Method for preparing Er2O3 coating

A technology of coating and sputtering method, which is applied in the field of reactive sputtering, can solve the problems of low sputtering efficiency of ceramic targets, difficult control of coating deposition rate, unfavorable scale application, etc., to achieve improved sputtering efficiency and stable deposition rate Control and improve the effect of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

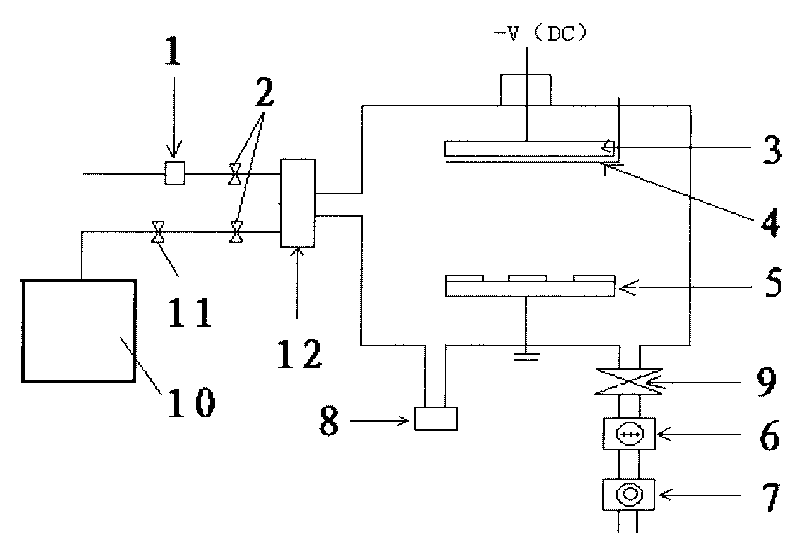

Method used

Image

Examples

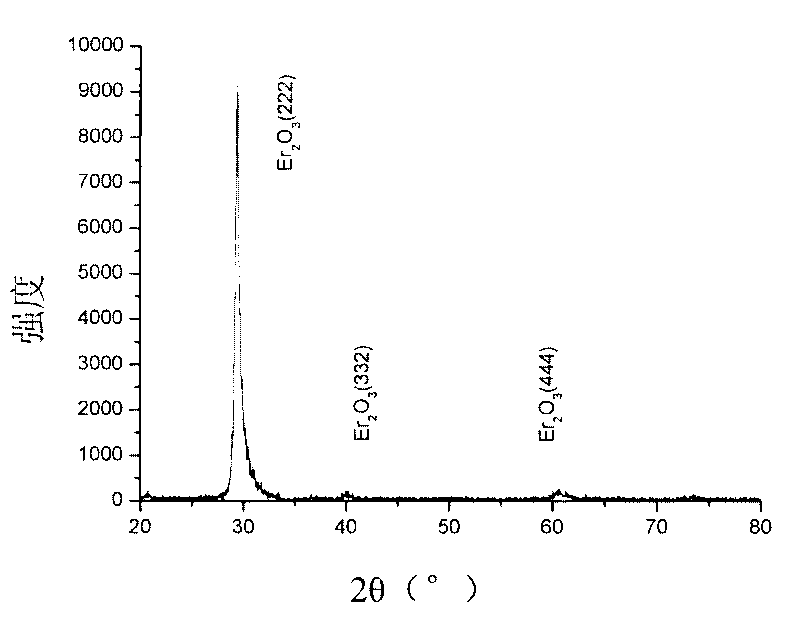

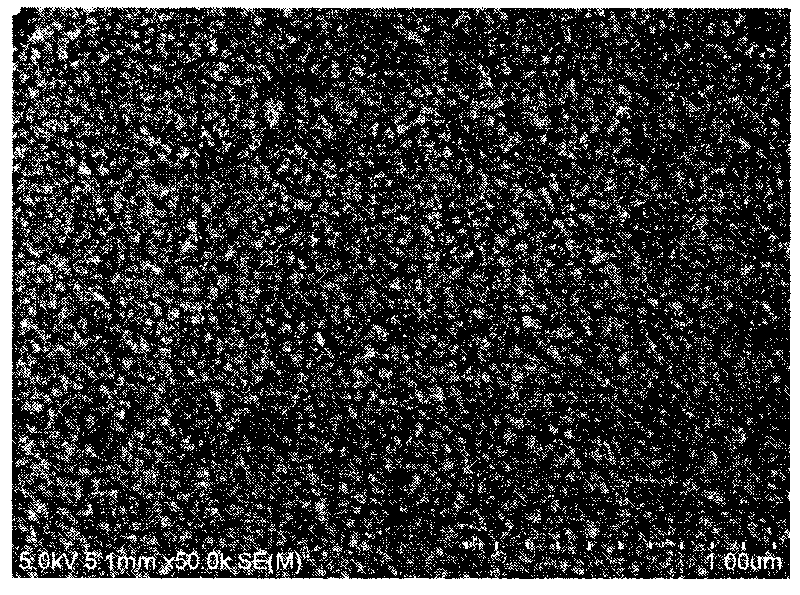

Embodiment 1

[0026] Preparation of Er by reactive sputtering 2 o 3 Coating, with the pure metal Er target (purity is 99.9%) of Φ75 * 5mm as target material, comprises the following steps:

[0027] (1) Put the quartz substrate in alcohol for 2 minutes for ultrasonic cleaning to remove the moisture on the surface; then put it in acetone for 3 minutes for ultrasonic cleaning to remove the oil on the surface; finally dry it with a hair dryer; place the quartz substrate on Install the target on the heater, and adjust the base distance of the target to 40mm;

[0028] (2) Vacuum until the degree of vacuum is not greater than 3.0×10 -3 Pa, turn on the power of the heater, and heat the substrate to 750°C;

[0029] (3) Introduce argon gas and adjust the water vapor control valve. The water vapor is provided by the water storage tank. The temperature of the water storage tank is kept at 25°C to keep the evaporation of water vapor constant. The vacuum gauge shows that the water vapor is 4.0×10 -2 ...

Embodiment 2

[0033] Preparation of Er by reactive sputtering 2 o 3 Coating, with the pure metal Er target (purity is 99.9%) of Φ75 * 5mm as target material, comprises the following steps:

[0034] (1) Put the quartz substrate in alcohol for 2 minutes for ultrasonic cleaning to remove the moisture on the surface; then put it in acetone for 3 minutes for ultrasonic cleaning to remove the oil on the surface; finally dry it with a hair dryer; place the quartz substrate on Install the target on the heater, and adjust the base distance of the target to 40mm;

[0035] (2) Vacuum until the degree of vacuum is not greater than 3.0×10 -3 Pa, turn on the power of the heater, and heat the substrate to 750°C;

[0036] (3) Introduce argon gas and adjust the water vapor control valve. The water vapor is provided by the water storage tank. The temperature of the water storage tank is kept at 25°C to keep the evaporation of water vapor constant. The vacuum gauge shows that the water vapor is 8.0×10 -2 ...

Embodiment 3

[0040] Preparation of Er by reactive sputtering 2 o 3 Coating, with the pure metal Er target (purity is 99.9%) of Φ75 * 5mm as target material, comprises the following steps:

[0041](1) Put the quartz substrate in alcohol for 2 minutes for ultrasonic cleaning to remove the moisture on the surface; then put it in acetone for 3 minutes for ultrasonic cleaning to remove the oil on the surface; finally dry it with a hair dryer; place the quartz substrate on Install the target on the heater, and adjust the base distance of the target to 40mm;

[0042] (2) Vacuum until the degree of vacuum is not greater than 3.0×10 -3 Pa, turn on the power of the heater, and heat the substrate to 800°C;

[0043] (3) Introduce argon gas and adjust the water vapor control valve. The water vapor is provided by the water storage tank. The temperature of the water storage tank is kept at 25°C to keep the evaporation of water vapor constant. The vacuum gauge shows that the water vapor is 4.0×10 -2 P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com