BCC-based high-strength, high-entropy and high-temperature alloy for coherent precipitation of cubic nano particles

A high-temperature alloy and nanoparticle technology, applied in the field of new materials, can solve the problems of high BCC strength, high alloy brittleness and low plasticity, and achieve improved alloy strength, excellent high temperature oxidation resistance and corrosion resistance, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

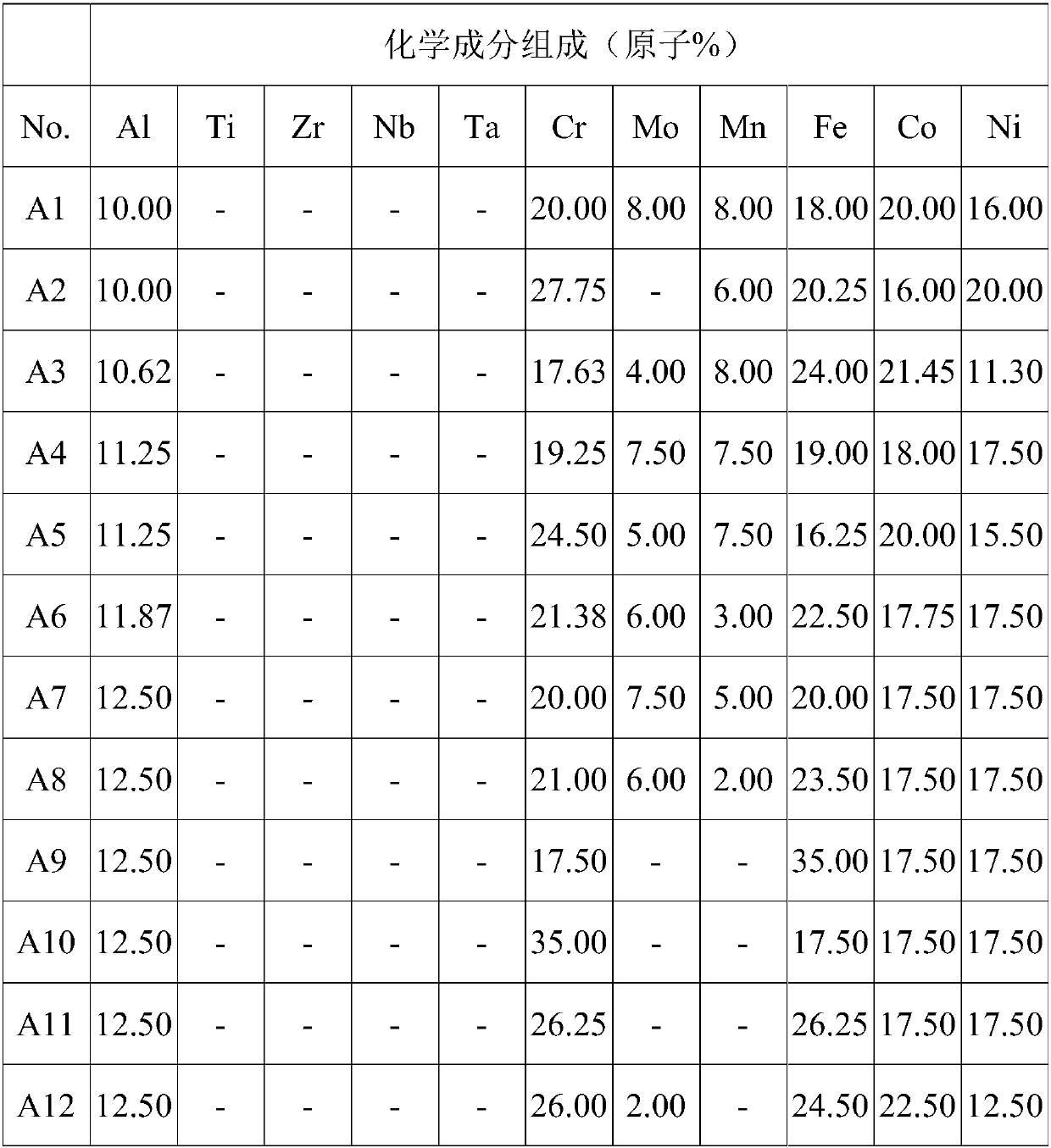

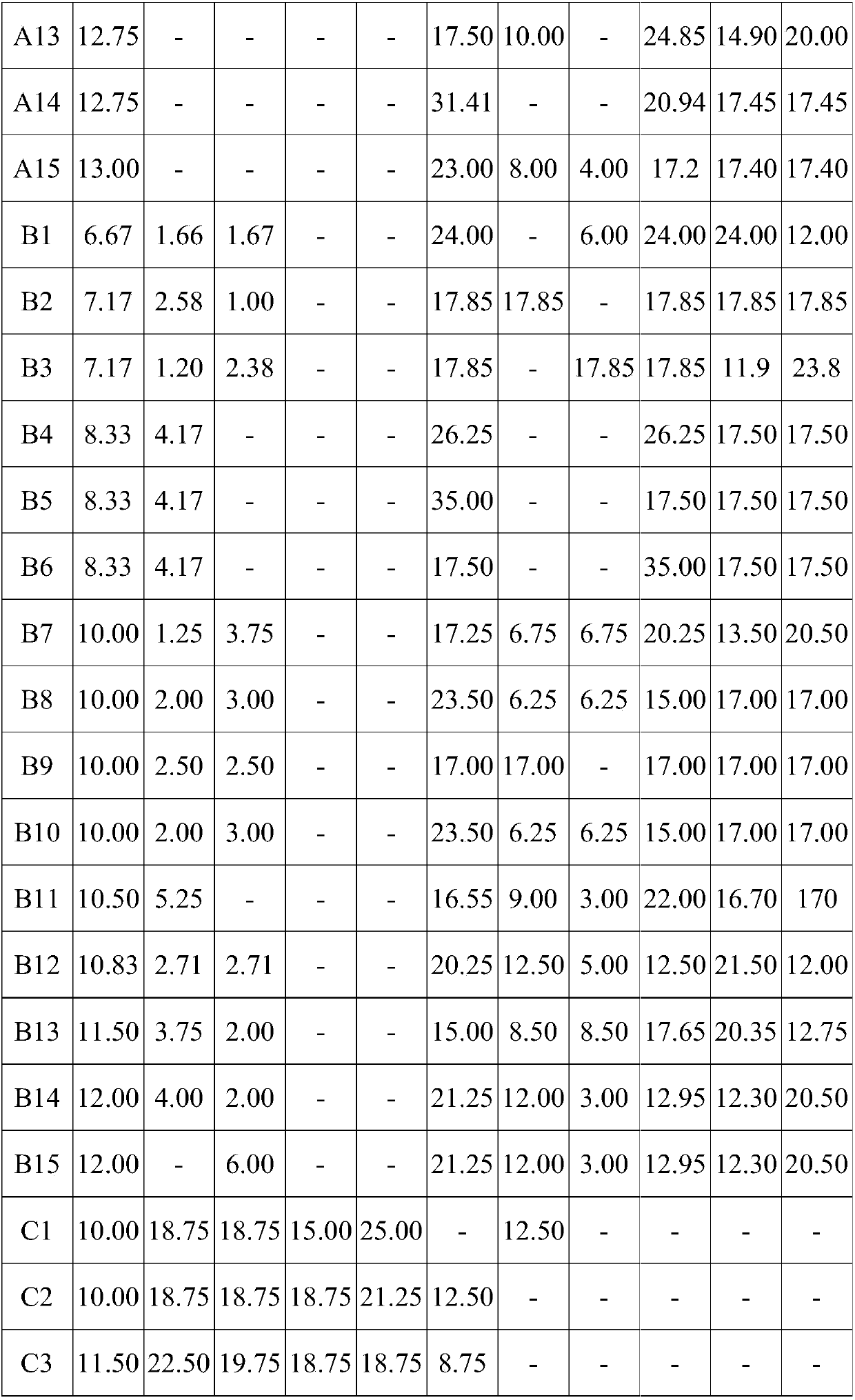

[0018] Example 1: Al 12.5 Cr 35 Fe 17.5 co 17.5 Ni 17.5 (at.%) Alloy

[0019] Step 1: Alloy Preparation

[0020] A BCC-based high-strength and high-entropy superalloy with coherent precipitation of cubic nanoparticles of the present invention belongs to Al-Cr-Mn-Fe-Co-Ni (conventional superalloy system) and satisfies the condition (a). The high-entropy alloy uses high-purity components, and the elements are dosed according to mass percentage, which is Al 6.49 Cr 35.05 Fe 18.82 co 19.86 Ni 19.78 (wt.%). Put 15g of the mixture in a water-cooled copper crucible of an electric arc melting furnace, and use a non-consumable arc melting method to melt under the protection of an argon atmosphere. Repeat this process for at least 5 times to obtain an alloy ingot with a uniform composition; The uniform alloy ingot is melted, and the melt is sucked into the cylindrical copper mold cavity by the copper mold suction casting process to obtain a rod with a diameter of 6mm.

[002...

Embodiment 2

[0024] Example 2: Al 8.33 Ti 4.17 Cr 26.25 Fe 26.25 co 17.5 Ni 17.5 (at.%) Alloy

[0025] Step 1: Alloy Preparation

[0026] A BCC-based high-strength and high-entropy superalloy with coherent precipitation of cubic nanoparticles of the present invention belongs to Al-Ti-Cr-Mn-Fe-Co-Ni (conventional superalloy system) and satisfies the condition (b). The high-entropy alloy uses high-purity components, and the elements are dosed according to mass percentage, Al 4.23 Ti 3.76 Cr 25.69 Fe 27.59 co 19.41 Ni 19.33 (wt.%). Put 15g of the mixture in a water-cooled copper crucible of an electric arc melting furnace, and use a non-consumable arc melting method to melt under the protection of an argon atmosphere. Repeat this process for at least 5 times to obtain an alloy ingot with a uniform composition; The uniform alloy ingot is melted, and the melt is sucked into the cylindrical copper mold cavity by the copper mold suction casting process to obtain a rod with a diameter...

Embodiment 3

[0030] Example 3: Al 12.5 Ti 12.5 Zr 12.5 Nb 25 Ta 25 Mo 12.5 (at.%) Alloy

[0031] Step 1: Alloy Preparation

[0032] A BCC-based high-strength and high-entropy superalloy with coherent precipitation of cubic nanoparticles of the present invention belongs to Al-Ti-Zr-Nb-Ta-Mo (refractory alloy system) and satisfies the condition (c). Using high-purity components, the elements are dosed according to mass percentage, Al 3.33 Ti 5.91 Zr 11.27 Nb 22.95 Ta 44.69 Mo 11.85 (wt.%). Put 15g of the mixture in a water-cooled copper crucible of an electric arc melting furnace, and use a non-consumable arc melting method to melt under the protection of an argon atmosphere. Repeat this process for at least 5 times to obtain an alloy ingot with a uniform composition; The uniform alloy ingot is melted, and the melt is sucked into the cylindrical copper mold cavity by the copper mold suction casting process to obtain a rod with a diameter of 6mm.

[0033] Step 2: Alloy structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com