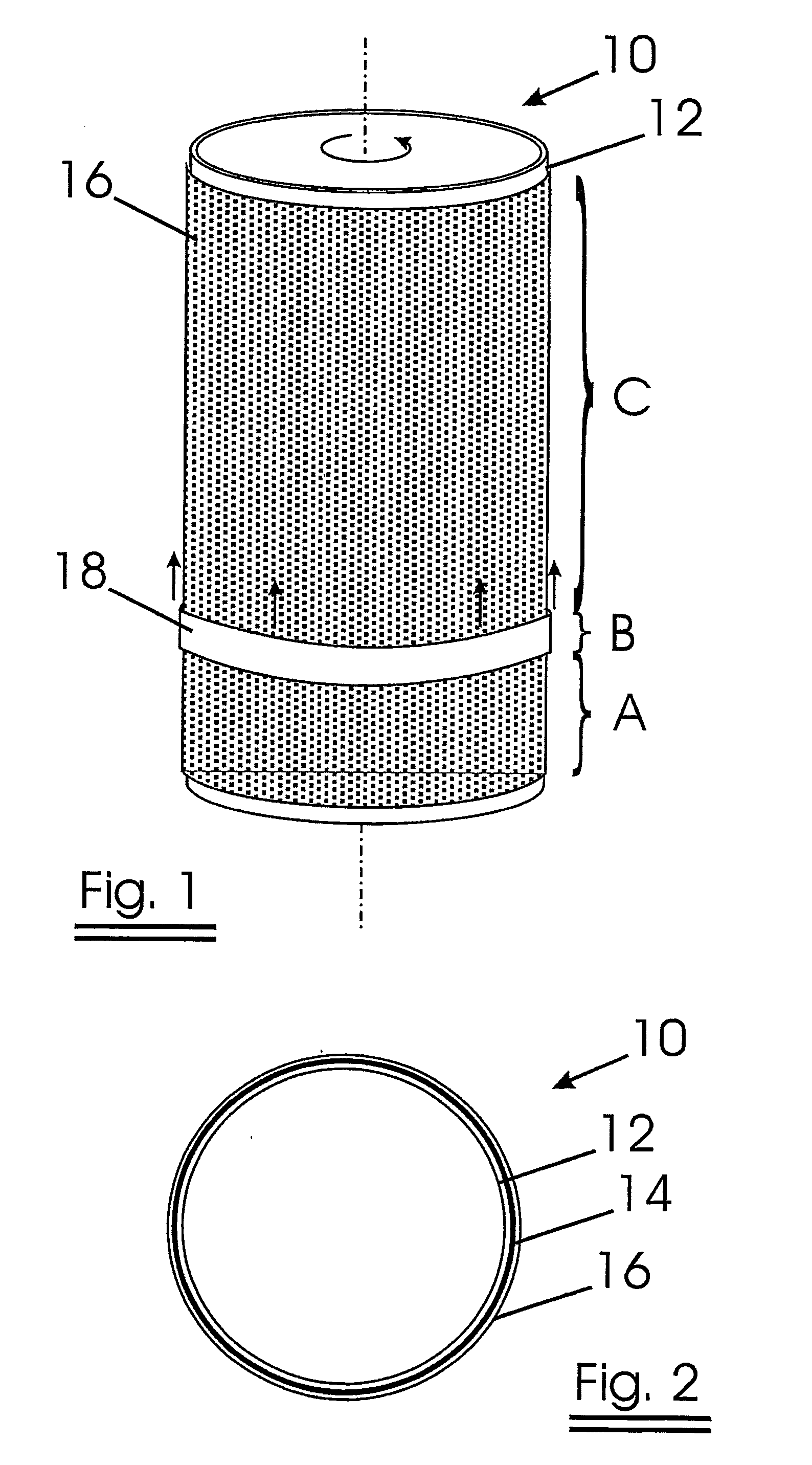

Sputter target

InactiveUS20040253382A1Easy to disassembleAvoid formingCellsHot-dipping/immersion processesMetal alloyZinc

The invention relates to a sputter target and more particularly to a zinc sputter target. The target comprises a target holder having an outer surface and a target material formed on said outer surface. The target material has a relative density higher than 92% of the theoretical density of the metal or metal alloy. Furthermore the invention relates to a process for the manufacturing of a sputter target.

Owner:NV BEKAERT SA

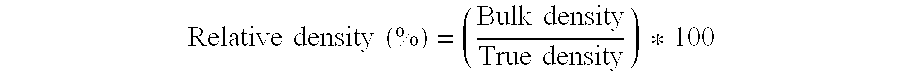

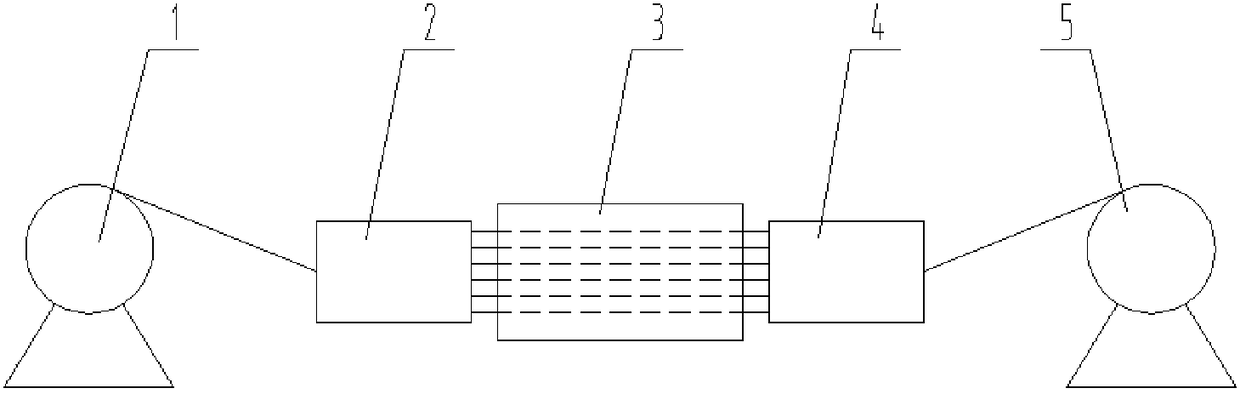

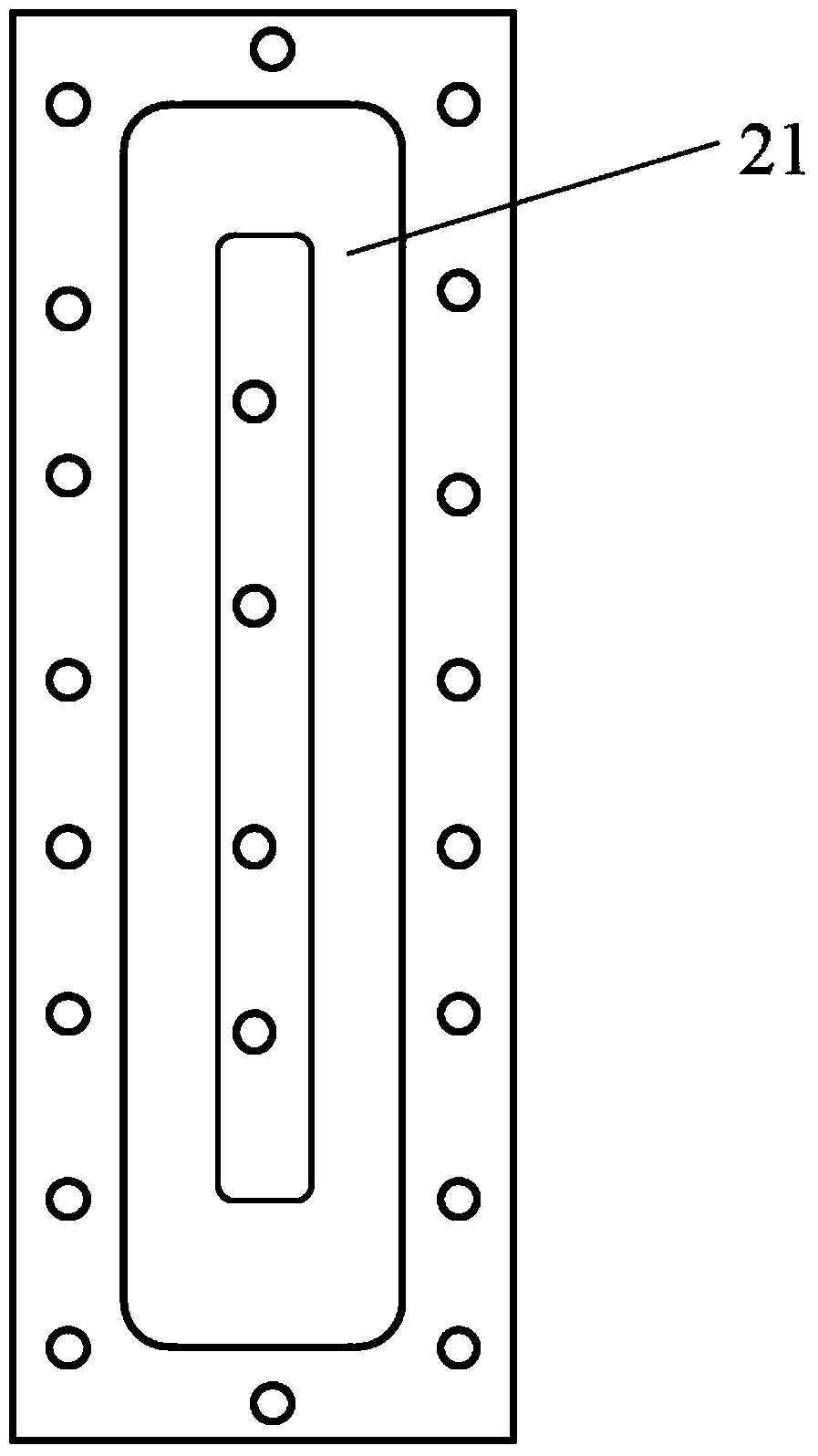

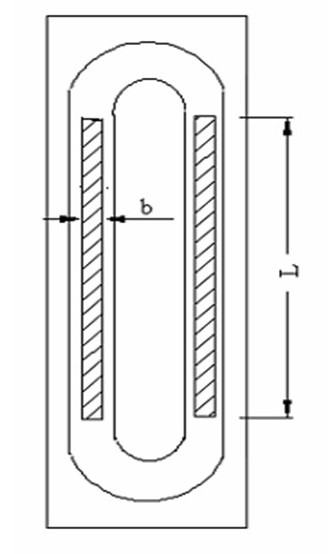

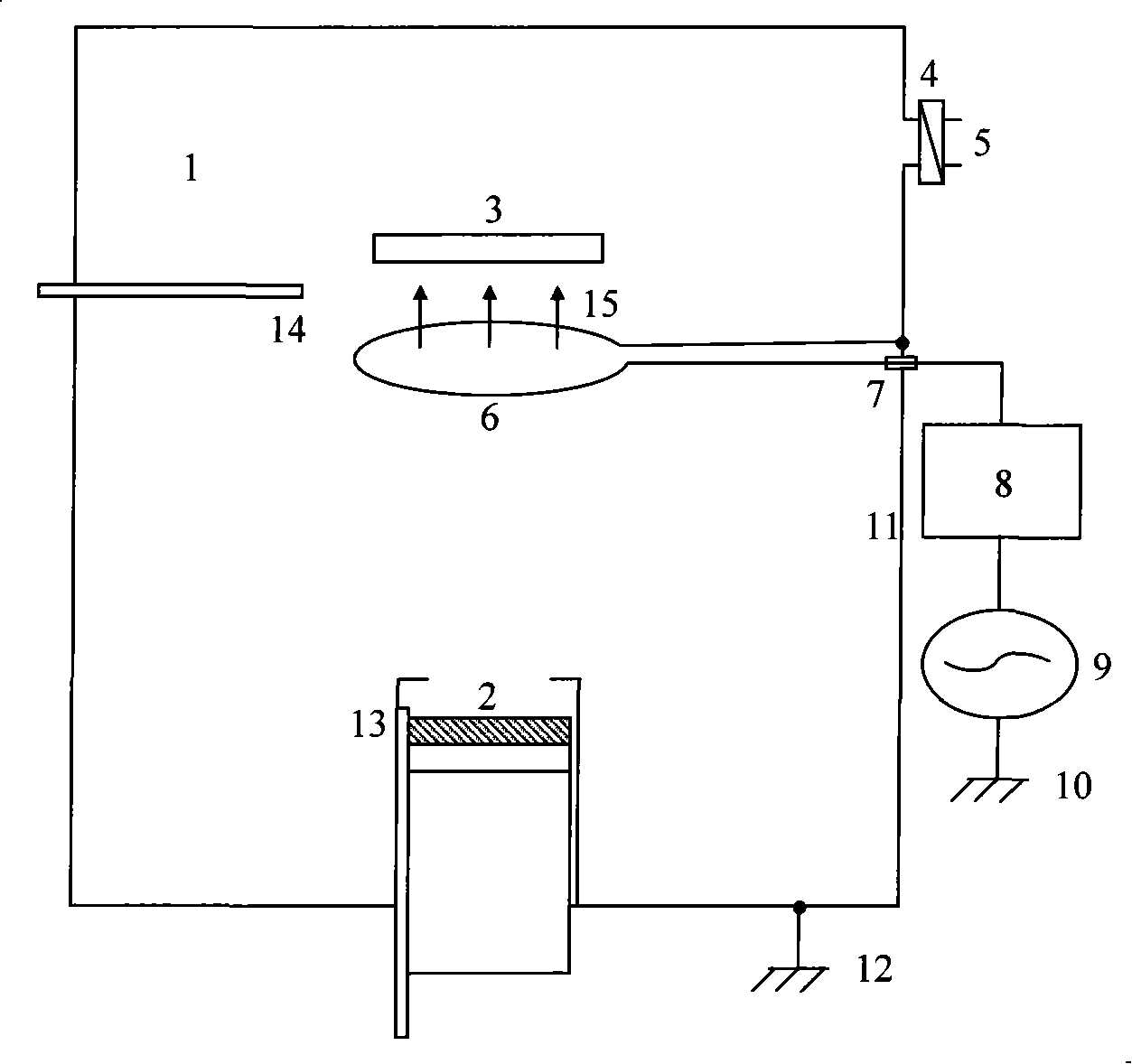

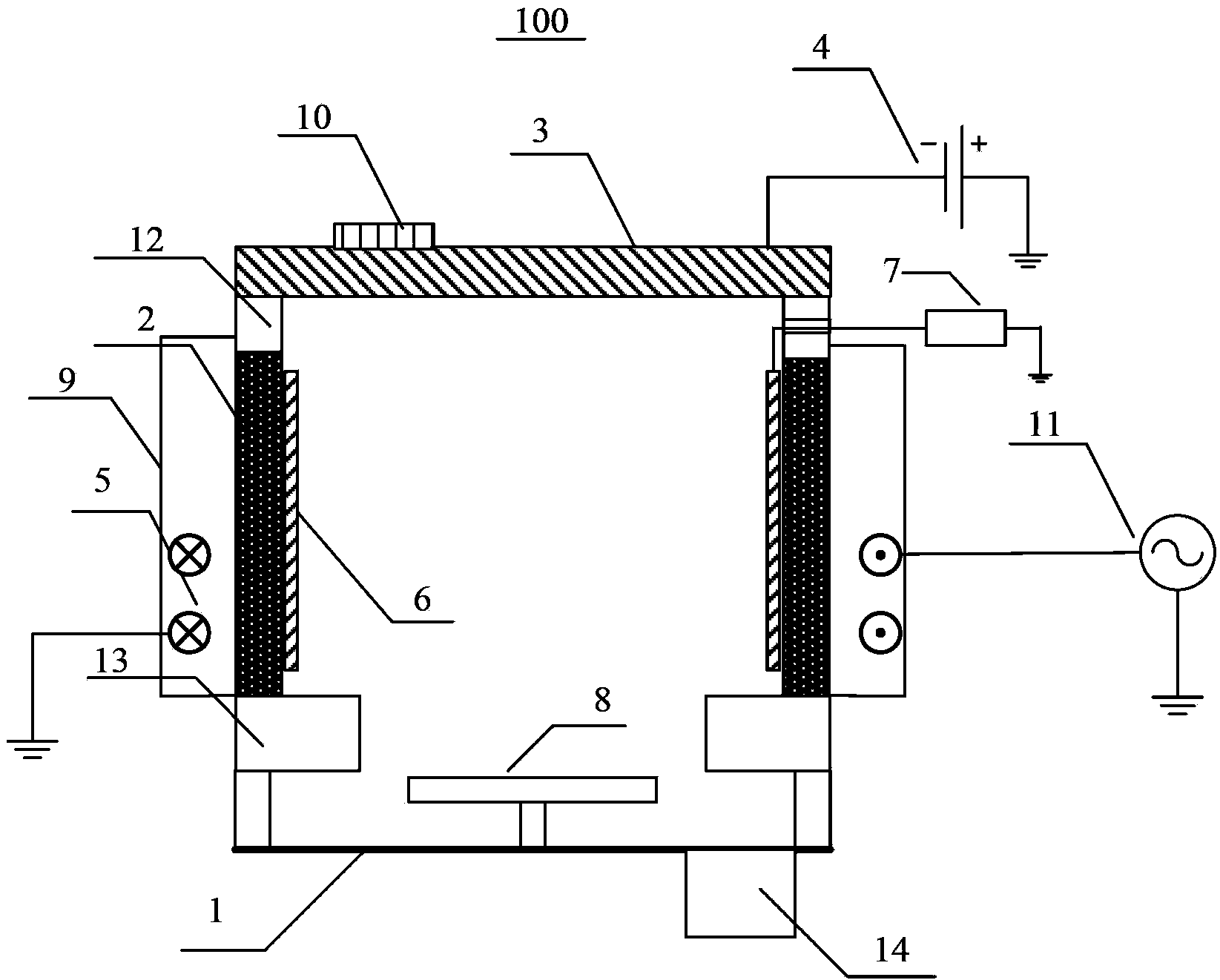

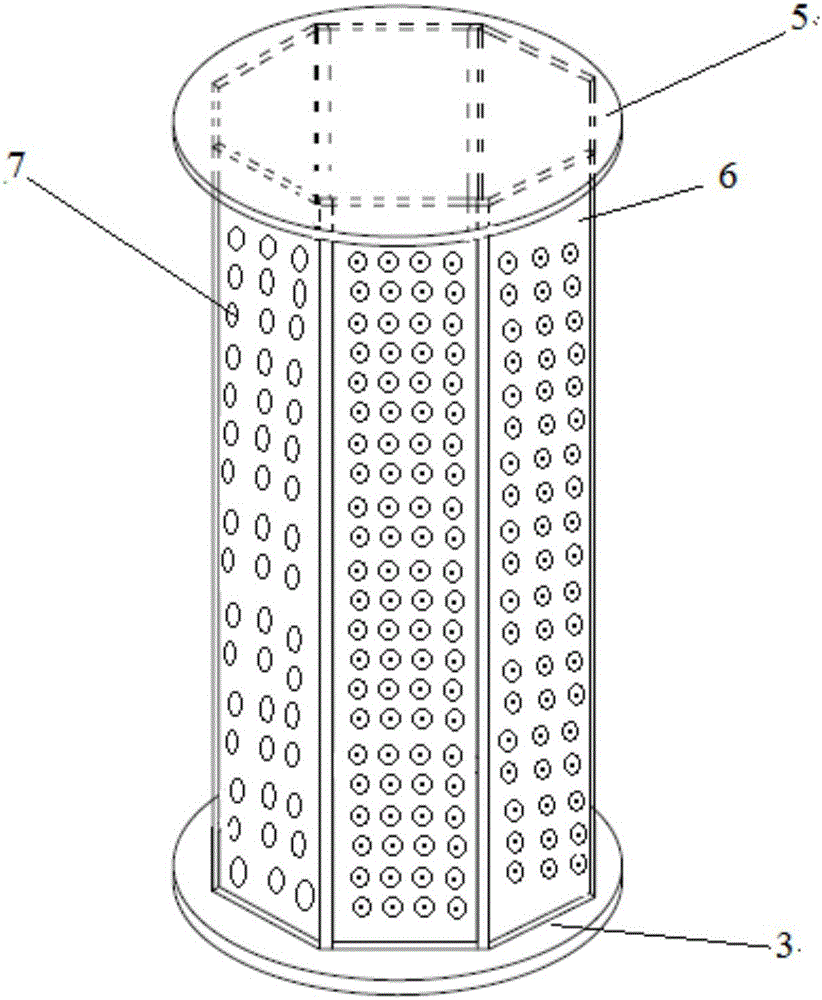

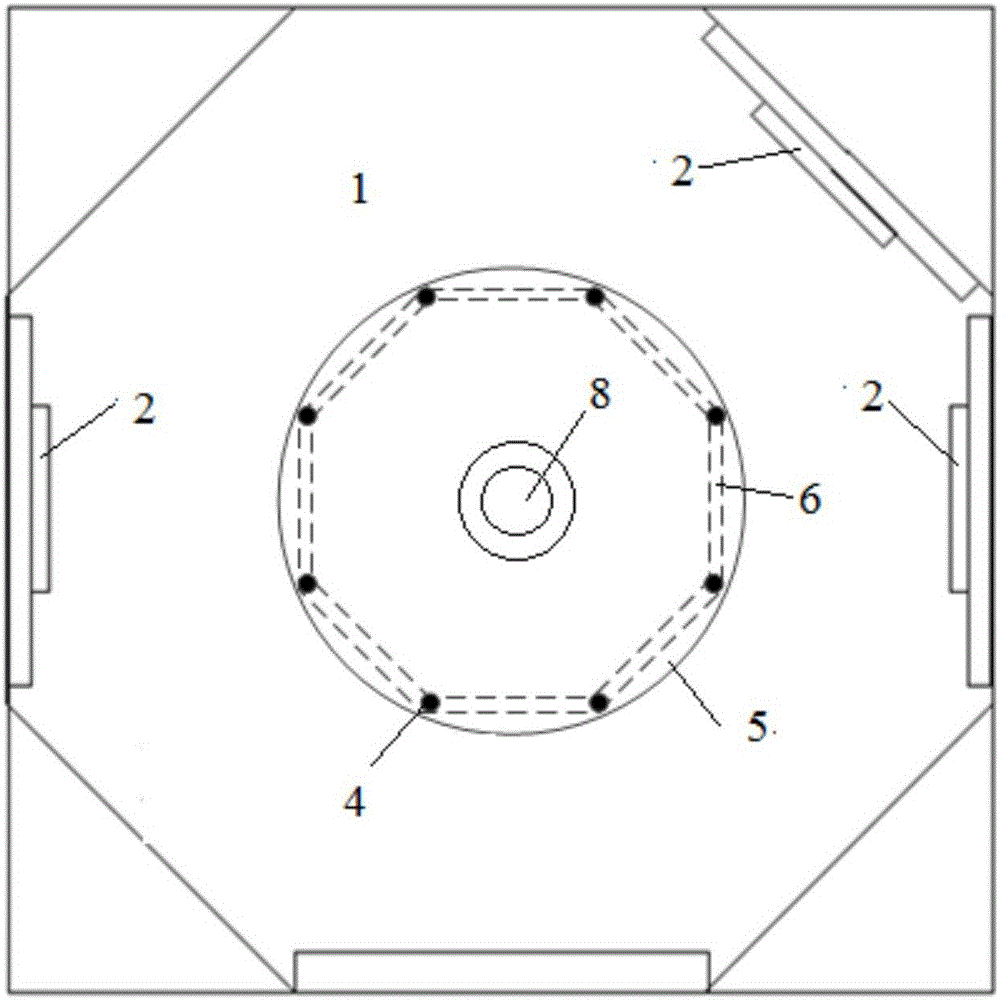

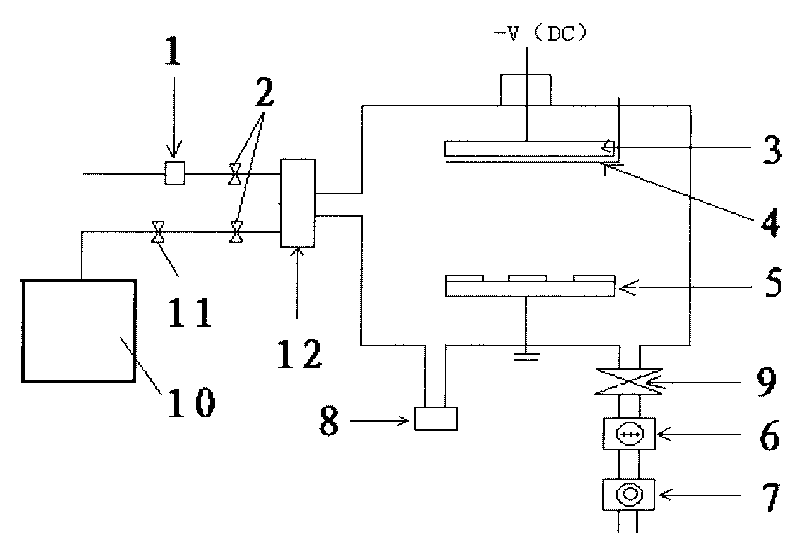

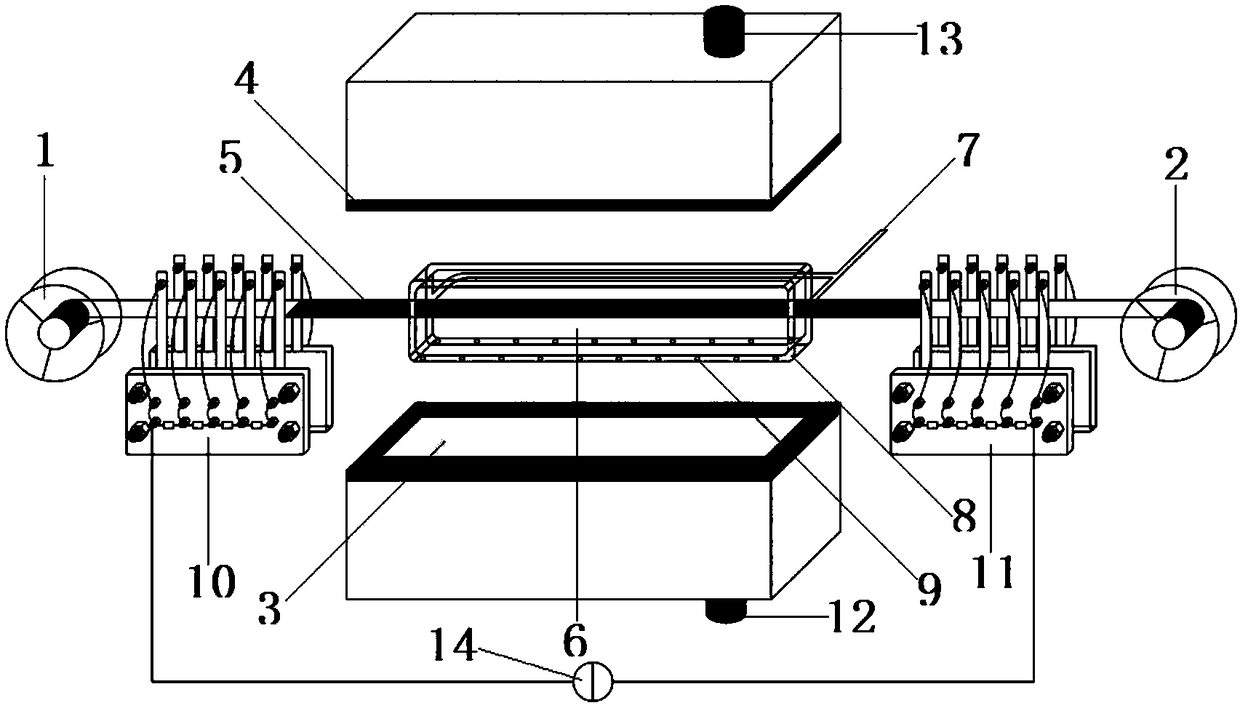

Device and method for depositing film on SiC fiber surface

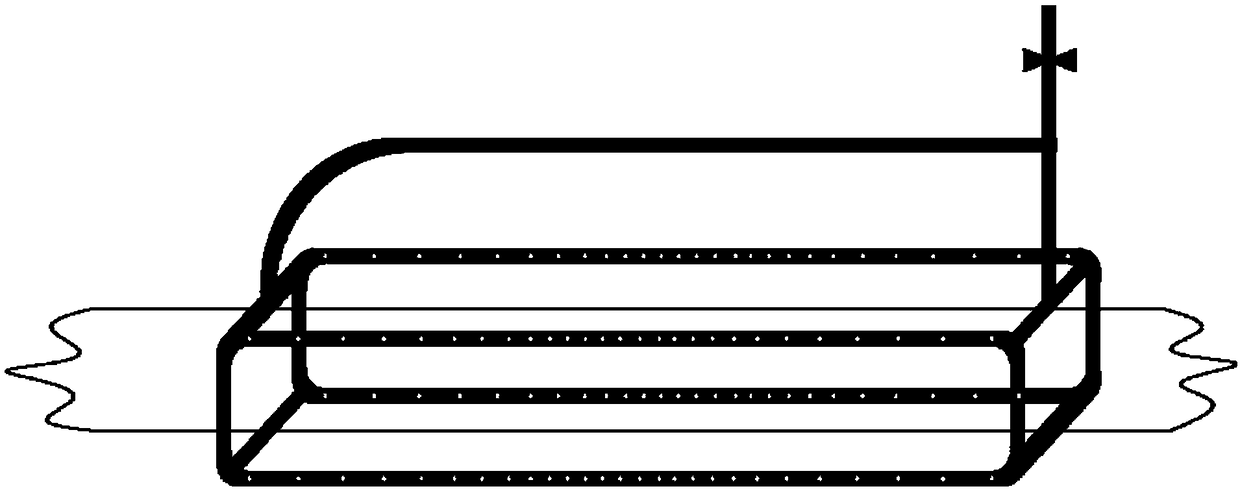

InactiveCN102251224AUniform thicknessPrevent escapeVacuum evaporation coatingSputtering coatingIntermediate frequencySputter deposition

The invention relates to vacuum coating magnetron sputtering deposition technology, and particularly a device and a method for depositing a film on a SiC fiber surface; on one hand, a film with a uniform thickness is deposited on a continuous SiC fiber surface; on the other hand, the problem of target material poisoning of compound film deposition is solved, and the continuity and stability of the deposition process is realized. The device is provided with a target material I, a target material II, a workpiece rotating shelf, an intermediate-frequency pulsed magnetron sputtering power supply, a magnetron sputtering vacuum chamber; the workpiece rotating shelf is disposed in the magnetron sputtering vacuum chamber; the target material I and the target material II are facingly disposed inside and outside the workpiece rotating shelf in the magnetron sputtering vacuum chamber; a cathode of the intermediate-frequency pulsed magnetron sputtering power supply is connected to the target material I; and an anode of the intermediate-frequency pulsed magnetron sputtering power supply is connected to the target material II. According to the invention, the gas flow, the reaction gas types, the sputtering time and the like in the vacuum chamber of the magnetron sputtering device are adjusted so as to realize the deposition of metals or compound films with different types and different thicknesses on a continuous SiC fiber surface, and to realize the surface modification of the SiC fiber.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Rotating target material

InactiveCN107663630ATight jointSimple processVacuum evaporation coatingSputtering coatingAdhesiveEngineering

The present invention provides a rotating target, which includes a target body, a backing tube, and a joint, the joint is arranged between the target body and the backing tube, and the joint includes a A compressible structure and an electrically and thermally conductive adhesive, the compressible structure is a compressible blanket or a compressible sheet. Using the adapter to join the target body and the backing tube can not only help to simplify the process of rotating the target, but also can improve the sputtering power resistance of the rotating target while maintaining the bonding strength between the target body and the backing tube. Acceptance, thereby improving its sputtering efficiency.

Owner:欧美达应用材料科技股份有限公司

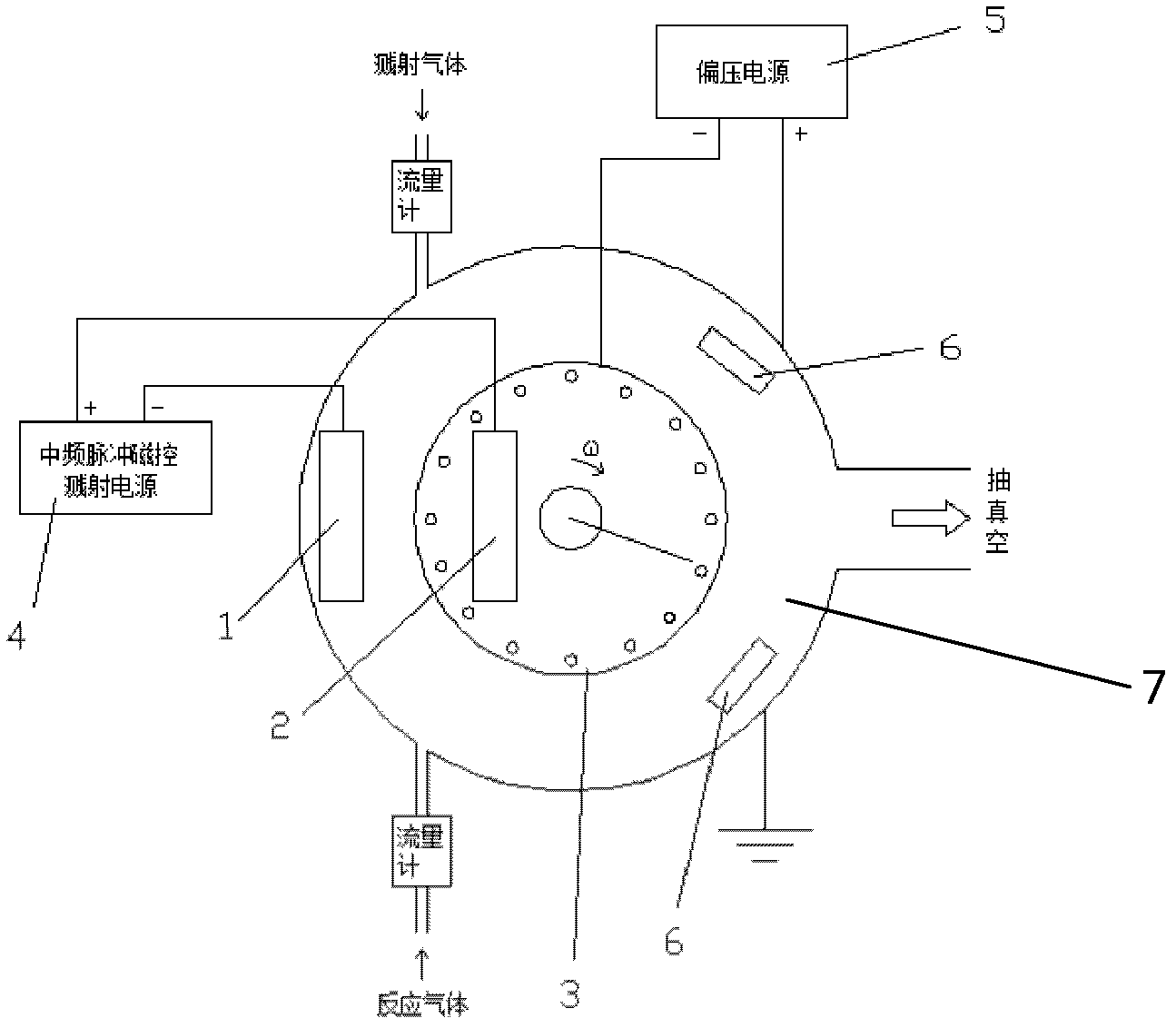

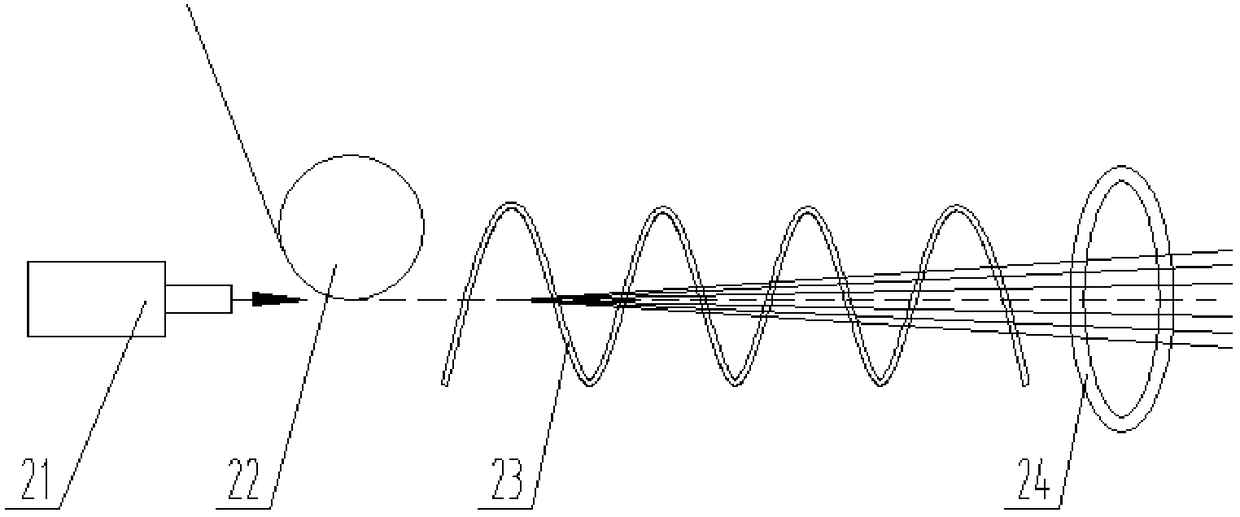

Fiber surface interface layer deposition equipment and method

ActiveCN108409348AIncrease profitAvoid damageFibre treatmentVacuum evaporation coatingFiber bundleInterface layer

The invention discloses fiber surface interface layer deposition equipment and method. The equipment comprises a filament release device, an electrostatic filament scattering device, a magnetron sputtering device, a solid adhesive device and a filament collecting device. The filament collecting device and the filament release device are positioned on two sides of the magnetron sputtering device, the electrostatic filament scattering device is positioned between the filament release device and the magnetron sputtering device, and the solid adhesive device is positioned between the filament collecting device and the magnetron sputtering device. When the equipment is in operation, fiber bundles are released from the filament release device, then move to the electrostatic filament scattering device to be scattered, enter the magnetron sputtering device in a scattered state and are bundled by the solid adhesive device after an interface layer is obtained through magnetron sputtering deposition, and the fiber bundles are finally collected by the filament collecting device. The SiC fiber surface interface layer obtained according to the preparation method is uniform in thickness distribution, controllable in thickness and low in fiber damage and is a quasi-graphene structure weak interface layer, and mechanical performances of composite materials can be remarkably improved.

Owner:CENT SOUTH UNIV

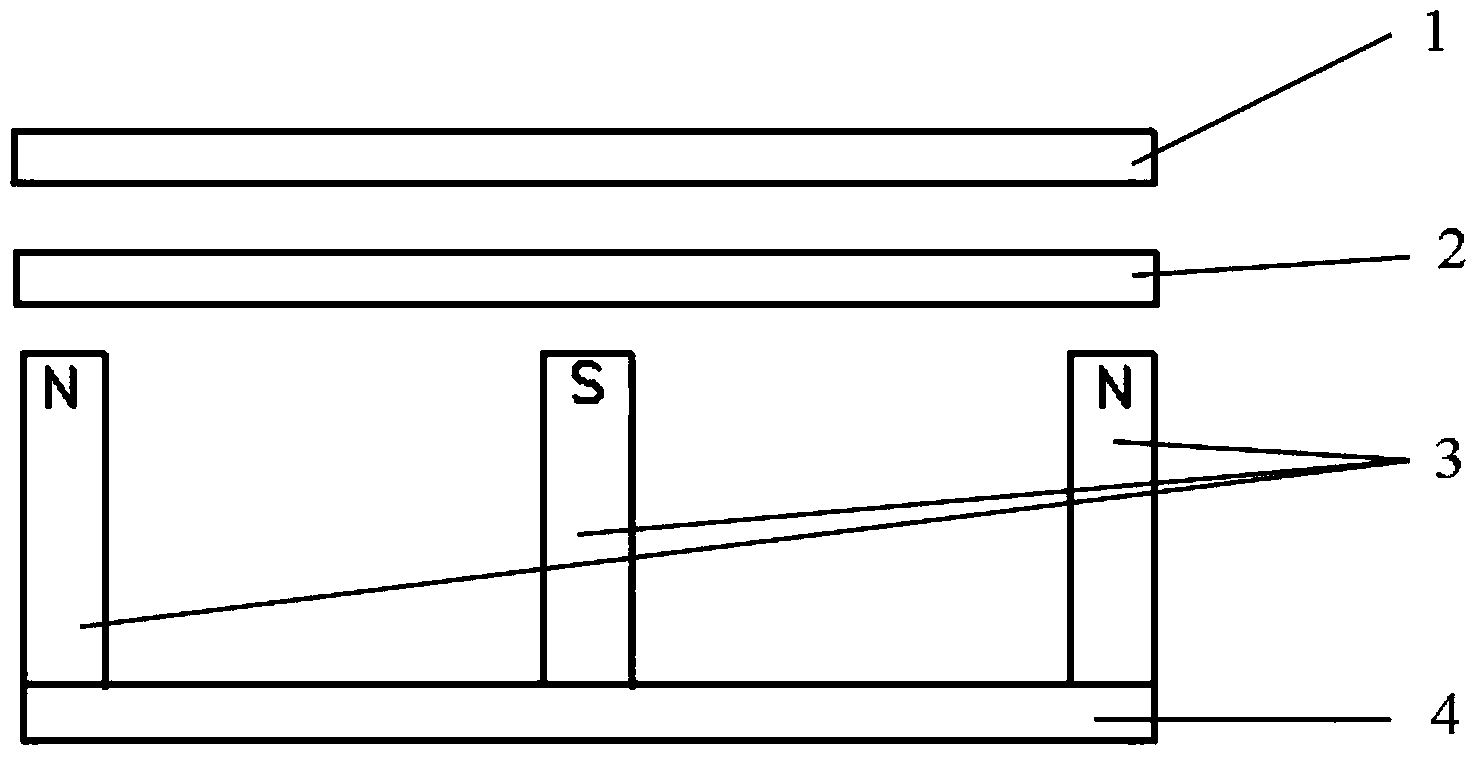

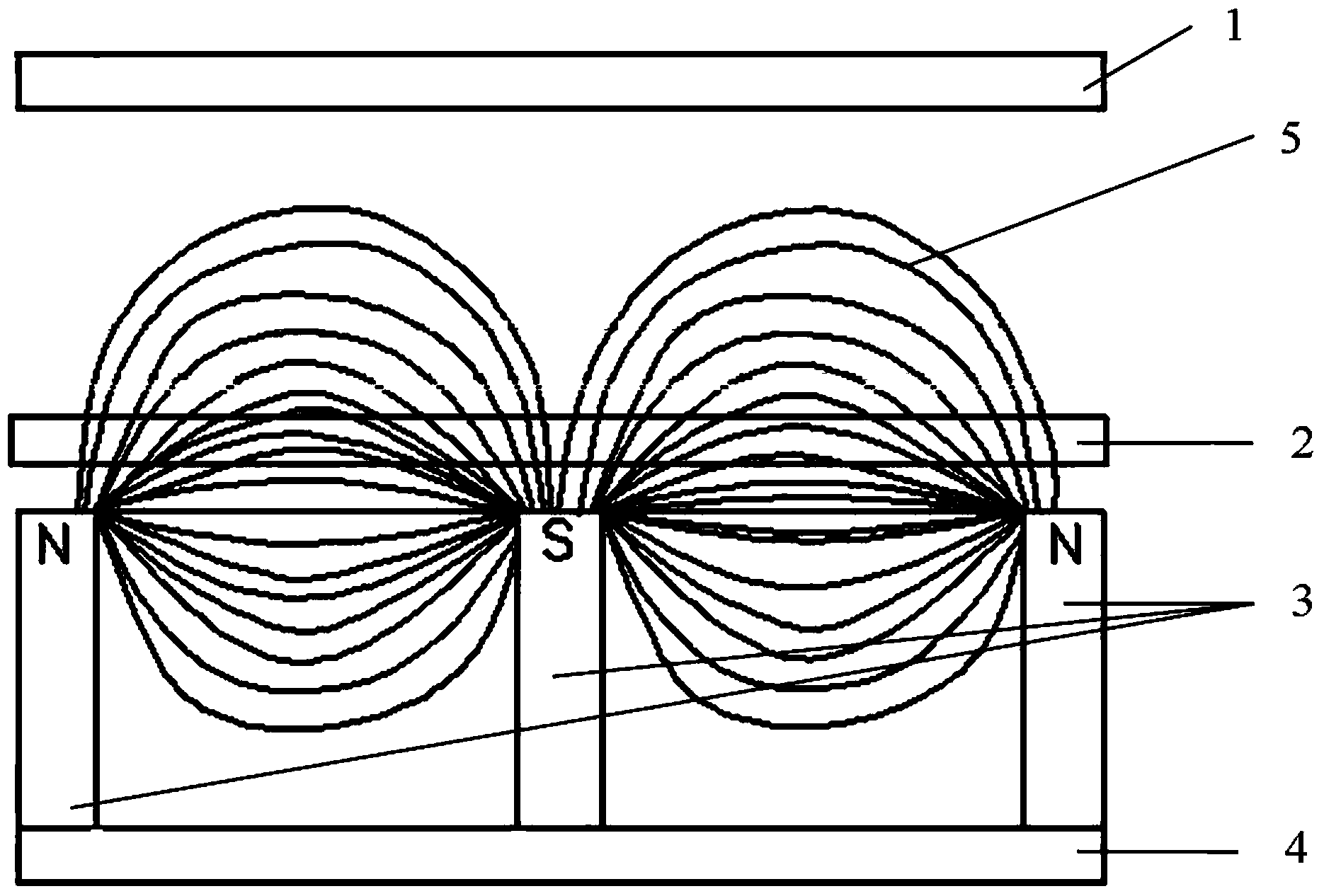

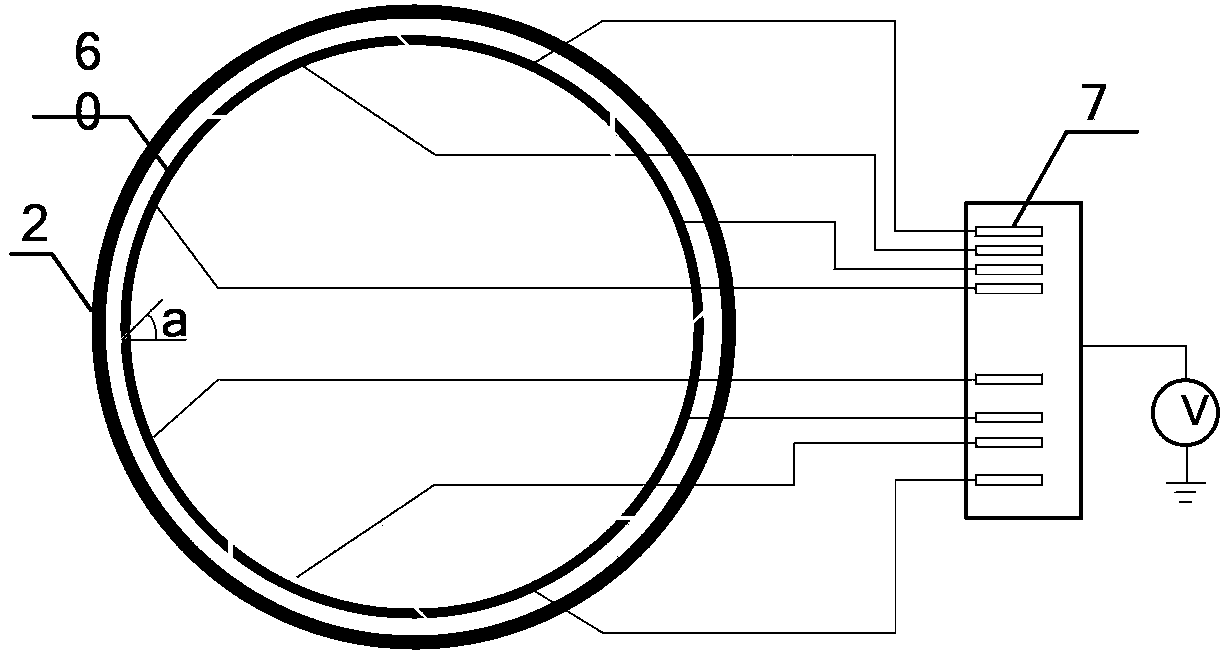

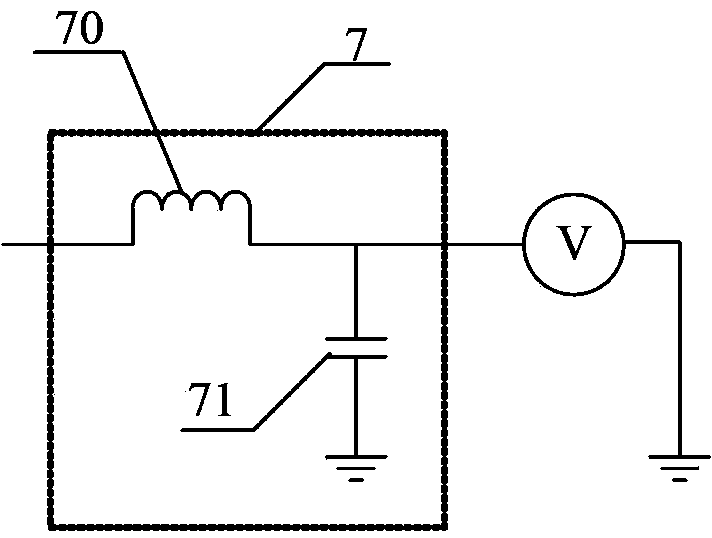

Self-adaptive magnetic field adjustment type magnetic-controlled sputter coating device and coating method thereof

ActiveCN103556122AReal-time monitoring of magnetic field strengthIncrease profitVacuum evaporation coatingSputtering coatingElectricityTarget surface

The invention discloses a self-adaptive magnetic field adjustment type magnetic-controlled sputter coating device. An electrified coil is arranged between adjacent permanent magnets; a hall sensor is arranged between the electrified coil and a magnet yoke; a length direction of the electrified coil is vertical to directions of magnetic poles of the permanent magnets; a magnetic field strength detecting system is externally connected with the hall sensor and applied to real-time monitoring of the magnetic field strength; a circuit control module is externally connected with the electrified coil and electrically connected with the magnetic field strength detecting system; current flowing through the electrified coil is adjusted according to data of the magnetic field strength detecting system, so that magnetic field distribution is changed and the magnetic field is in a most optimized state all the time, namely, magnetic force lines and a target surface are located on the same plane to the greatest extent, so that the effect of a maximum utilization rate of target material is achieved; meanwhile, the magnetic field strength can be monitored in real time and adjusted without the need of interrupting the coating process, so that the production efficiency is high.

Owner:SUZHOU JUZHEN PHOTOELECTRIC

Preparation methods of gold and silver embedded target and film thereof

InactiveCN102051497ALow costIncrease profitVacuum evaporation coatingSputtering coatingSputteringTransmittance

The invention relates to preparation methods of a gold and silver embedded target and a film thereof. The gold and silver embedded target contains 10-30 percent of gold and 70-90 percent of silver. When the target is prepared, a pure silver target is used for carrying out magnetron sputtering to obtain a sputtering runway, a gold slot is opened, and then gold is embedded into the gold slot by adopting a press method; and when an alloy film is prepared, gold and silver on the runway of the gold and silver embedded target are sputtered under the condition of magnetron sputtering to be mixed and deposited onto a substrate to form a gold and silver alloy film, wherein the magnetron sputtering is carried out under the conditions that the vacuum degree is 1*10<-3> to 5*10<-3>, the sputtering temperature is 20-40 DEG C, the sputtering rate is 20-200nm / minute, and the air pressure is 0.5-1Pa. In the gold and silver embedded target, gold is used for replacing partial silver on a silver target, and the gold and the silver are combined in an embedding mode, so that the utilization ratio of noble metals is high, the target cost is reduced; and the obtained target has the advantages of tight combination, high sputtering efficiency, stable property and good quality; and a prepared gold and silver alloy film has the advantages of stable property and components, higher visible light transmissivity and far infrared reflectivity than those of pure silver films, and better timeliness.

Owner:ZHENGZHOU UNIV

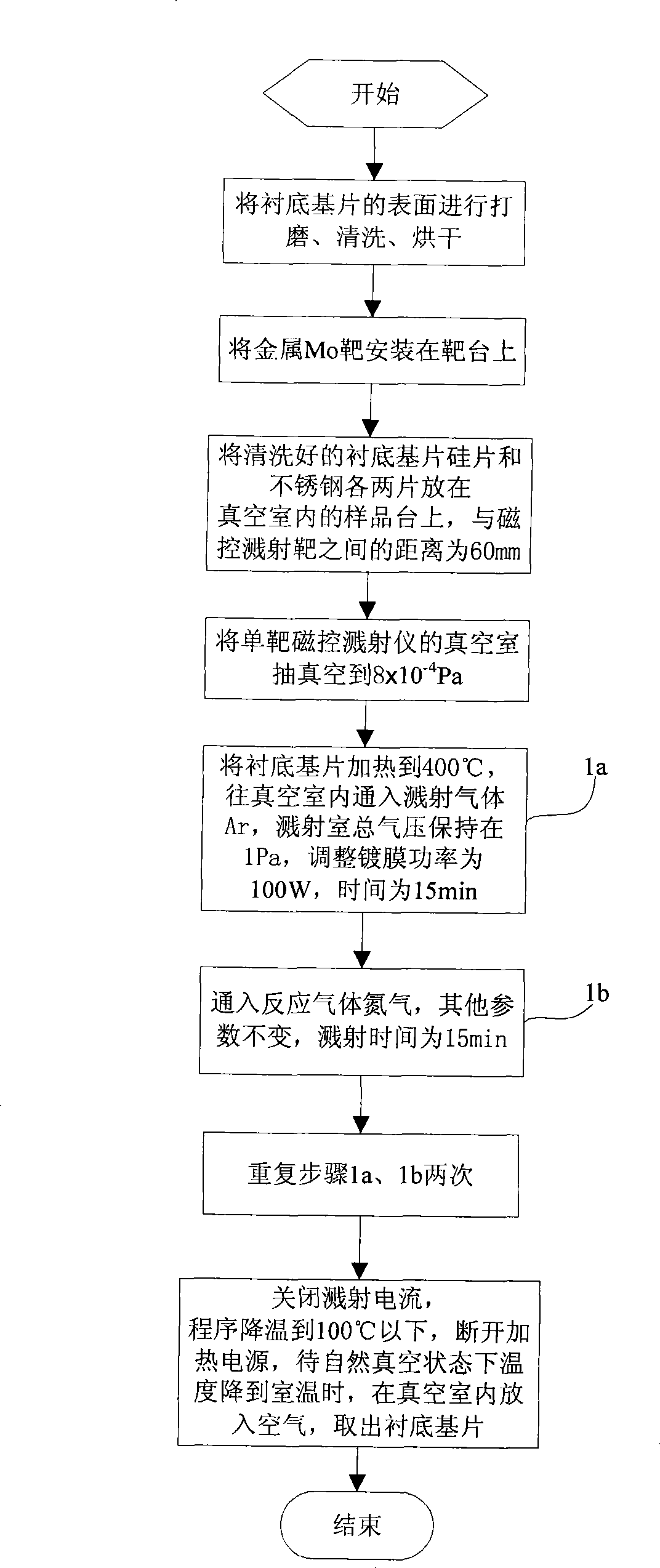

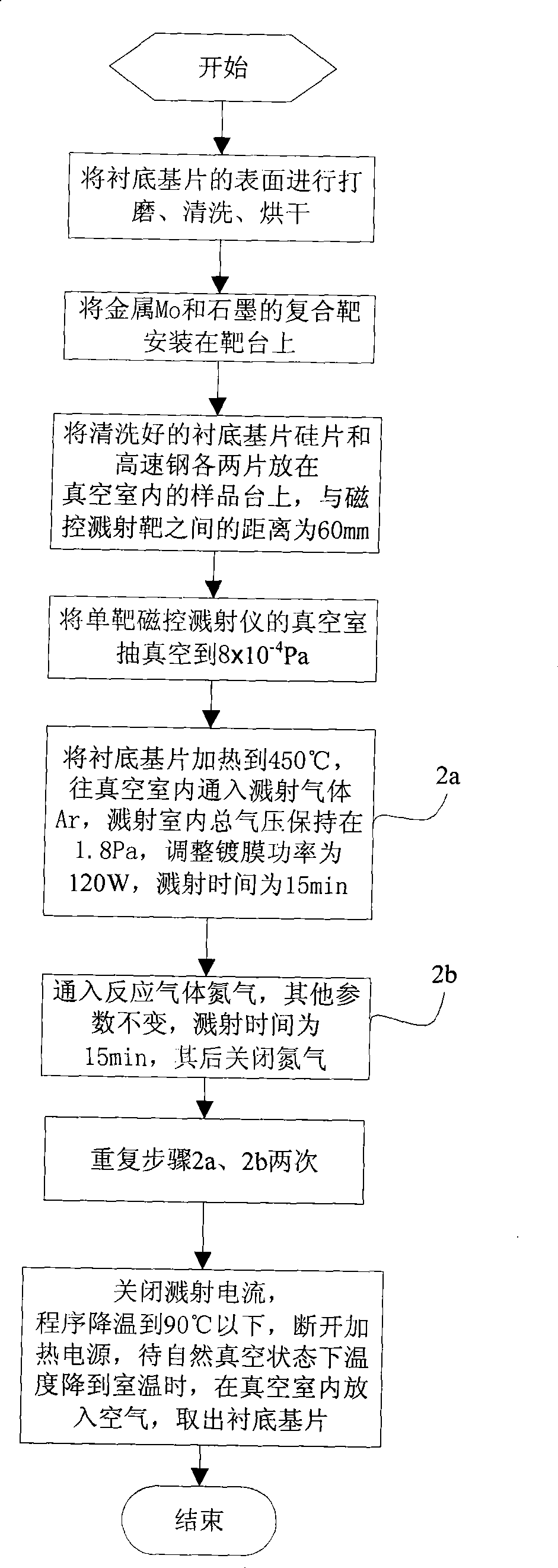

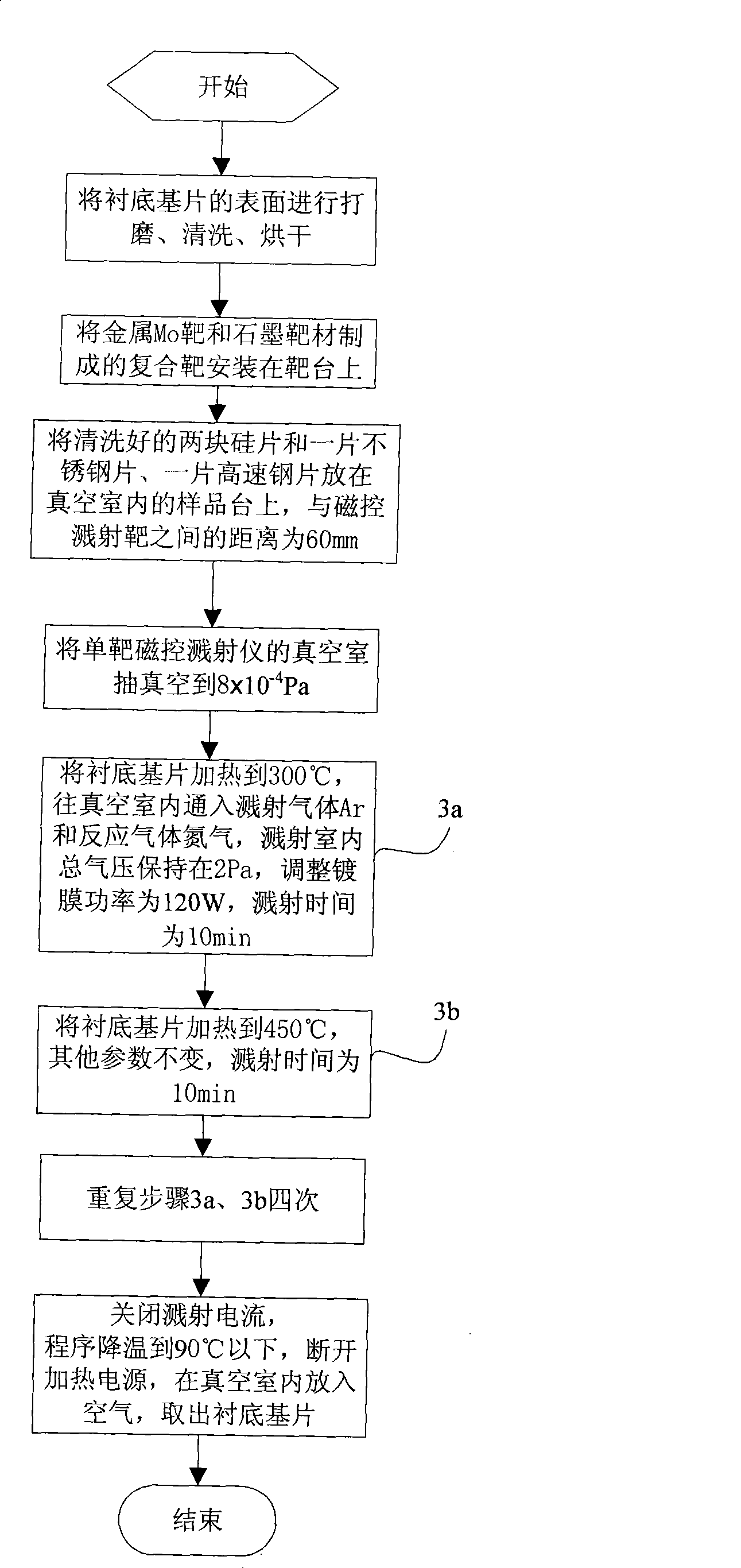

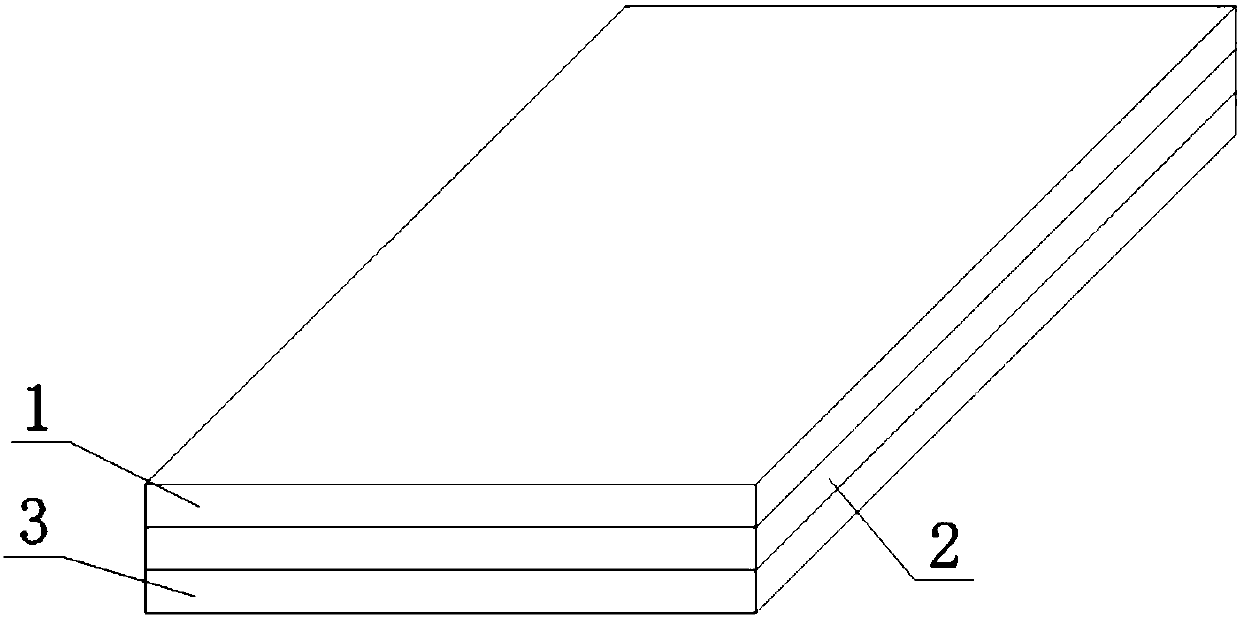

Method for preparing nano composite multiple layer hard film

InactiveCN101451232ALower requirementFree up timeVacuum evaporation coatingSputtering coatingMetallurgyMechanical equipment

The invention relates to a method for preparing a multilayer hard film. The method comprises the following steps: (1) polishing, washing and drying the surface of a substrate; (2) placing the washed substrate in a vacuum chamber, and vacuumizing the vacuum chamber; (3) opening a heat power supply to heat the substrate, introducing sputtered gas argon into the vacuum chamber, adjusting film coating power, and carrying out the first layer sputtering sedimentation on the substrate; (4) after sedimentation in first setting period, selecting a state in second period or reaction parameter setting, or opening a reaction gas nitrogen, or under a condition of introducing the reaction gas, changing total air pressure in the vacuum chamber, or changing the prior substrate temperature, or changing a ratio of the reaction gas and the sputtering gas; and (5) cooling and annealing. The method prepares the nanometer composite multilayer hard film by a single-target magnetron sputtering device, reduces the requirement on synthetic equipment, does not need mechanical equipment to make a sample holder rotated, and reduces noise pollution to environment and production cost.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

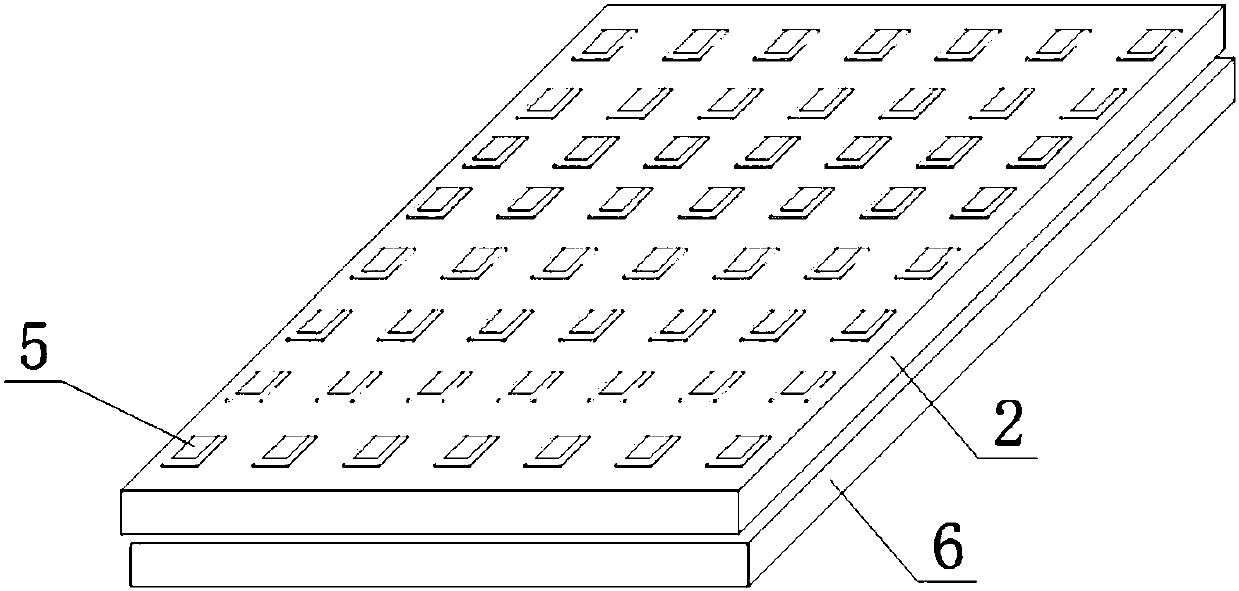

Chip sputtering jig and sputtering method

InactiveCN107779819AAchieve five-sided sputteringIncrease the number ofVacuum evaporation coatingSputtering coatingSputteringMaterials science

The sputtering fixture proposed by the present invention includes a pyrolytic adhesive layer, an upper backing paper, and a lower backing paper. When the sputtering fixture is used for sputtering, the upper backing paper is torn off, and the bottom surface of the chip that does not need to be sputtered is pasted on the bottom surface of the sputtering fixture. On the pyrolytic glue layer, the pyrolytic glue layer can firmly fix the chip at room temperature and during sputtering. After the sputtering is completed, the sputtering fixture is heated to a preset temperature, so that the pyrolytic glue The layer loses its stickiness, making it easy to separate the chip from the sputtering fixture. The invention can realize sputtering on five sides of the chip, and does not need positioning when pasting the chip, which simplifies the process of positioning the chip; at the same time, the chip can be easily peeled off without additional stripping process after sputtering, avoiding possible damage to the chip, The service life of the chip is guaranteed, the production cost is greatly reduced, and the sputtering efficiency is improved.

Owner:丰盛印刷(苏州)有限公司

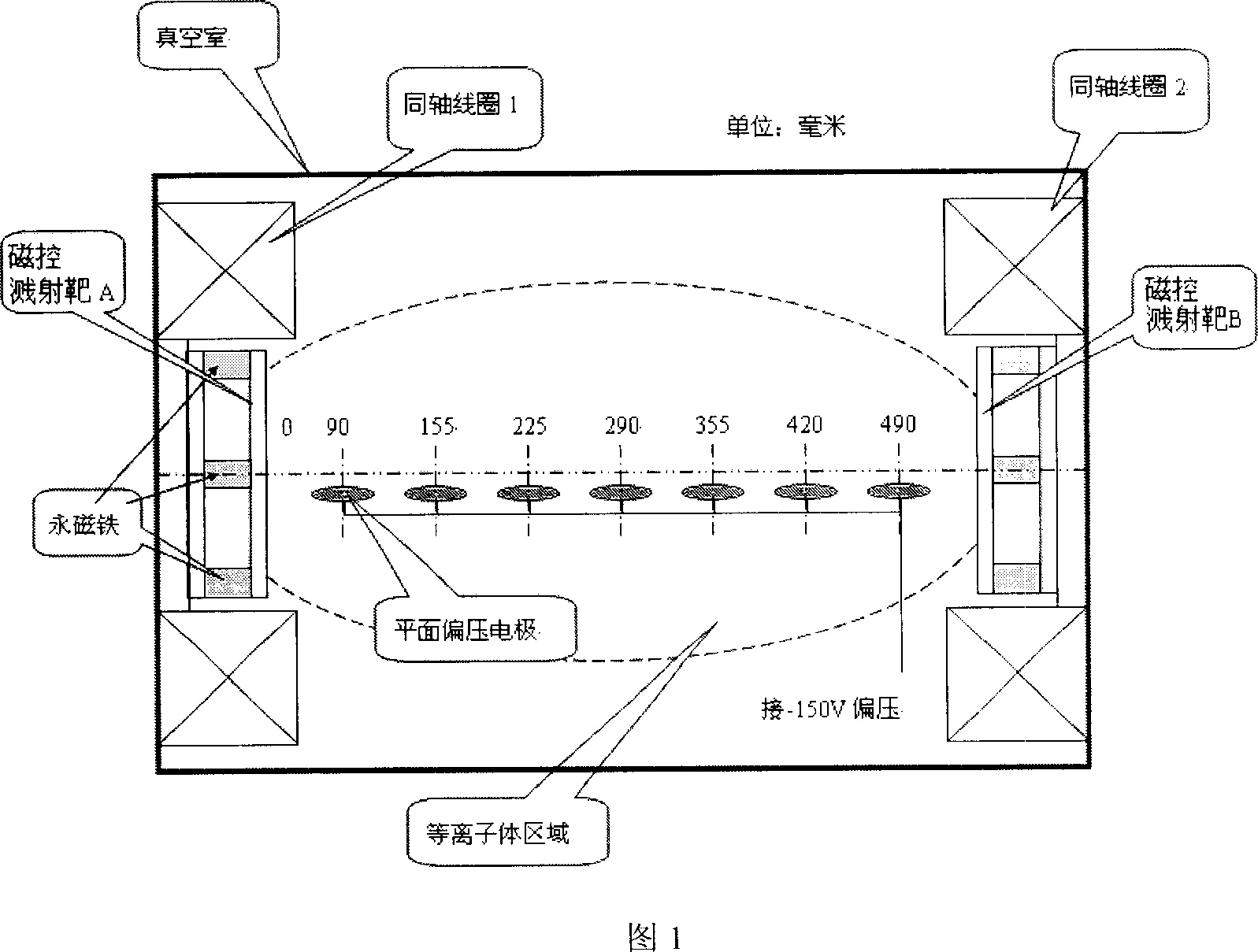

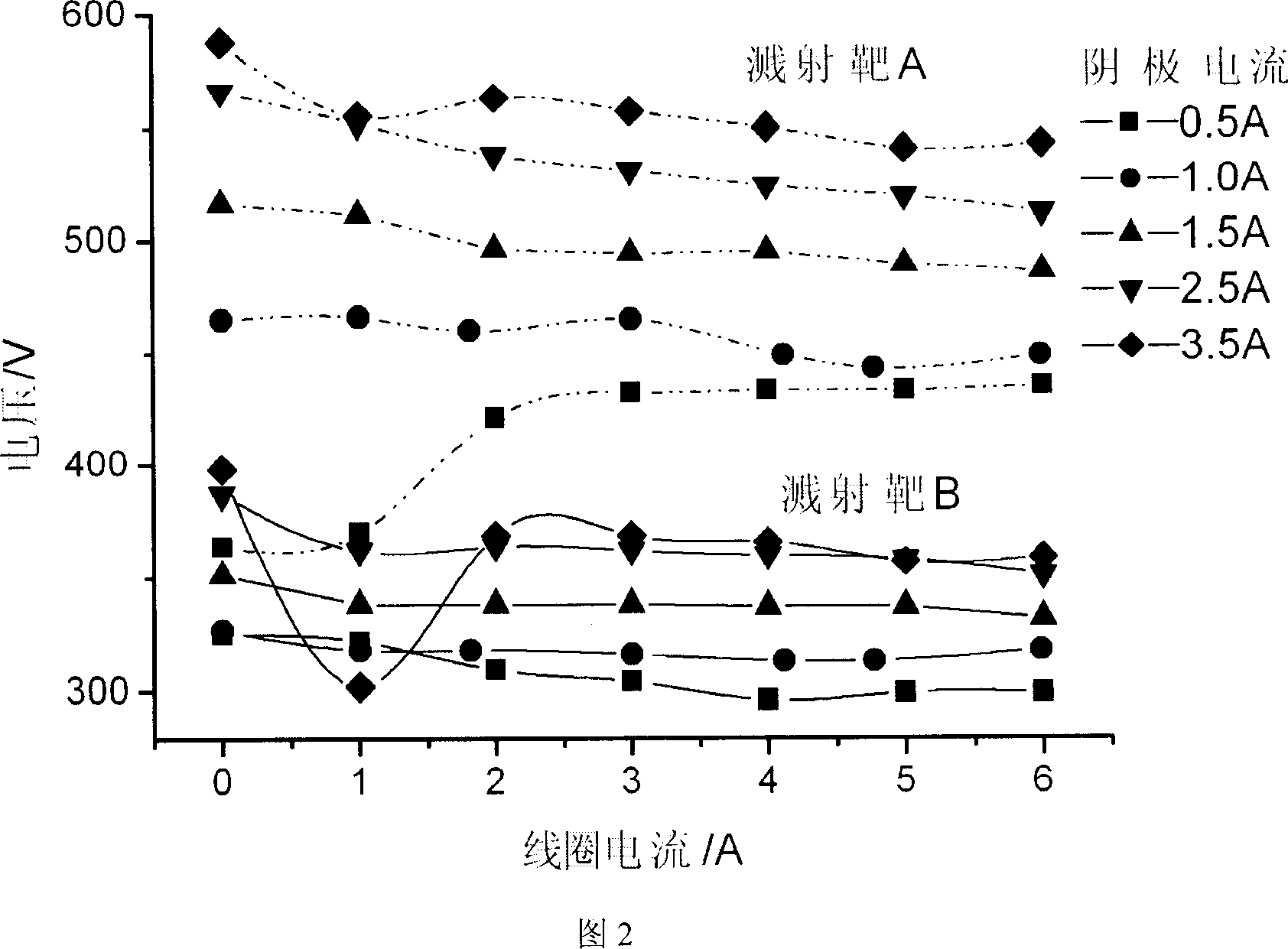

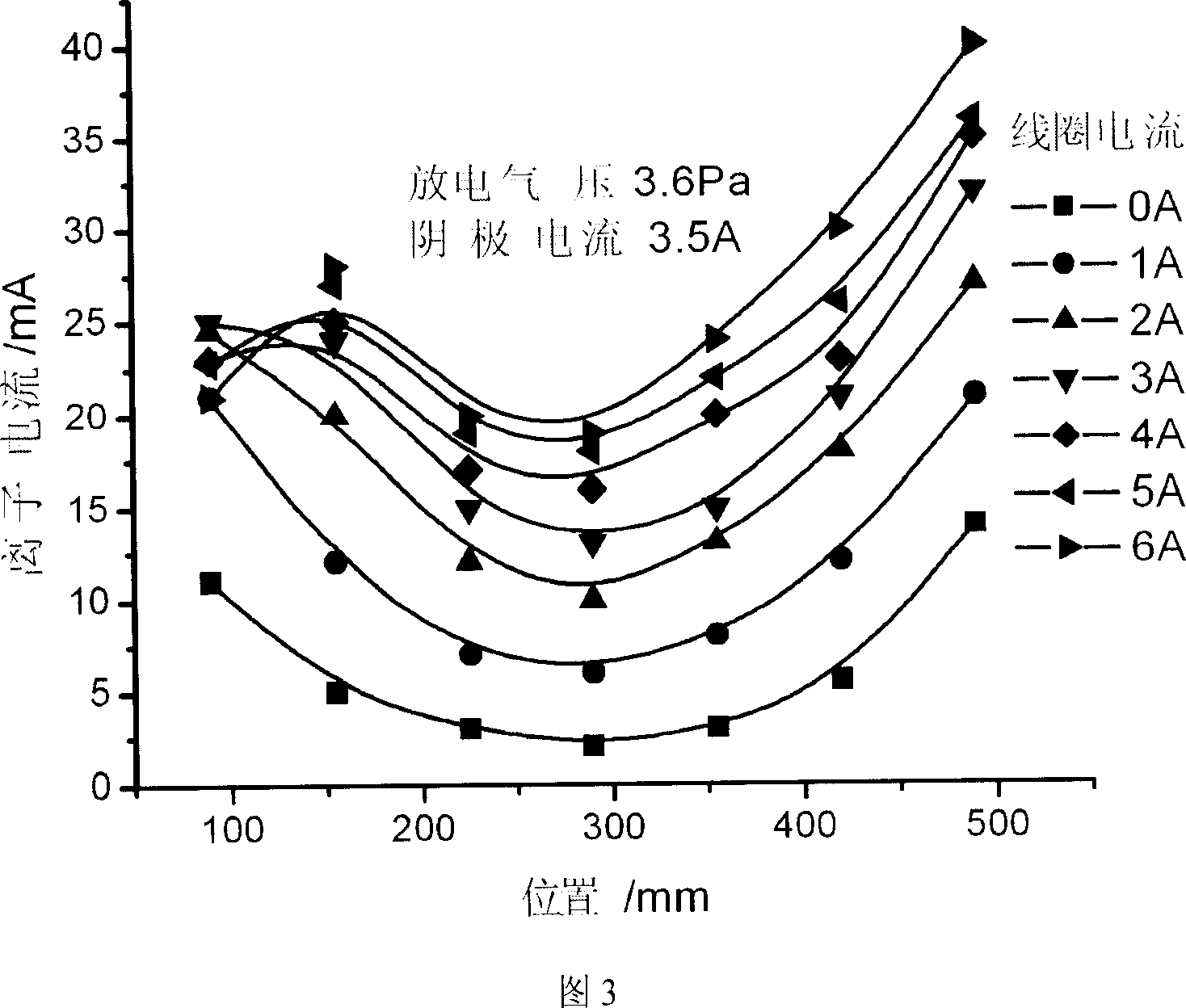

Magnetic mirror field constrained bitarget non balancing magnetron sputtering method

InactiveCN1948548AAchieve depositionRaise leadVacuum evaporation coatingSputtering coatingPower flowPlasma density

The invention discloses a opposite-target non-equilibrium magnetron spattering system with magnetic mirror field restriction, which is mainly used in technique field of surfacial project. It is characterized in that: Two electrified coaxial coils are set opposite two permanent-magnet magnetron targets. They can form a complete closed magnetic mirror field which is coaxial with magnetron targets. To control magnetic mirror field based on regulating current in coils, and adjust state, deposit parameter of discharging plasma subtly. Magnetic coils enhance cathode discharging, increase plasma derivation in cathode zone and advance plasma density in deposit zone. Applying coaxial magnetic mirror field to restrain plasma with adding coaxial coils can enlarge adjusting range of deposit parameter. Compared with routine magnetron spattering technique, non-equilibrium magnetron spattering technique has adjustable plasma state, high plasma leaving rate and high ion-atom arrival rate etc.

Owner:DALIAN UNIV OF TECH

Metal sputtering low-temperature preparation method for crystallization TiO2 film

InactiveCN101235479ABroaden your optionsImprove sputtering efficiencyVacuum evaporation coatingSputtering coatingOxygen ionsRadio frequency

The invention discloses a method for preparing crystal TiO2 film with metal sputtering low temperature in the coating technical field, which comprises following steps: firstly, separately supplying argon gas and oxygen, respectively forming a local rich argon gas zone on the target material surface or a local rich oxygen zone near a substrate, secondly, sputtering titanium atoms of a metal titanium target in a metal sputtering mode, thirdly, folding induced type coupling radio frequency plasmas whose concentration grade is more than 10<11>cm-3 near the substrate, fourthly, ionizing or decomposing oxygen modules which are in the rich oxygen zone near the substrate in the induced type coupling radio frequency plasmas, generating oxygen ions and oxygen atoms, fifthly, enabling the oxygen ions and the oxygen atoms which are ionized or decomposed in the induced type coupling radio frequency plasmas to reach the substrate when in coating, taking part in reaction, and sixthly irradiating ion beams whose concentration is number milliampere / square centimetre to the substrate when in coating. The method of the invention can prepare rutile type TiO2 film or ore titanium TiO2 film on a glass substrate with high speed and low temperature.

Owner:SHANGHAI JIAO TONG UNIV

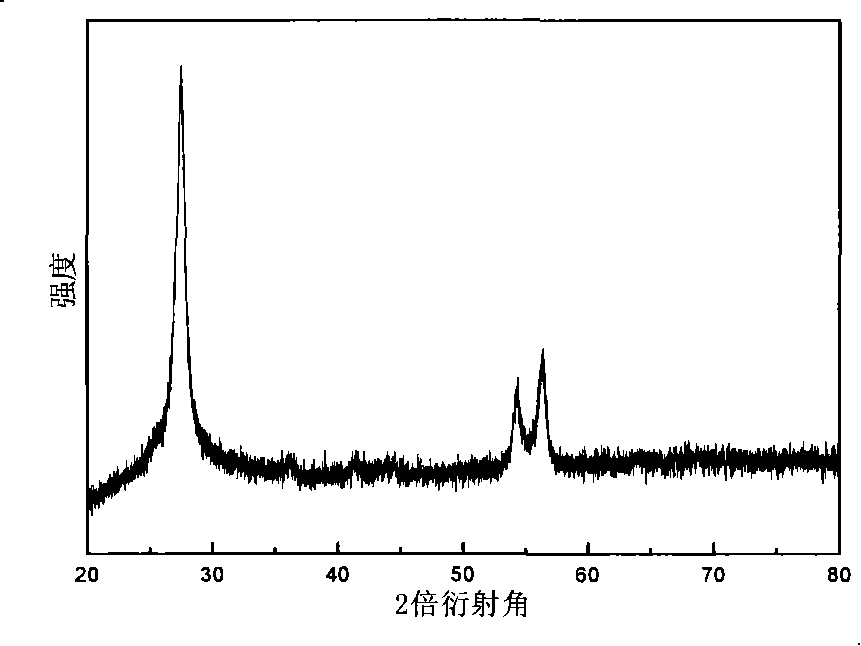

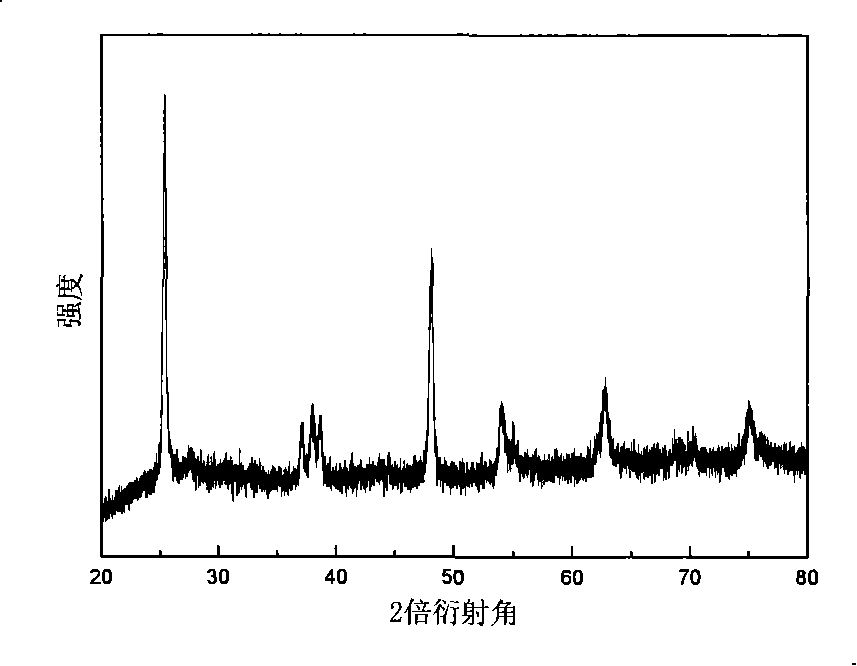

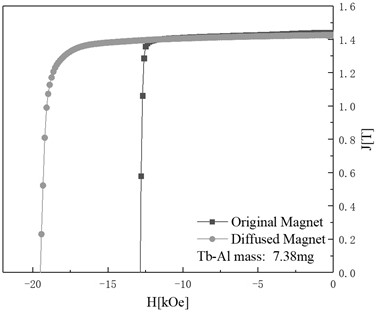

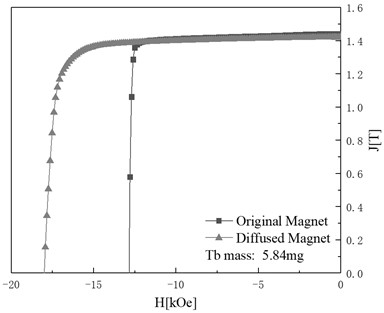

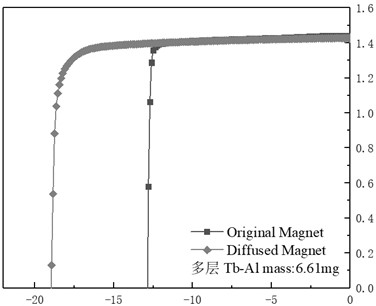

Method for preparing high-coercivity sintered neodymium-iron-boron magnet through grain boundary diffusion

PendingCN112927921AReduce dosageImprove bindingCathode sputtering applicationMagnetic materialsRare-earth elementTempering

The invention discloses a method for preparing a high-coercivity sintered neodymium-iron-boron magnet through grain boundary diffusion, belonging to the technical field of rare earth permanent magnet materials. The method comprises the following steps: preparing a heavy rare earth-alloy element multilayer film on the surface of a sintered neodymium-iron-boron magnet by adopting a magnetron sputtering method, then carrying out a vacuum thermal diffusion treatment process, and finally carrying out tempering treatment to obtain the high-coercivity neodymium-iron-boron magnet, wherein the temperature of the thermal diffusion treatment process is 600-900 DEG C, and the time of the thermal diffusion treatment process is 3-10 h. According to the method disclosed by the invention, time required for sputtering the heavy rare earth-alloy element thin film is shortened, and the diffusion depth of the thin film is deeper; and compared with a pure rare earth element diffusion method, the method of the invention has the advantages that the film diffusion depth is deeper, and the coercive force of the sintered neodymium-iron-boron magnet can be further improved.

Owner:KUNMING UNIV OF SCI & TECH +1

Physical vapor deposition device

ActiveCN103820758AAvoid the situation of local large currentExtend your lifeVacuum evaporation coatingSputtering coatingDielectric cylinderGas phase

The invention discloses a physical vapor deposition device, which comprises a chamber body, a radio frequency coil, a faraday shielding element, a plurality of unsymmetrical pressure regulation units and a base, wherein a dielectric cylinder and a target arranged at the top of the dielectric cylinder are arranged in the chamber body; the target is connected with a direct current power supply; the radio frequency coil is arranged in the chamber body, and is arranged on the outer side of the dielectric cylinder in a sleeving manner to excite process gas introduced into the chamber body into plasmas; the faraday shielding element is arranged on the inner wall of the dielectric cylinder, and comprises a plurality of shielding fragments which are distributed along the circumferential direction of the dielectric cylinder at intervals; the shielding fragments are connected to the unsymmetrical pressure regulation units in a one-to-one correspondence way, so that unsymmetrical pressure values of the shielding fragments are regulated respectively; the base is arranged in the chamber body, and is used for placing a chip to be processed. According to the physical vapor deposition device, the etching rate and deposition rate of the faraday shielding element are substantially equal, so that the probability of pollution to a chamber can be reduced, and the service life of the faraday shielding element can also be prolonged.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

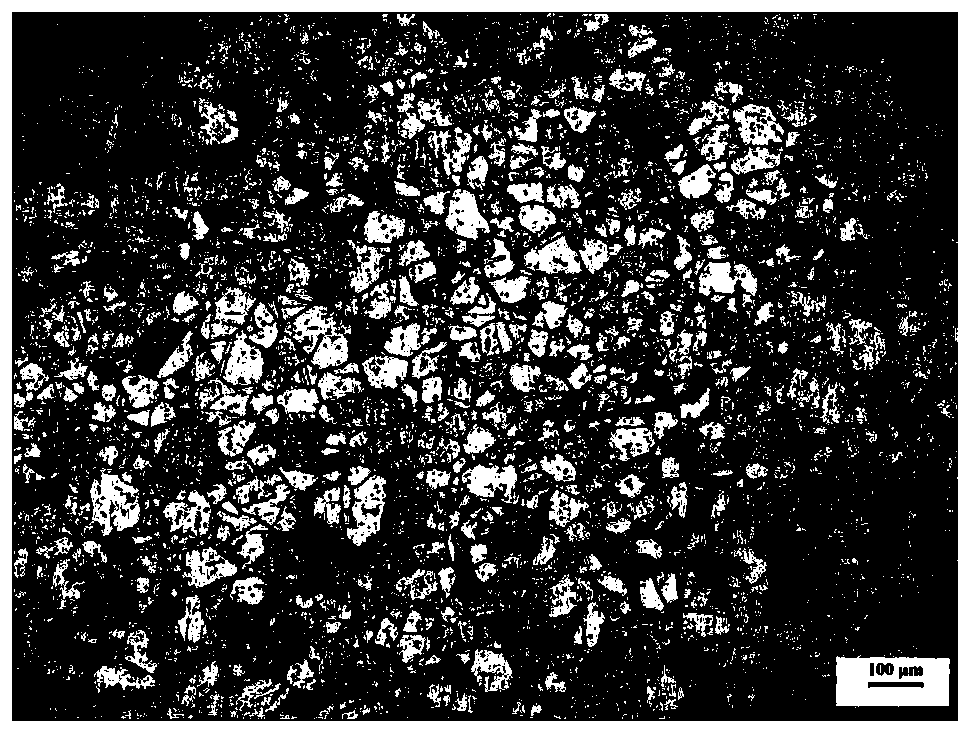

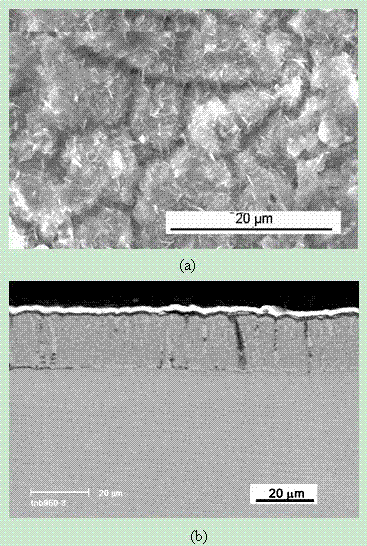

Method for preparing nickel-vanadium sputtering target material

ActiveCN111004985AHigh purityDense tissue structureVacuum evaporation coatingSputtering coatingMetallic materialsIngot

The invention belongs the technical field of metal material processing and microelectronic material manufacturing, and discloses a method for preparing a nickel-vanadium sputtering target material. The method for preparing the nickel-vanadium sputtering target material includes the steps that a nickel-vanadium ingot is sequentially subjected to (1) hot forging, (2) annealing, (3) cold deformation,and (4) secondary annealing. The content of V in the nickel-vanadium sputtering target material is 7 + / - 0.7%, and the purity of the nickel-vanadium ingot is 99.9% to 99.995%. The crystal grain sizeof the obtained nickel-vanadium sputtering target material is less than or equal to150 [mu]m, the crystal grains are fine, and distribution is uniform. The nickel-vanadium sputtering target material has high purity of above 99.9%; the organizational structure is dense without pores, the crystal grains are fine and uniform, the crystal grain size is less than or equal to 150 [mu]m, non-magnetic effect is achieved, the sputtering efficiency is high, and the method can be widely applied to electronic components, communications, solar photovoltaics and other industries.

Owner:GRIKIN ADVANCED MATERIALS +1

Sputtering target and thin film for optical information recording medium

ActiveCN101208451AStable sputteringExcellent adhesionVacuum evaporation coatingSputtering coatingCrystal systemIndium

The present invention relates to a sputtering target, wherein zinc sulfide and an oxide composed of indium oxide, zinc oxide and other trivalent positive elements A are used as main components, and the ratio of sulfur to all constituent components is 5 to 30 wt. %, the (111) peak intensity I1 of cubic ZnS measured by XRD and the (100) peak intensity I2 of hexagonal ZnS coexist and satisfy I1>I2. The object of the present invention is to provide a high-strength sputtering target capable of preventing the target from cracking when the target is manufactured or when a film is formed by sputtering, and a manufacturing method thereof, and to obtain a thin film for optical information recording media that is most suitable for use as a protective film, and to manufacture the same method.

Owner:JX NIPPON MINING & METALS CO LTD

Sputtering equipment and sputtering method

InactiveCN104109835AEnable continuous sputteringImprove sputtering efficiencyVacuum evaporation coatingSputtering coatingSputteringMaterials science

The invention discloses sputtering equipment and a sputtering method. The sputtering equipment comprises a cavity; and a rotary target material mechanism, which is arranged in the middle part of the cavity, wherein the two opposite sides of the target material mechanism are respectively provided with a first target material and a second target material. The rotary target material mechanism comprises a rotary shaft, and is capable of rotating around the rotary shaft. The rotary target material mechanism also comprises a sealing mechanism, which is arranged on the two sides of the rotary target material mechanism. The sealing mechanism couples the rotary target material mechanism and the cavity so as to divide the cavity into two enclosed chambers. A first substrate and a second substrate are respectively arranged in the chambers. The rotary target material mechanism comprise a first target material fixing member and a second target material fixing member, which are oppositely arranged and are used to fixed the first target material and the second target material respectively. The sputtering equipment is provided with a rotary target material mechanism, so the equipment can sputter two kinds of coated films in the same cavity at the same time, moreover, continuous sputtering is also achieved, and the sputtering efficiency is improved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

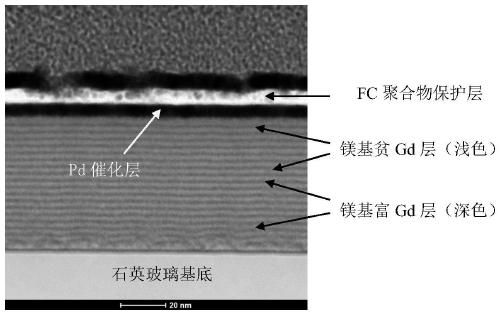

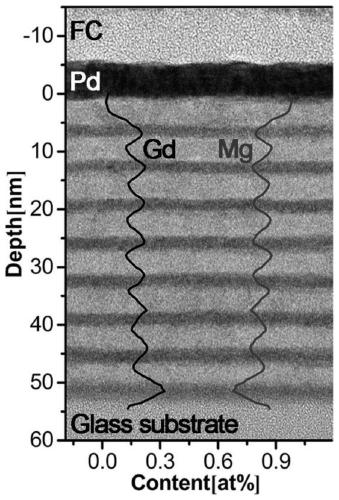

Magnesium base alloy modulated thin film and preparation method and application thereof

ActiveCN109881169AEasy to makeLow costLiquid surface applicatorsVacuum evaporation coatingElemental compositionHydrogen sensor

The invention discloses a magnesium base alloy modulated thin film and a preparation method and application thereof. The magnesium base alloy modulated thin film comprises a magnesium base alloy modulated layer, a catalyst layer and a polymer layer which are sequentially arranged; and elemental composition of the magnesium base alloy modulated layer is MgxM1-x, wherein x is greater than 0.5 and less than 1, and M is at least one of Gd, Ti, Ni, Mn, Fe, Co, Y, Nb, Ru, Zr, Ca, Ba, La, and Sm. The magnesium base alloy modulated thin film has the advantages of simple preparation process, low cost,wider practicality range and the like, a hydrogen sensor made of the magnesium base alloy modulated thin film is high in response speed and high in sensitivity, is not required to be warmed and forced, potential safety hazards do not exist, and recycling further can be achieved. In addition, the thin film optical performance change further can be realized by adjusting technological parameters, a hydrogen induced discoloration thin film with a larger optical conversion interval is obtained, and the magnesium base alloy modulated thin film has larger application value in other fields as well.

Owner:SHANGHAI JIAO TONG UNIV +1

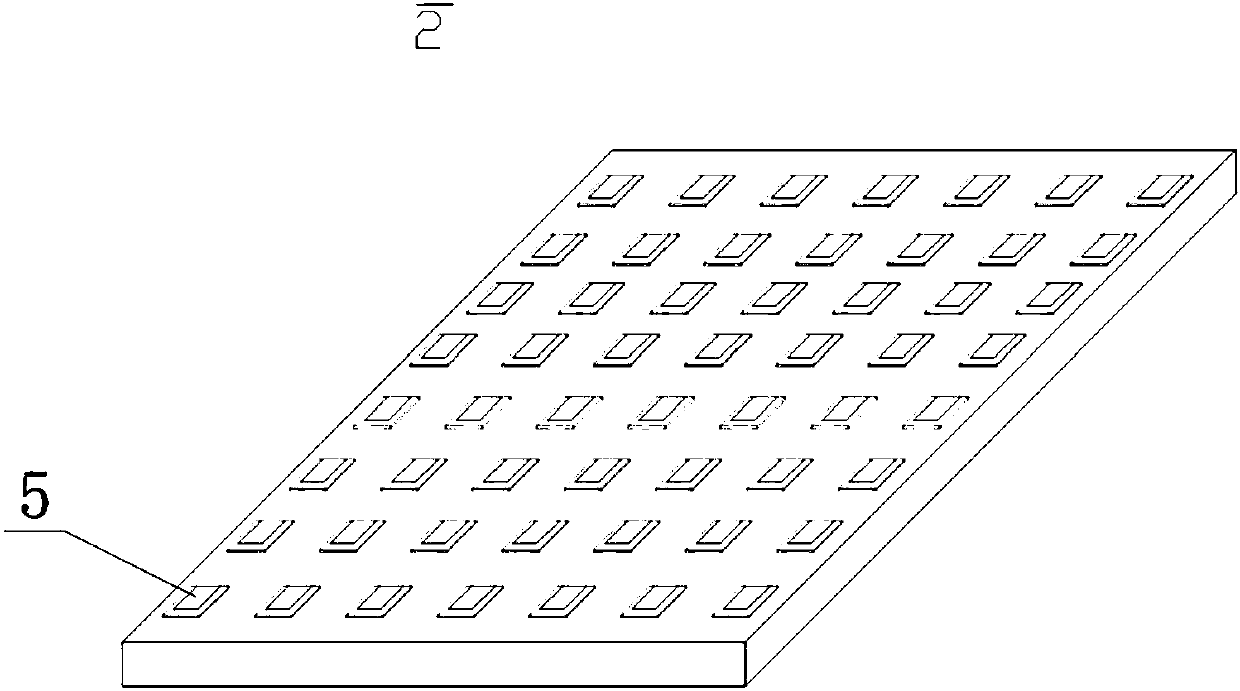

Clamp for clamping workpieces

InactiveCN105887036AImprove sputtering efficiencyVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

The invention discloses a clamp for clamping workpieces. The clamp comprises a base positioned at the chamber bottom of a sputtering chamber, stationary shafts on the base, workpiece clamping plates positioned between adjacent two stationary shafts, workpiece clamping holes formed in the workpiece clamping plates and a transmission shaft positioned between the base and the chamber bottom of the sputtering chamber. As at least two different types of workpieces can be simultaneously clamped by the workpiece clamping holes in each workpiece clamping plate, different types of workpieces can be simultaneously sputtered, and the sputtering efficiency is improved.

Owner:CHENGDU CVAC VACUUM TECH CO LTD

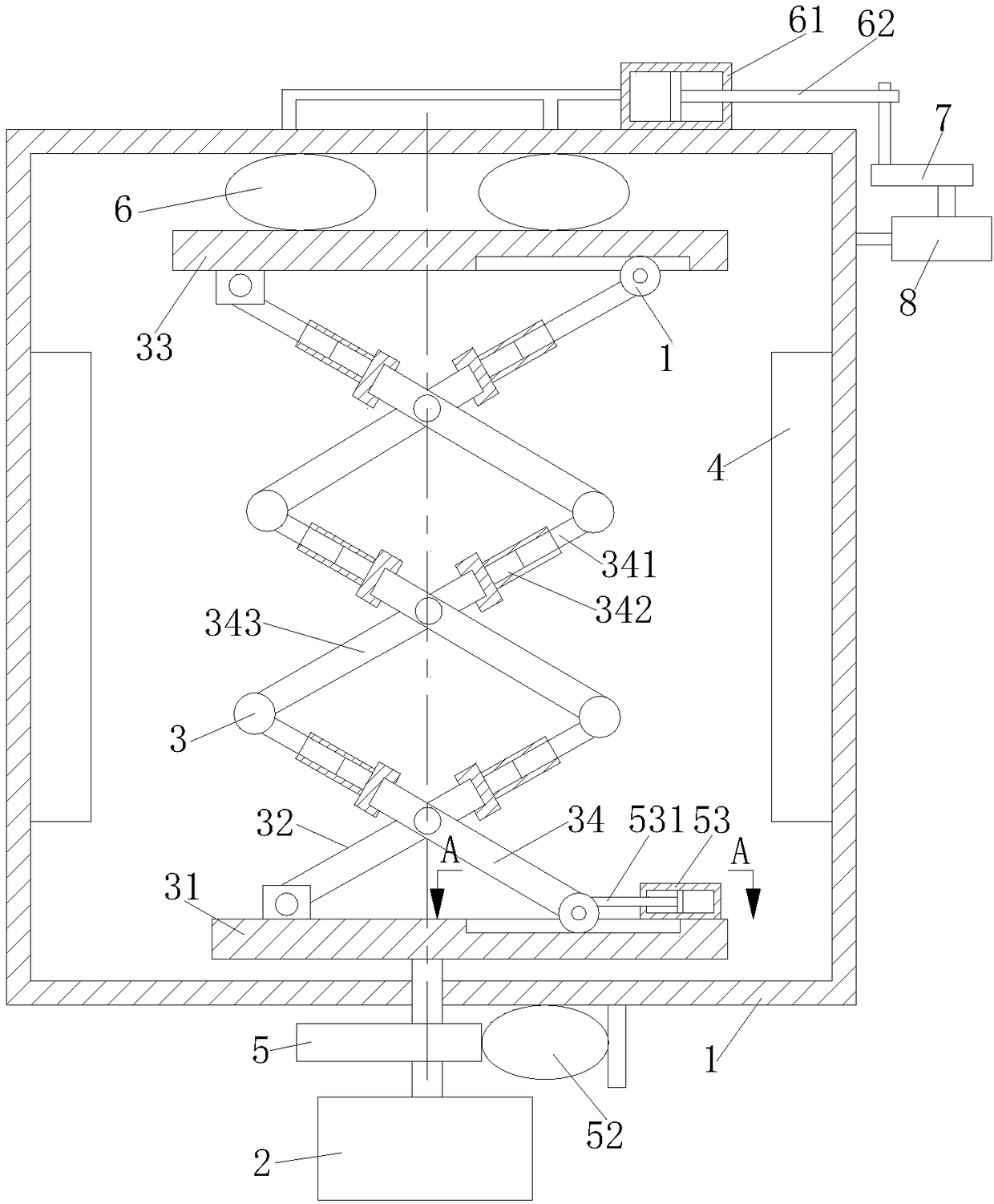

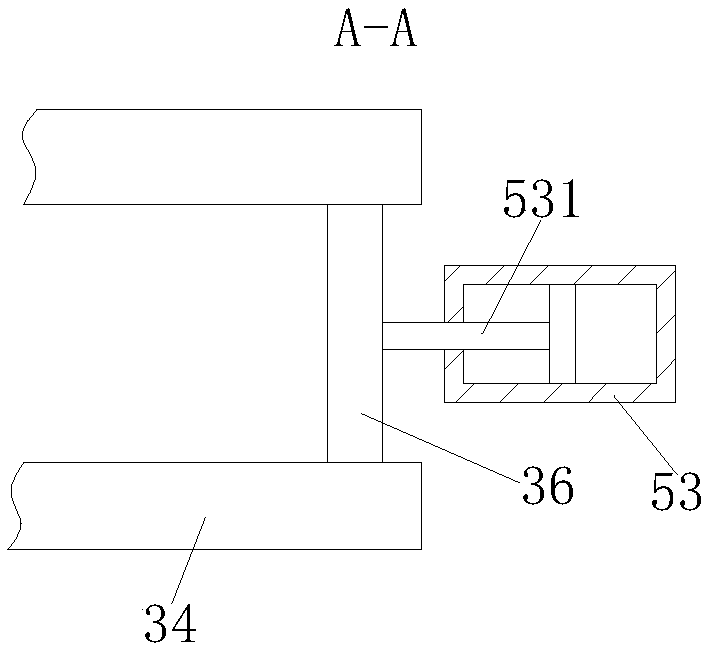

Film coating system for depositing metal on plastic substrate surface on basis of glow discharge principle

ActiveCN108950497AUniform sputteringImprove sputtering efficiencyVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

The invention belongs to the technical field of film coating, and particularly relates to a film coating system for depositing metal on the plastic substrate surface on the basis of the glow dischargeprinciple. The film coating system comprises a box body, a motor and a bearing device; the bearing device is driven by the motor and comprises a lower supporting plate, a shear fork mechanism and anupper supporting plate, and the shear fork mechanism is composed of a group of material rods which are hinged to one another; one end of the bottom of the shear fork mechanism is hinged to the lower supporting plate, and a roller rotatably connected to the other end of the bottom of the shear fork mechanism can slide in a sliding groove formed in the lower supporting plate; the top of the shear fork mechanism is hinged to one end of the upper supporting plate, and the top of the shear fork mechanism is slidably connected with the other end of the upper supporting plate; each material rod comprises an upper material rod, a middle material rod and a lower material rod, and the middle material rods can relatively rotate; and a first air cylinder is used for pushing the roller to slide in thesliding groove. According to the film coating system for depositing the metal on the plastic substrate surface on the basis of the glow discharge principle, through cooperation of the shear fork mechanism and the material rods, a workpiece can rotate when sputtering coating is conducted, therefore, a coating film of the coated workpiece is uniform, and then the film coating effect of a sputteringcoating device is improved.

Owner:阜阳知麓信息科技有限公司

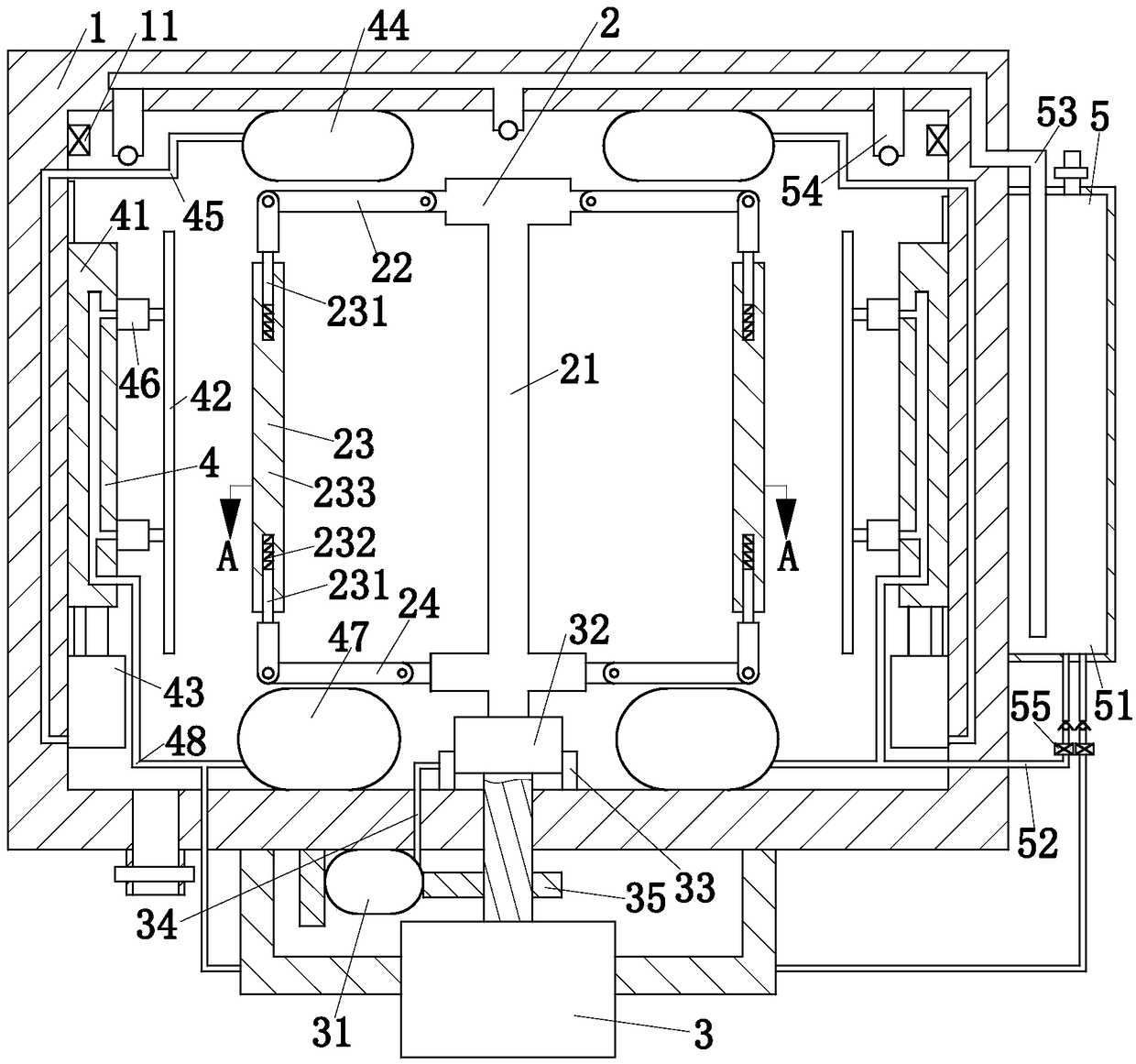

Sputtering plating system for plastic and rubber pipe

ActiveCN108977784AImprove cleaning efficiencyImprove efficiencyHollow article cleaningVacuum evaporation coatingSputteringComputer module

The invention belongs to the technical field of film plating, in particular to a sputtering plating system for a plastic and rubber pipe. The sputtering plating system comprises a sputtering plating box, a workpiece frame, a motor, a target module, a heater and an automatic cleaning module, wherein the motor is fixedly arranged at the exterior of the sputtering plating box; the workpiece frame ispositioned at the center of the interior of the sputtering plating box, and is driven by the motor to rotate; the target module is arranged at the inner wall of the sputtering plating box, can be moved up and down, and be moved along the transverse direction to get close to the workpiece frame; the automatic cleaning module is used for cleaning the sputtering plating box before sputtering plating;the heater is positioned at the upper end of the inner wall of the sputtering plating box, and is used for drying the cleaned sputtering plating box. The sputtering plating system has the advantagesthat the automatic cleaning module is used for spraying water into the sputtering plating box to clean, so that the efficiency in the whole sputtering plating process of the plastic and rubber pipe isimproved; the motor is used for driving the workpiece frame to rotate, and the sputtering plating of the plastic and rubber pipe is uniform; the target module is moved up and down, or is moved alongthe transverse direction, so as to complete uniform sputtering plating of the plastic and rubber pipe, and improve the sputtering plating quality of the plastic and rubber pipe.

Owner:莘县鲁开综合服务有限公司

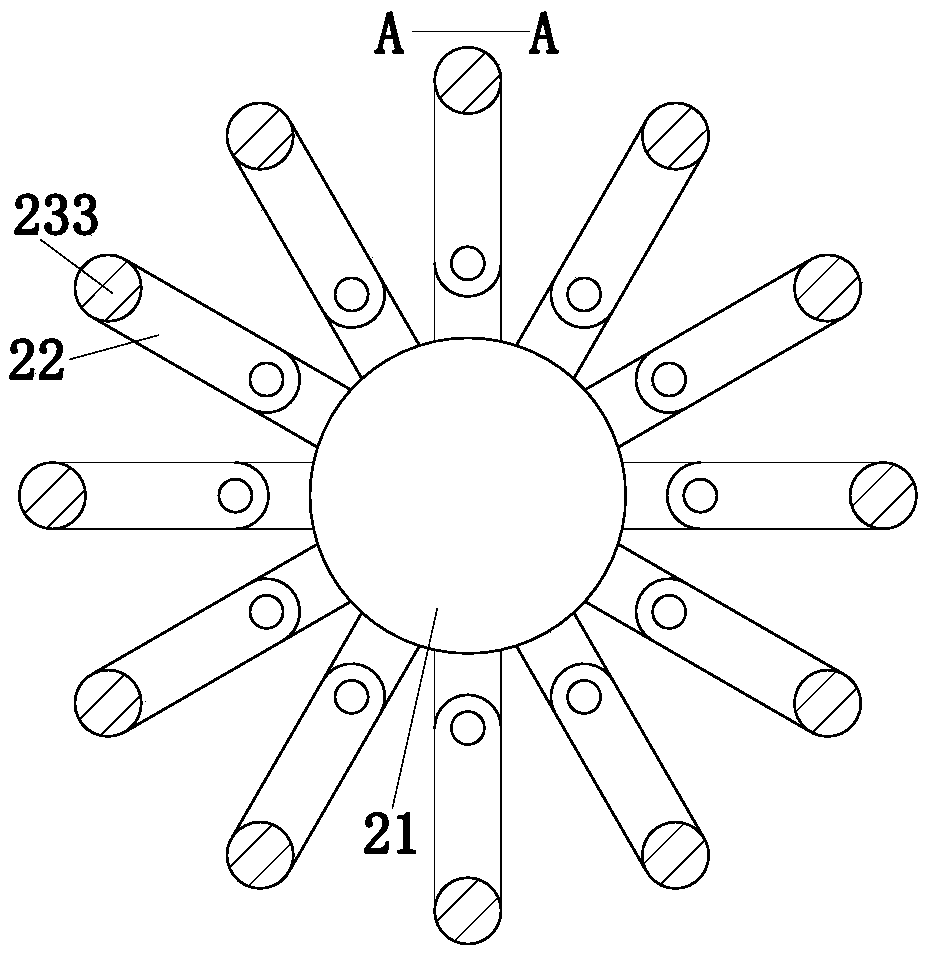

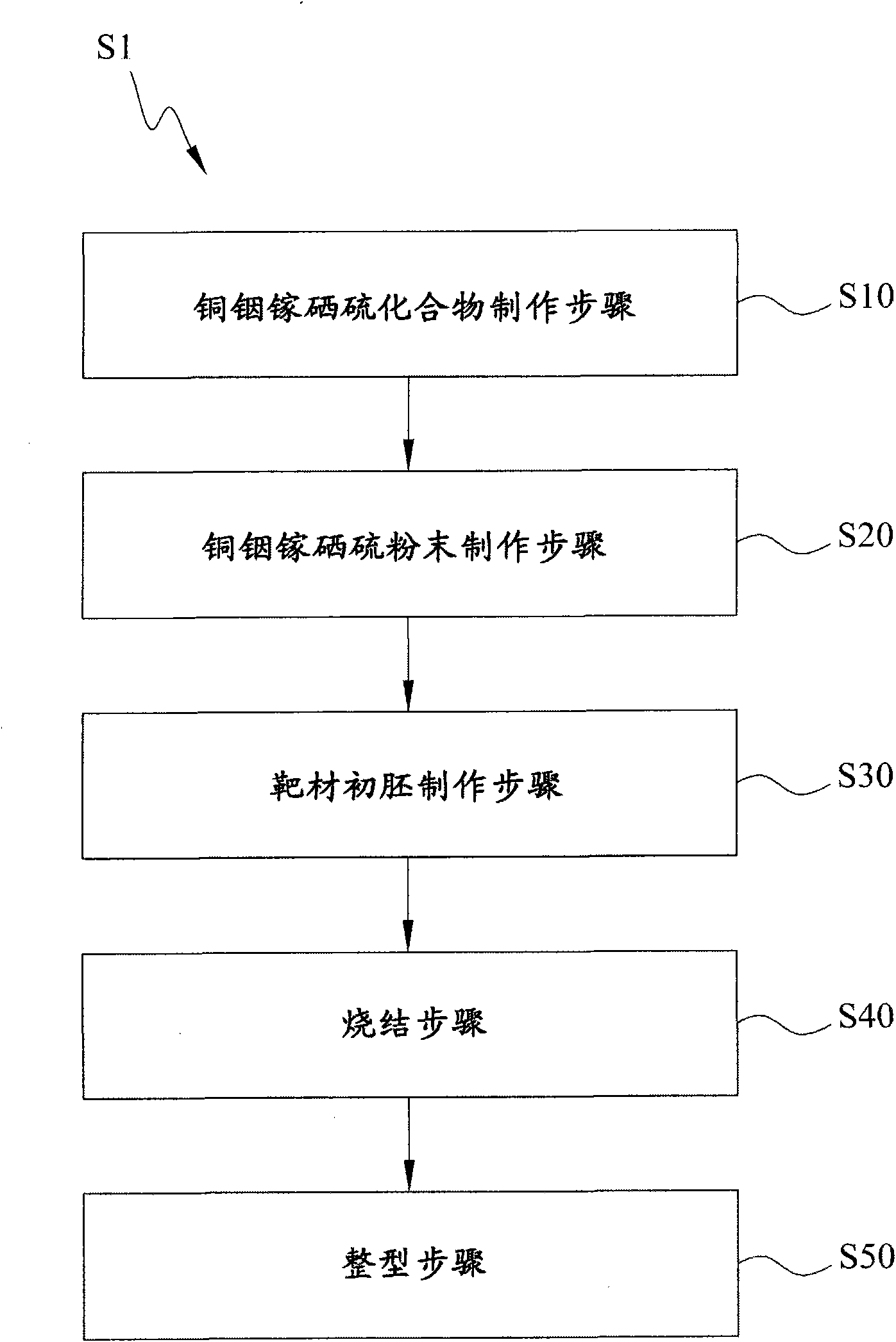

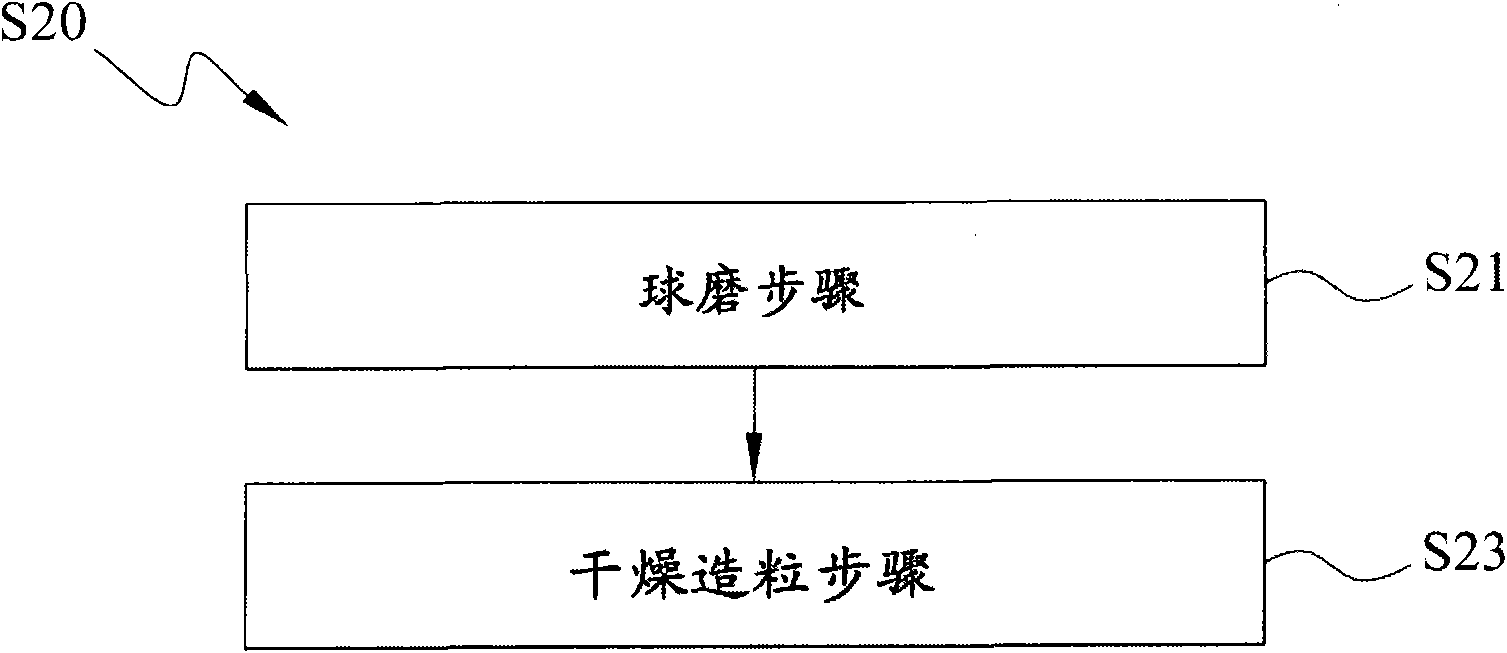

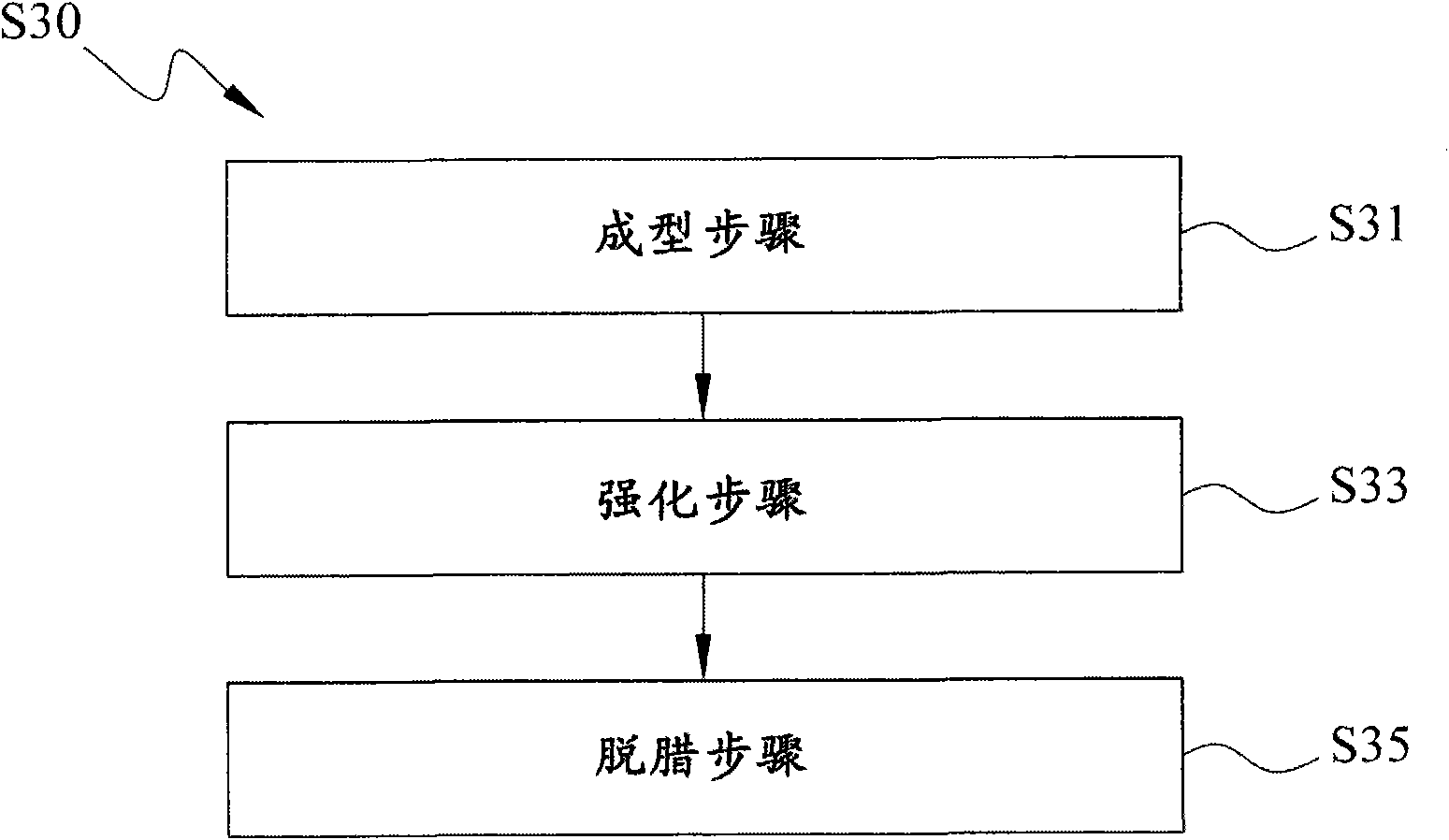

Manufacturing method of copper-indium-gallium-selenium-sulfur five-element target material

InactiveCN102463349AUniform compositionNo pollution in the processVacuum evaporation coatingSputtering coatingIndiumSulfur

The invention relates to a manufacturing method of a copper-indium-gallium-selenium-sulfur five-element target material. The manufacturing method comprises a manufacturing step of a copper-indium-gallium-selenium-sulfur compound, the manufacturing step of copper-indium-gallium-selenium powder, the manufacturing step of an initial billet of the target material, a sintering step and a shaping step, and the main process is as follows: mixing copper, indium, gallium, selenium and sulfur element powders through a synthetic solvent according to the atomic ratio, further synthesizing the copper-indium-gallium-selenium-sulfur compound through reaction, further manufacturing a copper-indium-gallium-selenium target material or mixing three-element or four-element compound powder as a precursor of the five-element target material in a mixing step, and performing high-pressure sintering. The copper-indium-gallium-selenium-sulfur five-element material is used for manufacturing a copper-indium-gallium-selenium thin film, then selenizing and sulfurizing steps can be omitted, and the safety in process is thus ensured; and furthermore, the conductivity of the target material is suitable for direct current sputtering and radio frequency sputtering, so that the sputtering efficiency can be upgraded and the copper-indium-gallium-selenium-sulfur thin film with no pollution and uniform components is formed.

Owner:HELIOHAWK OPTOELECTRONICS CORP

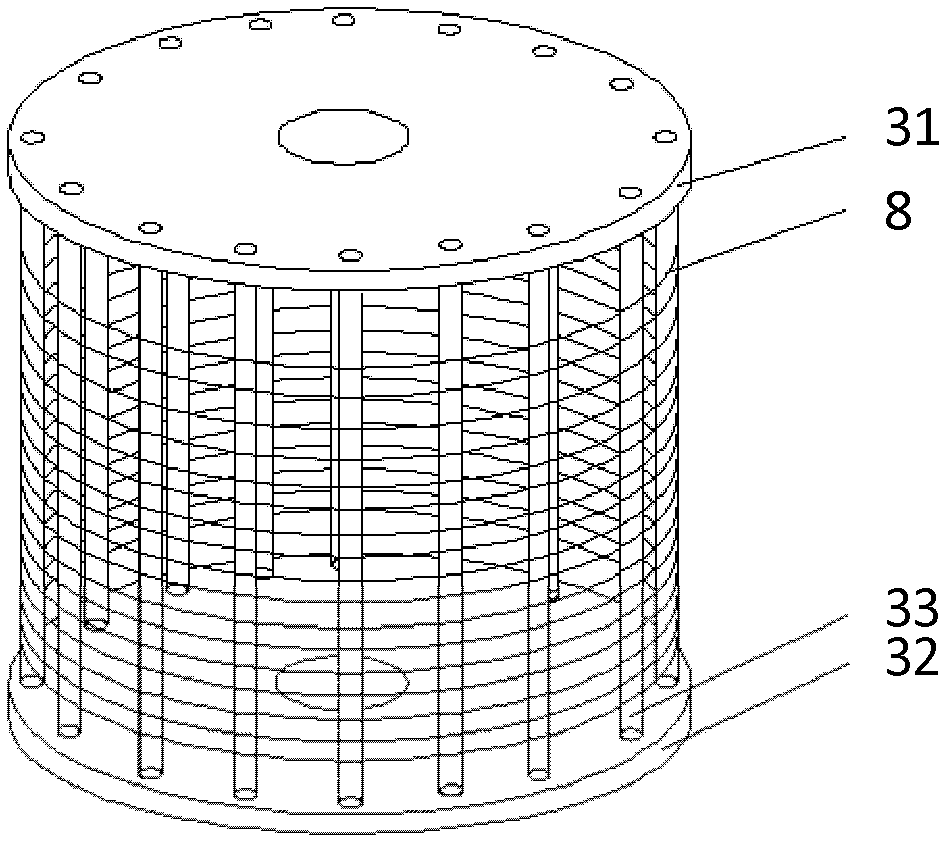

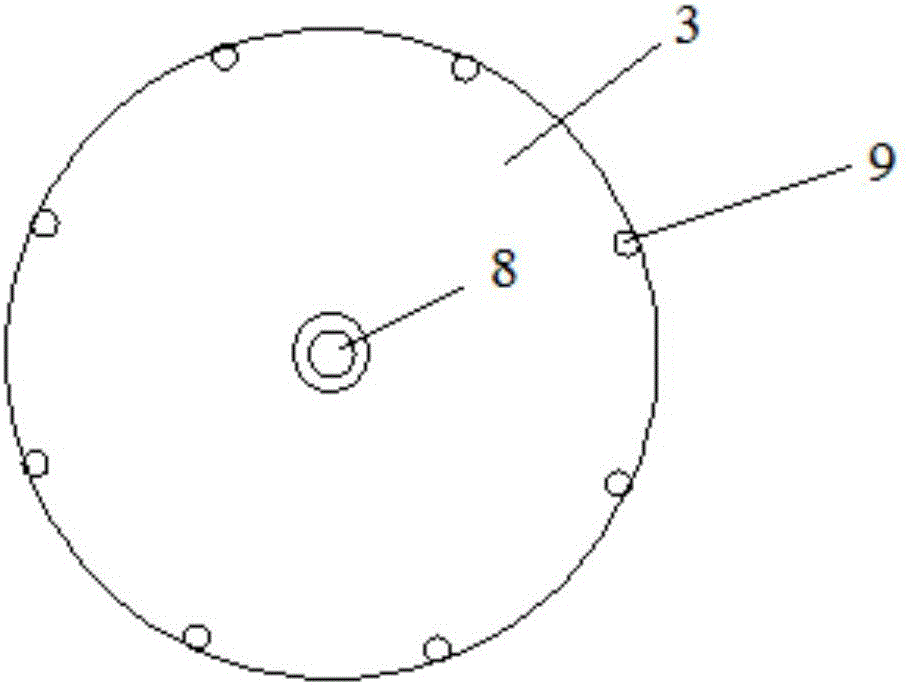

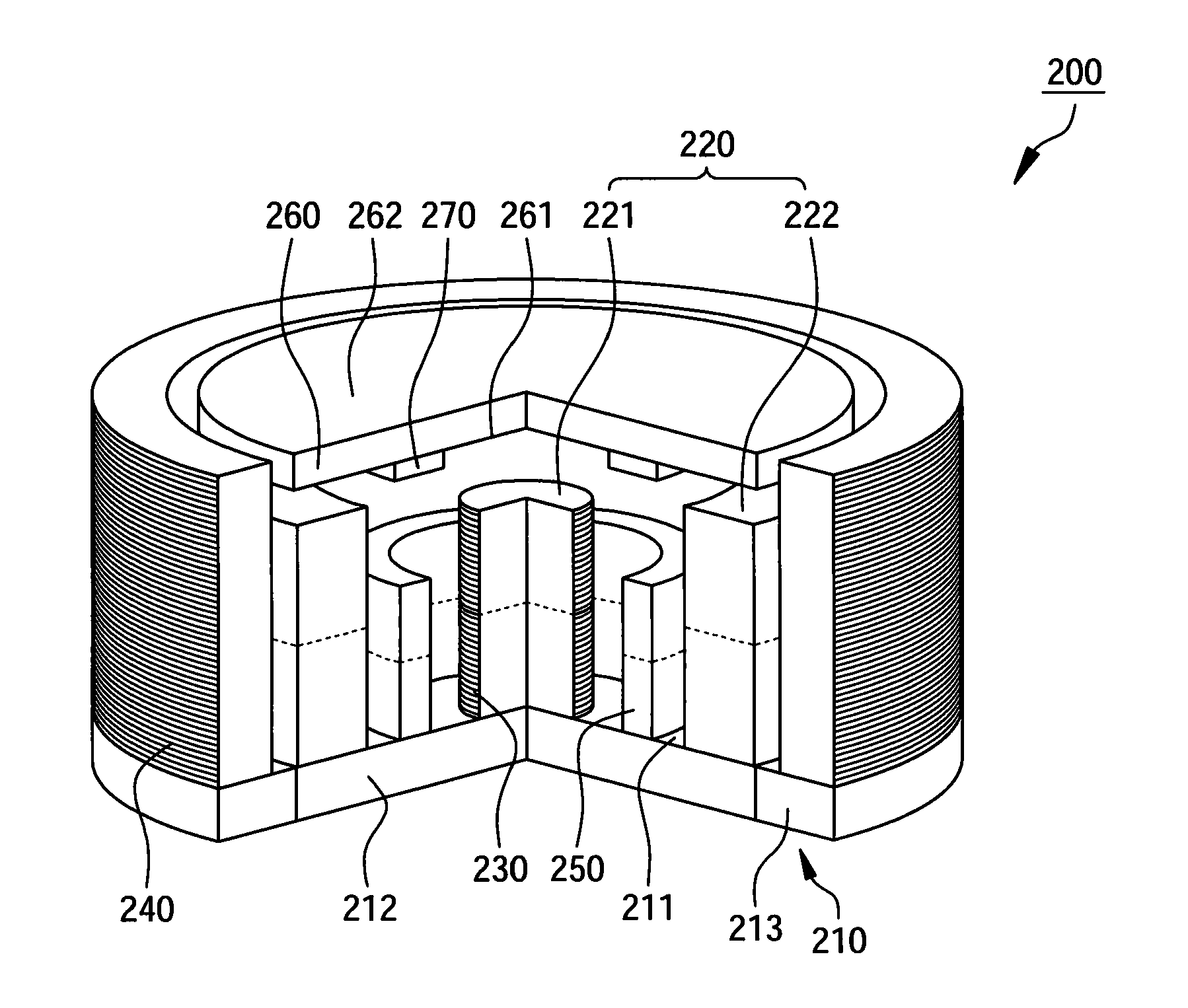

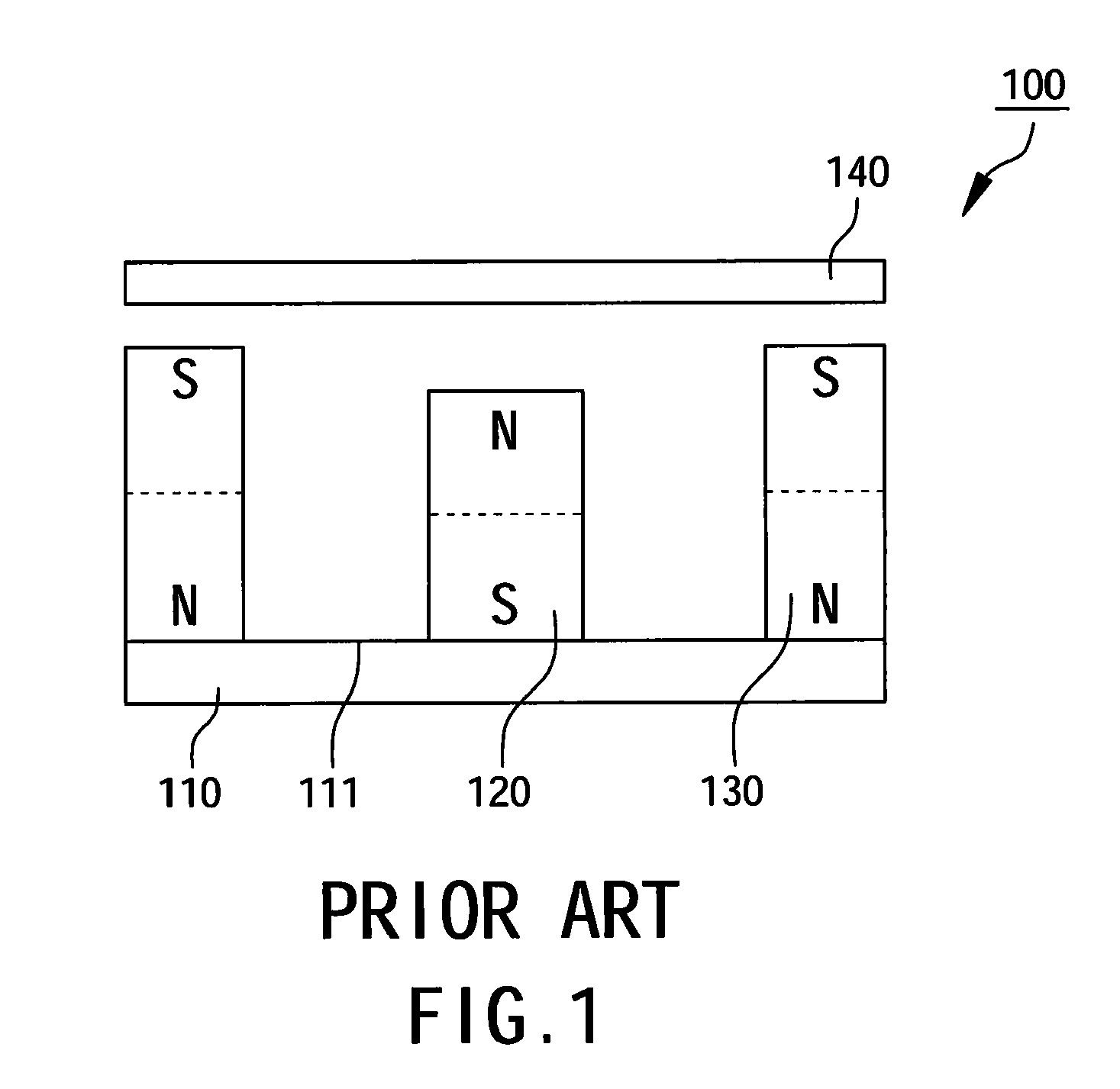

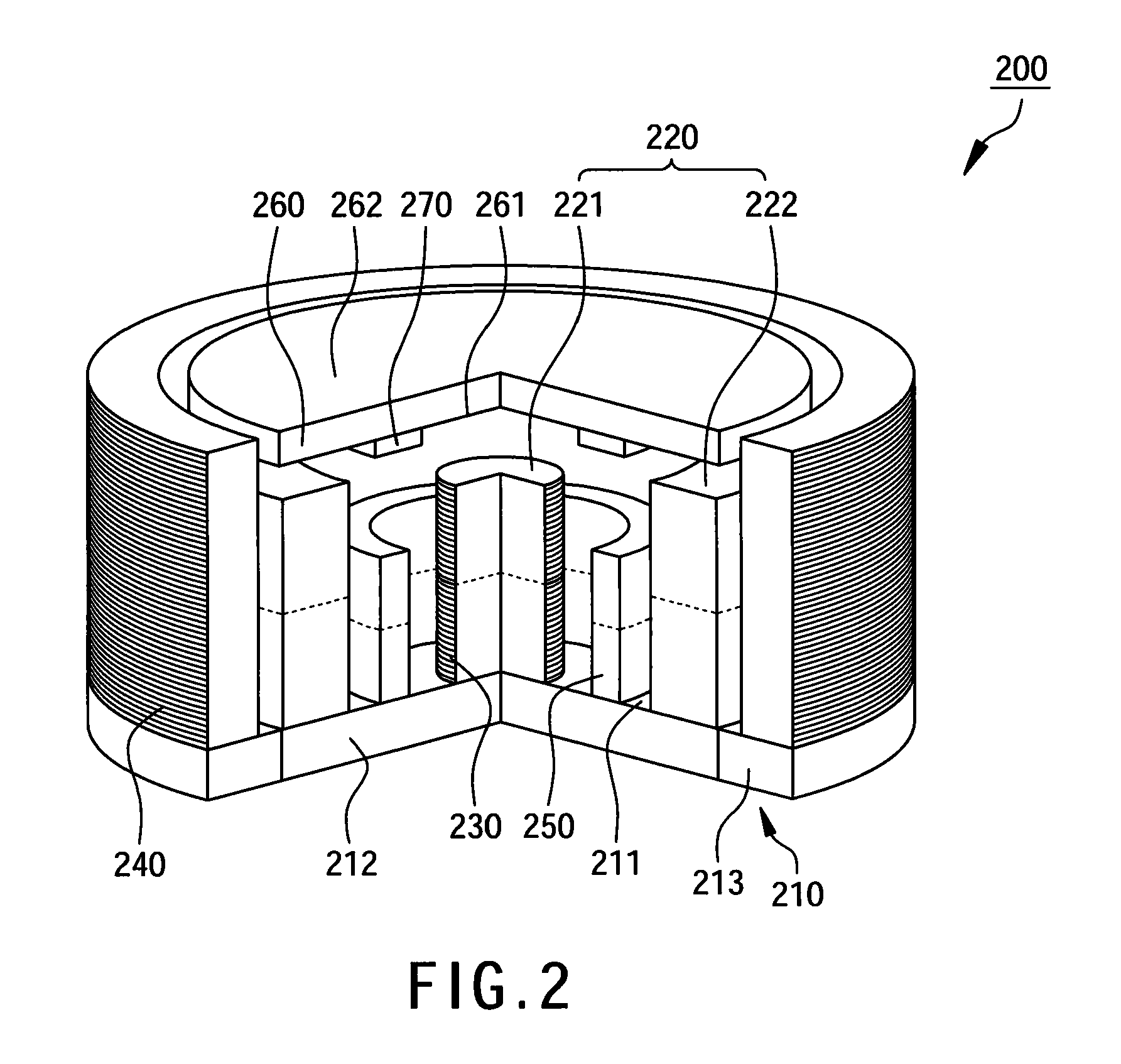

Magnetron sputter

InactiveUS20110108416A1Improve sputtering efficiencyLow costCellsElectric discharge tubesSputteringMicrowave

A magnetron sputter comprises a carrier, a magnet assembly, at least a middle magnetic ring, a target and at least a conducting magnetic ring. The magnet assembly is disposed on a carrying surface of the carrier comprising a permanent magnet and an external magnetic ring. The middle magnetic ring is disposed between the permanent magnet and the external magnetic ring of the magnet assembly. The target is disposed above the magnet assembly having a first surface which faces the carrying surface. The conducting magnetic ring is disposed on the first surface.

Owner:NAT SUN YAT SEN UNIV

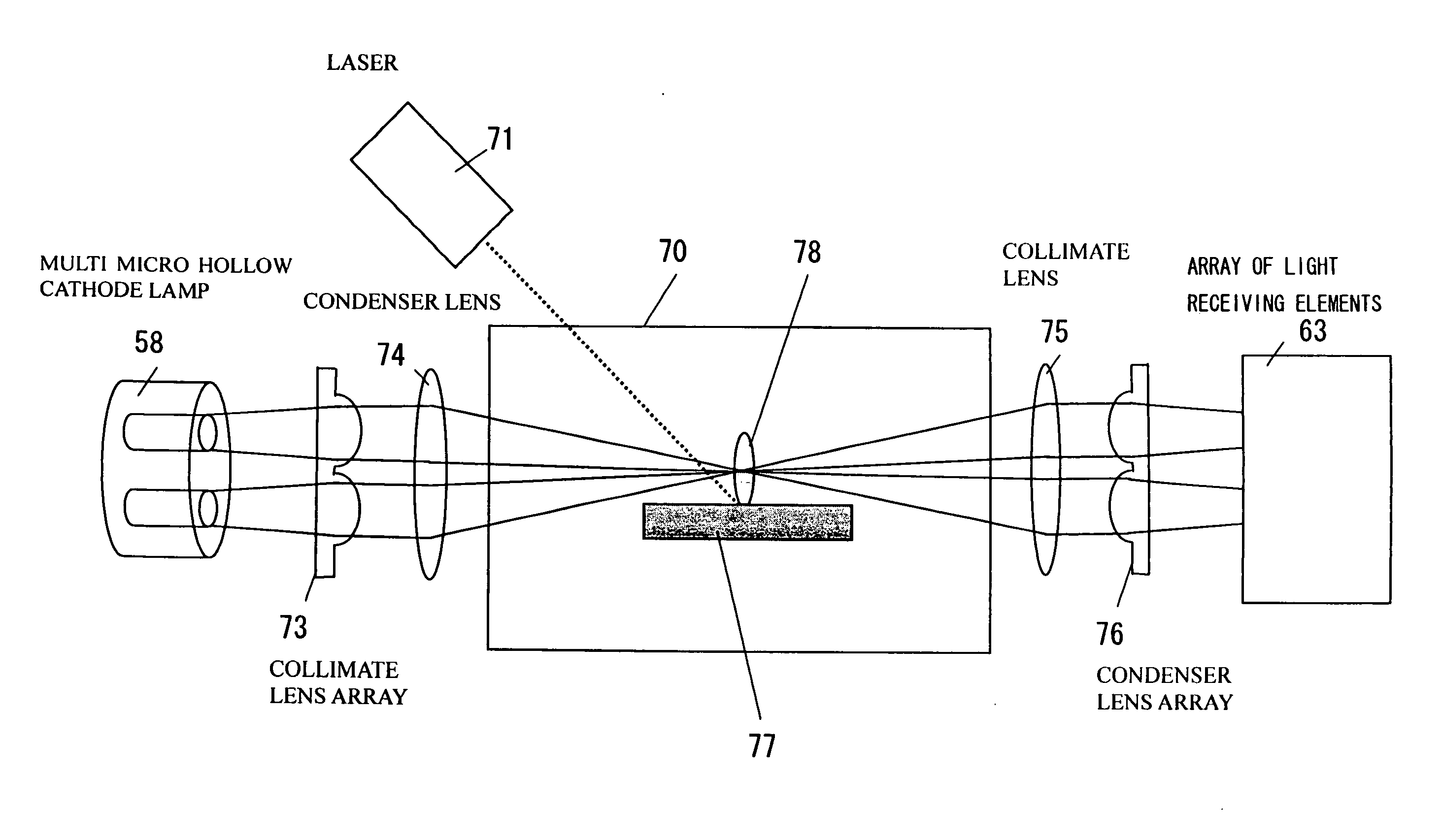

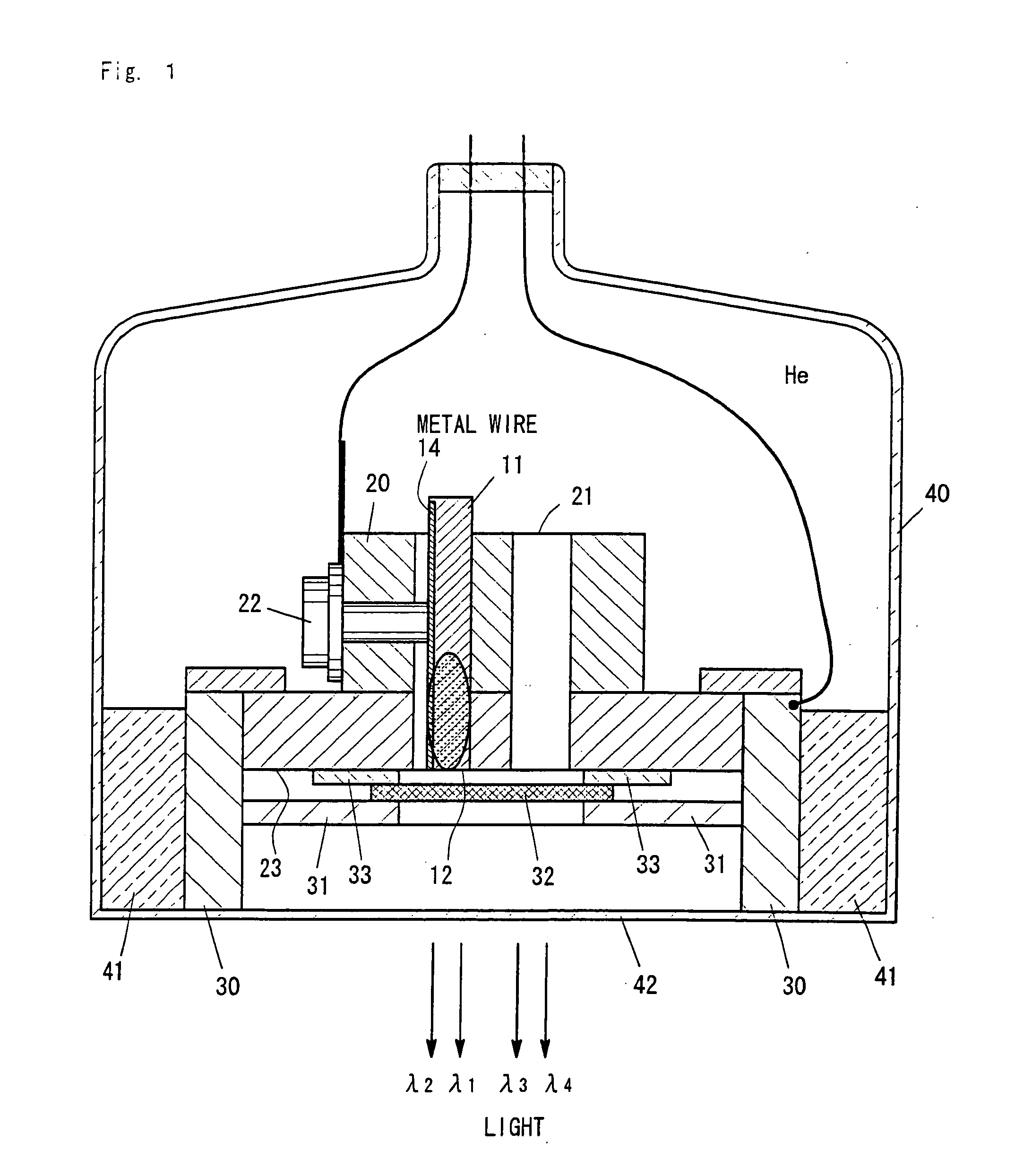

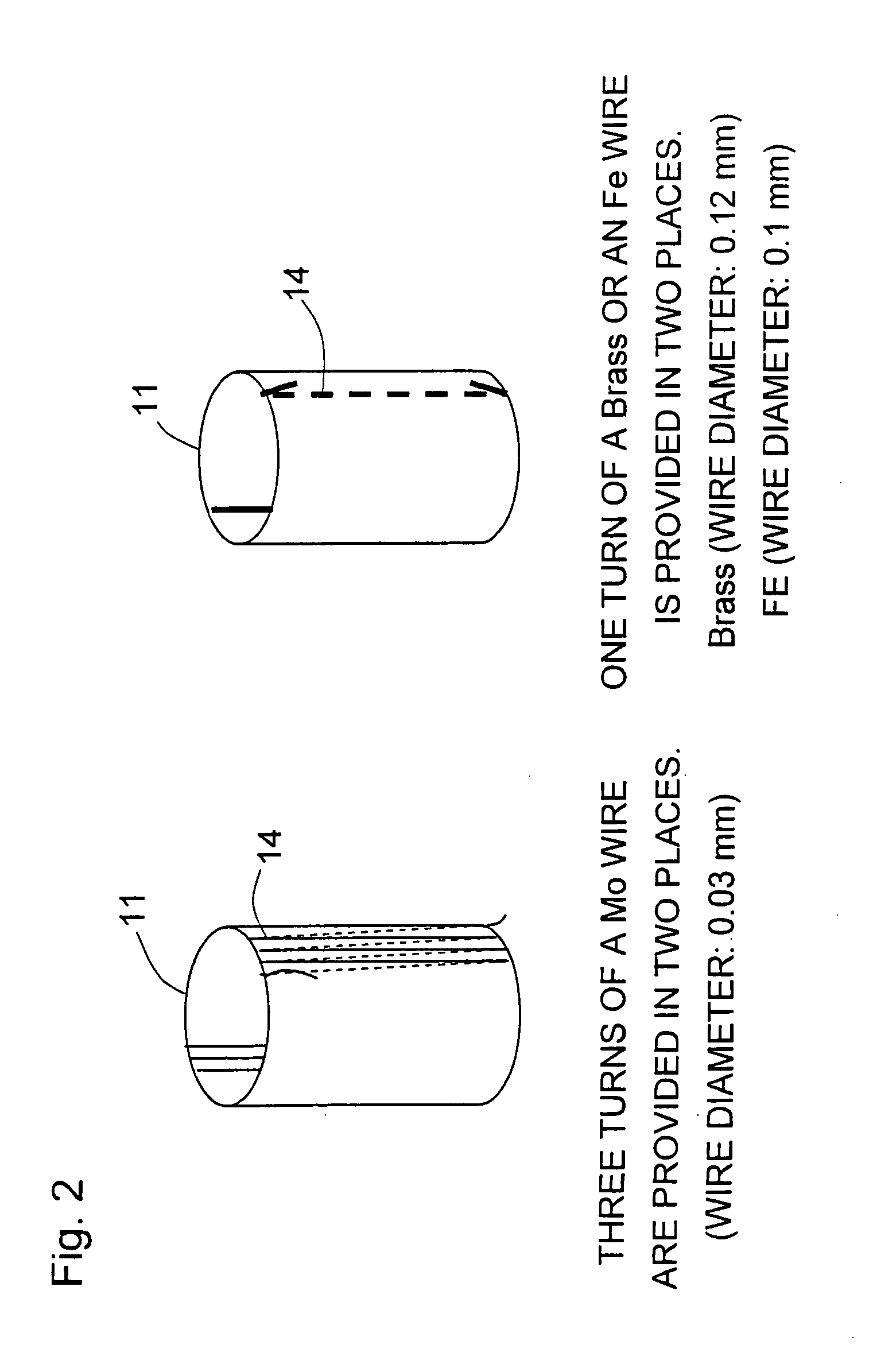

Multi Micro-Hollow Cathode Light Source and Multi-Atomic Simulataneous Absorption Spectrum Analyzer

InactiveUS20090310134A1Reduce power consumptionIncrease the number ofRadiation pyrometrySpectrum investigationGlass vesselSpectrum analyzer

[Object] To achieve a compact point light source exhibiting multielement emission spectra with which multi elements can be simultaneously analyzed.[Solving Means] The light source includes a glass vessel 40 containing He gas; a plurality of micro hollow pipes 11 that are cylindrical with a diameter of 1 mm or less and made of copper or a copper alloy; an anode mesh 32 provided at ends of the micro hollow pipes 11 with an insulating spacer 33 between the anode mesh 32 and the ends; a metal wire 14 provided in the micro hollow pipe 11, the metal wire being made of an element corresponding to a desired light-source spectrum.

Owner:NU ECO ENG

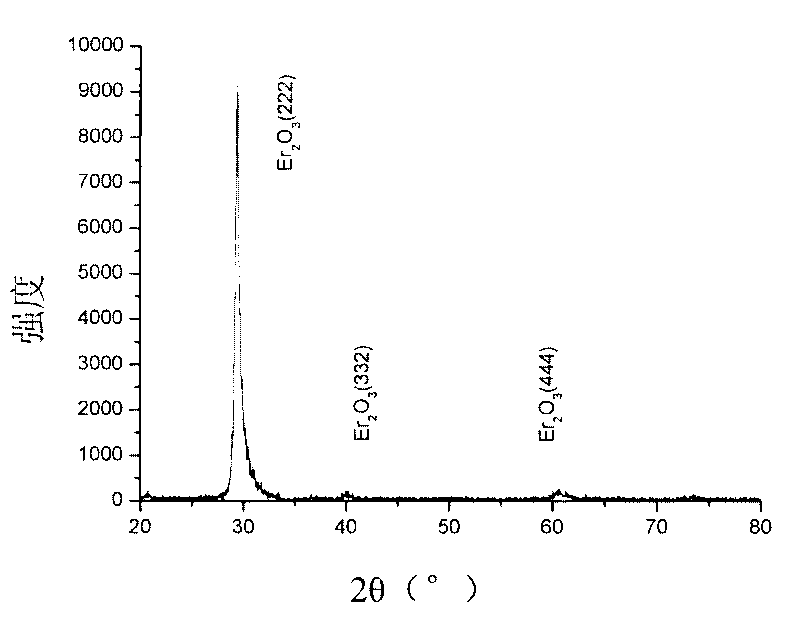

Method for preparing Er2O3 coating

ActiveCN101724819APrevent oxidationImprove sputtering efficiencyVacuum evaporation coatingSputtering coatingSputteringWater vapor

The invention belongs to the technical field of reactive sputtering, and more particularly relates to a method for preparing Er2O3 coating, comprising: putting a quartz substrate on a heater, installing target material, and adjusting the target substrate distance; vacuumizing until the vacuum degree is not more than 3.0*10-3Pa, and heating the substrate to be 700-800 DEG C; filling argon and steam, and adjusting the atmospheric pressure to be 0.1-0.8Pa, wherein the water pressure is 0.04-0.08Pa; sputtering, and increasing the sputtering power to be 80-100W; after stabilizing glow, moving a baffle away, and starting deposition; and after depositing for 20-40min, closing the baffle, stopping sputtering, disconnecting the argon and the steam, cutting off a heating power supply, turning off a vacuum system, and obtaining the Er2O3 coating. The reactive sputtering of the method improves the sputtering efficiency, taking the steam as reactant gas, prevents the surface of the target material from being oxidized, and improves the controllability of the rate of deposition. The method preparing the Er2O3 coating is rapid and controllable in the rate of deposition.

Owner:GRIMAT ENG INST CO LTD

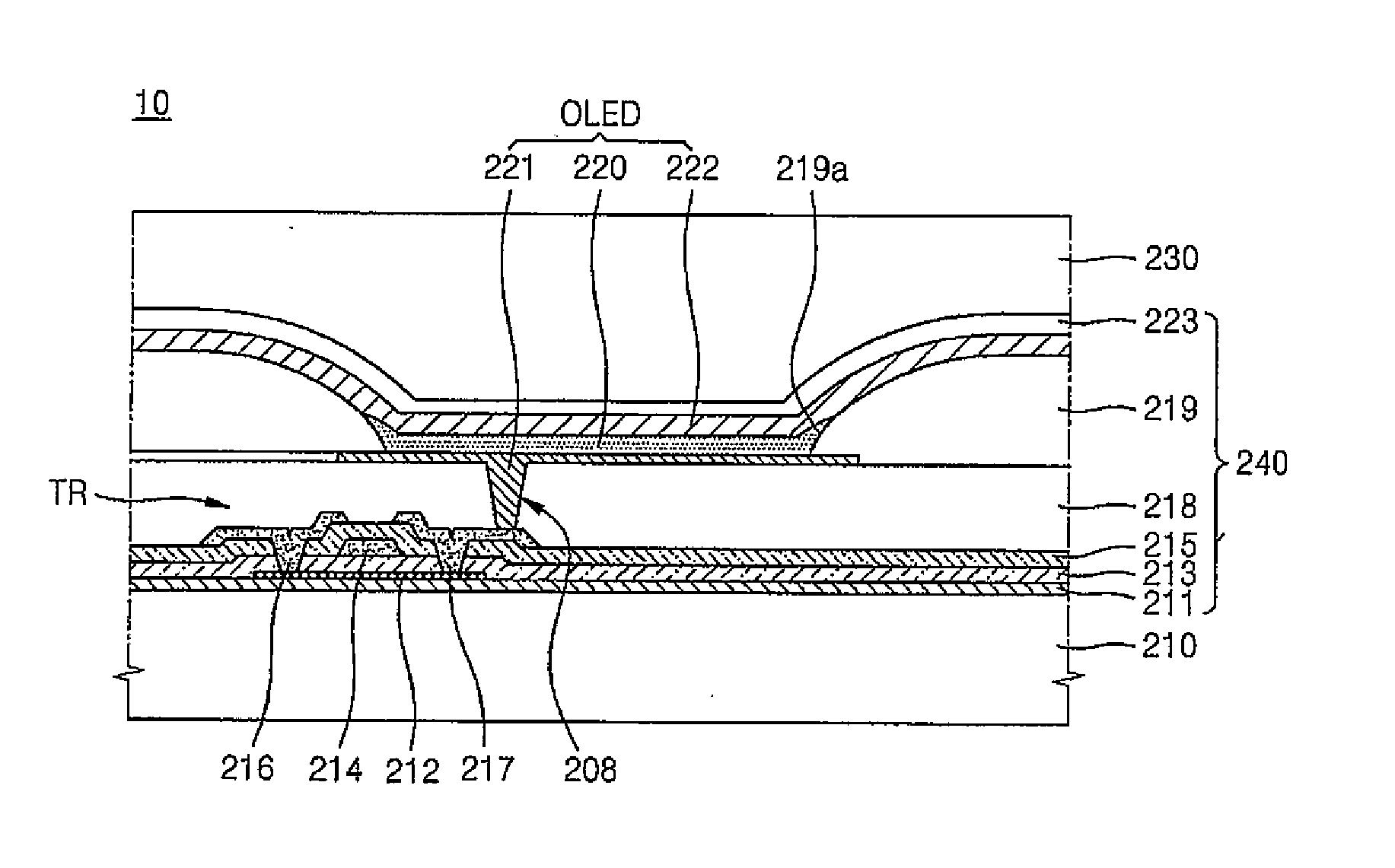

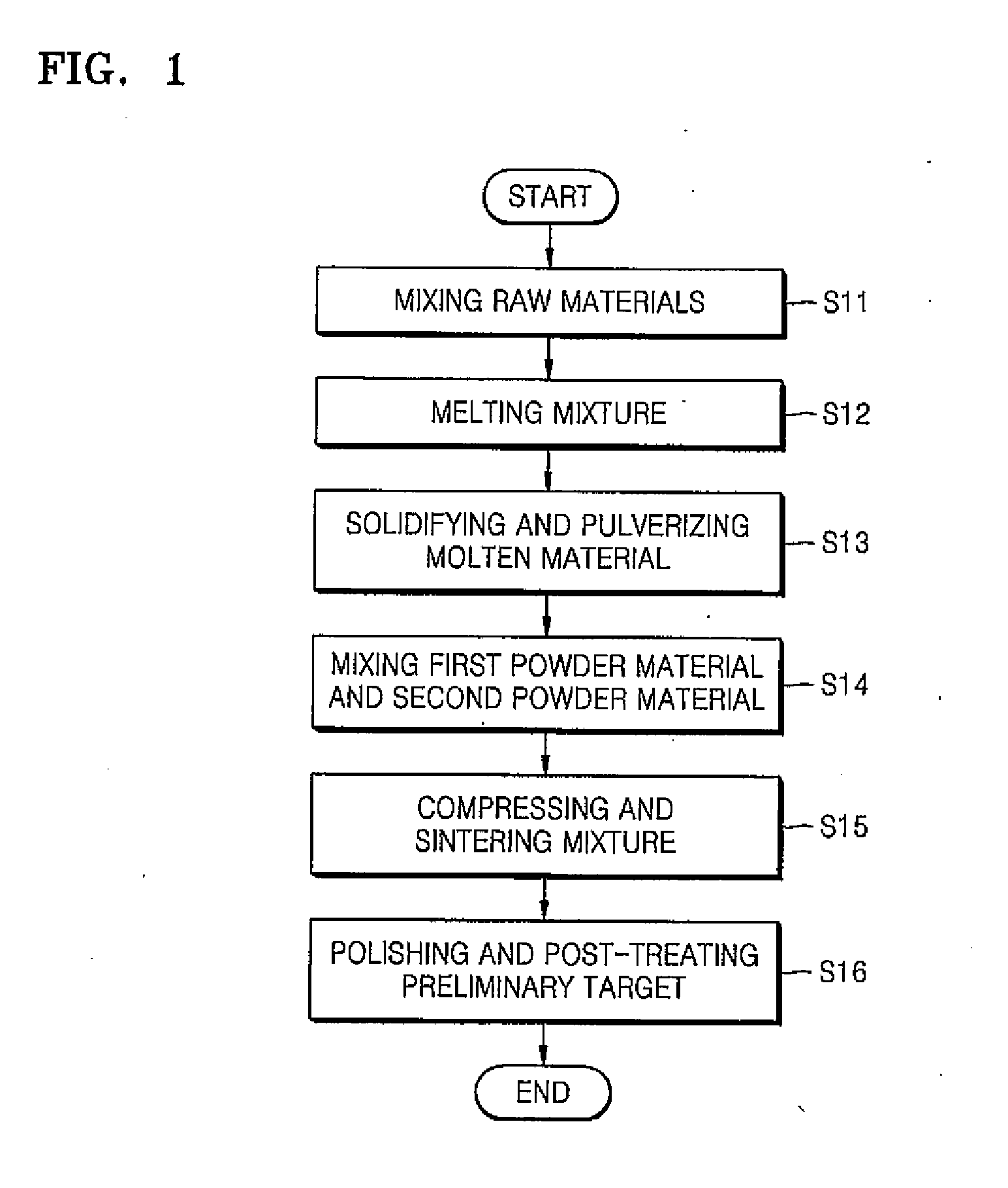

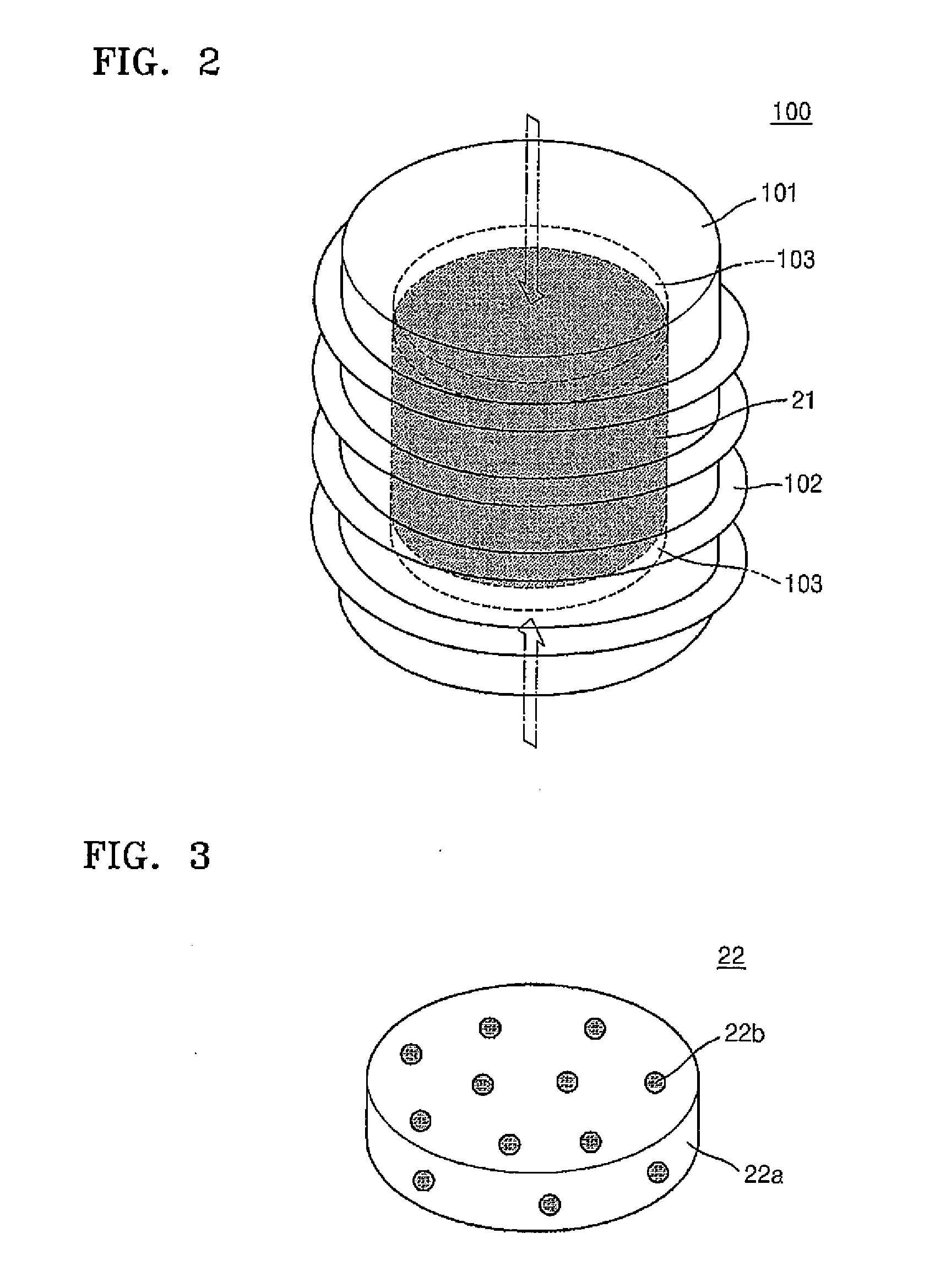

Method of fabricating a sputtering target, sputtering target fabricated by using the method, and an organic light-emitting display apparatus fabricated using the sputtering target

InactiveUS20150014652A1Improve sputtering efficiencyImprove barrier propertiesCellsVacuum evaporation coatingDopantCopper fluoride

A method of fabricating a sputtering target, a sputtering target fabricated by the method, and an organic light-emitting display apparatus fabricated by using the sputtering target. The sputtering target may be used for forming a thin film encapsulation layer. The sputtering target includes tin oxide as a main component, and a copper fluoride compound as a dopant.

Owner:SAMSUNG DISPLAY CO LTD

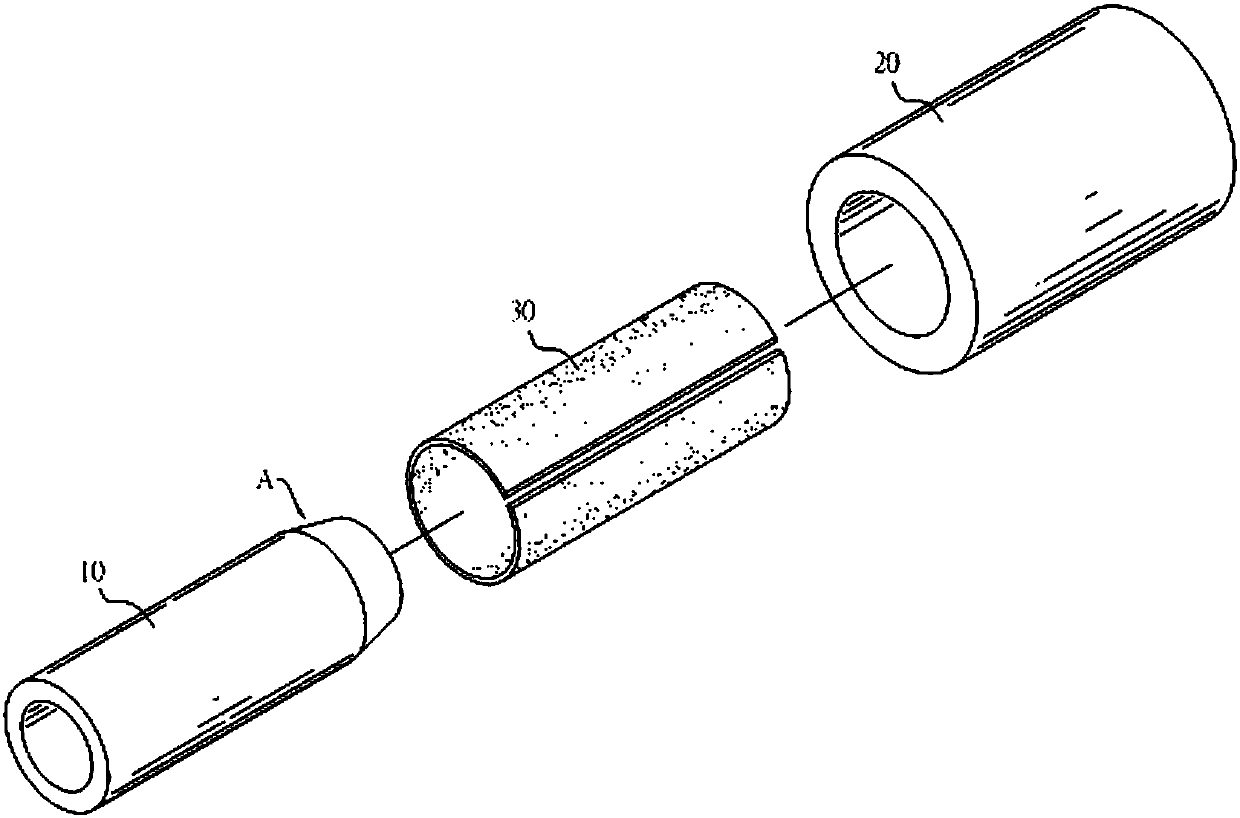

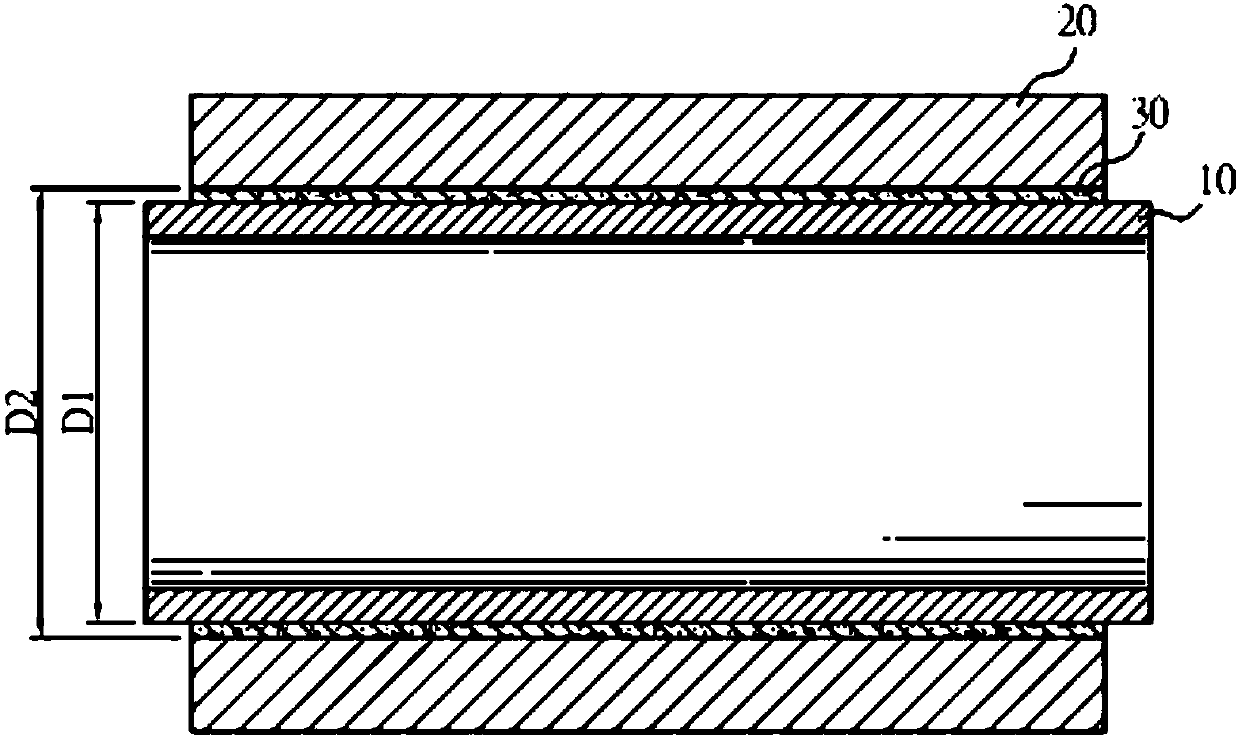

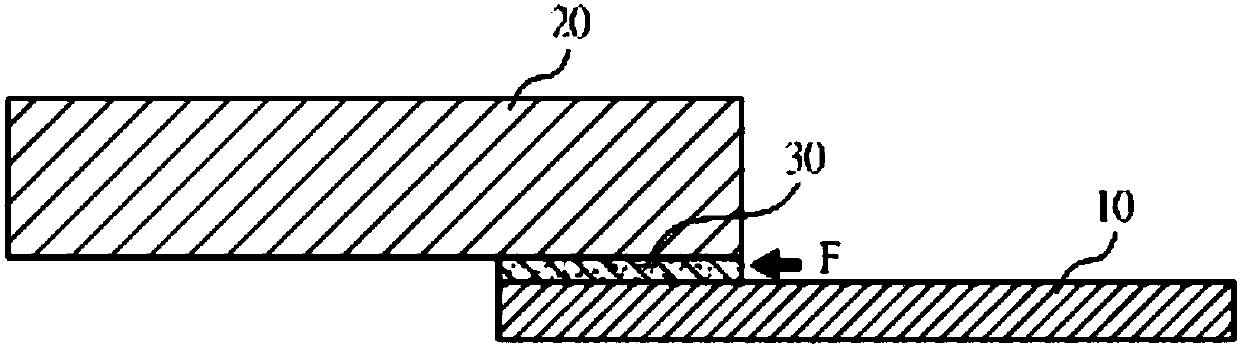

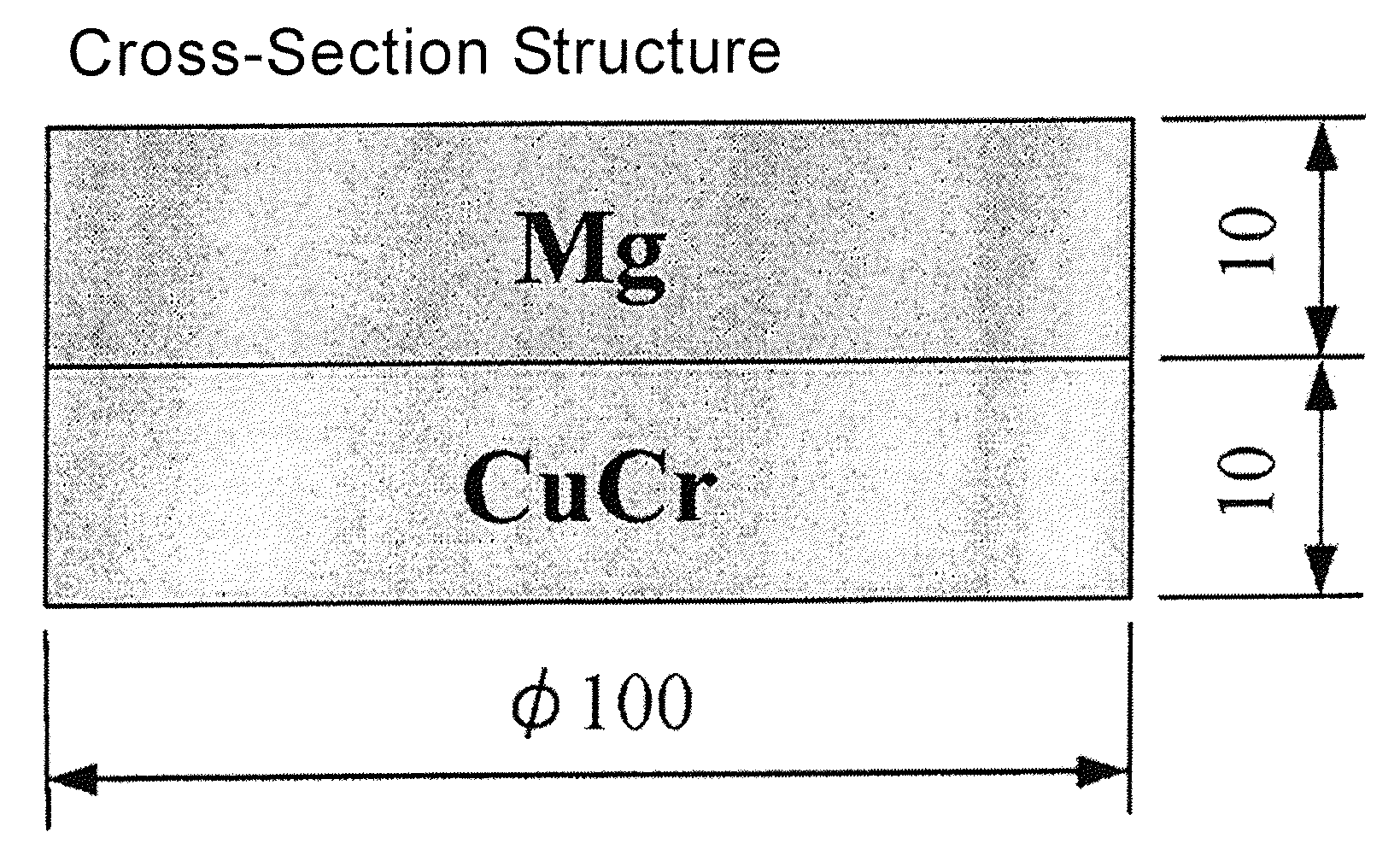

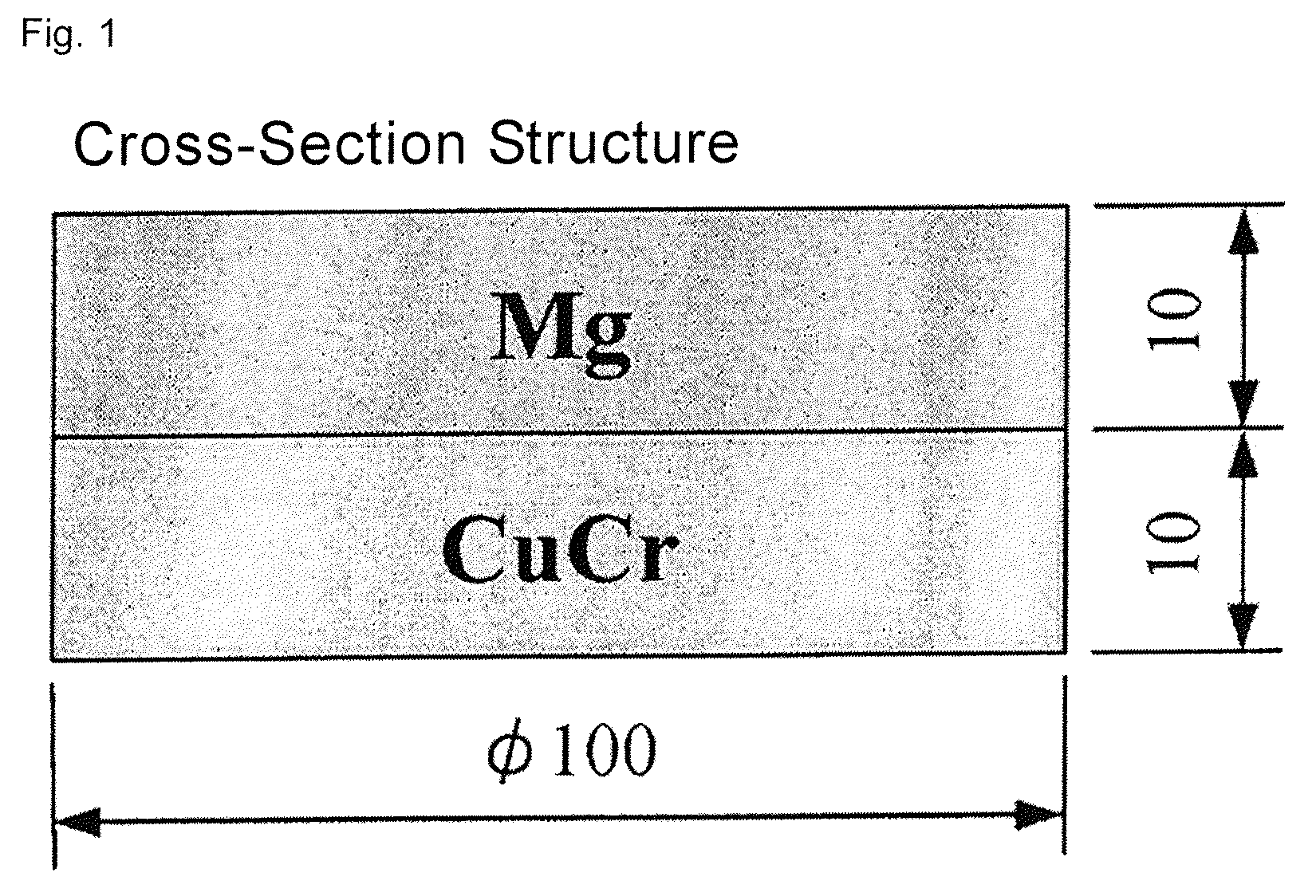

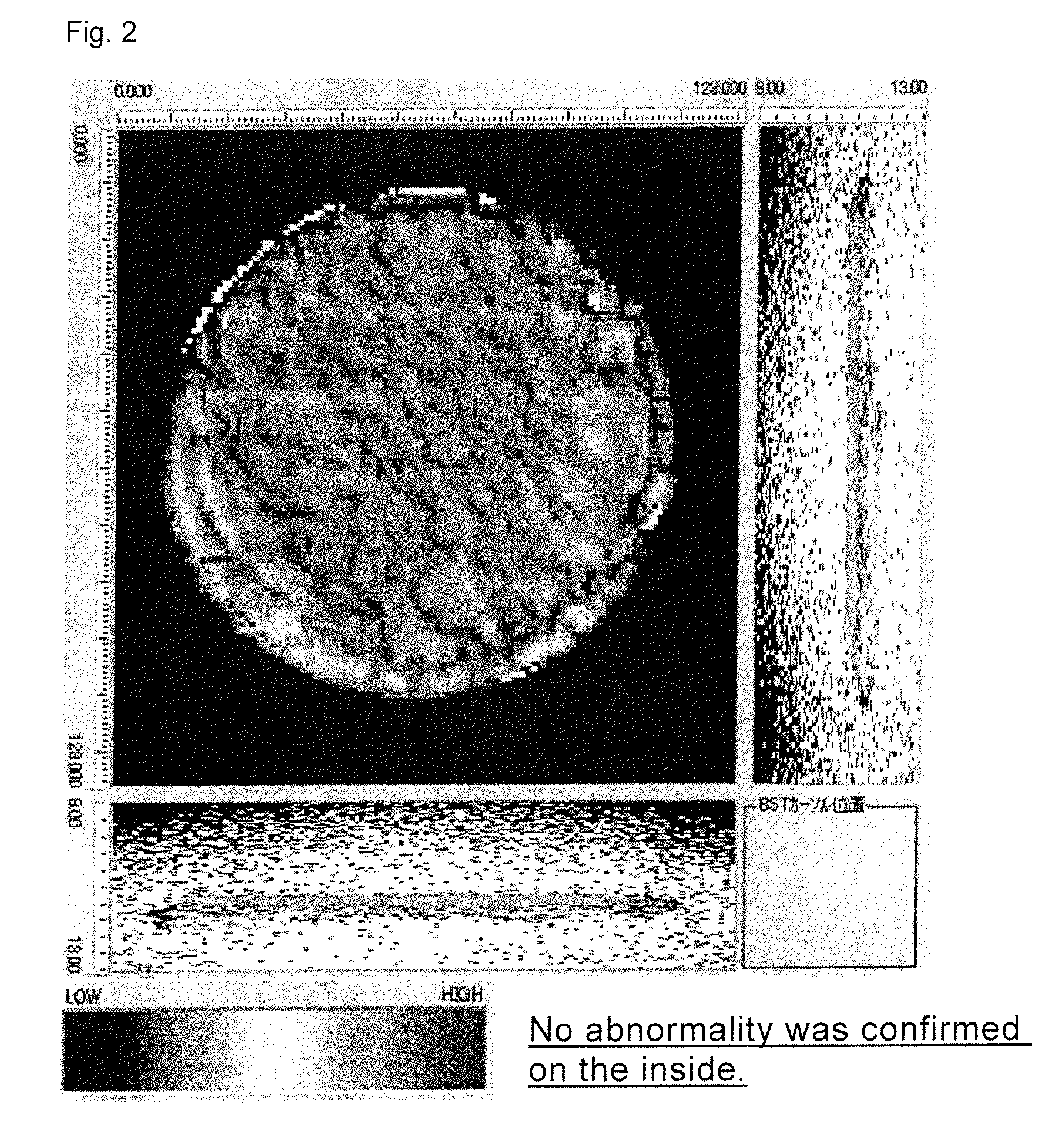

Sputtering target-backing plate assembly, and its production method

ActiveUS9062371B2High bonding strengthImprove sputtering efficiencyVacuum evaporation coatingSputtering coatingAlloyUltimate tensile strength

A sputtering target-backing plate assembly obtained by bonding a target material of Mg to a backing plate of Cu—Cr alloy, wherein the target material and the backing plate are bonded via a layer of Ni or an alloy comprising Ni as a main component at the interface therebetween. An object of the present invention is to provide a sputtering target-backing plate assembly that is used when magnesium (Mg) is the sputtering target material, and to resolve problems inherent in magnesium (Mg) and problems related to the selection of a backing plate to be compatible with magnesium by improving the bonding strength between the target and the backing plate in order to improve the sputtering efficiency.

Owner:JX NIPPON MINING & METALS CORP

Method for preparing homoepitaxial double-sided MgO thin films based on middle-frequency sputtering

InactiveCN109023276ASolve the problem of uneven structurePrevent oxidationVacuum evaporation coatingSputtering coatingGas phaseMiddle frequency

The invention belongs to the technical field of thin film preparation, and relates to a method for preparing homoepitaxial MgO thin films on the two sides of a flexible Hastelloy base band with the two sides simultaneously plated with IBAD (ion beam assisted deposition)-MgO / SDP-Y2O3, in particular to a method for preparing double-sided homoepitaxial MgO thin films based on middle-frequency (MF) magnetron reactive sputtering. According to the method, symmetrically-structured vent holes in a gas dispersion tube are adopted and used for evenly dispersing mixed gas, and therefore the problem thatthe thin films which are prepared through middle-frequency magnetron reactive sputtering are nonuniform is solved. The vent holes are designed in a one-way manner, so that the surfaces of target materials do not make contact with oxygen directly, and metal targets are prevented from oxidizing. The sputtering efficiency is improved by means of the air inflow mode, and uniformity and consistency ofthe double-sided simultaneous-growing MgO thin films are advantageously guaranteed. Compared with a traditional high-cost and complicated-technology physical vapor deposition (PVD) method, according to middle-frequency automatic-extensional MgO, the cost of a buffer layer is reduced, the price-performance ratio of superconducting tapes is increased, and the deposition rate is high.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

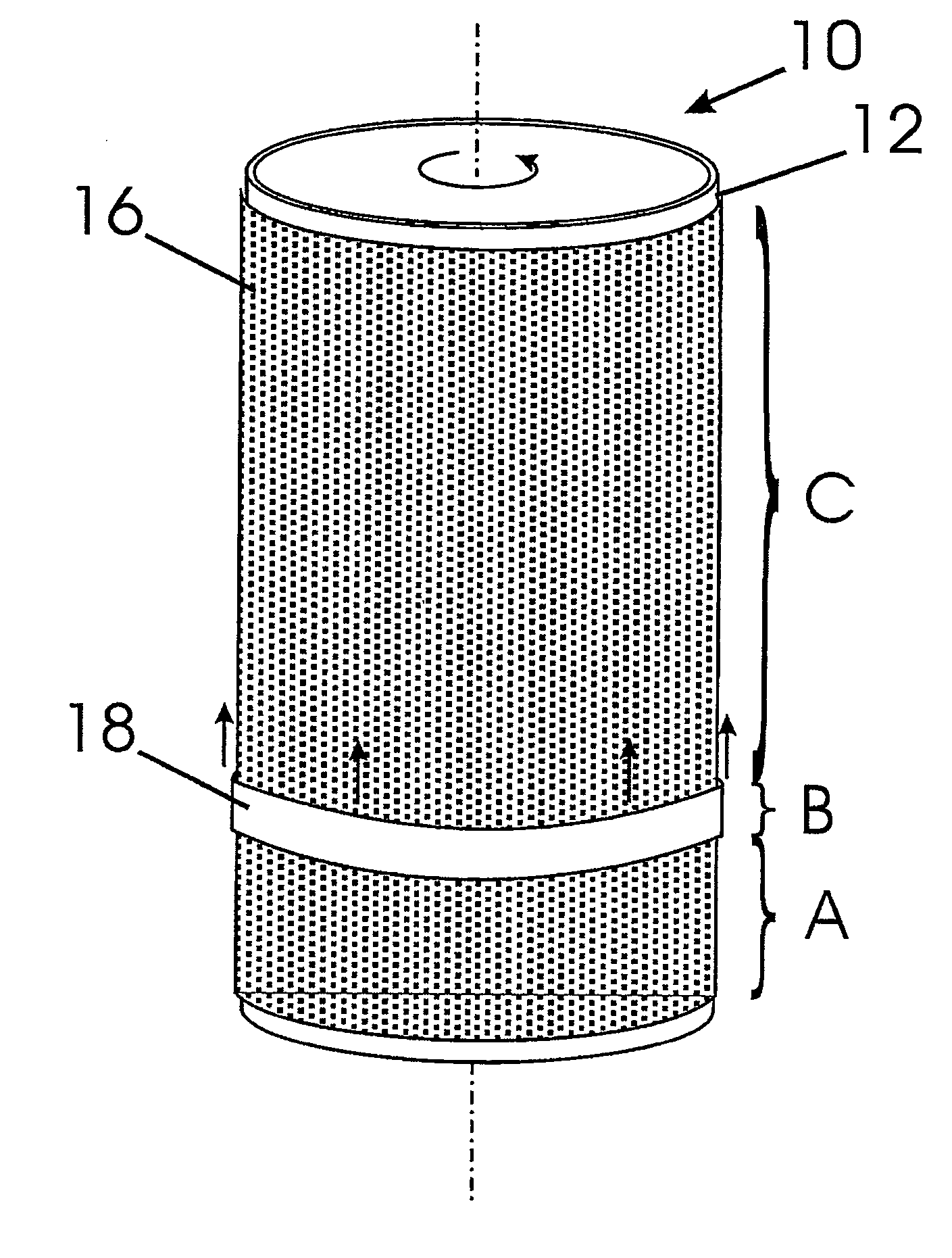

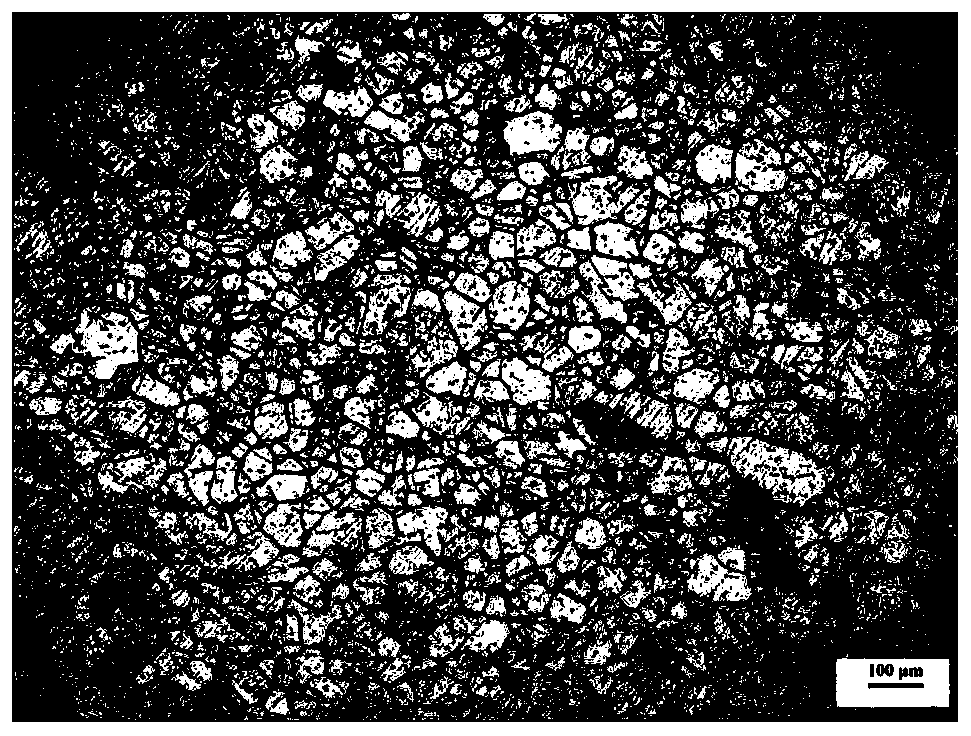

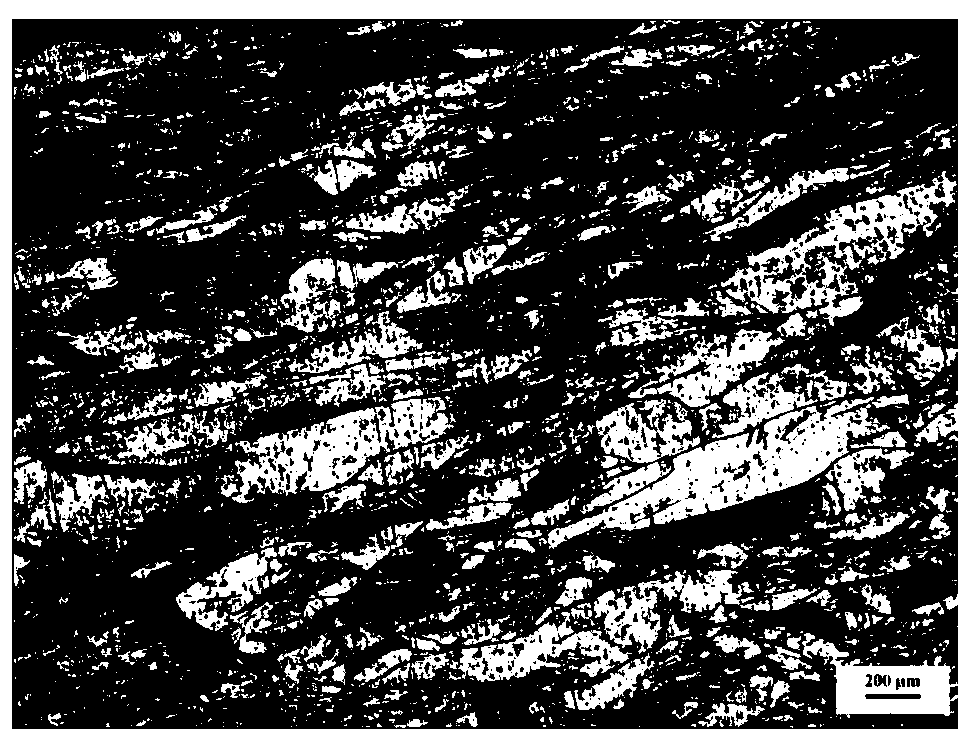

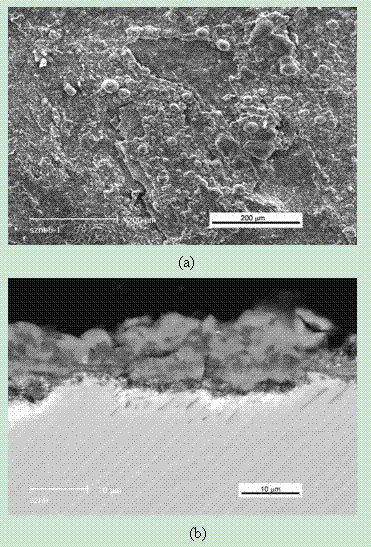

Nickel-vanadium alloy magnetron sputtering rotating target containing trace rare earth elements and preparation method

ActiveCN103710577BReduce magnetismImprove sputtering efficiencyVacuum evaporation coatingSputtering coatingRare-earth elementElectrolysis

A nickel vanadium alloy magnetron sputtering rotary target containing trace rare earth elements and its preparation method, the chemical composition of the target is 0.002wt~0.05wt%RE, 5~9wt%V, the balance is Ni and unavoidable Impurities. Through vacuum melting, casting, hot forging, hot perforation or hot extrusion into tube shape, cold drawing, annealing, machining and other processes. The raw materials used include electrolytic nickel with a purity of 99.95%, sponge vanadium with a purity of 99.9%, and mixed rare earth elements with a purity of 99.9%. Through vacuum smelting, adding sponge vanadium after electrolytic nickel smelting and refining can significantly improve the oxidation resistance and corrosion resistance of the rotating target, improve the stability and thermal hardness of the target and the sensitivity to material overheating, adding a small amount of Rare earth elements can improve the purity of the material, realize the refinement and uniformity of the microstructure of the target material, help to improve the density and material plasticity of the Ni-V-RE rotating target material, and prolong the service life of the material. The rotating target is widely used in electronic components, communications, solar energy and other industries.

Owner:NANJING DAMAI SCI&TECH IND CO LTD +1

Corrosion-resistant and high-temperature-resistant coating applicable to titanium aluminum alloy and preparation method thereof

InactiveCN102453870AGood high temperature corrosion resistanceReduce the temperatureVacuum evaporation coatingSputtering coatingAluminum substrateSilver coating

The invention relates to a corrosion-resistant and high-temperature-resistant coating applicable to a titanium aluminum alloy. The coating alloy has the nominal ingredients of 39 to 45 at percent of Ti, 47 to 49 at percent of Al, 7 to 9 at percent of Cr and 1 to 3 at percent of Ag. A magnetron sputter plating method is adopted for preparing the coating. The titanium aluminum based titanium aluminum chromium silver is adopted as coating materials of the titanium aluminum alloy, the performance that the coating and a substrate have the same expansion coefficient at high temperature and the like is utilized, and the effect of the chromium and the sliver for improving the anti-corrosion performance in the titanium aluminum is also considered. The magnetron sputter plating characteristic is used for preparing the titanium aluminum chromium silver coating with the firm combination on the titanium aluminum substrate, and the anti-corrosion performance of the titanium aluminum alloy is obviously improved at high temperature.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com