Corrosion-resistant and high-temperature-resistant coating applicable to titanium aluminum alloy and preparation method thereof

A titanium-aluminum alloy and corrosion-resistant technology, applied in the field of high-temperature-resistant alloys, can solve the problems of high-temperature resistance and low corrosion resistance of titanium-aluminum alloys, and achieve superior high-temperature corrosion resistance, uniform film structure and thickness, and strong adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

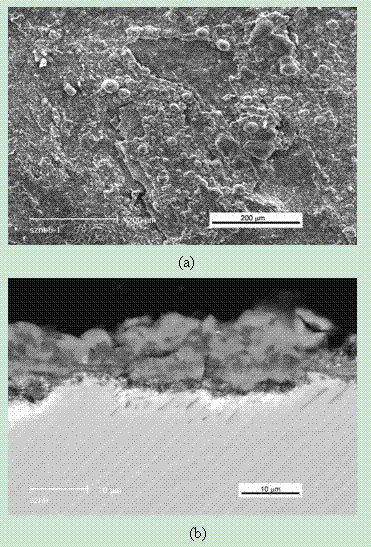

[0014] Embodiment 1 preparation alloy composition is Ti 42 -Al 48 -Cr 8 -Ag 2 (at%) coating

[0015] (1) Coating preparation method

[0016] Deposition of Ti on Titanium Alloy Using SBH-5115D Magnetron Sputtering Apparatus 42 -Al 48 -Cr 8 -Ag 2 (at%) coating. Ti for sputtering target 42 -Al 48 -Cr 8 -Ag 2 (at%) alloy, the size is 380 mm × 126 mm × 7 mm, and the size of the matrix as-cast alloy is 10 mm × 10 mm × 2.5 mm. Before sputtering, the substrate samples were polished with No. 600 sandpaper, and then ultrasonically cleaned with acetone for 15 min. The sputtering parameters are as follows: the degree of vacuum is 0.5×10 -2 Pa, the argon pressure is 0.2-0.3 Pa , The substrate temperature is 200 0 C, the power is 1800 W, and the sputtering time is 8 h. Rotary sputtering.

[0017] (2) High temperature salt corrosion experiment

[0018] The high temperature hot corrosion adopts the salt immersion method, and the experimental temperature is 900 o c. Th...

Embodiment 2

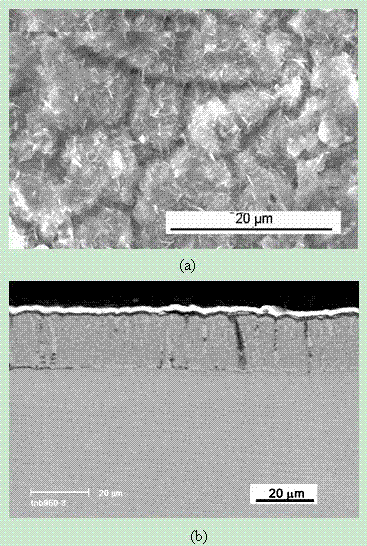

[0019] Embodiment 2 preparation alloy composition is Ti 39 -Al 49 -Cr 9 -Ag 3 (at%) coating

[0020] (1) Coating preparation method

[0021] Deposition of Ti on Titanium Alloy Using SBH-5115D Magnetron Sputtering Apparatus 39 -Al 49 -Cr 9 -Ag 3 (at%) coating. Ti for sputtering target 39 -Al 49 -Cr 9 -Ag 3 (at%) alloy, the size is 380 mm × 126 mm × 7 mm, and the size of the matrix as-cast alloy is 10 mm × 10 mm × 2.5 mm. Before sputtering, the substrate samples were polished with No. 600 sandpaper, and then ultrasonically cleaned with acetone for 15 min. The sputtering parameters are as follows: the degree of vacuum is 0.5×10 -2 Pa, the argon pressure is 0.2-0.3 Pa , The substrate temperature is 200 0 C, the power is 1800 W, and the sputtering time is 8 h. Rotary sputtering.

[0022] (2) High temperature salt corrosion experiment

[0023] The high temperature hot corrosion adopts the salt immersion method, and the experimental temperature is 900 o c. Th...

Embodiment 3

[0024] Embodiment 3 preparation alloy composition is Ti 45 -Al 47 -Cr 7 -Ag 2 (at%) coating

[0025] (1) Coating preparation method

[0026] Deposition of Ti on Titanium Alloy Using SBH-5115D Magnetron Sputtering Apparatus 45 -Al 47 -Cr 7 -Ag 2 (at%) coating. Ti for sputtering target 45 -Al 47 -Cr 7 -Ag 2 (at%) alloy, the size is 380 mm × 126 mm × 7 mm, and the size of the matrix as-cast alloy is 10 mm × 10 mm × 2.5 mm. Before sputtering, the substrate samples were polished with No. 600 sandpaper, and then ultrasonically cleaned with acetone for 15 min. The sputtering parameters are as follows: the degree of vacuum is 0.5×10 -2 Pa, the argon pressure is 0.2-0.3 Pa , The substrate temperature is 200 0 C, the power is 1800 W, and the sputtering time is 8 h. Rotary sputtering.

[0027] (2) High temperature salt corrosion experiment

[0028] The high temperature hot corrosion adopts the salt immersion method, and the experimental temperature is 900 o c. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com