Method of treating surface of Ti-Al alloy and Ti-Al alloy obtained by the same

A surface treatment, ti-al technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems that have not been raised, high temperature corrosion resistance, oxidation resistance degradation, etc., to achieve improved resistance High temperature oxidation resistance, effect of improving high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Sponge titanium (sponge titanium) with a purity of 99.8% and aluminum with a purity of 99.99% were weighed to form the target composition, and a melting furnace was used to vacuum exhaust once to reach 10 -4 After Torr or more, it was melted and solidified in an Ar gas atmosphere to produce an ingot (Ti-48 atomic % Al). A plate-shaped test piece of 30 mm×10 mm×3 mm was cut out from the ingot, and the surface of the test piece was polished with No. 1000 SiC paper, and then ultrasonically cleaned in acetone to obtain a test piece.

[0049] With this test piece as embodiment A~E, by containing 2 volume % of NF 3 gas, balance by N 2 In the fluorine source gas atmosphere composed of gas and impurity gas, the method of maintaining at 200-400° C. for 5-120 minutes was used to prepare the test piece subjected to the fluorine-concentrated treatment. The thickness of the fluorine-concentrated layer and the maximum concentration of F are measured using ESCA (X-ray photoelectron ...

Embodiment 2

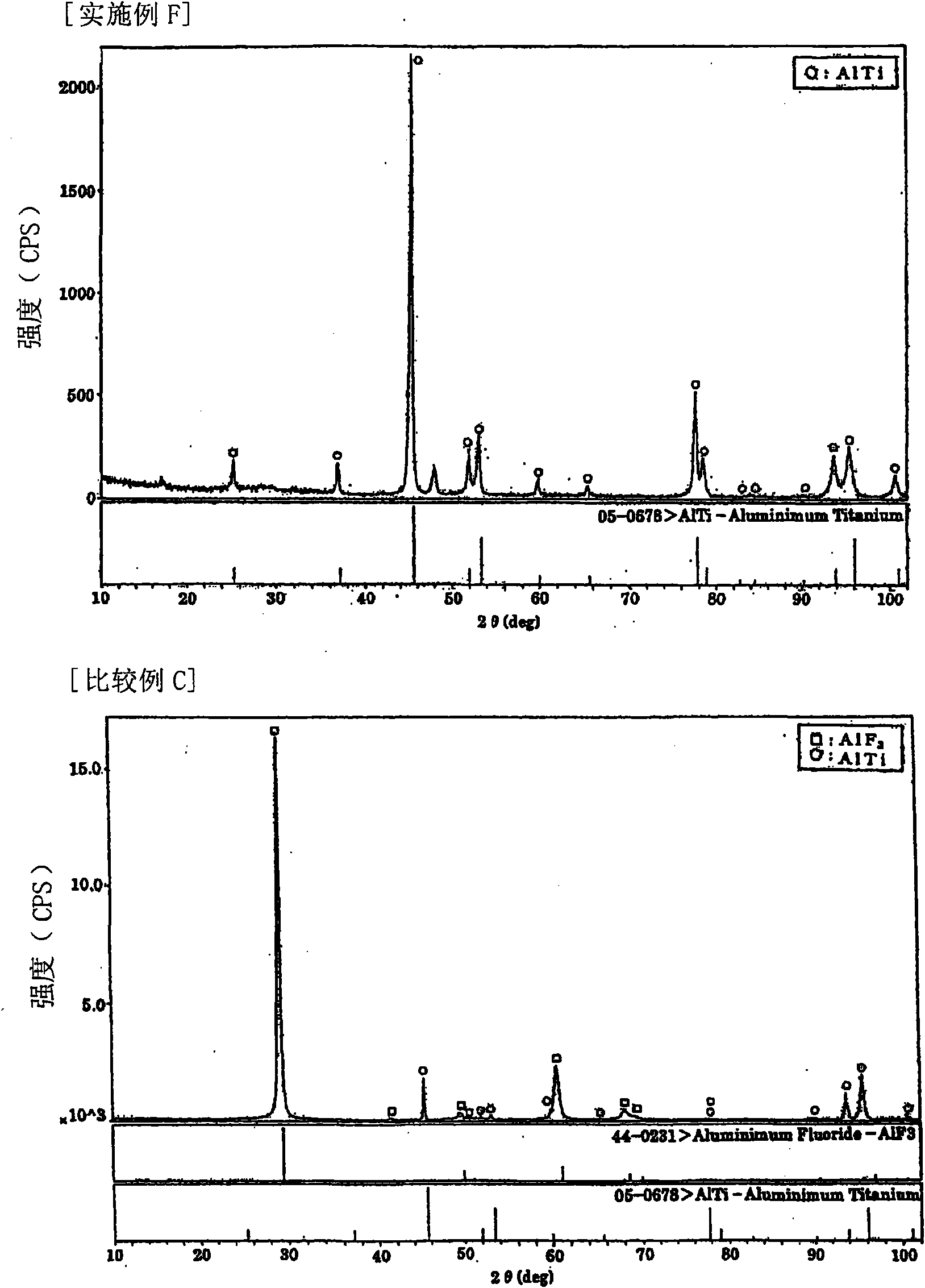

[0056] In order to investigate the influence of the highest F concentration in the fluorine-concentrated layer, the same test piece as in Example 1 was produced, and the concentration of the fluorine gas in the atmosphere was changed to make the thickness of the fluorine-concentrated layer equal. The highest F concentration in the fluorine-intensified layer varies and so is handled. The test piece of embodiment F is in the NF containing 3 volume % 3 gas, balance by N 2 In the fluorine source gas atmosphere composed of gas and impurity gas, it was kept at 350°C for 60 minutes. In addition, the test piece of Comparative Example C was made of NF containing 30% by volume. 3 gas, balance by N 2 In a fluorine source gas atmosphere composed of fluorine gas and impurity gas, the temperature was kept at 350° C. for 60 minutes. Thereafter, the same oxidation test as in Example 1 was performed at 1000° C.×100 hr (in air). The results are shown in Table 2.

[0057] Table 2

[0058] ...

Embodiment 3

[0064] In order to investigate the influence of the Al content of the Ti-Al alloy, the raw material was weighed so that the Al content was 15 atomic %, 30 atomic %, 45 atomic %, and 55 atomic %, so that the raw material reached the target composition as in Example 1, It was melted and solidified to produce an ingot, and a plate-shaped test piece of 30 mm×10 mm×3 mm was cut out, and then the surface was ground and ultrasonically cleaned in acetone to obtain a test piece.

[0065] For these test pieces with different compositions, when containing 2% by volume of NF 3 gas, balance by N 2 In the fluorine source gas atmosphere composed of gas and impurity gas, the fluorine densification treatment was carried out at 300°C for 120 minutes, and then the oxidation test was carried out in the air at 1000°C for 100 hours. The results are shown in Table 3 below. In addition, the thickness of the fluorine-concentrated layer of the test pieces subjected to the fluorine-concentrated treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com