High-temperature-resistant hole sealing agent for hot-dip plating sink roll as well as preparation method and coating method of high-temperature-resistant hole sealing agent

A technology of sealing agent and submerged roller, which can be used in coatings, anti-corrosion coatings, fire-resistant coatings, etc., and can solve problems such as difficulty in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A hot dip-plated hydrophone resistant to high temperature sealing agent is mainly from 100 parts of silica sol, 100 parts of aluminum sol, 100 parts of tetramethoxysilane, 104 parts of the boron nitride dispersion, nitrate 1.82 The mixture of parts and micro-hydrochloric acid solutions is formed.

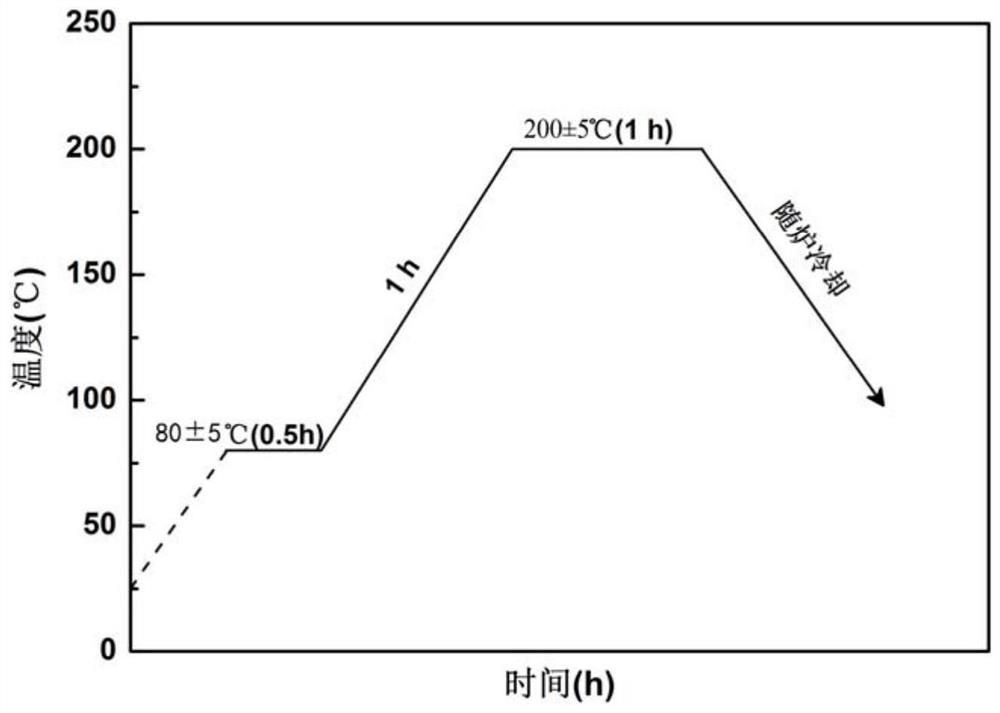

[0040] The preparation method of thermal dip plating aperture resistant to high temperature sealing agent, including the following steps:

[0041] Step 1, mixed the silica sol with the aluminum sol by mass 100: 60, under room temperature, and the rotation speed was stirred for 1 hour.

[0042] Step 2, the above-mentioned step 1, the aluminum composite sol with tetramethoxysilane is mixed by mass 100: 62.5, under room temperature, and the rotation speed is 500 rpm for 3 hours.

[0043] Step 3, in the above-described step 2, an aluminum composite sol with a mixture of tetrametoxysilane (HBN) dispersion, the added boron nitride dispersion and the mixture of mixed liquid obtained by ...

Embodiment 2

[0048] The thermal dip plating of the present embodiment is mainly controlled by: 100 parts of silica sol, 100 parts of aluminum sol, 240 pieces of tetraethoxysilane, 264 servic boron nitride dispersions, nitrate 7.04 The mixture of parts and micro-hydrochloric acid solutions is formed.

[0049] The preparation method of thermal dip plating aperture resistant to high temperature sealing agent, including the following steps:

[0050] Step 1, mixing the silica sol with the aluminum sol by mass 100: 100, under room temperature conditions, stirring at 450 rpm for 1.5 hours.

[0051] Step 2, the above-mentioned step 1, the aluminum composite sol with tetraethoxysilane is mixed by mass 100: 120, under room temperature, and the rotation speed is 400 rpm for 3 hours.

[0052] Step 3, in the above-described step 2, the aluminum composite sol with tetraethoxysilane is added to the mixture of tetraethoxysilane (HBN) dispersion, and the mixture of boron nitride dispersion obtained from the bo...

Embodiment 3

[0057] Another hot dip plating pressure resistant to high temperature sealing agent is mainly from 100 parts of silica sol, 80 parts of aluminum sol, 198 parts of methyltrimethoxysilane, 189 son boron nitride dispersions, nitrate 4.54 parts and micro-hydrochloric acid solutions were mixed.

[0058] The preparation method of thermal dip plating aperture resistant to high temperature sealing agent, including the following steps:

[0059] Step 1, mixing the silica sol with the aluminum sol by mass 100: 80, under room temperature, and the rotation speed is 500 rpm for 2 hours.

[0060] Step 2, the above-mentioned step 1, the aluminum composite sol with the methyltrimethoxysilane is mixed at a mass ratio of 100: 110, and the rotation speed is 500 rpm for 3 hours under room temperature conditions.

[0061] Step 3, the silicon obtained by the above step 2, the aluminum composite sol is added to the mixture of the methyltrimethoxysilane (HBN) dispersion, and the boron nitride dispersion l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com