Patents

Literature

97results about How to "Excellent high temperature oxidation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

TiSiN+ZrSiN composite nanometer coated cutting tool and preparation method thereof

InactiveCN103273687AImprove friction and wear propertiesReduce residual stressVacuum evaporation coatingSputtering coatingAlloyDry machining

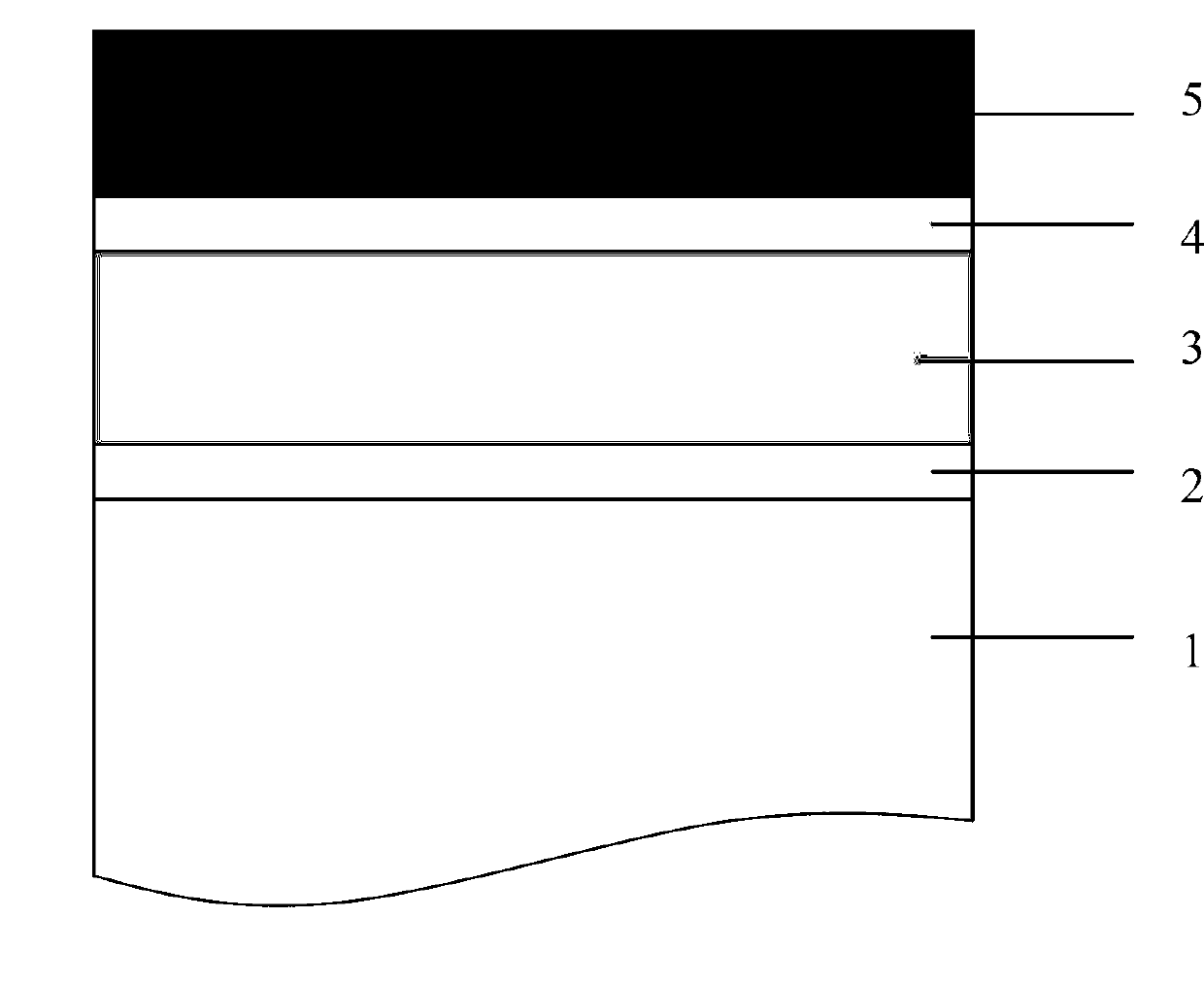

The invention provides a TiSiN+ZrSiN composite nanometer coated cutting tool and a preparation method thereof and belongs to the field of mechanical machining. A base material of the coated cutting tool is a hard alloy or high-speed steel. The TiSiN+ZrSiN composite nanometer coated cutting tool is manufactured by adopting a multi-arc ion plating+intermediate frequency magnetron sputtering method. The TiSiN+ZrSiN composite nanometer coated cutting tool is of multilayered structure, a ZrSiN coating is formed on the surface of the cutting tool, a TiZrSiN transition coating is formed between the ZrSiN coating and a TiSiN coating, and a Ti transition coating is formed between the TiSiN coating and a substrate, wherein the atomic percentage of Si content in the TiSiN coating and the ZrSiN coating is 6%-10%. The TiSiN+ZrSiN composite nanometer coated cutting tool well combines the high hardness of the TiSiN coating and the low friction coefficient of the ZrSiN coating and has high hardness, good friction and wear property and excellent high-temperature oxidation resistance; and the bonding can be alleviated in the cutting process, and the wearing of the cutting tool is reduced, so that the service life of the cutting tool is prolonged. The coated cutting tool can be widely applied to drying machining and machining of difficult-to-machine materials.

Owner:SHANDONG UNIV

Combination circulation steam turbine lubricating oil composition

ActiveCN101240212AExcellent high temperature oxidation resistanceMeet lubrication needsAdditivesAntioxidantRust

The invention relates to a combined-cycle gas turbine lubricant combination which is suitable to be used in a large-scale gas steam combined-cycle gas turbine, and the composition and content of the combined-cycle gas turbine lubricant combination by weight percentage of antioxidant of 0.1 to 2 percent, anti-wear agent of 0.01 to 1 percent, no gray rust-proof agent of 0.01 to 1 percent, metal deactivating agent of 0.01 to 1 percent, anti-foam agent of 0.001 to 1 percent, the allowance is based oil, which is Class II or Class III paraffin-based oil, and the sulfur content is less than 0.03 percent, the lubricant combination of the invention has an extremely long induction period of oxidation and excellent performance of high temperature oxidation, excellent extreme pressure antifriction property and corrosion, good water separation, air separation and filterability, and can well meet the lubricating demand of large-scale combined cycle gas turbine.

Owner:PETROCHINA CO LTD

PVD nano multiple-layer coating for cutting stainless steel and preparation method thereof

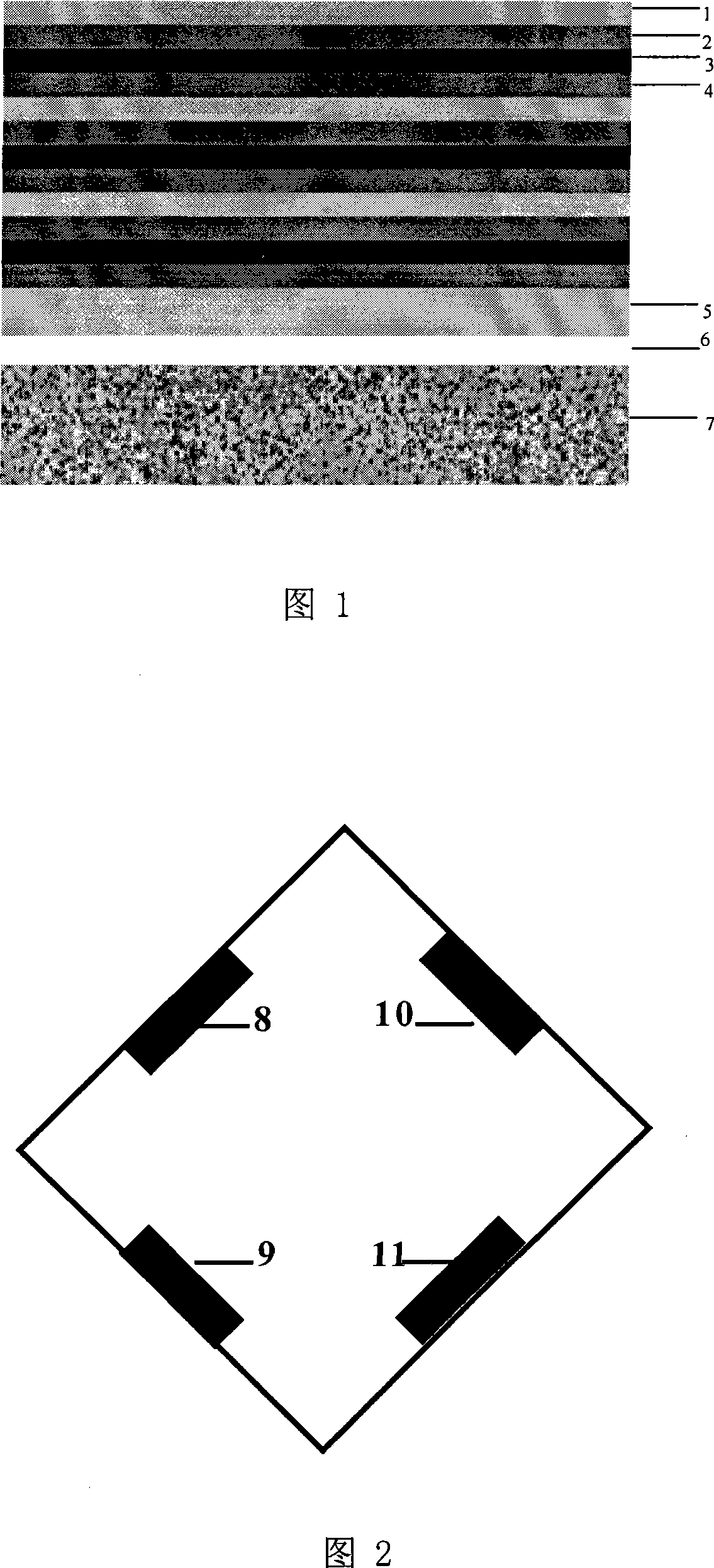

InactiveCN101200797AHas high temperature oxidation resistanceExcellent high temperature oxidation resistanceLayered productsVacuum evaporation coatingSurface cleaningOxidation resistant

The invention discloses a PVD nanometer multiple-layer coating used for cutting stainless steel and a preparation method thereof. The specific manufacturing process is as follows: firstly, implementing the surface cleaning treatment on carbide base; secondly, adopting a multiple targets magnetic sputtering method to alternatively deposit the nanometer multiple-layer coating which takes TiN (Tix, Al1-x)N / (Tiy, Al1-y)N / (Tix, Al1-x)N as a modulation period on the rotating carbide base; adopting Ar2 as the sputtering gas. The flow of Ar is 180-300cm3 / s, the partial pressure is 1.7-9.0'10<-1>Pa, the reaction gas is N2, and the total pressure is controlled through controlling the partial pressure of N2. The invention introduces TiAlN with high Al content and perfect high temperature oxidation resistance into a multiple-layer coating material system, improves the high temperature oxidation resistance and the hardness of the coating, enhances the toughness of the coating through the microstructure optimization design and enables the coating to obtain both the high temperature oxidation resistance and excellent mechanical properties. The nanometer multiple-layer coating prepared through the invention is provided with great application value in the stainless steel cutting process.

Owner:CENT SOUTH UNIV

Nickel alloy composition

InactiveUS20060239852A1Save timeExcellent high-temperature oxidation resistanceBlade accessoriesMachines/enginesOxidation resistantAluminium

Owner:ROLLS ROYCE PLC

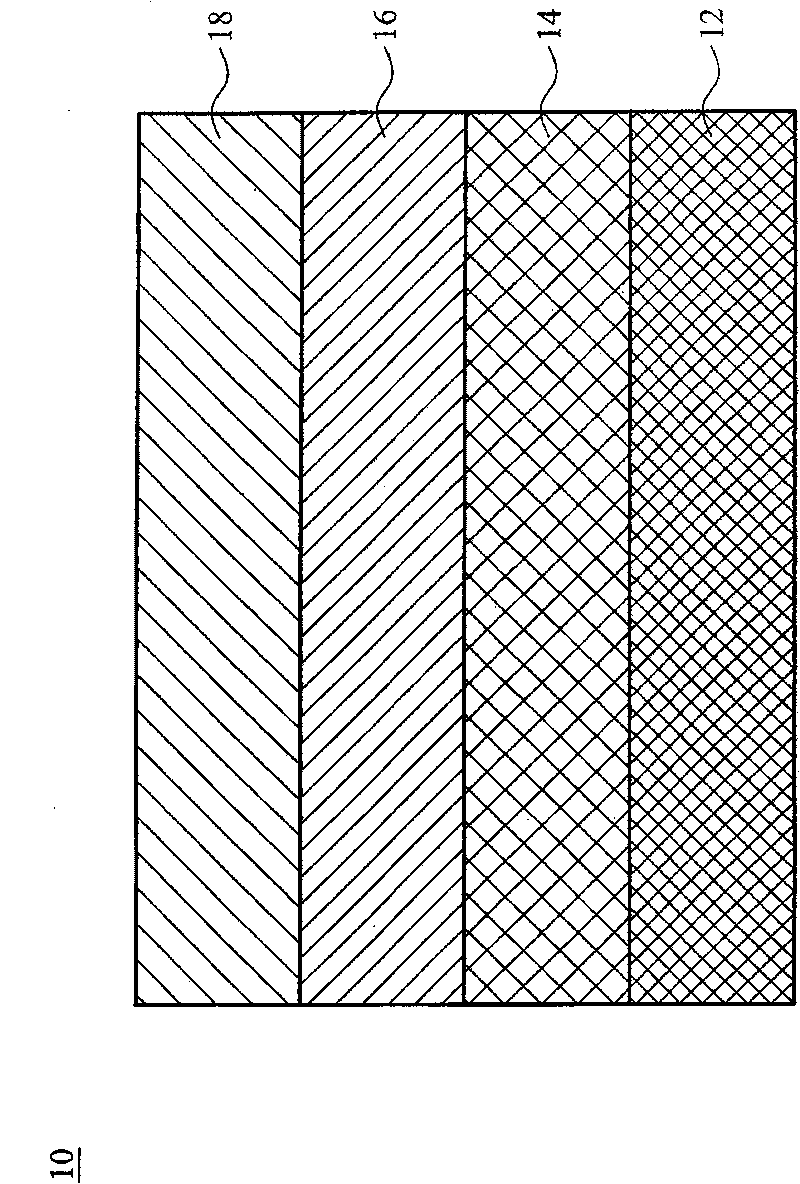

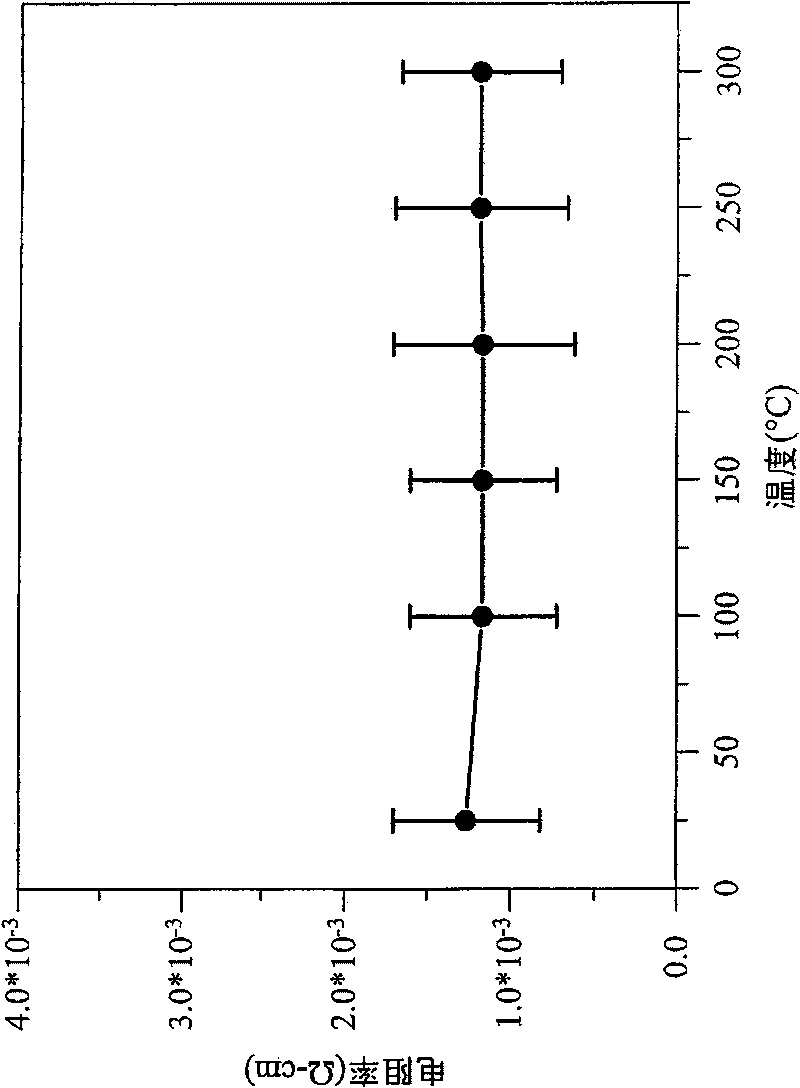

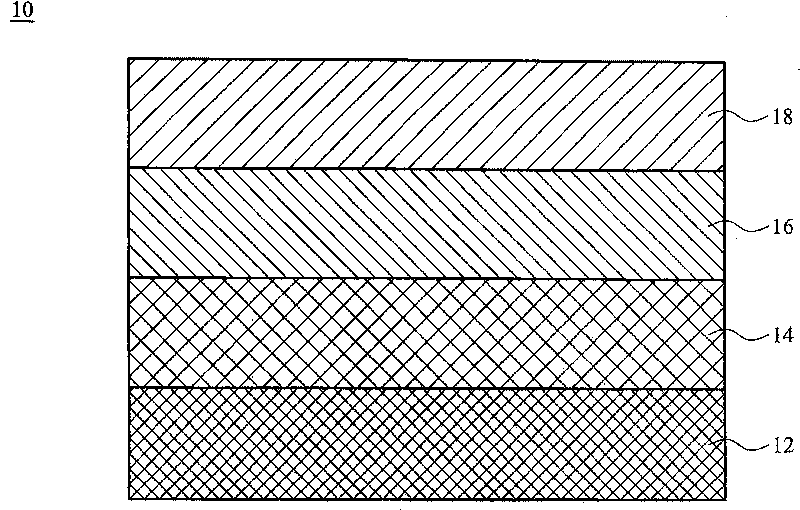

Compound cathode foil and solid electrolytic capacitor comprising same

ActiveCN101752091AExcellent high temperature oxidation resistanceHigh abrasion resistance and adhesionSolid electrolytic capacitorsCapacitor electrodesAluminiumAluminum electrolytic capacitor

The invention provides a compound cathode foil comprising an aluminum base material, a metal layer, a metallic carbide layer and a carbon layer, wherein the metal layer is formed on the aluminum base material, and metal is selected from a class composed of the free IVB group elements, the VB group elements and the VIB group elements; the metallic carbide layer is formed on the metal layer; and the carbon layer is formed on the metallic carbide layer. The invention also provides a solid electrolytic capacitor comprising the compound cathode foil.

Owner:IND TECH RES INST

WC-Co hard alloy with binding phase enhanced by Ni3Al and preparation method thereof

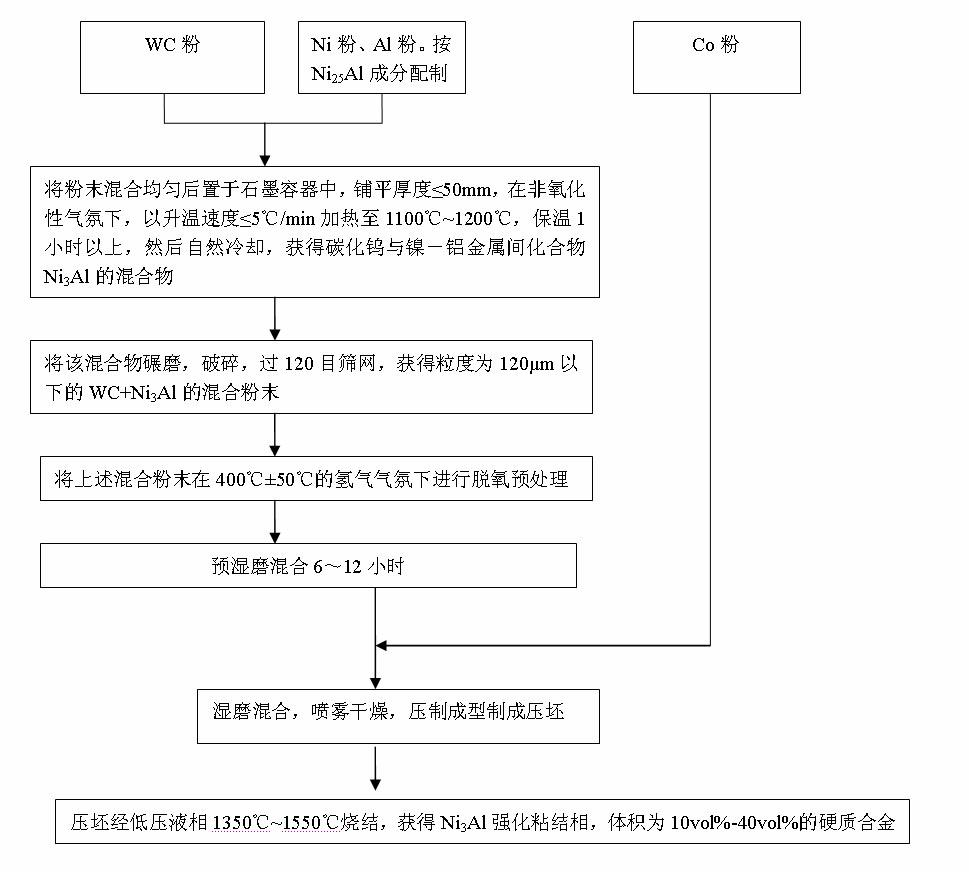

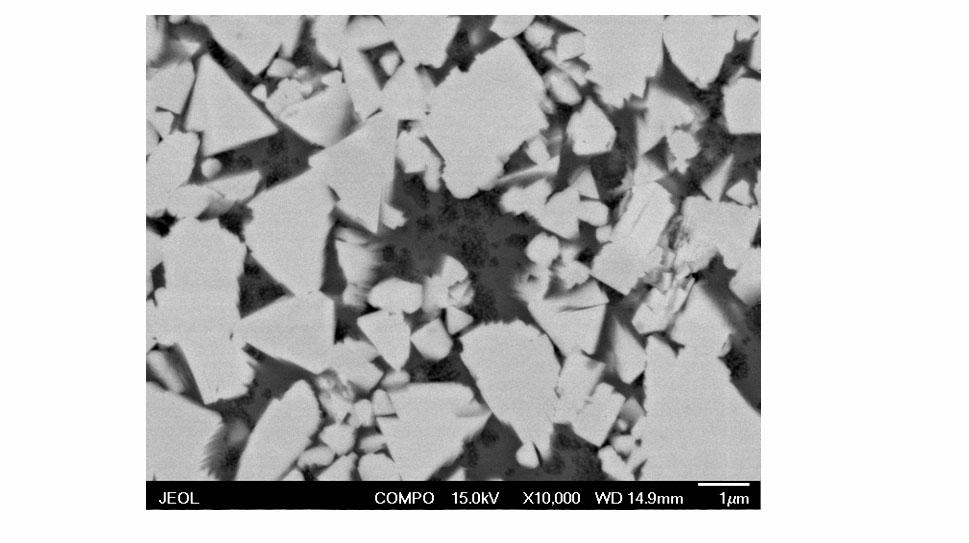

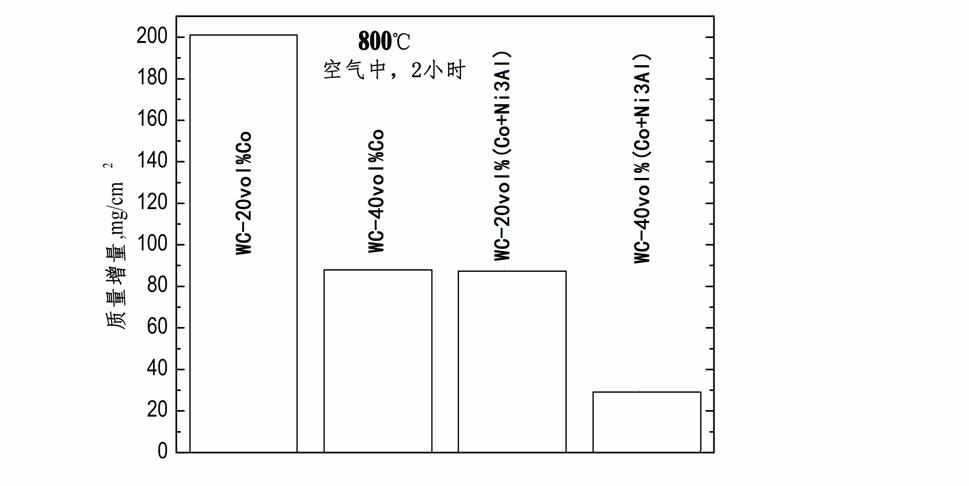

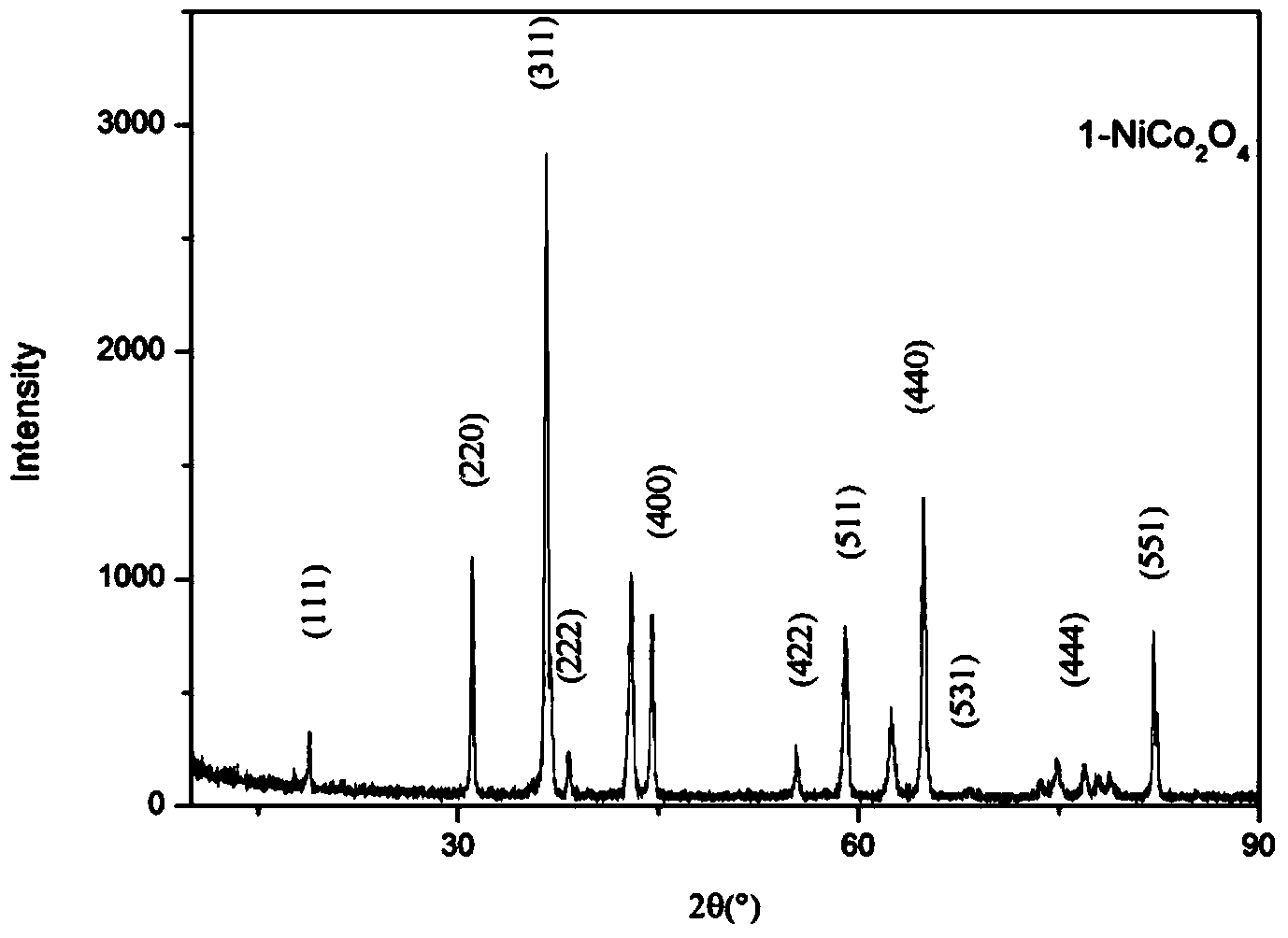

The invention discloses a toughness-enhanced hard alloy with a Co binding phase enhanced by Ni3Al. The hard phase of the hard alloy is WC, and the binding phase is Co and Ni3Al of which the volume percent is 10-40%. The preparation method of the hard alloy comprises the following sequential steps of: uniformly mixing 2.07-16.05wt% of Ni powder and Al powder with WC powder according to a composition ratio of Ni25Al; placing the uniformly mixed powder in a graphite container at the thickness not more than 50 mm, heating to 1100-1200 DEG C in a non-oxidative atmosphere at a speed not more than 5DEG C / min, maintaining the temperature for more than 1 hour, and naturally cooling to obtain a mixture of WC and Ni3Al; grinding, pulverizing and screening to obtain mixed powder with a particle sizebelow 120 mu m; carrying out deoxidation pretreatment in 400+ / -50 DEG C hydrogen; carrying out pre-wet-grinding and mixing on 83.26-97.62wt% of mixed powder obtained after deoxidation pretreatment for 6-12 hours, then adding the balance of Co powder, and carrying out wet grinding for 18-36 hours; carrying out spray drying and pressure shaping on the wet-ground mixed material; and carrying out low-pressure liquid-phase sintering on the pressed blank at 1350-1550 DEG C to obtain the WC-Co hard alloy with the binding phase enhanced by Ni3Al. The hard alloy has the advantages that: a gamma' phaseis dispersed and distributed in the binding phase, the binding phase is uniformly distributed, and the alloy has high compactness, high strength, good wear resistance and excellent high-temperature oxidation resistance and corrosion resistance.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Solid oxide fuel cell stainless steel bipolar connector and manufacturing method thereof

InactiveCN104393315AExcellent high temperature oxidation resistanceGood electronic conductivityFinal product manufactureFuel cell detailsOxideIron based

The invention discloses a solid oxide fuel cell stainless steel bipolar connector and a manufacturing method thereof. The iron-based connector comprises a base and a surface modification layer arranged on the surface of the base. The base is a ferrite stainless steel plate with thickness of 0.3-3.0mm and chromium content of 10-30wt%. The surface modification layer is a spinel-structure alloy oxide with thickness of 3-30 microns. The solid oxide fuel cell stainless steel bipolar connector has excellent high temperature oxidation resistance and good electronic conductivity. The manufacturing method has simple processes and realizes compact combination of the spinel oxide modification layer and the base. The solid oxide fuel cell stainless steel bipolar connector has excellent interfacial compatibility, produces modification layer and base synergism and can be massively produced easily.

Owner:DALIAN MARITIME UNIVERSITY

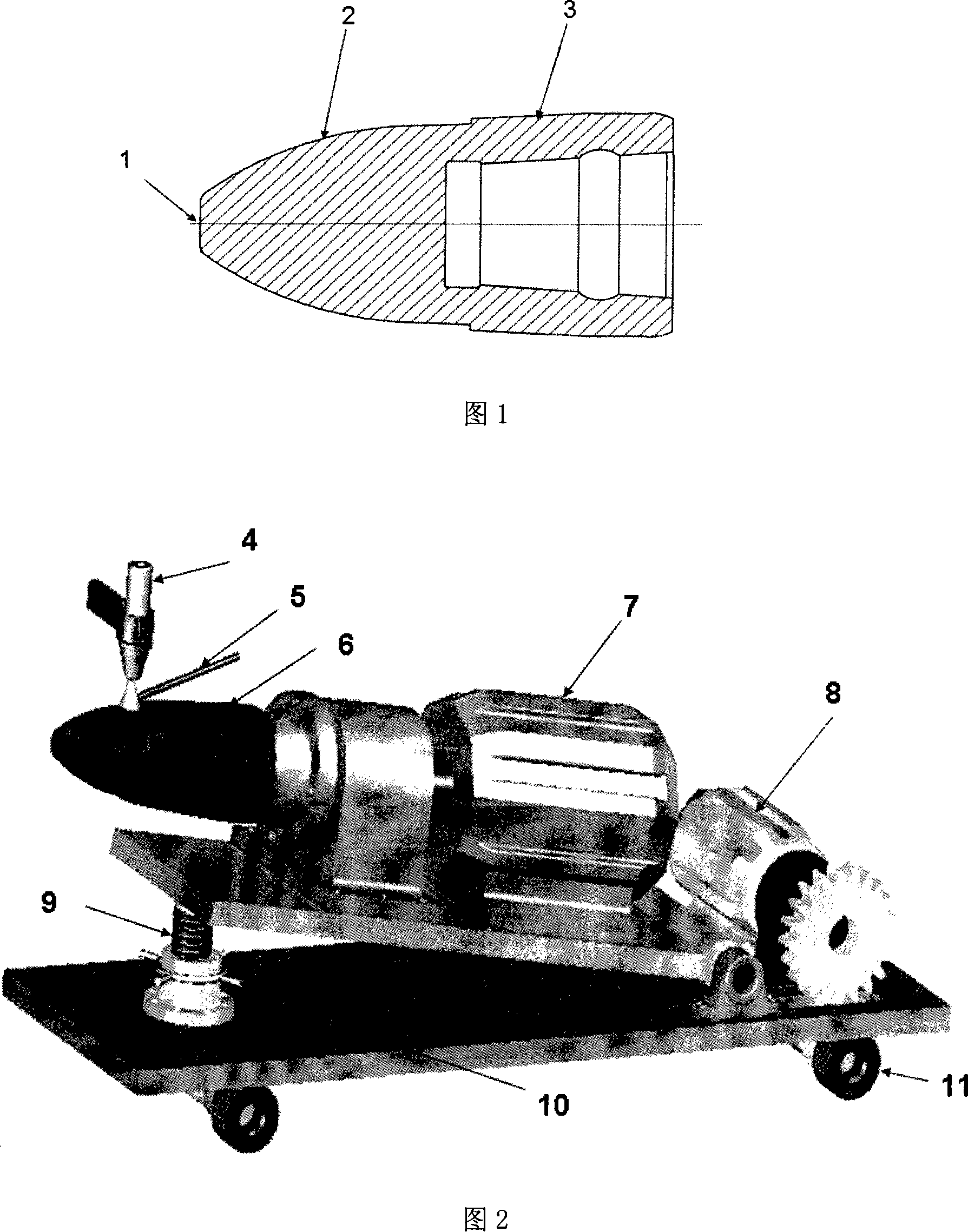

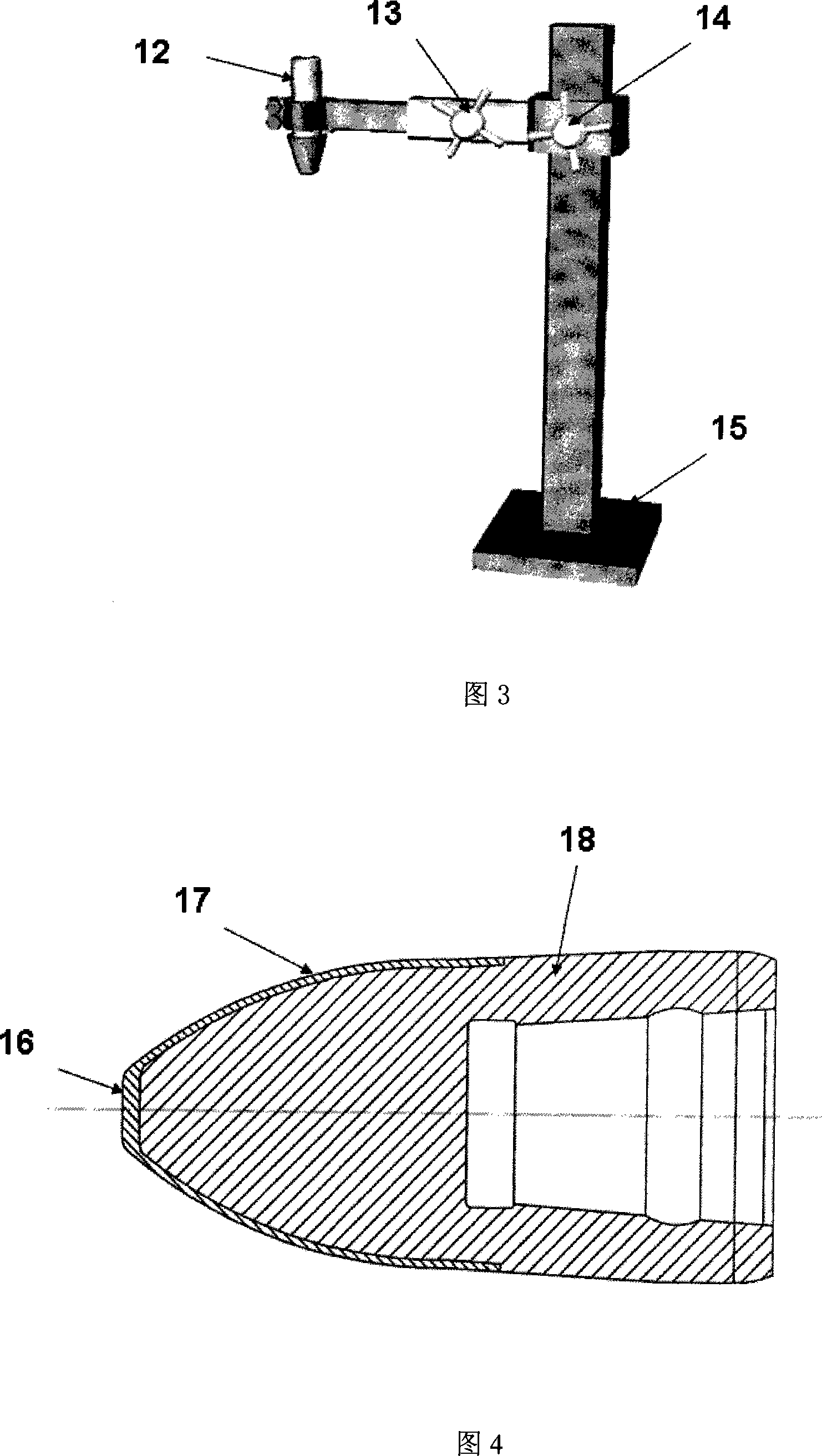

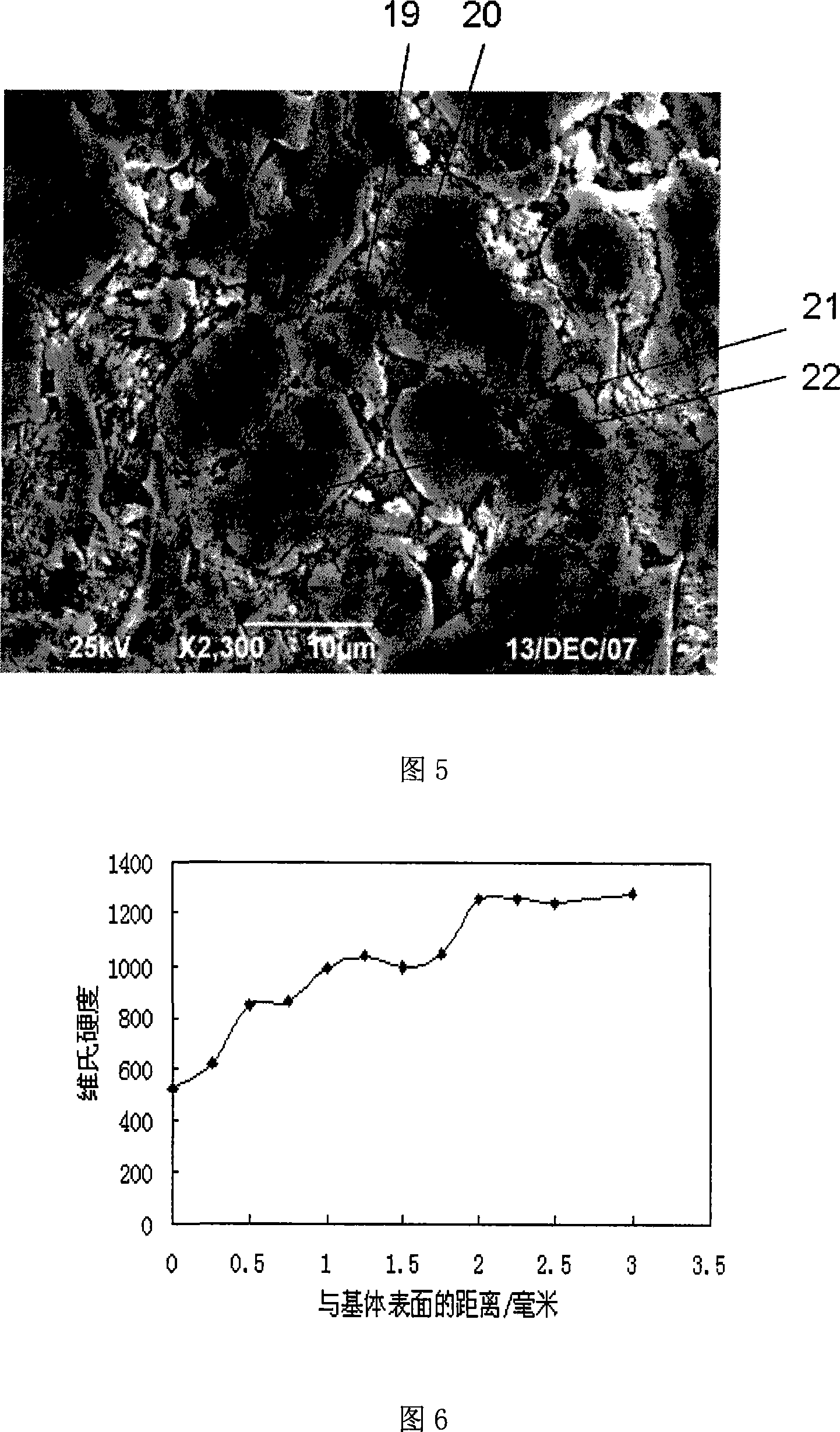

Ceramic-metallic composite cladding layer top head for tube inserting machine and method for producing the same

InactiveCN101195126AExcellent high temperature oxidation resistanceImprove high temperature strengthMolten spray coatingArc welding apparatusApplication areasCeramic metal

The invention discloses a plug of a cladding layer which is made of ceramic-metal composite materials and used for pipe lining machines and a process for preparation. The invention belongs to the application field of metal pipe rolling mills. The cladding layer which is made of the ceramic-metal composite materials and has thickness of 2.5-5mm is clad on the working conical surface of the plug and nasal portion end face through using a cladding method of plasma arcs. The cladding layer and matrix materials are bonded metallurgically with a process that die steel and structural steel are taken as the matrix materials, the matrix materials are processed into a designed size of the plug, the cladding method of plasma arcs is used to enable powder-cored wires to be clad on the working conical surface of the plug and the nasal portion end face under high-temperature effects of the plasma arcs, the cladding layer which is made of the ceramic-metal composite materials and has the thickness of 2.5-5mm is obtained through single-layer claddings and lapping claddings. The geometry size of a nasal portion of the plug can reach a designed size through turning and grinding to the cladding layer. The invention has the advantages of long service life, non-molybdenum and low cost, and the invention increases pipe lining quality.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

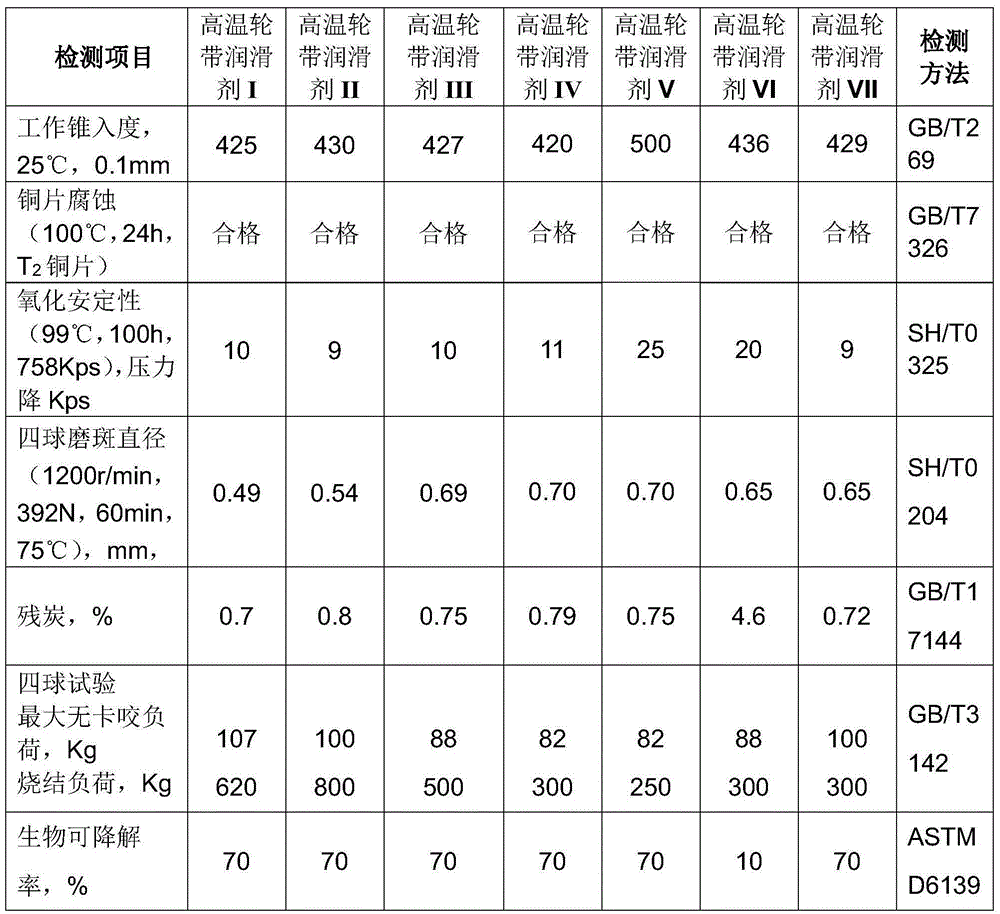

Lubricant and preparation method thereof

ActiveCN105038925AInhibition of oxidation failureReduce labor intensityLubricant compositionBase oilTackifier

The invention provides a lubricant and a preparation method thereof. The lubricant is prepared from the following components by mass percent: (a) 50 to 59 percent of base oil, (b) 10 to 20 percent of a tackifier, (c) 1 to 6 percent of an anti-wear reagent at extreme pressure, (d) 1 to 5 percent of an antioxygen, (e) 20 to 35 percent of a solid additive, and (f) 0.5 to 5 percent of a dispersant. The lubricant has better high-temperature lubrication adhesion, high temperature resistance and extreme pressure antiwear property, and is specially suitable for lubrication of a high temperature tyre.

Owner:埃优诺特种新材料科技(山东)有限公司

Silicon carbide short fiber toughened and strengthened silicon carbide ceramics and preparation method thereof

The invention discloses a preparation method of silicon carbide short fiber toughened and strengthened silicon carbide ceramics, which takes silicon carbide powder, yttrium aluminum garnet and silicon carbide short fiber as the main materials and sequentially comprises the following steps of: 1) adding the main materials, a caking agent and a dispersant into de-ionized water and preparing water-based silicon carbide slurry after ball-mill mixing; 2) adopting a sponging drying technique to carry out spray drying to the water-based silicon carbide slurry; 3) adopting 160-200MPa to carry out dry pressing and shaping to the obtained strengthened silicon carbide palletizing powder to obtain a silicon carbide biscuit; and 4) arranging the silicon carbide biscuit in a vacuum pressureless sintering furnace for sintering to obtain the silicon carbide short fiber toughened and strengthened silicon carbide ceramics. The invention simultaneously provides the silicon carbide short fiber toughened and strengthened silicon carbide ceramics prepared by the method. The silicon carbide ceramics is characterized by larger fracture toughness, high mechanical strength, and the like.

Owner:ZHEJIANG UNIV

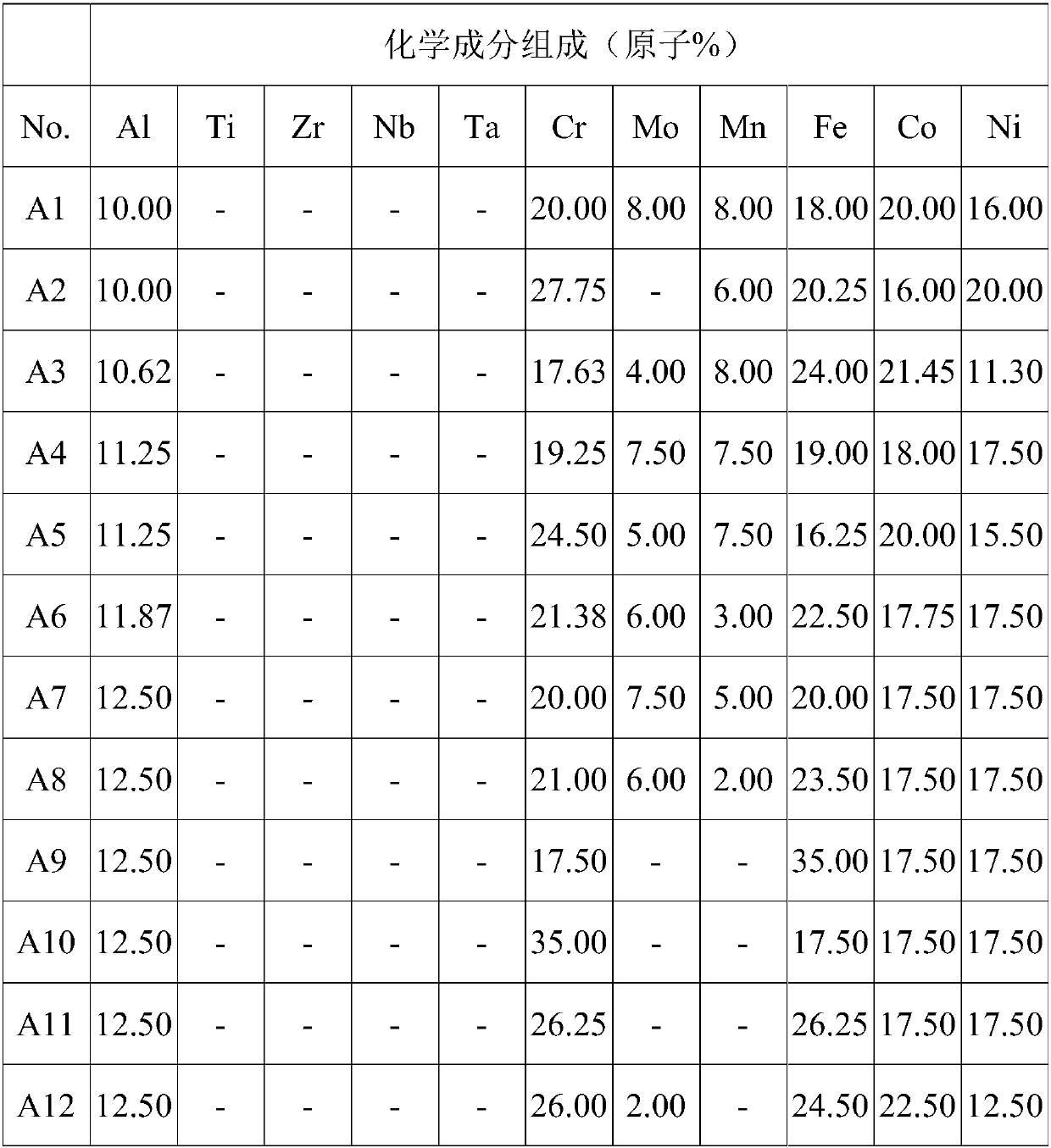

BCC-based high-strength, high-entropy and high-temperature alloy for coherent precipitation of cubic nano particles

ActiveCN107557645AHigh strengthImprove high temperature performanceRoom temperaturePerformance index

The invention relates to a BCC-based high-strength, high-entropy and high-temperature alloy for coherent precipitation of cubic nano particles, and belongs to the technical field of new materials. Thealloy comprises Fe, Co, Ni, Mn, Cr, Mo, Nb, Ta, Al, Ti and Zr, and the atomic percentage expression of the alloy composition is Alx(Ti, Zr)y(Nb, Ta)z(Cr, Mo, Fe)m(Co, Ni)n, where x=5-18%, y=0-55%, z=0-55%, m=0-60%, n=0-40%, and x+y+z+m+n=100%. The material performance indexes are: tensile strength Sigma b=1200-2150 MPa, and hardness HV=550-650 at room temperature; Sigma b=350-900 MPa, and HV=120-350 at 700 DEG C; Sigma b=200-450 MPa, and HV=70-200 at 1000 DEG C. According to the BCC-based high-strength, high-entropy and high-temperature alloy provided by the invention, through composition design, the organization and control of the coherent precipitation of BBC / B2 cubic particles are achieved, so that the maximum improvement of the alloy strength is ensured, and the high-temperature strength, creep resistance, oxidation resistance and corrosion resistance of the alloy are improved. The alloy is a kind of novel high-temperature alloy.

Owner:DALIAN UNIV OF TECH

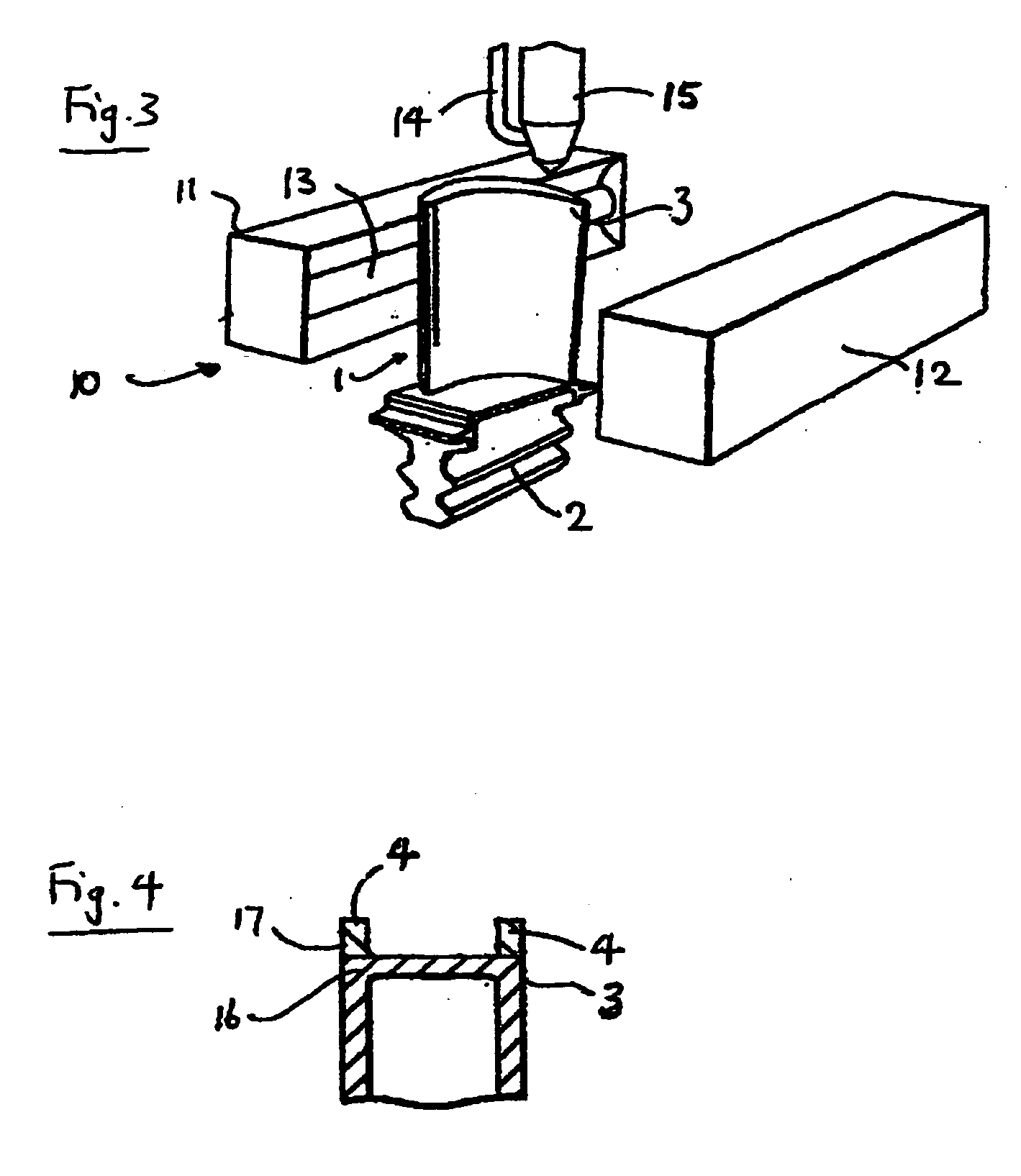

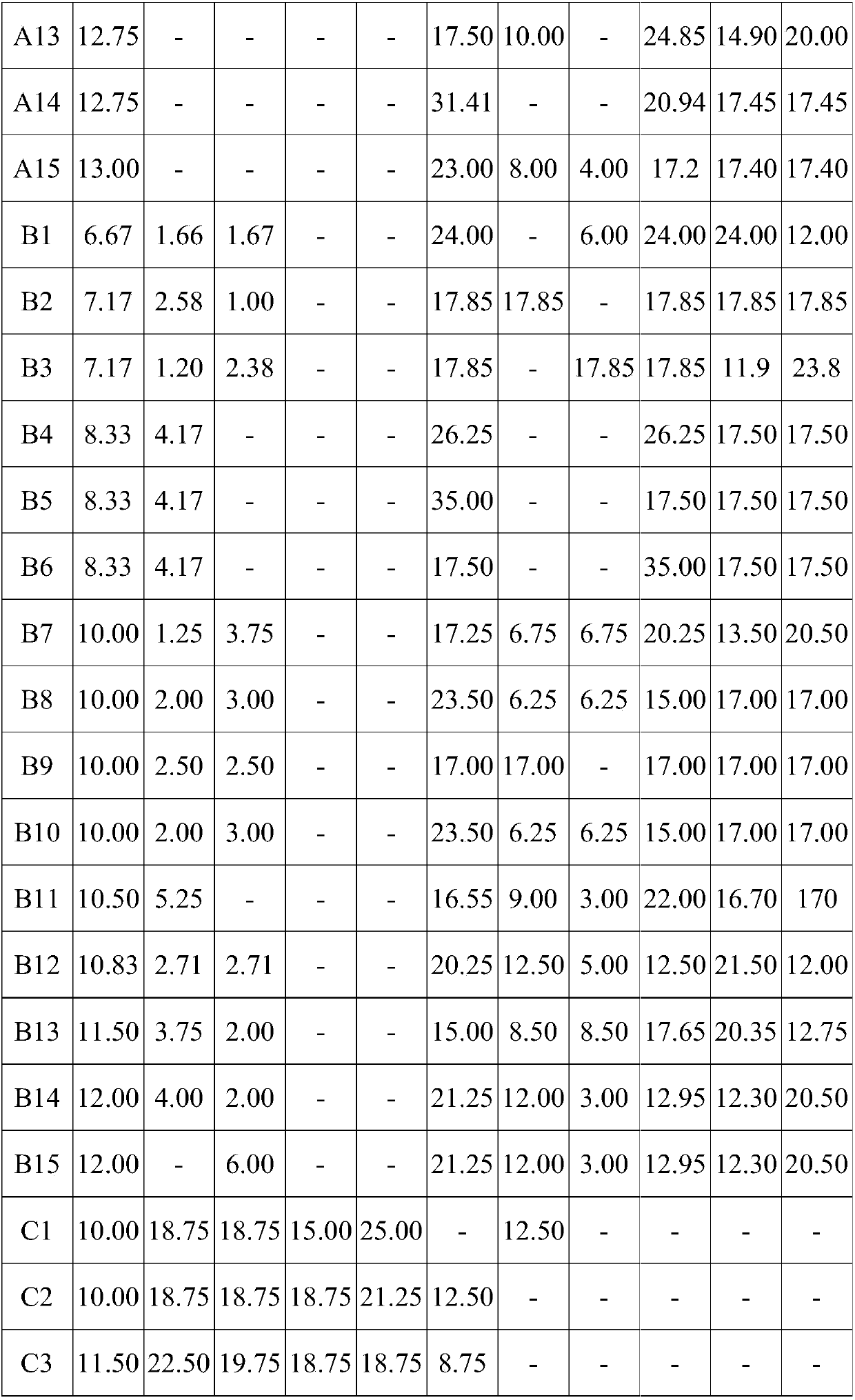

Manufacturing method of wear-resisting lining plate for rolling mill inlet guide

The invention discloses a manufacturing method of a wear-resisting lining plate for a rolling mill inlet guide, and belongs to the field of a wear-resisting lining plate. The manufacturing method comprises the steps: step one, a substrate is manufactured; step two, the substrate is subjected to surface degreasing and activation; step three, the substrate is preheated; step four, flame spray welding is carried out; and step five, post processing is carried out. The substrate material in the invention is forging 40 Cr hardened and tempered steel, and the material of a spray welding layer is self-fluxed alloy powder. The wear-resisting lining plate has the advantages that the tenacity is excellent; the surface hardness is high; the abrasion performance is excellent; the service life of the wear-resisting lining plate is obviously prolonged; the production efficiency of a rolling mill and the product dimensional precision are ensured; the production cost is reduced; according to the characteristic of a flame spray welding technology, after the spray welding layer is worn, spraying and refusion can be carried out repeatedly; the abrasive resistance is equivalent to the abrasive resistance after first spray welding, so that the wear-resisting lining plate which loses efficacy can be easily repaired.

Owner:HEFEI ORIENT METALLURGICAL EQUIP

High-strength Al-Cr-SC alloy through 3D printing

ActiveCN111001800AReduce anisotropyEasy to manufactureAdditive manufacturing apparatusIncreasing energy efficiencyHigh densityMetal powder

The invention discloses a high-strength Al-Cr-SC alloy through 3D printing. The metal powder for a high-strength aluminum-chromium alloy through 3D printing comprises the following components, by masspercentage, 2.5-10% of Cr, 0.5-2.5% of Mg, 0.1-0.9% of Sc, 0.2-0.7% of Zr, 0.1-0.3% of Si, 0.2-0.45% of Mn, 0.1-0.35% of Fe, 0.1-0.25% of Ti, 0.05-0.5% of AlCl3 powder, 0.05-0.3% of CaCl2 + NaCl andthe balance Al. The preparation method of the metal powder comprises the following steps that Al, Cr, Mg, Sc, Zr, Si, Mn, Fe, Ti pure metal block raw materials are weighed to be heated and melted, atomized for powder making, sieving and heat preservation for drying are conducted, AlCl3, CaCl2 and NaCl powder are added, and milling and mixing are conducted. According to the high-strength Al-Cr-SC alloy through 3D printing, the printed aluminum alloy part has no cracks and has high density, and the mechanical properties, wear resistance, corrosion resistance and high temperature and oxidation resistance are high.

Owner:CENT SOUTH UNIV +1

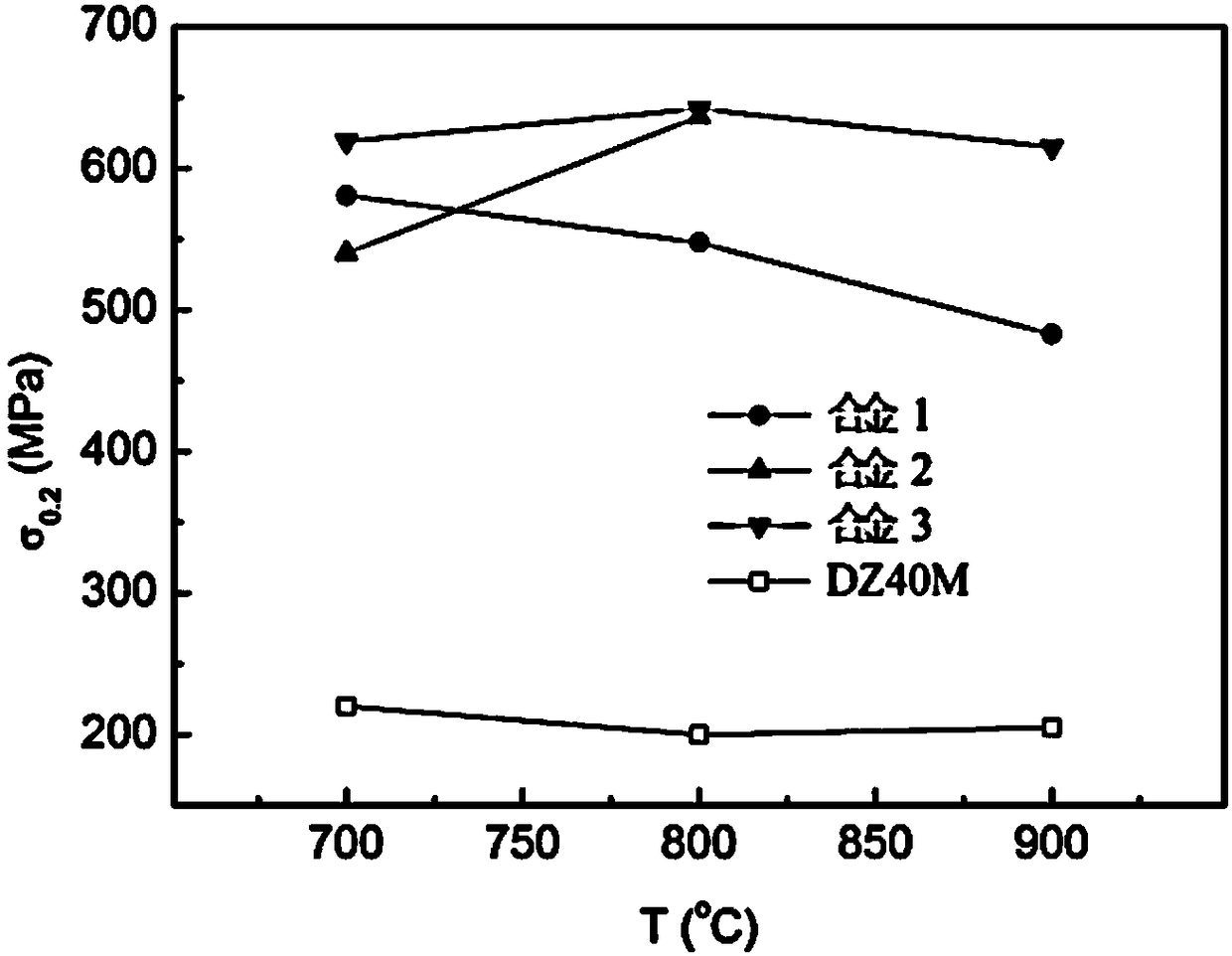

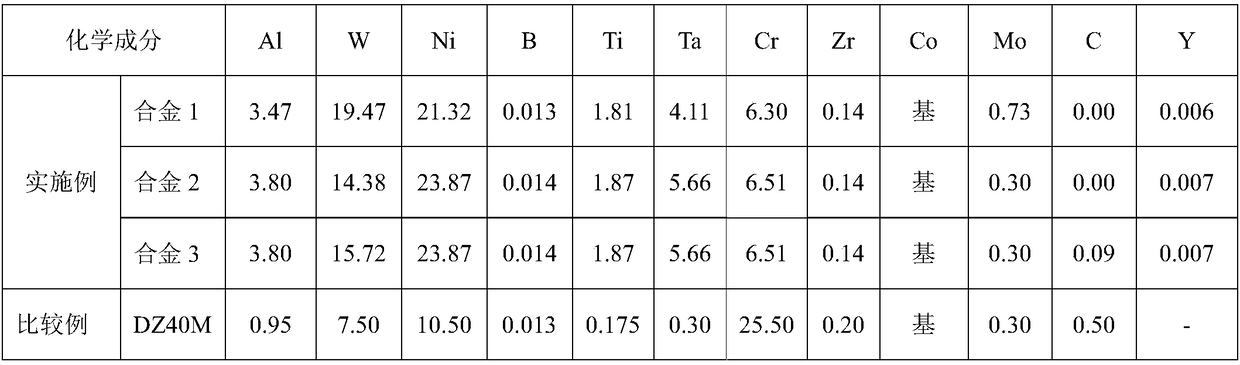

High-strength gamma'-phase-strengthened cobalt-based high-temperature alloy

InactiveCN108411163AGood high temperature oxidation resistanceExcellent high temperature corrosion resistanceStatorsMachines/enginesElemental compositionWorking temperature

The invention discloses a high-strength gamma'-phase-strengthened cobalt-based high-temperature alloy which is mainly prepared from the elements: Co, Ni, Al, W, Cr, Ta, Ti and the like. The high-strength gamma'-phase-strengthened cobalt-based high-temperature alloy is prepared from the elements in percentage by mass: 20.0 to 24.5 percent of Ni, 14.5 to 19.5 percent of W, 3.4 to 6.0 percent of Al,3.0 to 6.8 percent of Cr, 4.0 to 5.8 percent of Ta, 1.5 to 2.0 percent of Ti, 0.3 to 1.0 percent of Mo, 0 to 0.14 percent of Zr, 0.01 to 0.015 percent of B, 0 to 0.1 percent of C, 0 To 0.007 percent of Y, and the balance Co. A main composition phase of the alloy is (a) cobalt-based solid solution gamma+intermetallic compound gamma', or (b) cobalt-based solid solution gamma+intermetallic compound gamma'+MC type carbide+crystal boundary disperse precipitation intermetallic compound mu. The alloy can be applied to turbo machine hot end components in the industrial fields such as metallurgy, petroleum, energy and electric power, and the working temperature of the alloy can reach to 900 DEG C. The alloy is higher in high-temperature strength; the yield strength of the alloy under the high temperature condition (700 to 900 DEG C) is about 2 to 3 times of DZ40M; and the endurance property, the high temperature oxidation resistance and the hot corrosion performance of the alloy are excellent and superior to a traditional cobalt-based high-temperature alloy.

Owner:NORTHEASTERN UNIV

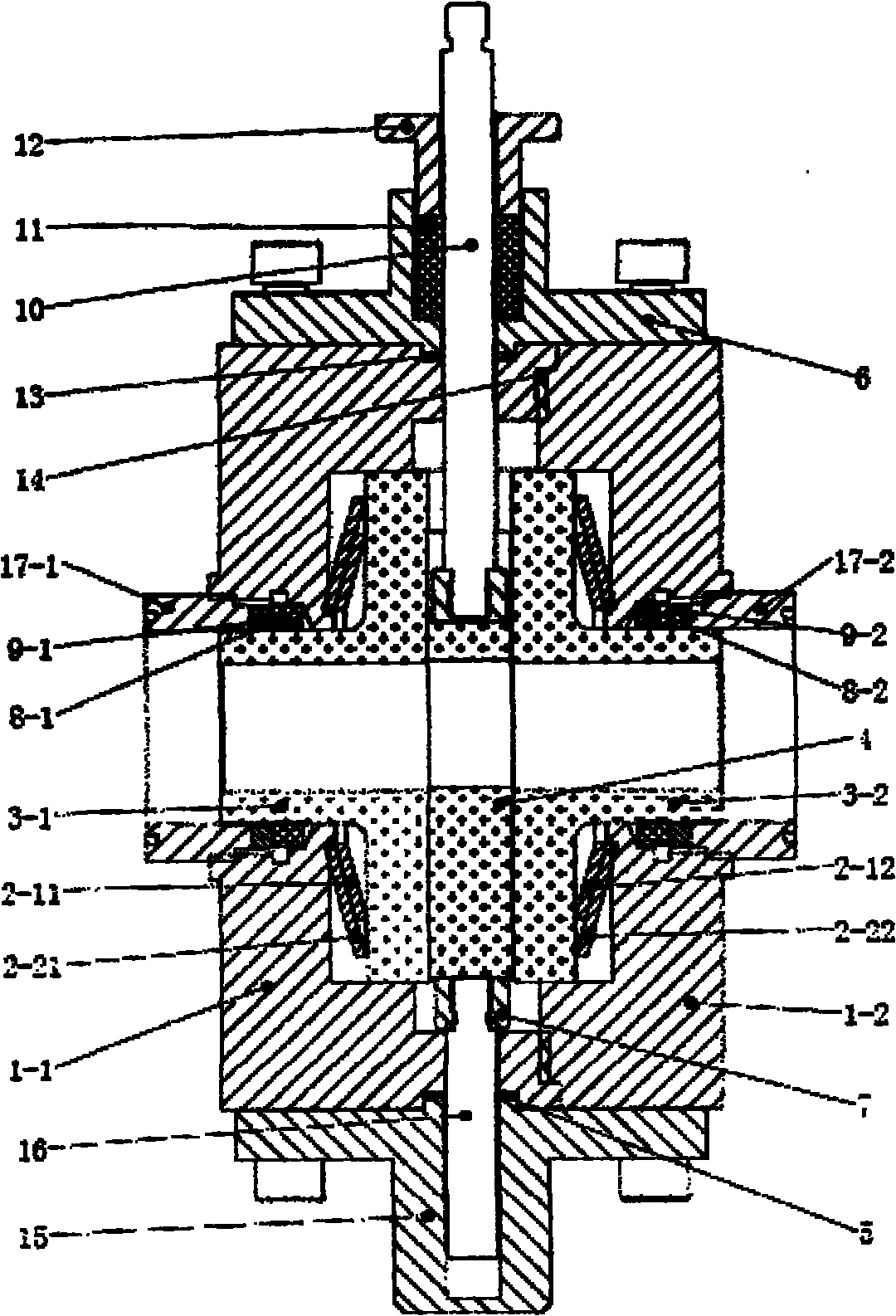

High-hardness TiSiBN nano-composite structure protective coating and preparation method thereof

InactiveCN104805408AHigh hardnessExcellent high temperature oxidation resistanceLayered productsVacuum evaporation coatingHigh loadRadio frequency

The invention relates to a high-hardness TiSiBN nano-composite structure protective coating and a preparation method thereof. The preparation method comprises the following steps: (1) cleaning a substrate and then carrying out ion cleaning; (2) preparing a TiB2 transition layer, namely feeding the substrate processed in the step (1) into a sputtering chamber and depositing a 200-300nm TiB2 transition layer, wherein a TiB2 target is controlled by a radio frequency cathode; (3) preparing a TiSiBN layer, wherein a TiSiB composite target is controlled by the radio frequency cathode, and a 2-5 mu. m TiSiBN nano-composite structure coating is deposited. The coating disclosed by the invention not only has ultrahigh hardness over 40GPa, but also has excellent high-temperature oxidation resistance and corrosion resistance, and can be used as a protective coating for high-speed and dry cutting tools and high-load-bearing equipment in other fields; the preparation method disclosed by the invention has the characteristics of simple process, high deposition speed, low cost, high bonding strength and the like, and has the advantages of high production efficiency, low energy consumption, relatively low requirement on equipment and the like.

Owner:SHANGHAI IKEN PRECISION TOOLS

Preparation method of nano beta-manganese dioxide-graphite oxide-polytetrafluoroethylene wear-resistant anti-friction composite material

The invention relates to a preparation method of a nano beta-manganese dioxide-graphite oxide-polytetrafluoroethylene wear-resistant anti-friction composite material. The method mainly comprises the following steps: preparing graphite oxide powder, carrying out ultraviolet irradiation and amination treatment on polytetrafluoroethylene powder, carrying out hydrothermal synthesis to prepare a nano beta-manganese dioxide-graphite oxide composite material, preparing mixed powder for preparing the nano beta-manganese dioxide-graphite oxide-polytetrafluoroethylene wear-resistant anti-friction composite material, and finally, sequentially carrying out cold compression molding and series heat treatment, thereby preparing the nano beta-manganese dioxide-graphite oxide-polytetrafluoroethylene wear-resistant anti-friction composite material. The nano beta-manganese dioxide-graphite oxide-polytetrafluoroethylene wear-resistant anti-friction composite material has the advantages of small friction factor, low wear rate, high heat stability, high mechanical strength and long service life, and can be widely used in the fields of chemical industry, machinery, aerospace and the like.

Owner:YANSHAN UNIV

Composite metal ceramic powder, furnace roller coated with same and preparation method thereof

ActiveCN101838767AImprove compactnessImprove structural uniformityMolten spray coatingChromium carbideSurface layer

The invention discloses a composite metal ceramic powder, a furnace roller coated with the same and a preparation method thereof. The composite metal ceramic powder contains the following components in percentage by weight: 35-70 percent of MCrAlY or MCrAlTaY, 25-45 percent of Cr3C2 and 5-20 percent of Na2Ti6O13 or K2Ti6O13, wherein M is Ni, Co or Ni-Co alloy. The furnace roller comprises a workpiece substrate and a coating sprayed on the workpiece substrate, wherein the coating comprises a surface layer and a bottom layer or a single surface layer, and the surface layer is made of the composite metal ceramic powder. The furnace roller is prepared by adopting a high-speed oxygen flame spraying method and has excellent heat resistance, wear resistance and nodule resistance performances and average service period reaching over 2 years.

Owner:BAOSHAN IRON & STEEL CO LTD

Self-lubricating wear-resistant composite film containing nano two-dimensional black-phosphorus and preparation method of composite film

The invention relates to a self-lubricating wear-resistant composite film containing nano two-dimensional black-phosphorus and a preparation method of the composite film. The preparation method comprises the following steps: 1, preparing a nano two-dimensional black-phosphorus composite material: (1) preparing black phosphorus and composite nano powder of black phosphorus and graphite, and (2) preparing a solution of a black-phosphorus composite material: a, preparing a mixed solution of black phosphorus and polytetrafluoroethylene, and b, preparing a micro-powder mixed solution of black phosphorus and polytetrafluoroethylene; and 2, preparing the nano two-dimensional black-phosphorus composite film: (1) carrying out smoothness treatment on a sample, and (2) preparing the film by using a glue spreading machine or an electrostatic spraying method. The preparation method has the advantages of simple and convenient forming process and low preparation cost; and the prepared nano two-dimensional black-phosphorus self-lubricating wear-resistant composite film has excellent self-lubricating property, wear resistance, stability and high-temperature oxidation resistance, and can be appliedin special environments with high temperature, air or vacuum, corrosion, radiation, high load and the like.

Owner:TSINGHUA UNIV

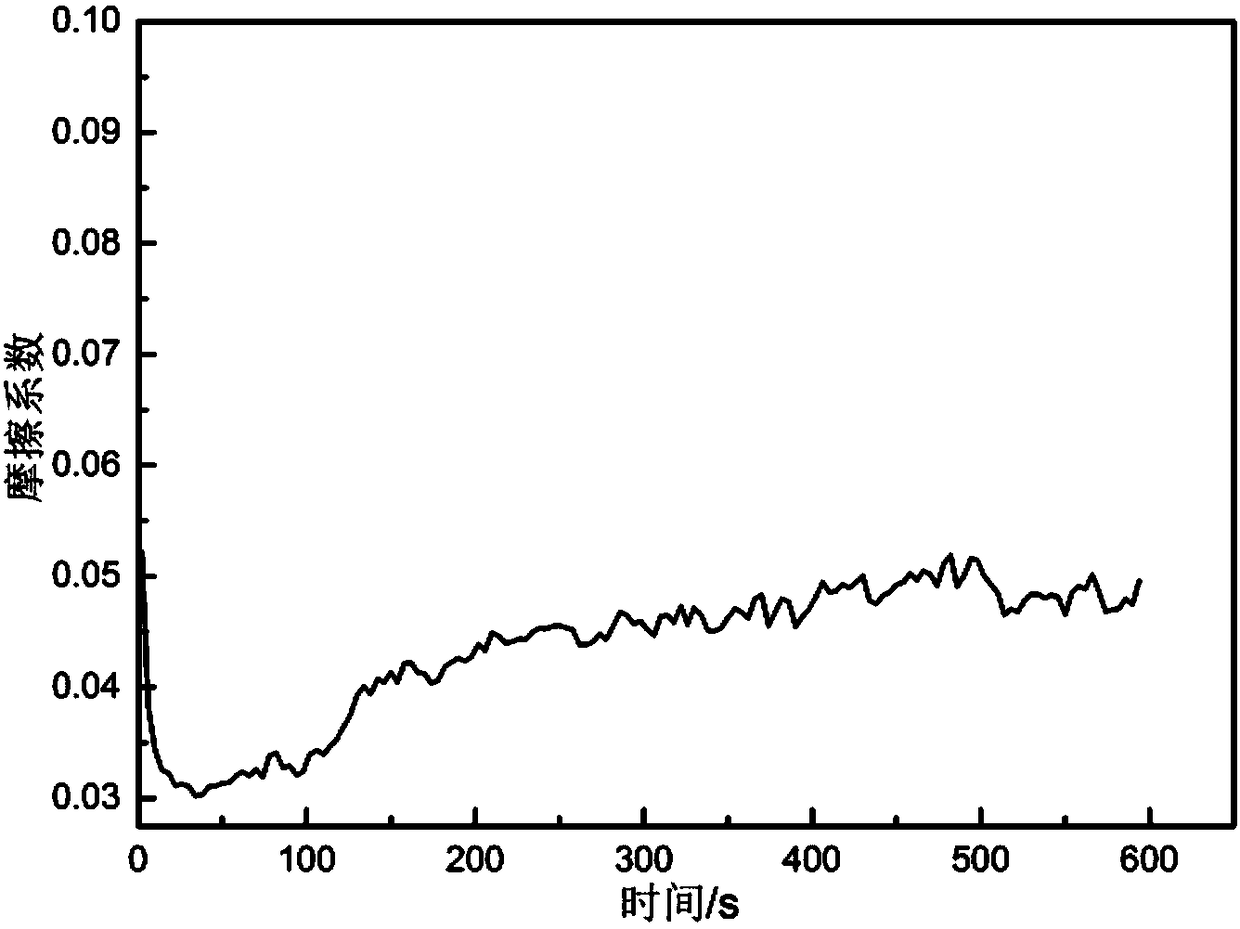

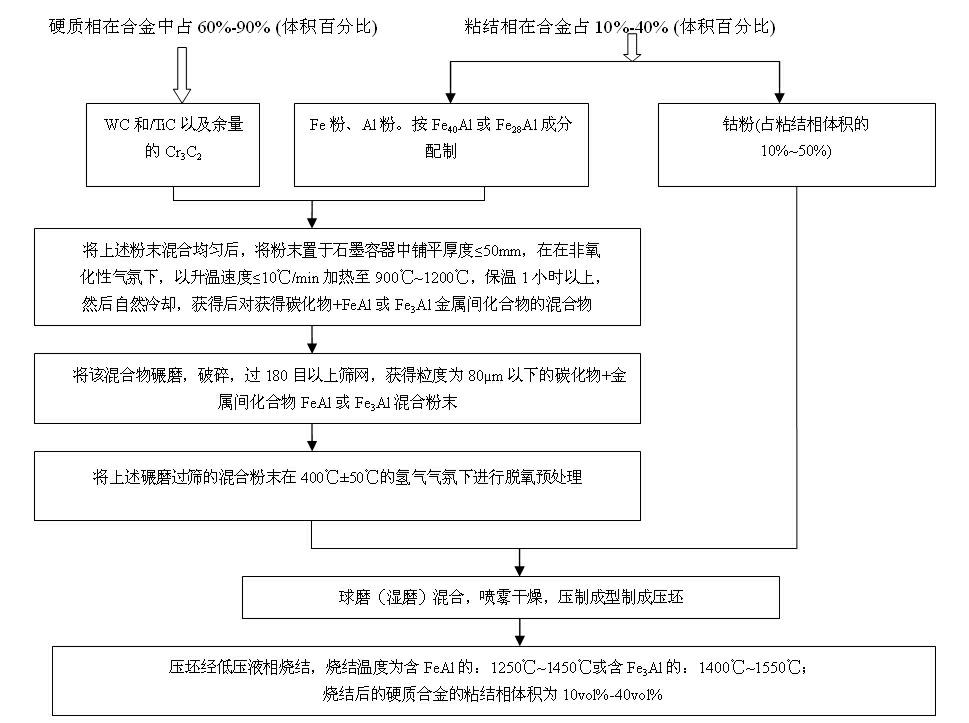

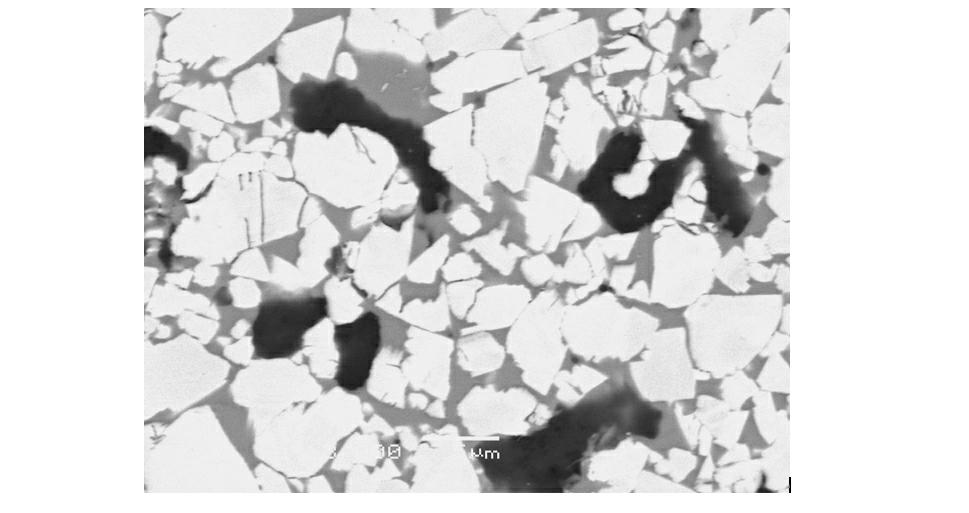

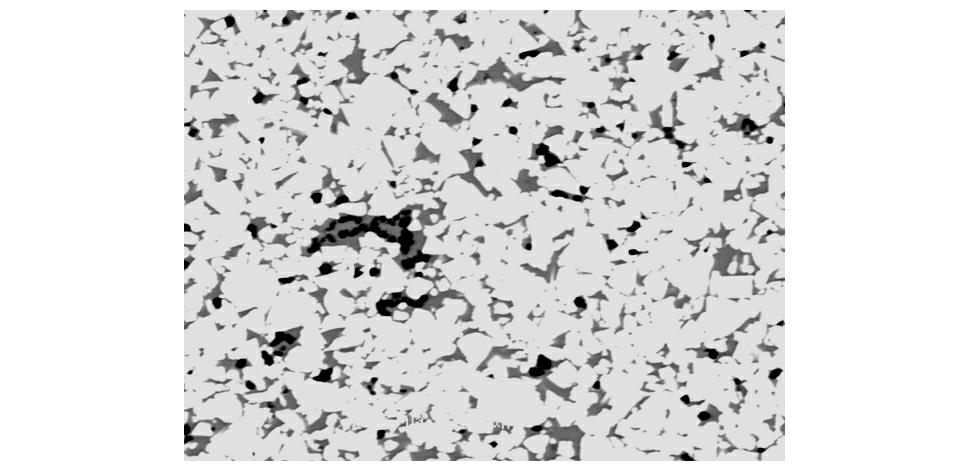

Hard alloy with iron-aluminum intermetallic compound as main binding phase and preparation method of hard alloy

The invention discloses a hard alloy with an iron-aluminum intermetallic compound FeAl or Fe3Al as a main binding phase, cobalt as a secondary binding phase, and tungsten carbide and / or titanium carbide and Cr3C2 as a hard phase, and the preparation method of the hard alloy comprises the steps in sequence of: uniformly mixing iron powder and aluminum powder with WC and / or TiC powder based on the component ratio of Fe40Al or Fe28Al; under a non-oxidative atmosphere, heating, preserving heat and cooling to obtain a mixture of WC and / or TiC and FeAl or Fe3Al; grinding and crushing the mixture to obtain the mixed powder of WC and / or TiC and FeAl or Fe3Al with the grain size below 120 microns; carrying out deoxygenization pretreatment; wetly grinding and mixing cobalt powder and Cr3C2 powder having certain mass ratio with the balance of the mixture powder of WC and / or TiC and FeAl or Fe3Al; spray drying and compacting to obtain a green compact; and subjecting the green compact to liquid phase sintering at a low pressure to obtain the hard alloy with FeAl or Fe3Al as the main binding phase. The hard alloy disclosed by the invention has the advantages of uniform organizational structure, high densification, high intensity, good abrasive resistance, excellent high temperature oxidation resistance and sulfidation corrosion resistance, simple preparation process and low manufacturing cost.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

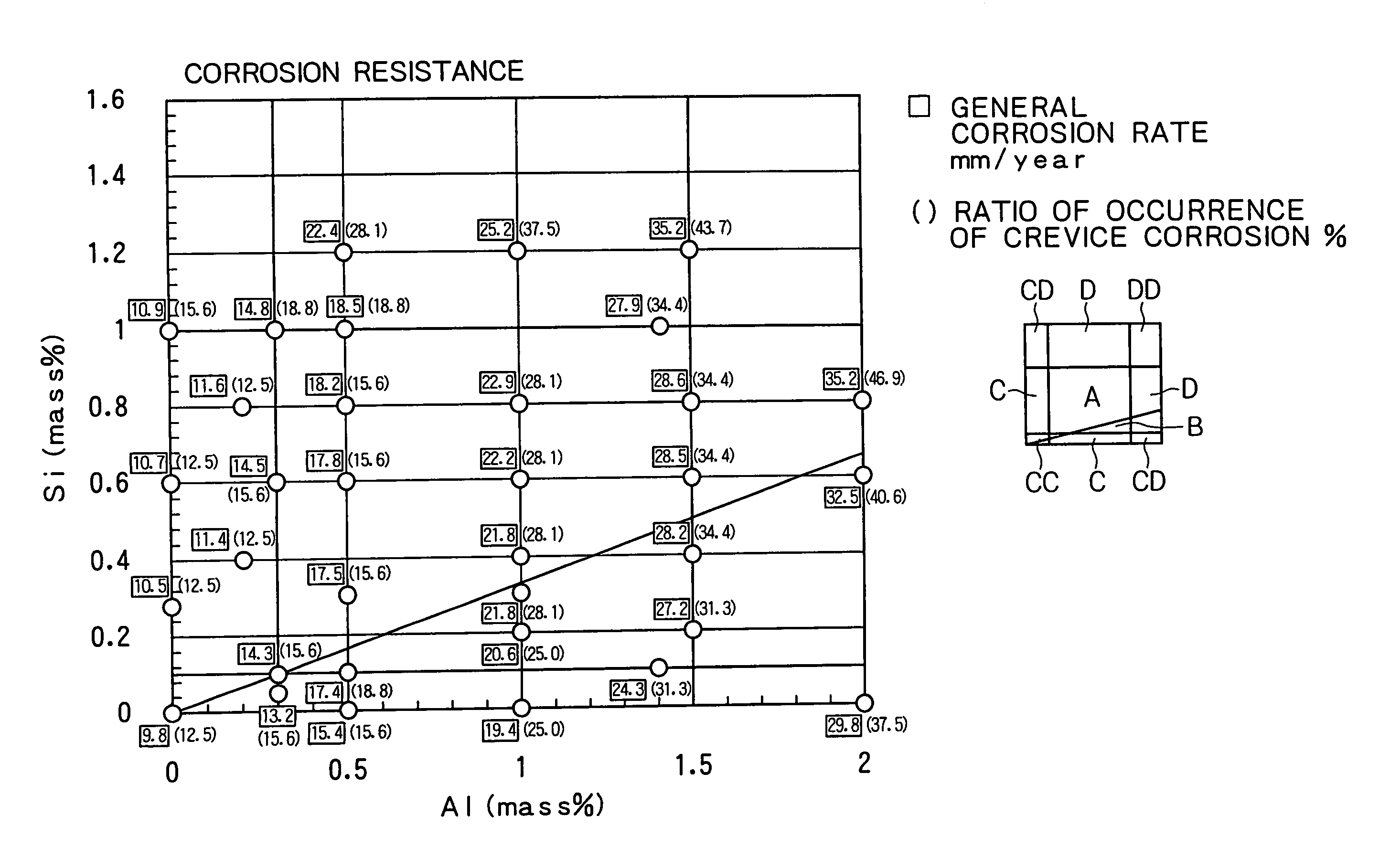

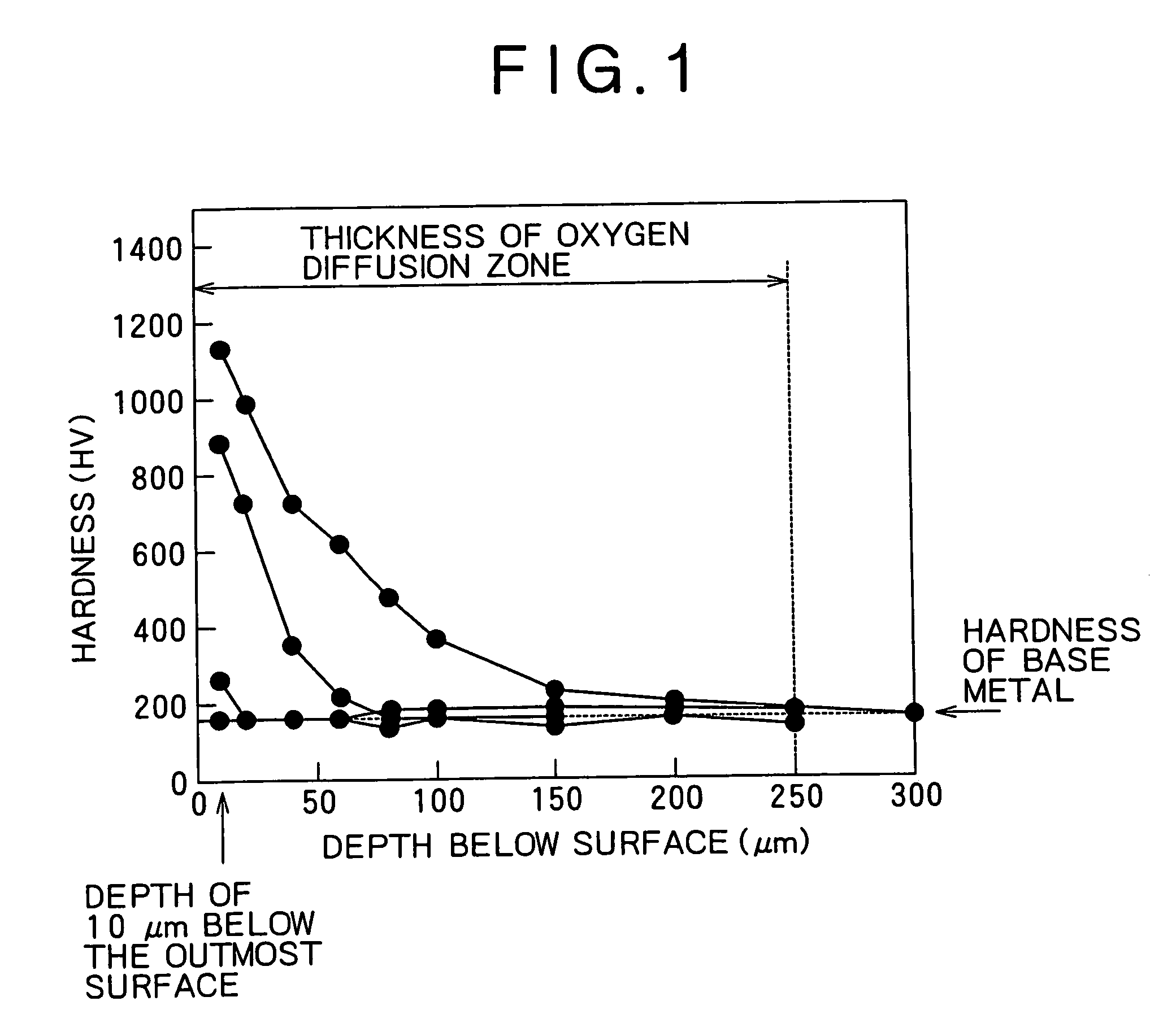

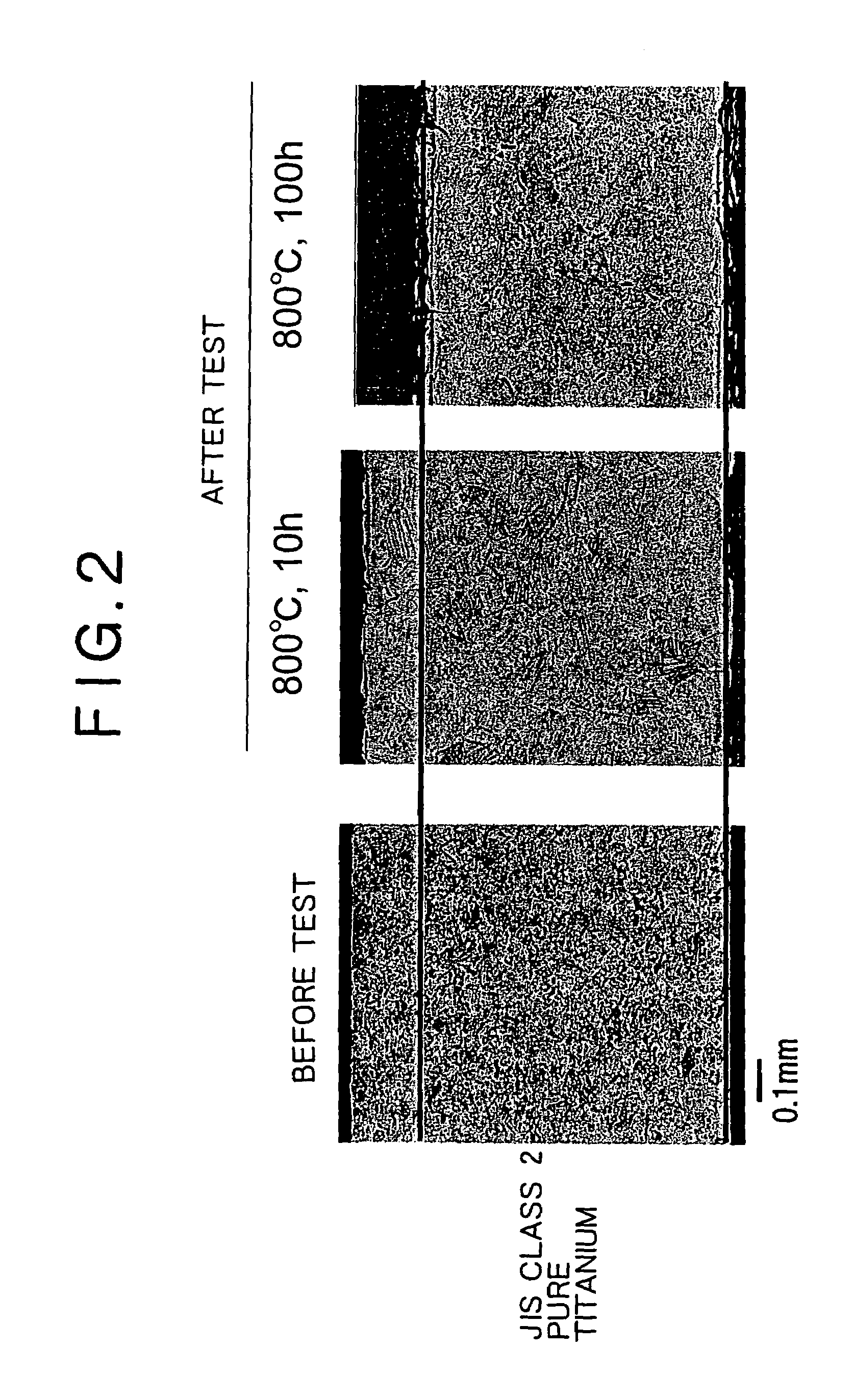

Titanium alloy having excellent high-temperature oxidation and corrosion resistance

ActiveUS7166367B2Excellent high-temperature oxidation resistanceOutstanding resistanceHot-dipping/immersion processesExhaust apparatusMachinabilityCorrosion

A titanium alloy having excellent high-temperature oxidation and corrosion resistance is disclosed which comprises, by mass, Al: 0.30–1.50%, and Si: 0.10–1.0%. Preferably, amass ratio Si / Al is not less than 1 / 3. More preferably, the titanium alloy further comprises Nb: 0.1–0.5% by mass. The titanium alloy is useful as an exhaust system material for a vehicle or a motorbike, which enhances corrosion and high-temperature oxidation resistance, while utilizing inherent lightness and corrosion resistance of an original titanium alloy without impairing economy and workability.

Owner:KOBE STEEL LTD

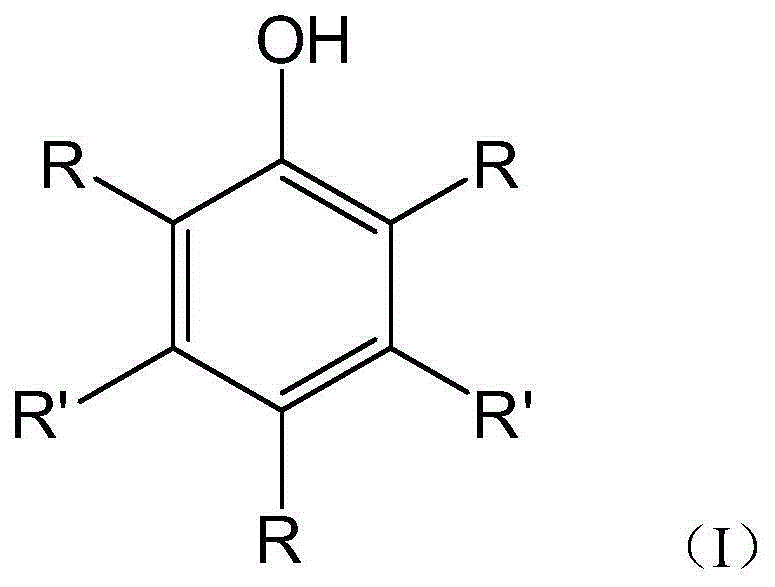

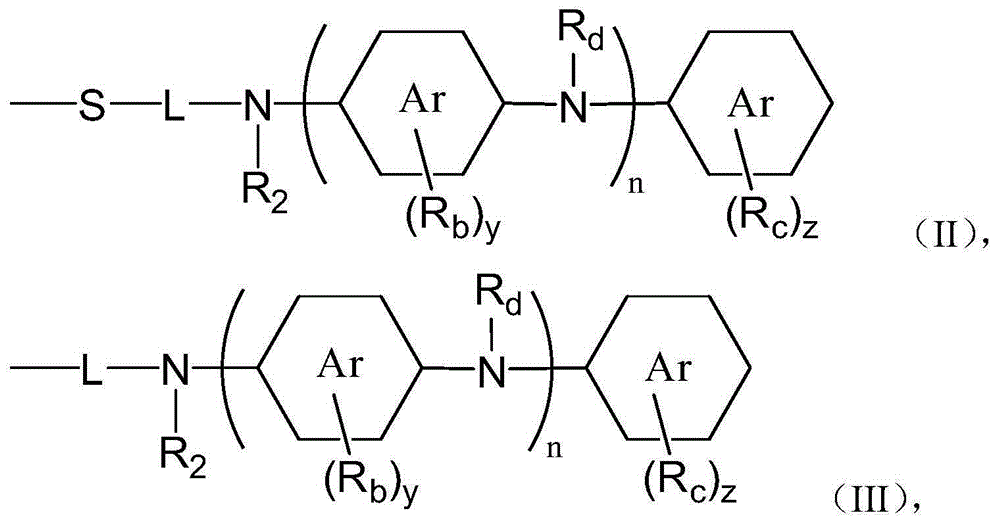

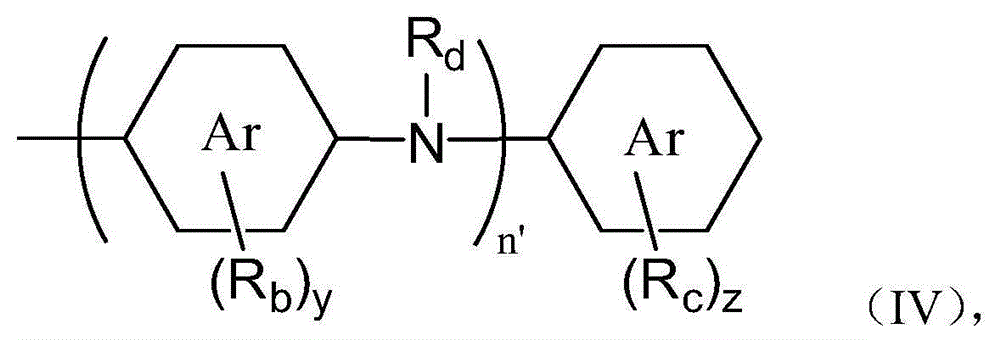

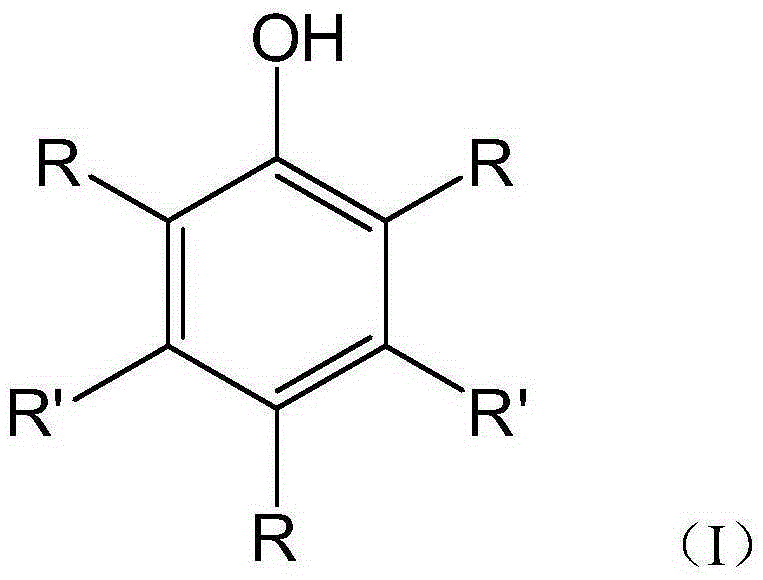

Complex calcium-based lubricating grease and preparing method thereof

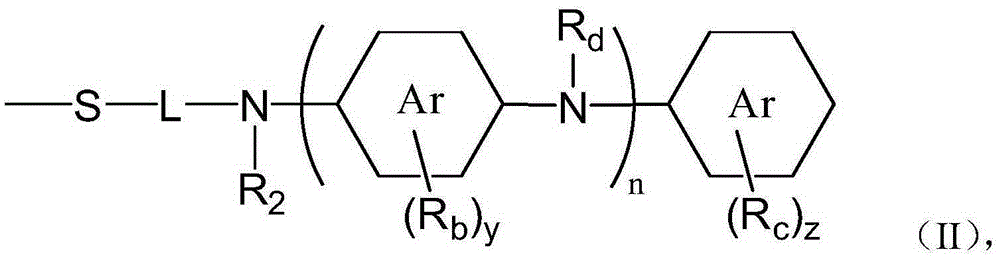

ActiveCN106590886ADrop point highGood mechanical stabilityAdditivesHeat stabilityMechanical equipment

The invention provides a complex calcium-based lubricating grease and a preparing method thereof. The lubricating grease comprises 0.01%-1.0% of hindered phenol compound, 5%-35% of complex calcium-based thickening agent and a main amount of lubricating base oil, wherein the structure of the hindered phenol compound is shown in the specifications. According to the complex calcium-based lubricating grease and the preparing method thereof, the complex calcium-based lubricating grease has a high dropping point, good mechanical stability, excellent heat stability, colloid stability, high-temperature oxygen resistance, anti-corrosion performance, anti-water spraying performance, and anti-extreme pressure performance, hardening conditions of the complex calcium-based lubricating grease are improved to some extent, thus the complex calcium-based lubricating grease is capable of being qualified in lubrication of various kinds of motors, electric generators, air blowers, transportation industries, iron and steel enterprises and other various kinds of commercial units, and is especially applicable to lubrication of friction parts of various kinds of mechanical equipment under high-temperature and moist conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

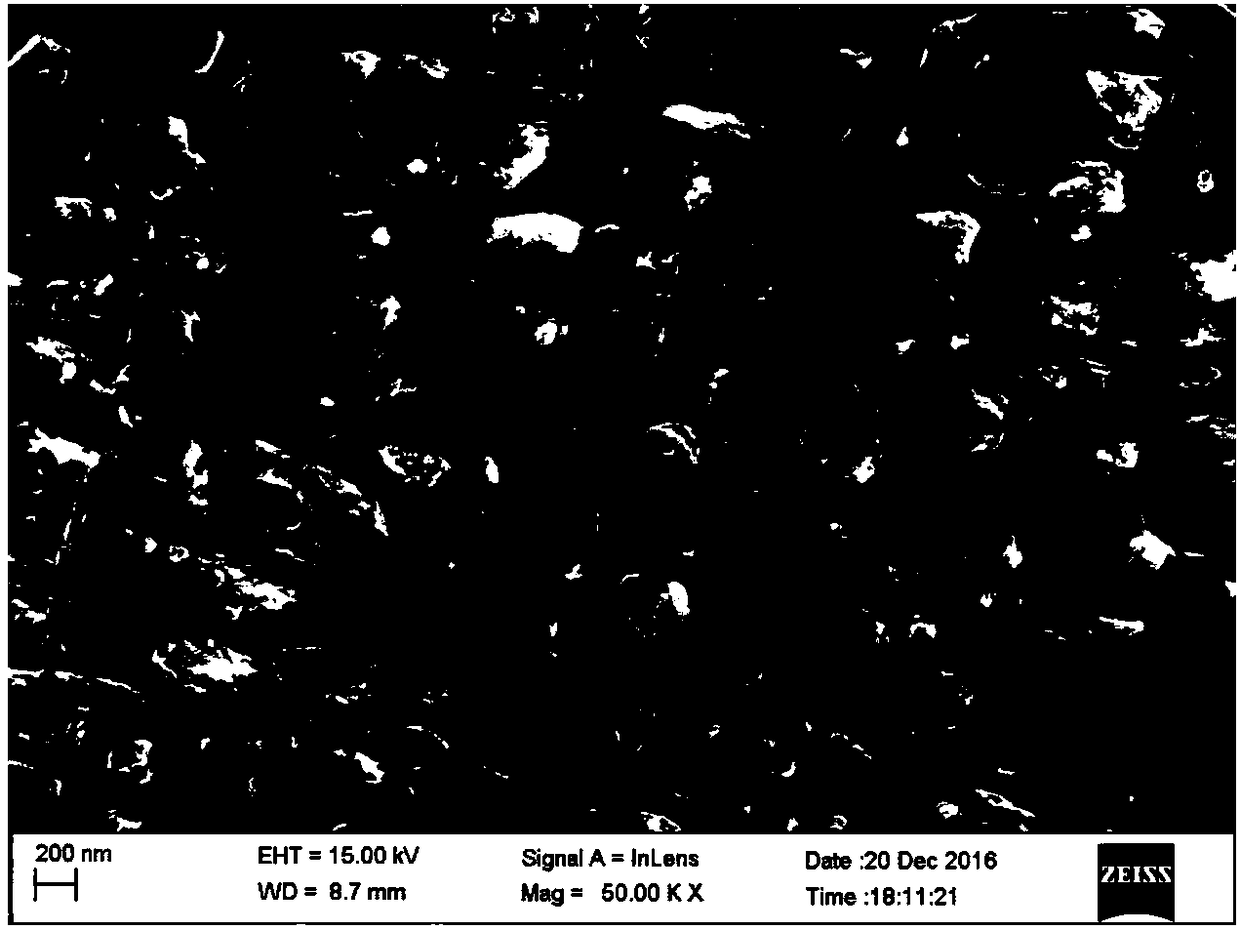

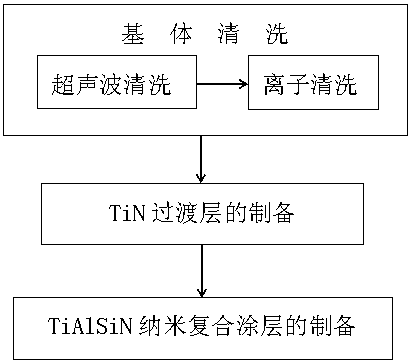

Preparation technology of Si doped nano composite coating with ultrahigh hardness

InactiveCN107190233AHigh hardnessExcellent high temperature oxidation resistanceVacuum evaporation coatingSputtering coatingRadio frequencySi doped

The invention discloses a preparation technology of an Si doped nano composite coating with ultrahigh hardness. The preparation technology comprises the steps of (1) matrix cleaning, including ultrasonic cleaning and ion cleaning; (2) preparation of a TiN transition layer: sending a matrix treated in the step (1) into a sputtering chamber, and carrying out deposition to obtain the TiN transition layer with the thickness of 100 nm to 200 nm; and (3) preparation of a TiAlSiN nano composite coating: carrying out deposition to obtain the TiAlSiN nano composite coating with the thickness of 2 <mu>m to 5 <mu>m on the matrix coated with the TiN transition layer through a TiAlSi composite target material controlled by a radio frequency cathode. The obtained TiAlSiN coating has hardness higher than 40 GPa, and has excellent high-temperature oxidation resistance and corrosion resistance, a coating preparation method has the characteristics of simple technology, high deposition speed, low cost, high bonding strength and the like, and has the advantages of high production efficiency, low energy consumption, relatively low equipment requirement and the like, and the coating can be adopted as a cutter coating of high-speed and dry cutting and a protective coating in other fields.

Owner:SHANGHAI ZENIX VACUUM COATING TECH

Method for compositely plating Ni/CrAl/Y2O3 gradient plated layer on T91 steel surface

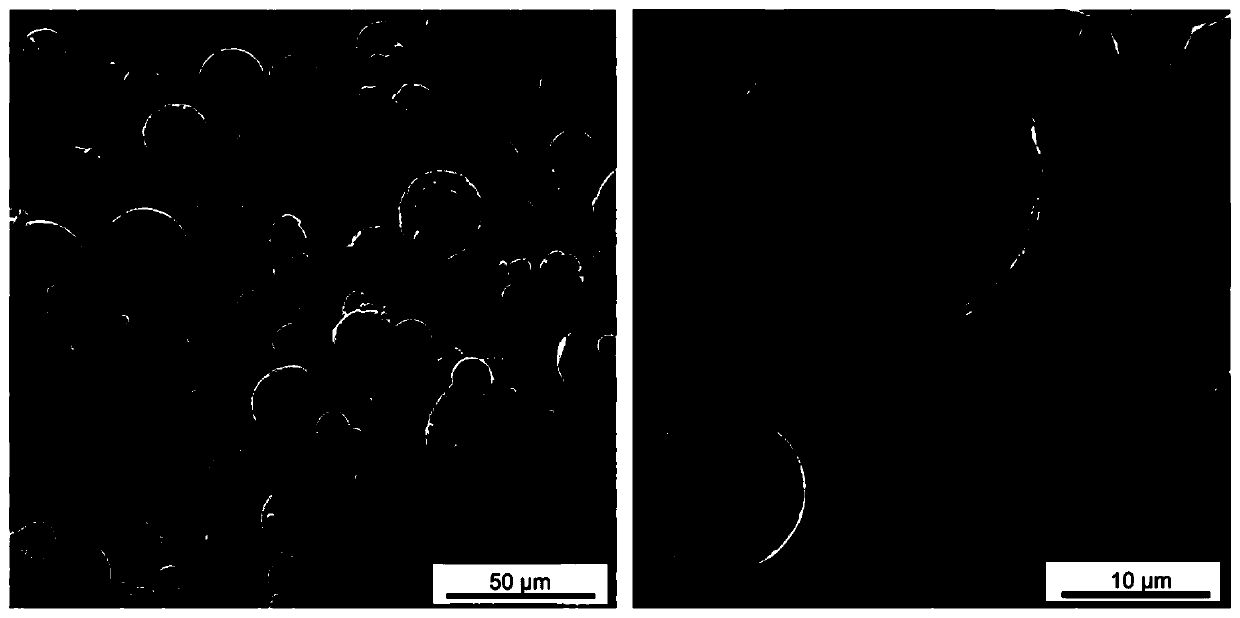

InactiveCN103343379AStrong combinationExcellent high temperature oxidation resistanceElectrolytic coatingsMicro nanoOxidation resistant

The invention relates to a method for compositely plating Ni / CrAl / Y2O3 gradient plated layer on a T91 steel surface. The method comprises the steps of preparing CrAl / Y2O3 powder, carrying out T91 steel surface treatment and compositely plating. CrAl / Y2O3 micro nano spherical powder is obtained by controlling a high-speed milling process; an appropriate amount of CrAl / Y2O3 micro nano powder is added into a Watts plating liquid, and the Ni / CrAl / Y2O3 gradient plated layer which has excellent corrosion resistance and oxidation resistance is prepared through composite plating. The Ni / CrAl / Y2O3 gradient plated layer provided by the invention is good in bonding force with a base material, low in porosity, free of crack and unlikely to peel off, the CrAl / Y2O3 content of the plated layer from the inner layer to the outer layer changes in a linear gradient manner, and the plated layer has excellent corrosion resistance and oxidation resistance, and has the advantages of low cost and simplicity in operation and industrialization is easy to realize.

Owner:NANCHANG HANGKONG UNIVERSITY

Ceramic-embedded plate valve

InactiveCN102121537AGood high temperature mechanical propertiesGood chemical resistanceSlide valveValve housingsEngineeringGraphite

The invention discloses a ceramic-embedded plate valve, which comprises a left valve body, a right valve body, an upper flange, a lower flange, disc springs, a valve rod outer sealing member, a valve body pipe orifice outer sealing member and an inner sealing member, wherein the inner sealing member consists of a ceramic flat plate, a flat plate frame and fixing valve plates; a first disc spring is tightly attached to one side of a left fixing valve plate and one side of a right fixing valve plate; a second disc spring of which the outer diameter is larger than that of the first disc spring is arranged among the first disc spring, the left valve body and the right valve body; a third disc spring of which the outer diameter is larger than that of the second disc spring is arranged among the second disc spring, the left valve body and the right valve body; the inner peripheries of the outer sides of the left valve body and the right valve body are provided with annular grooves; and a component force flat washer and a graphite packing are fixed in the annular grooves in turn respectively by using a gland bush from outside to inside. The ceramic-embedded plate valve has the advantages of high performance, balanced stress on the fixing valve plates due to tower combination of the disc springs and component force action of the packing, and difficulty in smashing.

Owner:淄博汇华阀业有限公司

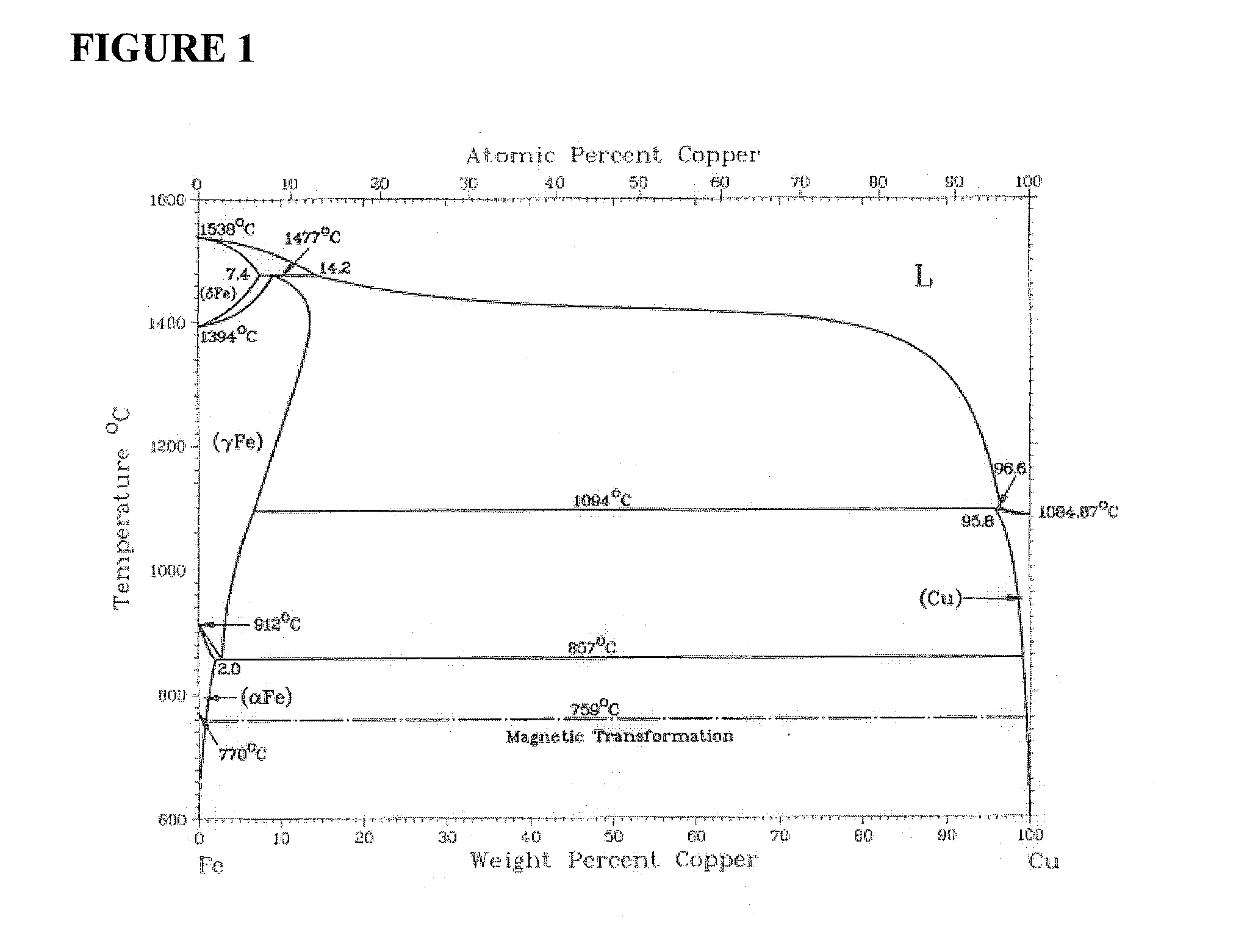

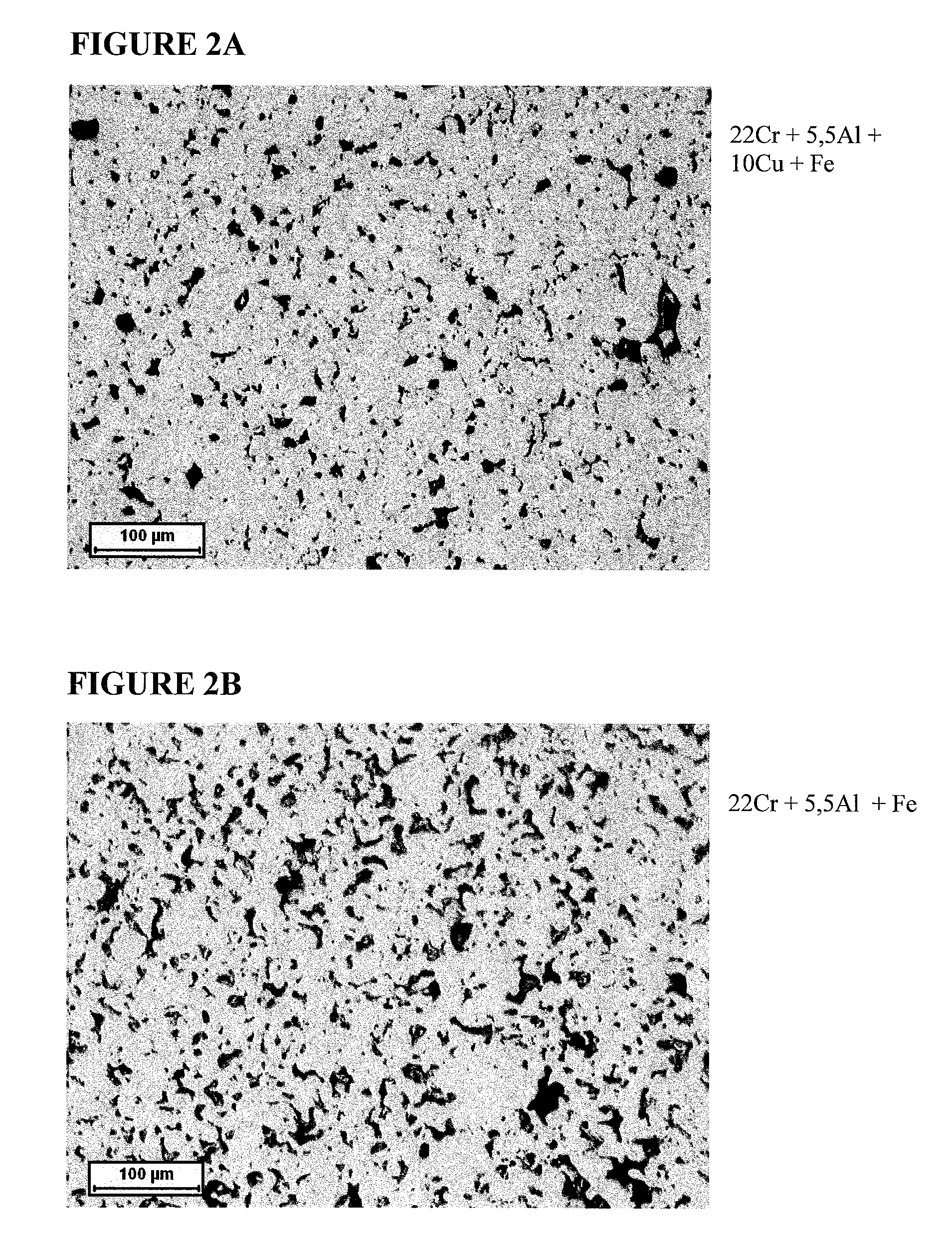

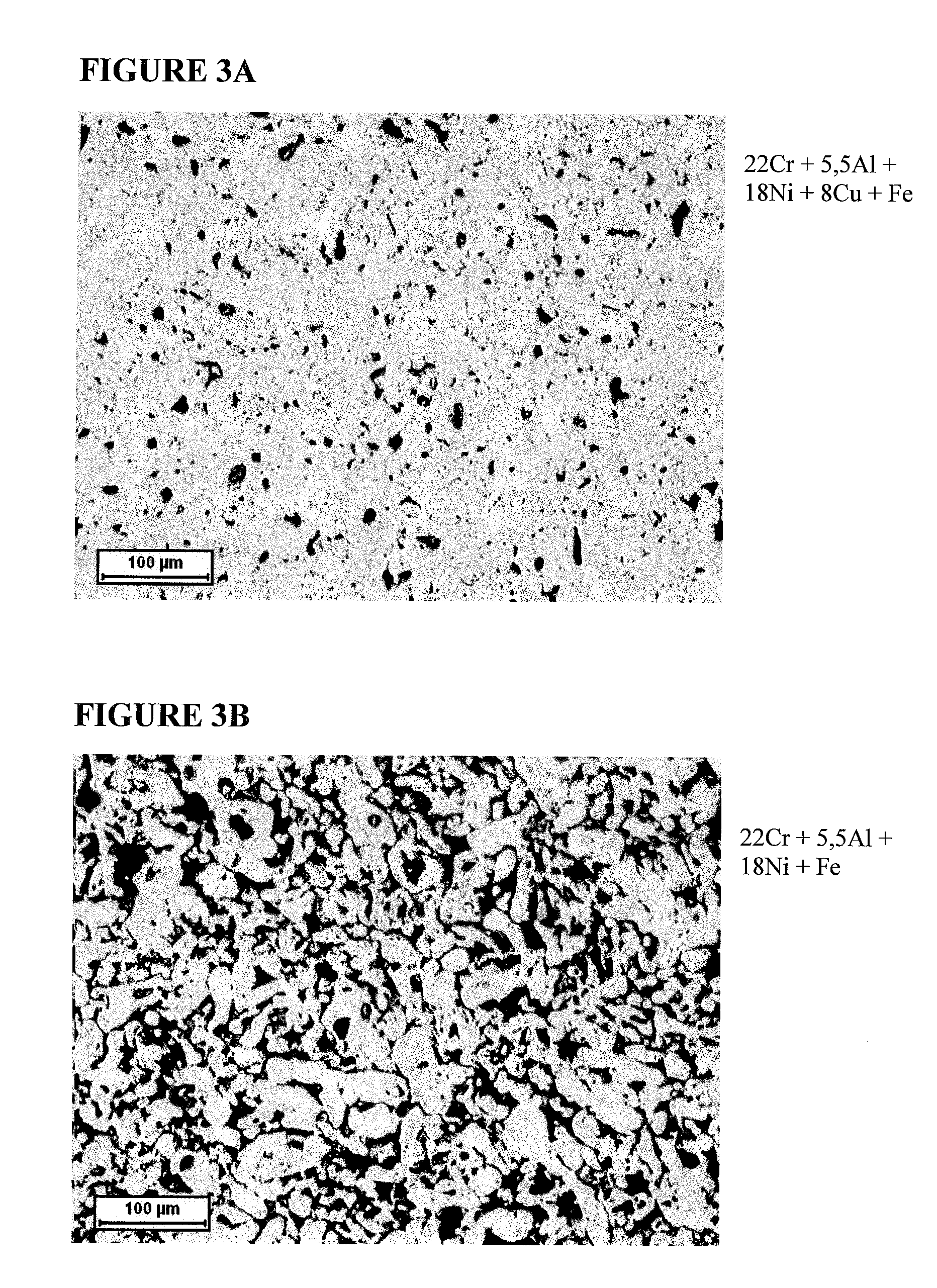

Iron-based powder

InactiveUS20080019858A1Good sintered structureEasy to sinterTransportation and packagingMetal-working apparatusManganeseCopper

An atomised pre-alloyed iron-based powder which comprises by weight-%10.5-30Cr 3-15Al 5-20Cumax 0.1Cmax 0.2Nmax 3.0Mnmax 2.5Simax 3.0Mobalance essentially only iron and unavoidable impurities.

Owner:HOGANAS AB

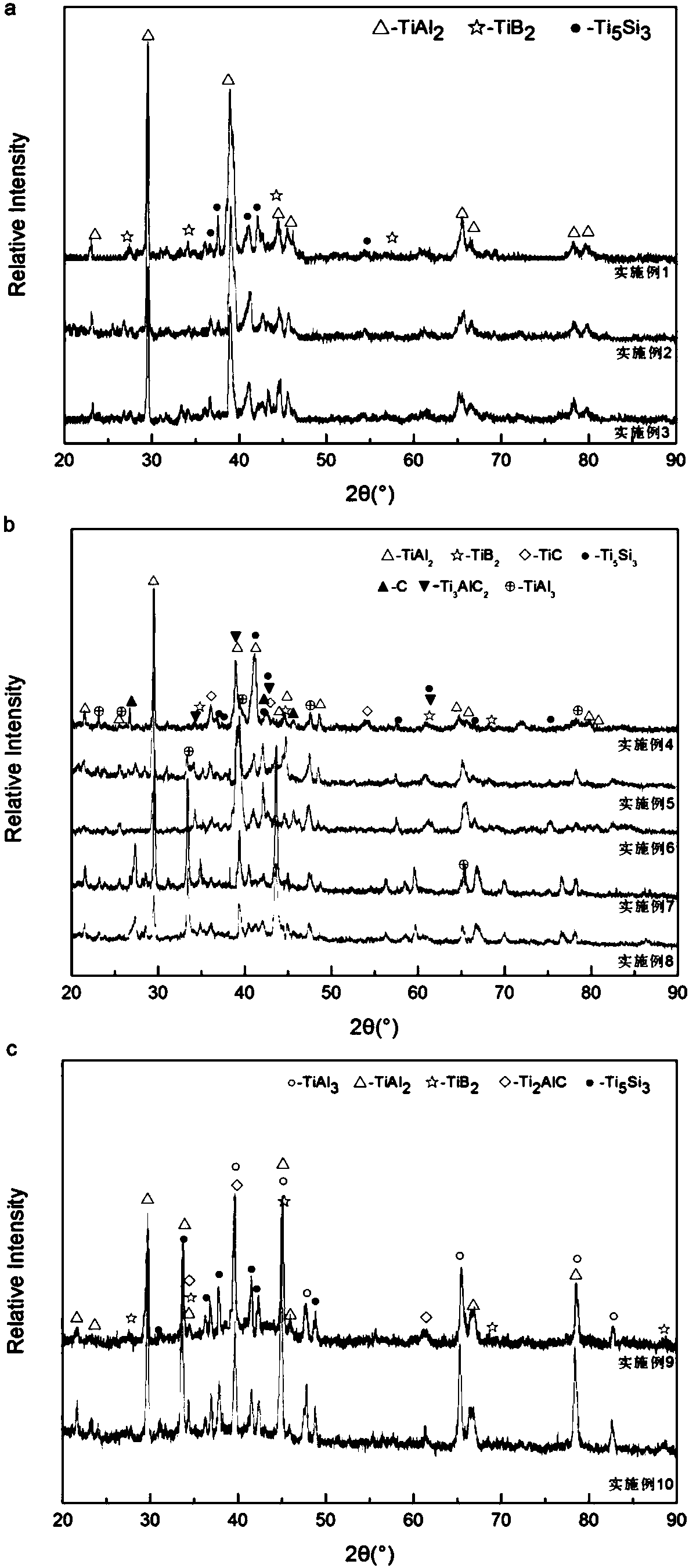

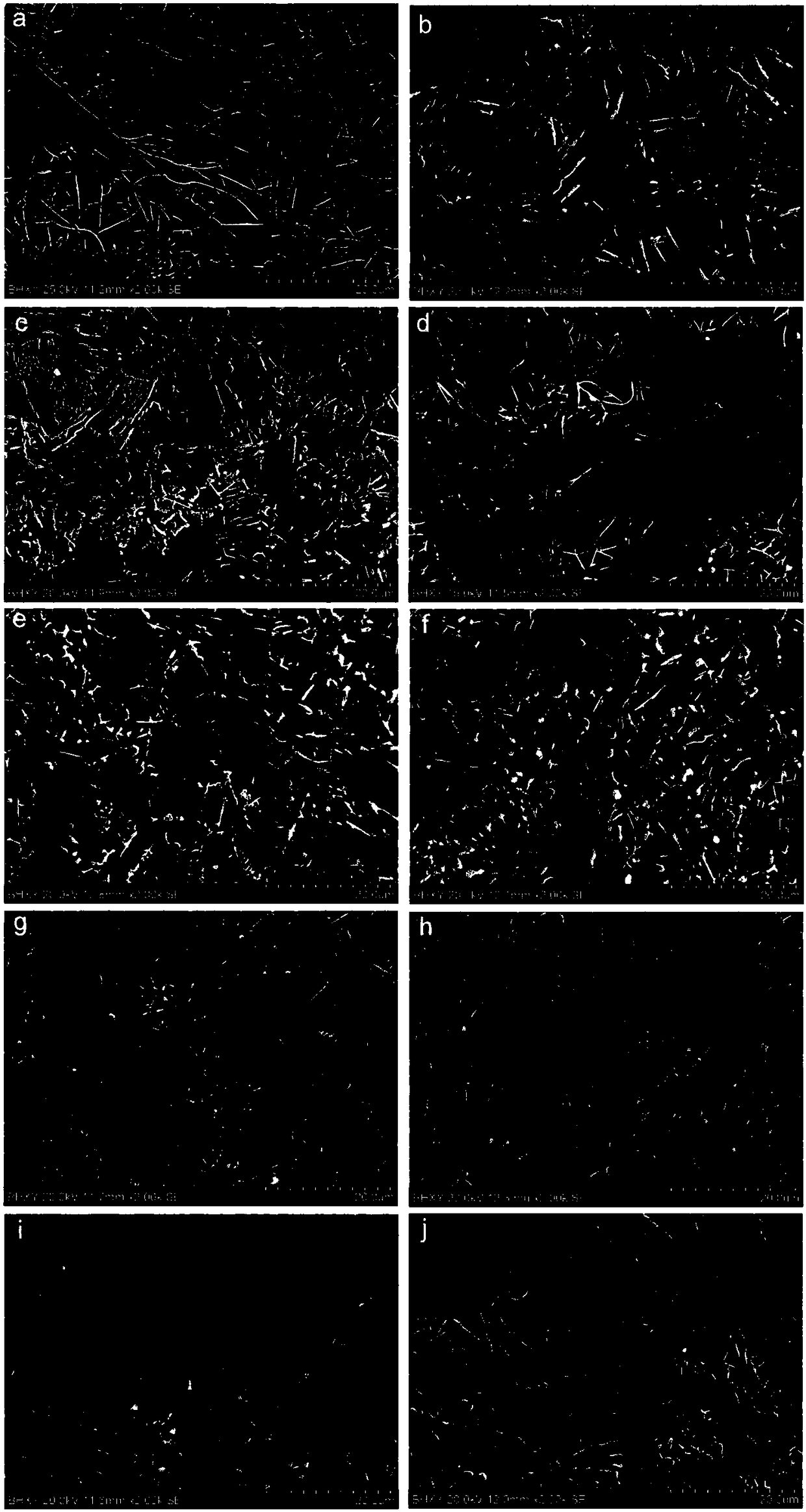

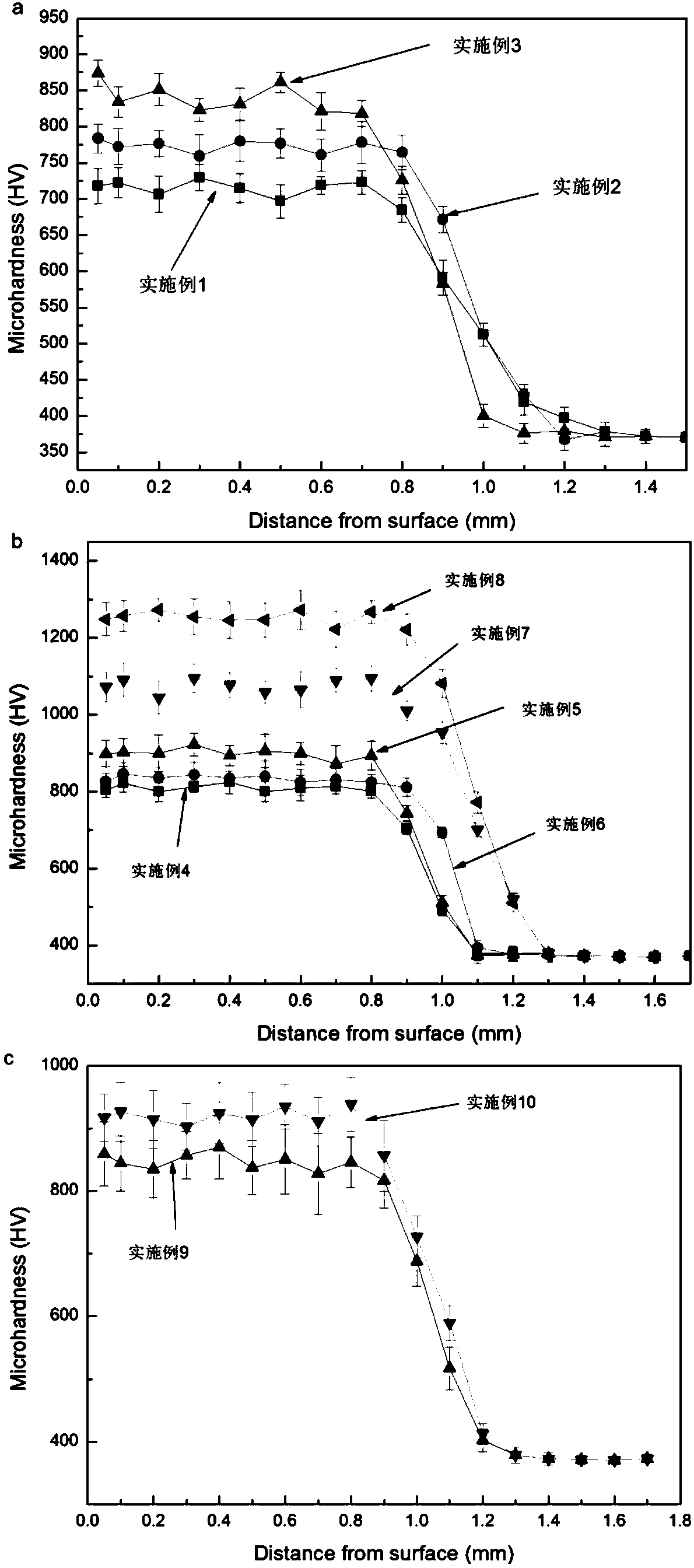

Titanium alloy surface high-temperature-resisting coating and preparation method thereof

ActiveCN108220957AGood resistance to high temperature oxidationExcellent high temperature oxidation resistanceMetallic material coating processesAlloy surfaceHardness

The invention relates to a titanium alloy surface high-temperature-resisting coating and a preparation method thereof. The ingredient system of the original raw materials of the coating is (45-750%Al-(10-20)%Nb-(5-20)%Si-(0-15)%B-(0-20)%B4C-(0-10)%C. The manner of laser surface alloying is adopted, the in-situ generated high-temperature-resisting coating is prepared on the surface of a titanium alloy and is subjected to typical metallurgical bonding with a base body, and the coating has excellent high temperature oxidation and abrasion resistance; and meanwhile the thickness of the coating isgreatly increased, the problem that the thickness, hardness and abrasion resistance of the coating can hardly be improved in balance in the prior art is solved well, and good application prospects areachieved.

Owner:QINGDAO BINHAI UNIV

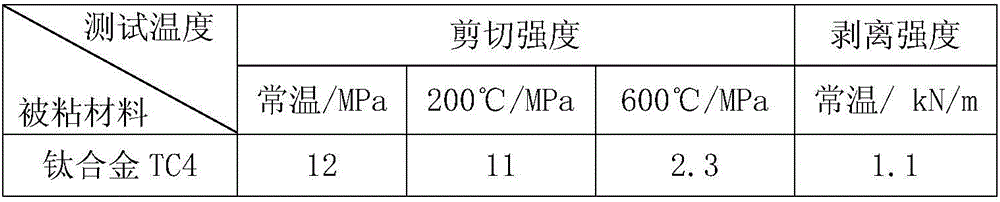

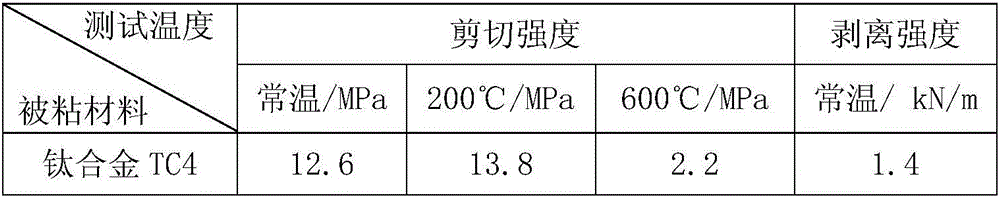

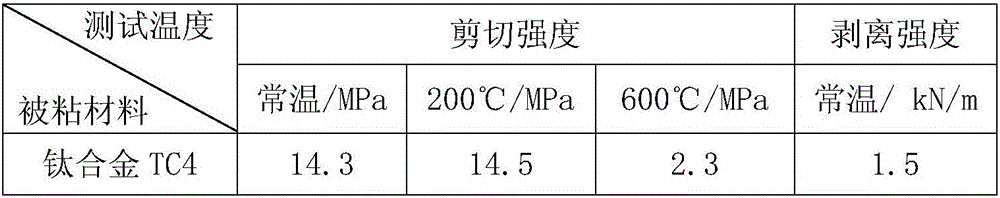

Vinyl polycarbosilane modified phenol-formaldehyde adhesive and preparation method thereof

InactiveCN105801785AHigh activityHigher than the moldAldehyde/ketone condensation polymer adhesivesAdhesiveDistillation

The invention relates to a vinyl polycarbosilane modified phenol-formaldehyde adhesive and a preparation method thereof. The invention aims at solving the technical problems of existing phenol-formaldehyde adhesive that fragility is high, toughness is poor and peel strength is low. The vinyl polycarbosilane modified phenol-formaldehyde adhesive is prepared from phenol, formaldehyde, an alkaline catalyst, vinyl polycarbosilane and ethyl acetate. The preparation comprises the following steps of: firstly weighing phenol, formaldehyde, alkaline catalyst and vinyl polycarbosilane; secondly, mixing raw materials; and thirdly, carrying out reaction and pressure distillation, and preparing solution. According to the invention, vinyl polycarbosilane with excellent heat resistance is grafted with POSS modified phenol-formaldehyde adhesive for preparing phenol-formaldehyde adhesive with high heat resistance, and adhesion of ceramic materials and high temperature resistant metal materials is met. The preparation method provided by the invention is used for preparing the vinyl polycarbosilane modified phenol-formaldehyde adhesive.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

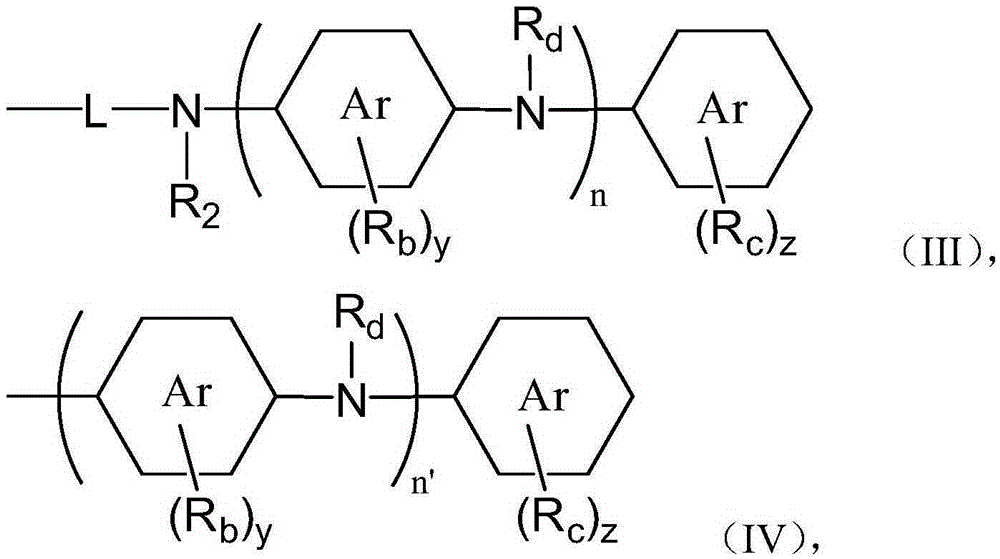

Complex lithium-calcium-based lubricating grease and preparation method thereof

ActiveCN106590822ADrop point highGood mechanical stabilityAdditivesSulfide preparationIndustrial equipmentMechanical equipment

The invention provides complex lithium-calcium-based lubricating grease. The lubricating grease is prepared from components in terms of the total weight of lubricating grease as follows: 0.01%-10% of a shielding phenol compound, 5%-35% of a complex lithium-calcium-based thickening agent and a major amount of lubricating base oil; the structure of the shielding phenol compound is shown in the specification. The complex lithium-calcium-based lubricating grease has high dropping point, good mechanical stability, high-temperature reversibility, pumpability, excellent thermal stability, colloid stability, high-temperature oxidation resistance, antirust performance, water spraying resistance and extreme pressure property, has good compatibility with other lubricating grease, can be qualified for lubrication of various motors, generators, air blowers, transportation industry, iron and steel enterprises and other industrial equipment and is particularly applicable to lubrication of friction parts of mechanical equipment under higher temperature and humid conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of treating surface of Ti-Al alloy and Ti-Al alloy obtained by the same

InactiveCN101802246AImprove high temperature oxidation resistancePrevent intrusionSolid state diffusion coatingTurbine wheelTurbine blade

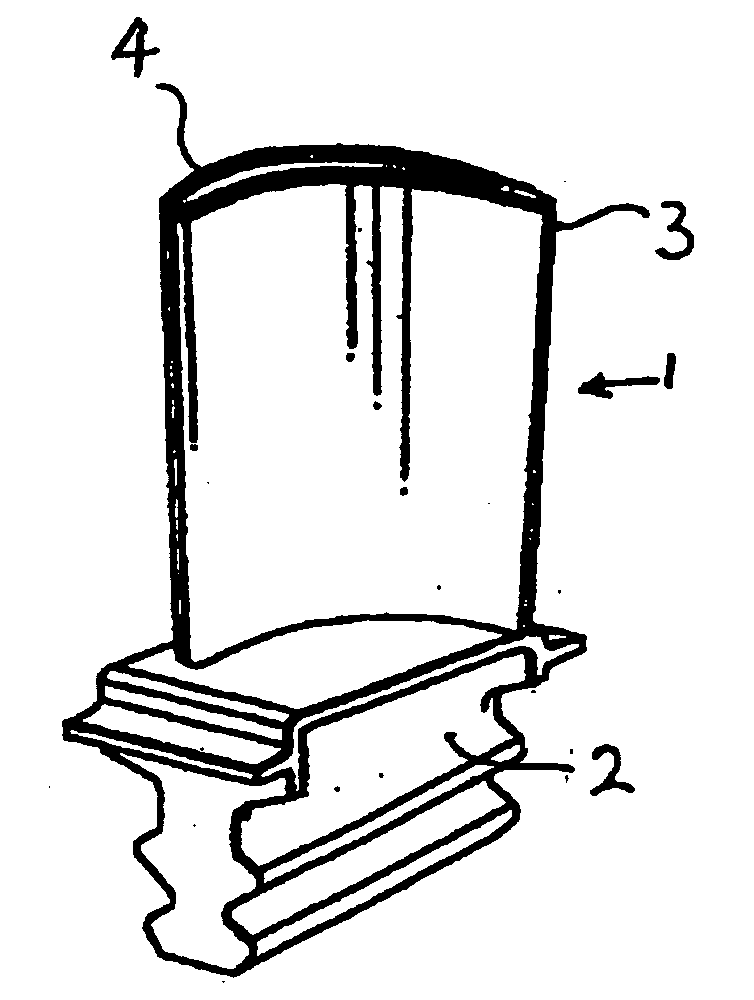

A surface treatment method for improving the unsusceptibility of a Ti-Al alloy to oxidation at high temperatures in a manner suitable for mass production; and a Ti-Al alloy. A Ti-Al alloy base containing 15-55 at.% aluminum is held with heating in a gas atmosphere containing a fluorine source gas to form a fluorine-rich layer having a thickness of 0.1-10 [mu]m on the surface of the base. The fluorine-rich layer is regulated so as to have a maximum fluorine concentration of 2-35 at.%. When exposed to a high-temperature oxidizing atmosphere, this surface of the Ti-Al alloy base is coated with an Al2O3 coating film having extremely low oxygen permeability. This alloy hence has excellent unsusceptibility to high-temperature oxidation. Thus, the poor unsusceptibility to high-temperature oxidation which is a most serious defect of the Ti-Al alloy, which is lightweight and has a high high-temperature strength, can be improved in a manner suitable for mass production. The Ti-Al alloy thus treated can be advantageously used as, e.g., a turbine wheel for superchargers, engine bulb, or turbine blade for gas turbines.

Owner:AIR WATER INC

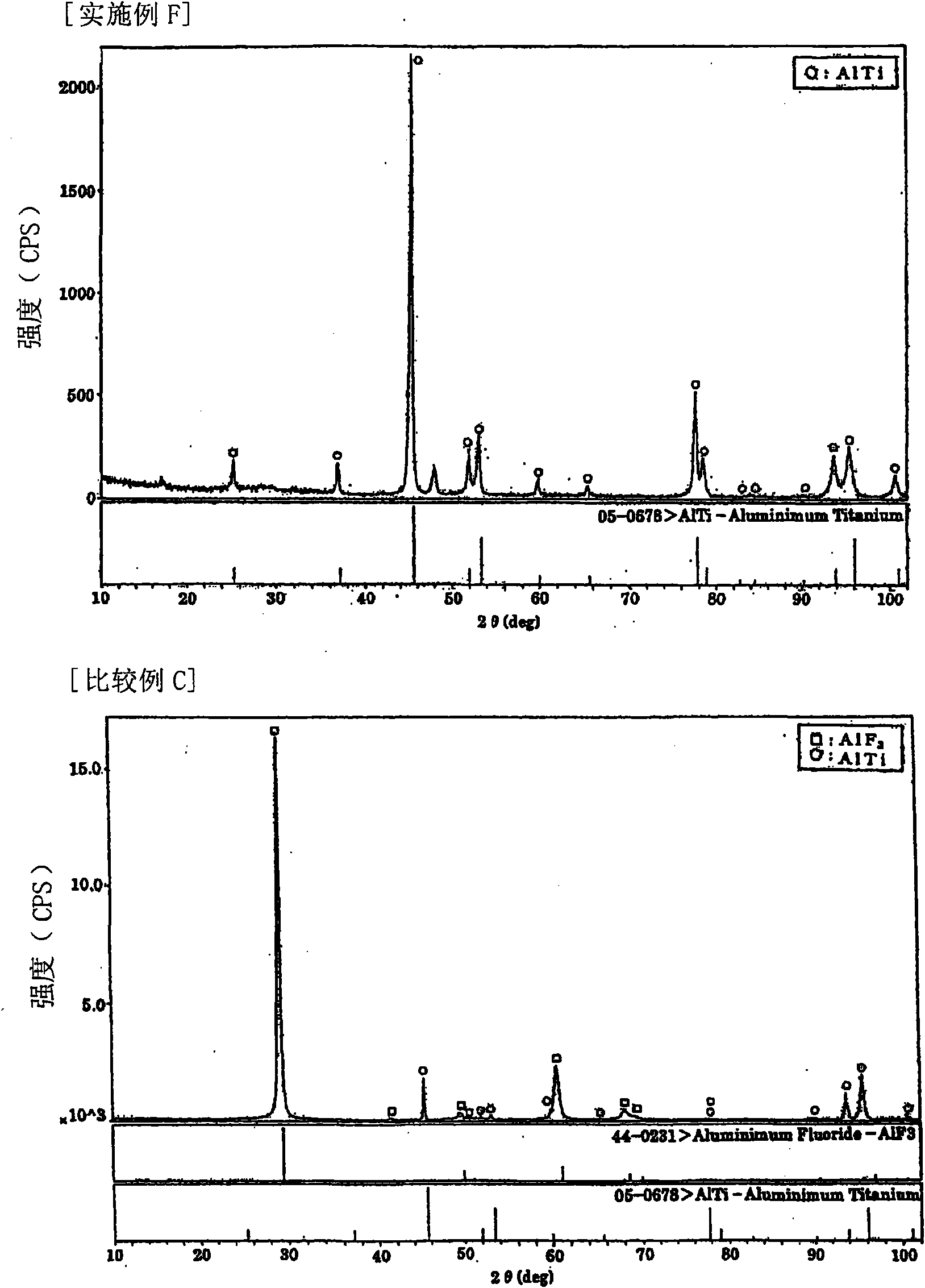

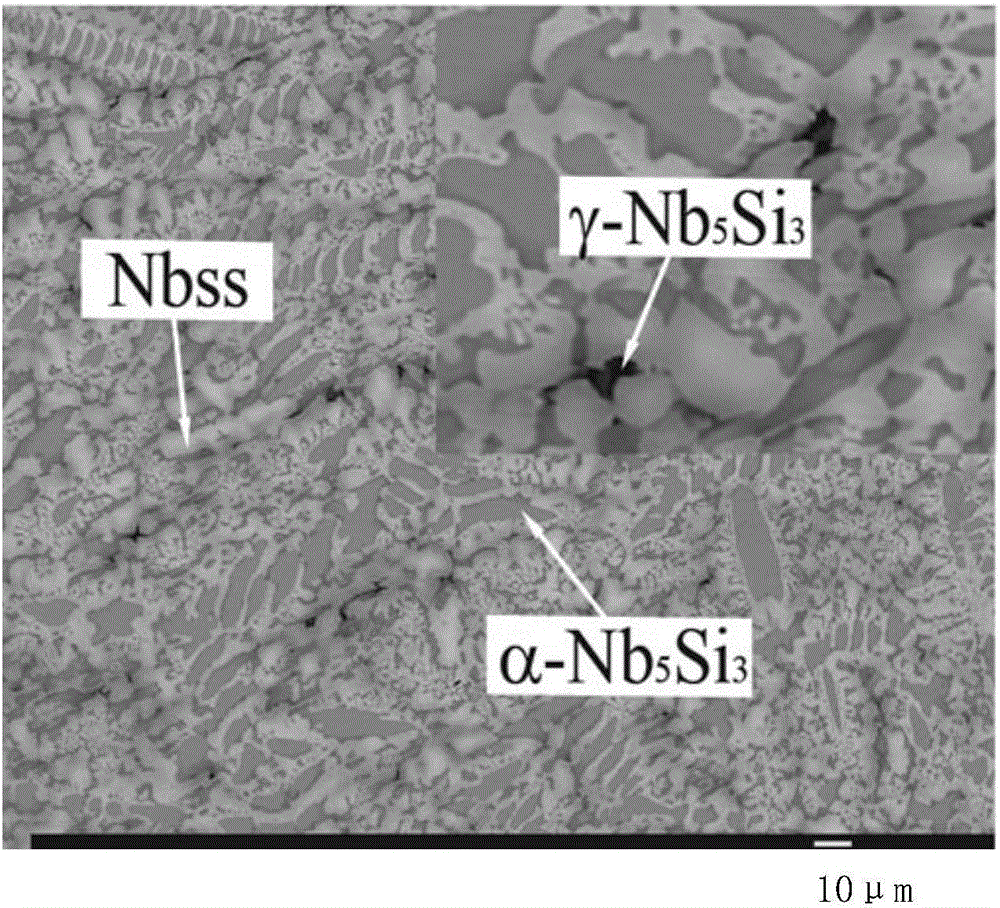

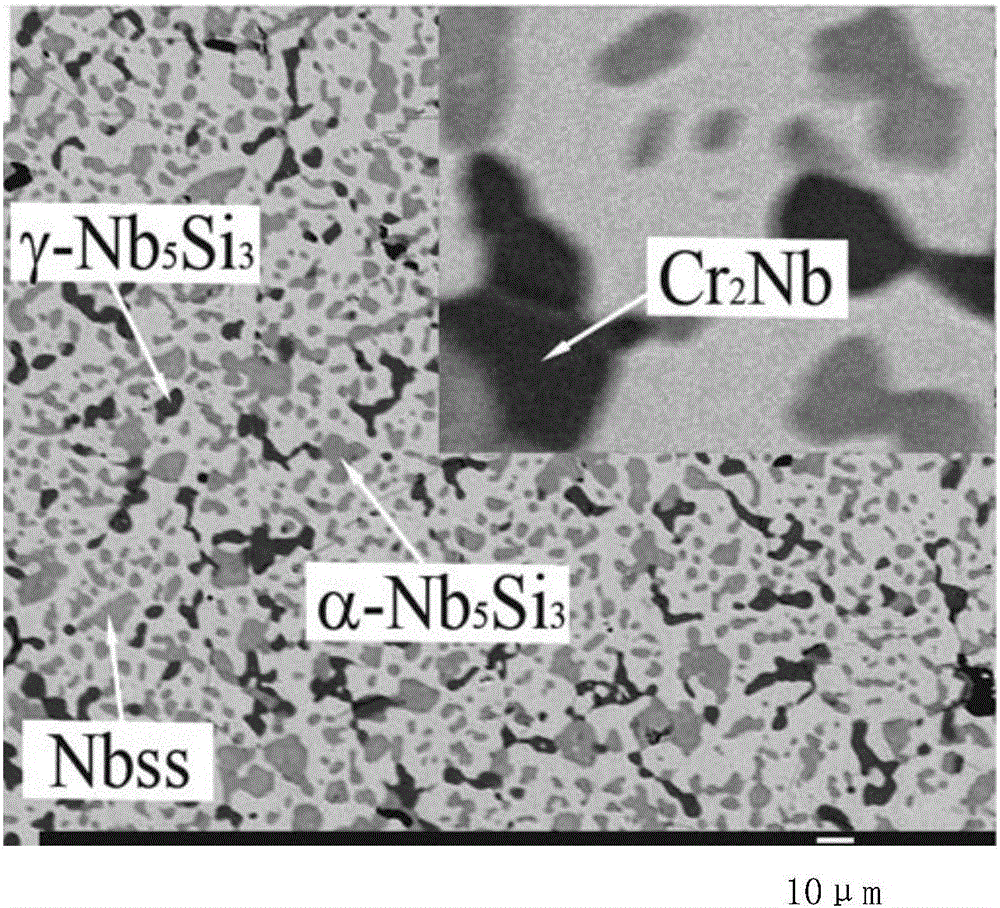

Hafnium-free high-anti-oxidation Nb-Si-based alloy and preparation method thereof

ActiveCN106011574AImprove thermal stabilityExcellent high temperature oxidation resistanceBlade accessoriesMachines/enginesTO-18Electric arc furnace

The invention discloses hafnium-free high-anti-oxidation Nb-Si-based alloy and a preparation method thereof, and relates to Nb-Si-based alloy. The hafnium-free high-anti-oxidation Nb-Si-based alloy is prepared from the following raw materials in atomic percentage: 12 to 24 atomic percent of Ti, 12 to 18 atomic percent of Si, 2 to 12 atomic percent of Cr, 3 to 8 atomic percent of Al and the balance of Nb. The preparation method comprises the following steps: (1) weighing the raw materials, i.e., the Nb, the Si, the Ti, the Cr and the Al according to the component proportion; (2) smelting the raw materials by adopting an electric arc furnace, and casting the raw materials after smelting is completed; (3) carrying out homogenization treatment on a cast material in an argon atmosphere; then quenching by ice water, thus obtaining the Nb-Si-based high-temperature alloy containing Nbss / Nb5Si3 / Cr2Nb complex tissues, i.e., the hafnium-free high-anti-oxidation Nb-Si-based alloy.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com