Device and method for depositing film on SiC fiber surface

A fiber surface and thin film technology, applied in the field of vacuum coating magnetron sputtering deposition, can solve the problems of target poisoning, achieve uniform thickness, improve sputtering efficiency and ionization rate, and uniform film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

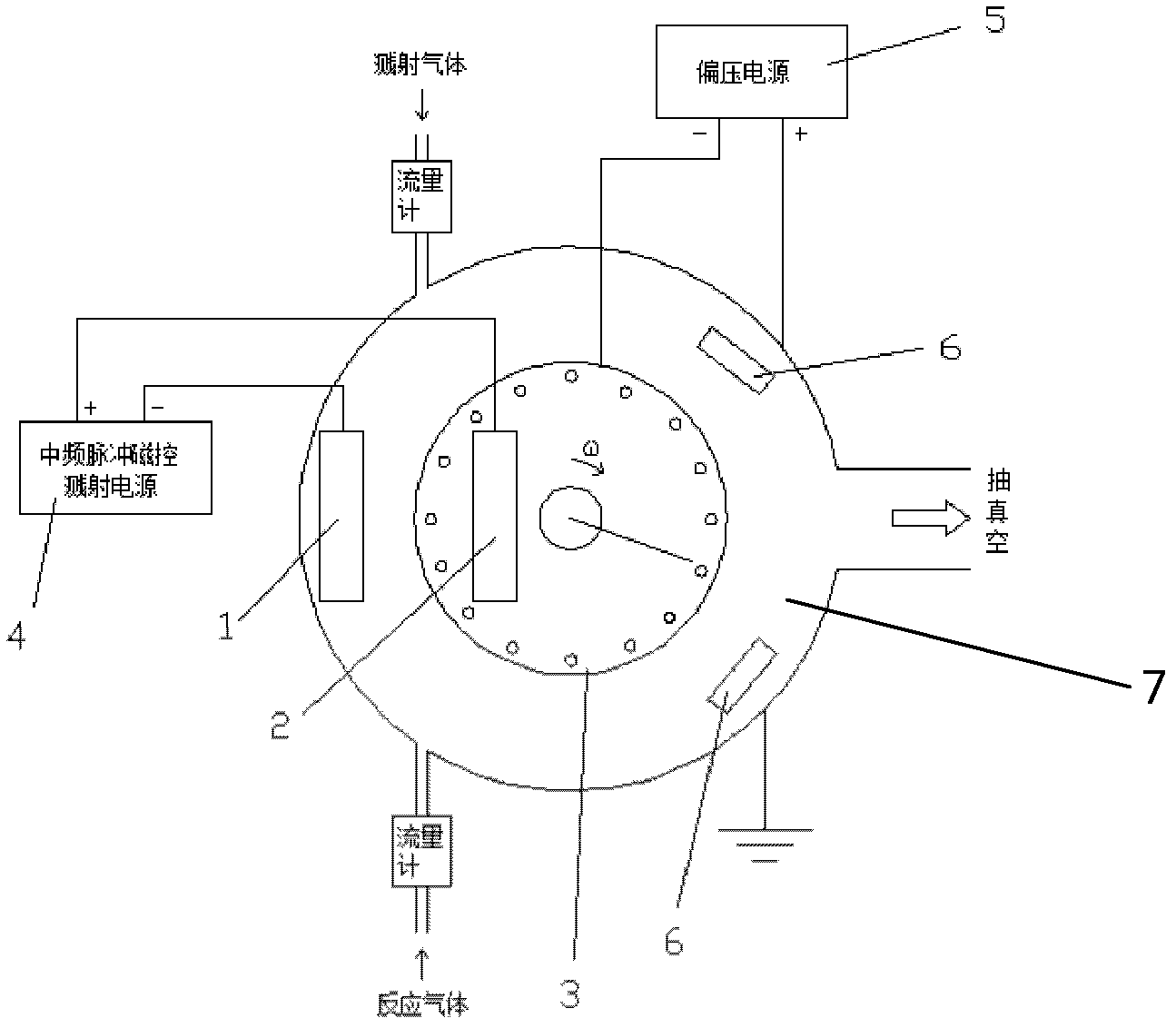

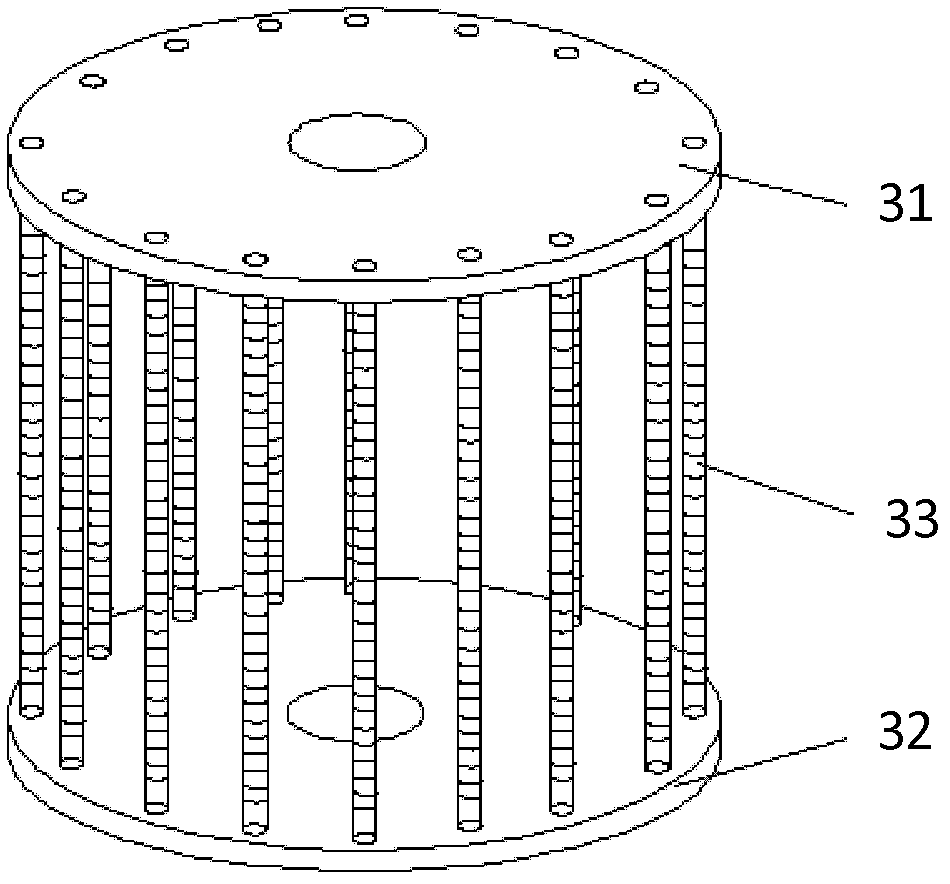

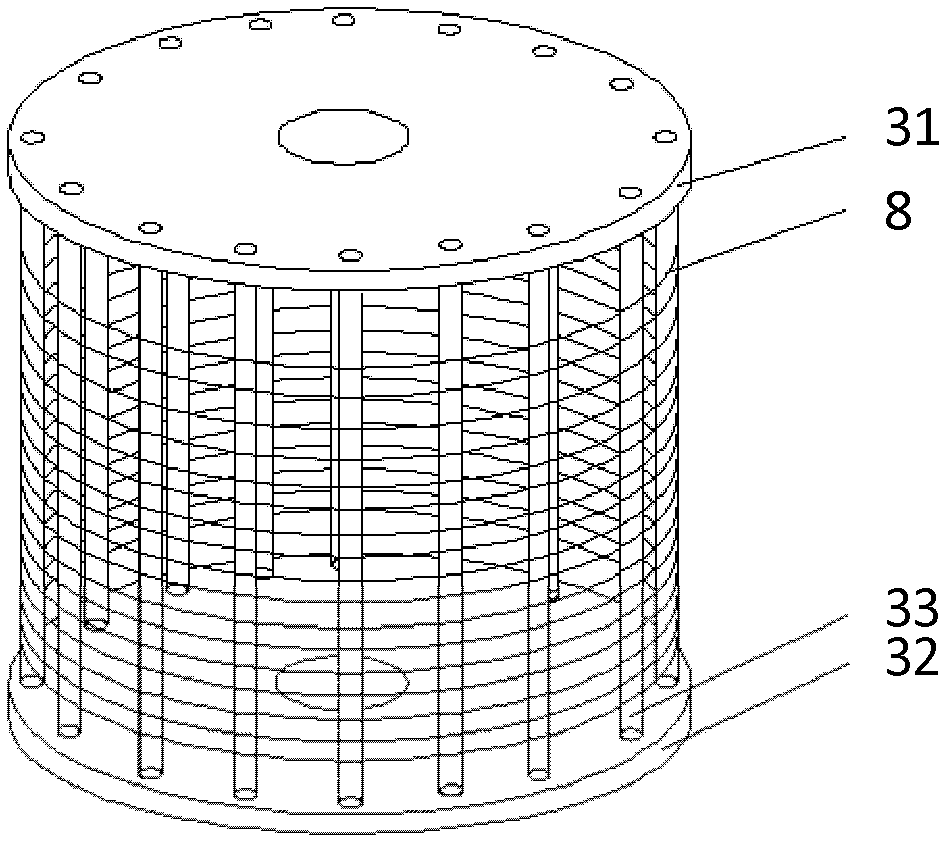

[0052] Such as Figure 1-3 As shown, the Al target is used to deposit Al on the surface of SiC fiber 2 o 3 Thin film, the purity of Al target is 99.99wt%, the size is 272×68×10mm. The cathode of the medium-frequency pulse magnetron sputtering power supply 4 is connected to the target material I1, and the anode is connected to the target material II2. The distance between the target material I and the target material II is 120mm, and permanent magnets are arranged on the inner and outer layers of the magnetron target. The magnetic field strength of the inner permanent magnet is 3000 Gauss and the magnetic field strength of the outer permanent magnet is 4500 Gauss. Wind the continuous SiC fiber on the groove of the supporting rod on the workpiece turret 3, the depth of the groove is 2mm, put it into the magnetron sputtering vacuum chamber 7, and vacuumize until the vacuum degree reaches 3×10 -3 Pa, the sputtering gas Ar gas and the reaction gas O with a volume purity of 99.99...

Embodiment 2

[0055] In this example, Cr is used as a target to deposit Cr on the surface of SiC fiber. 2 o 3 Thin film, the purity of Cr target is 99.99wt%, the size is 272×68×10mm. The cathode of the medium-frequency pulse magnetron sputtering power supply 4 is connected to the target material I1, and the anode is connected to the target material II2. The distance between the target material I and the target material II is 80mm, and permanent magnets are arranged on the inner and outer layers of the magnetron target. The magnetic field strength of the inner permanent magnet is 2800 Gauss and the magnetic field strength of the outer permanent magnet is 3800 Gauss. Wind the continuous SiC fiber on the groove of the support rod on the workpiece turret 3, the depth of the groove is 4mm, put it into the magnetron sputtering vacuum chamber 7, and vacuumize until the vacuum degree reaches 4×10 -3 Pa, the sputtering gas Ar gas and the reaction gas O with a volume purity of 99.999% are introduce...

Embodiment 3

[0057] In this example, TiO is deposited on the surface of SiC fiber by using Ti as the target. 2 The thin film, the purity of the Ti target is 99.99wt%, and the size is 272×68×10 mm. The cathode of the intermediate frequency pulse magnetron sputtering power supply 4 is connected to the target material I1, and the anode is connected to the target material II2. The distance between the target material I and the target material II is 180mm, and permanent magnets are arranged on the inner and outer layers of the magnetron target. The magnetic field strength of the layer permanent magnet is 3500 Gauss and that of the outer layer permanent magnet is 5100 Gauss. Wind the continuous SiC fiber on the groove of the supporting rod on the workpiece turret 3, the depth of the groove is 0.5 mm, put it into the magnetron sputtering vacuum chamber 7, and vacuumize until the vacuum degree reaches 2×10 -3 Pa, the sputtering gas Ar gas and the reaction gas O with a volume purity of 99.999% are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com