Nickel alloy composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

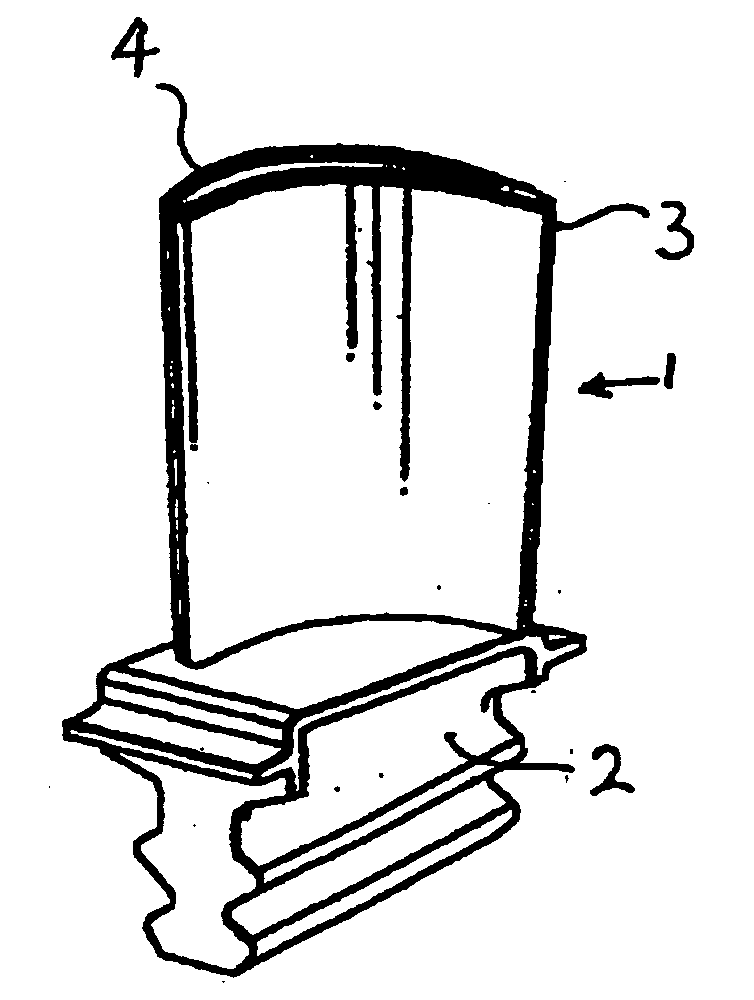

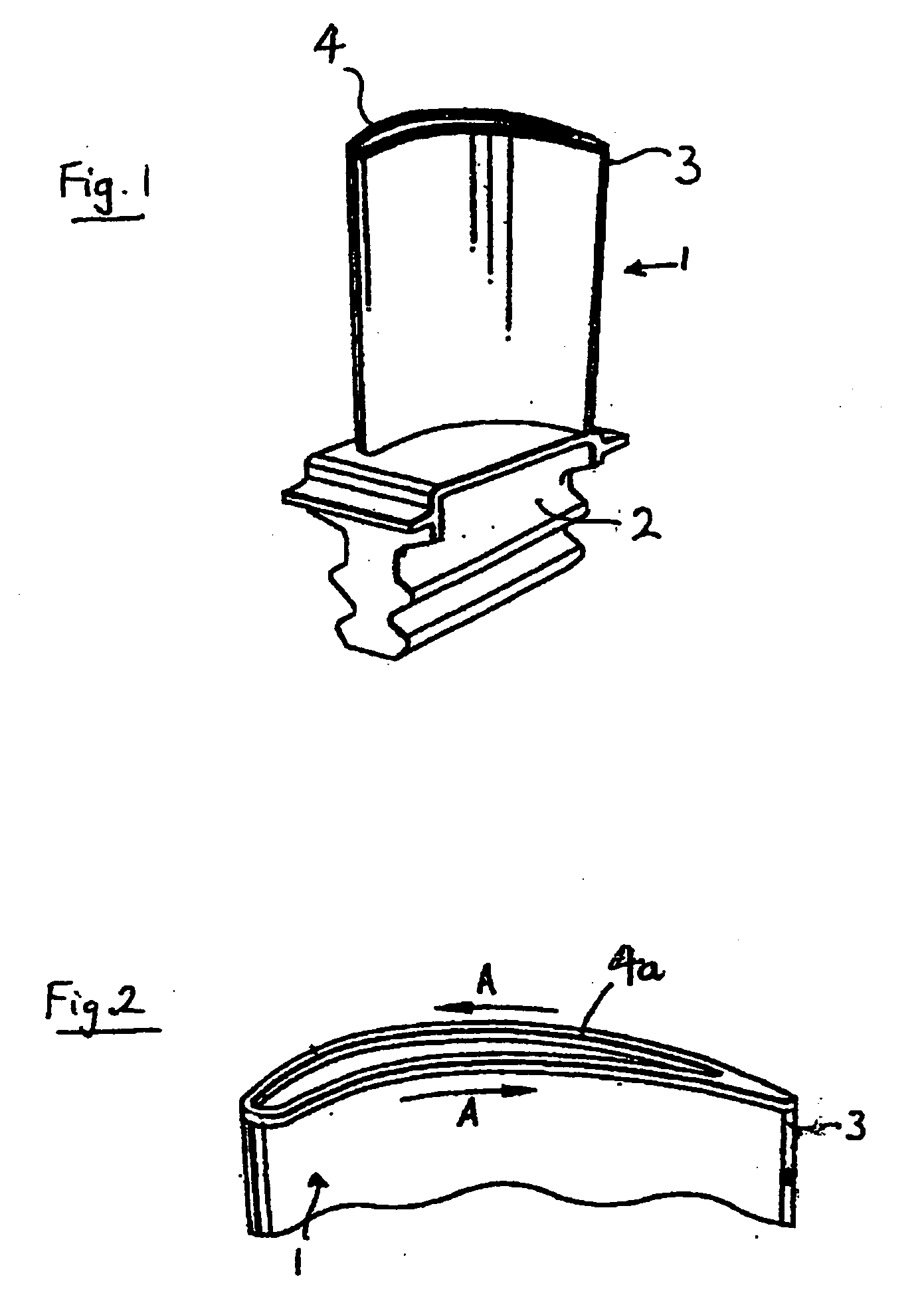

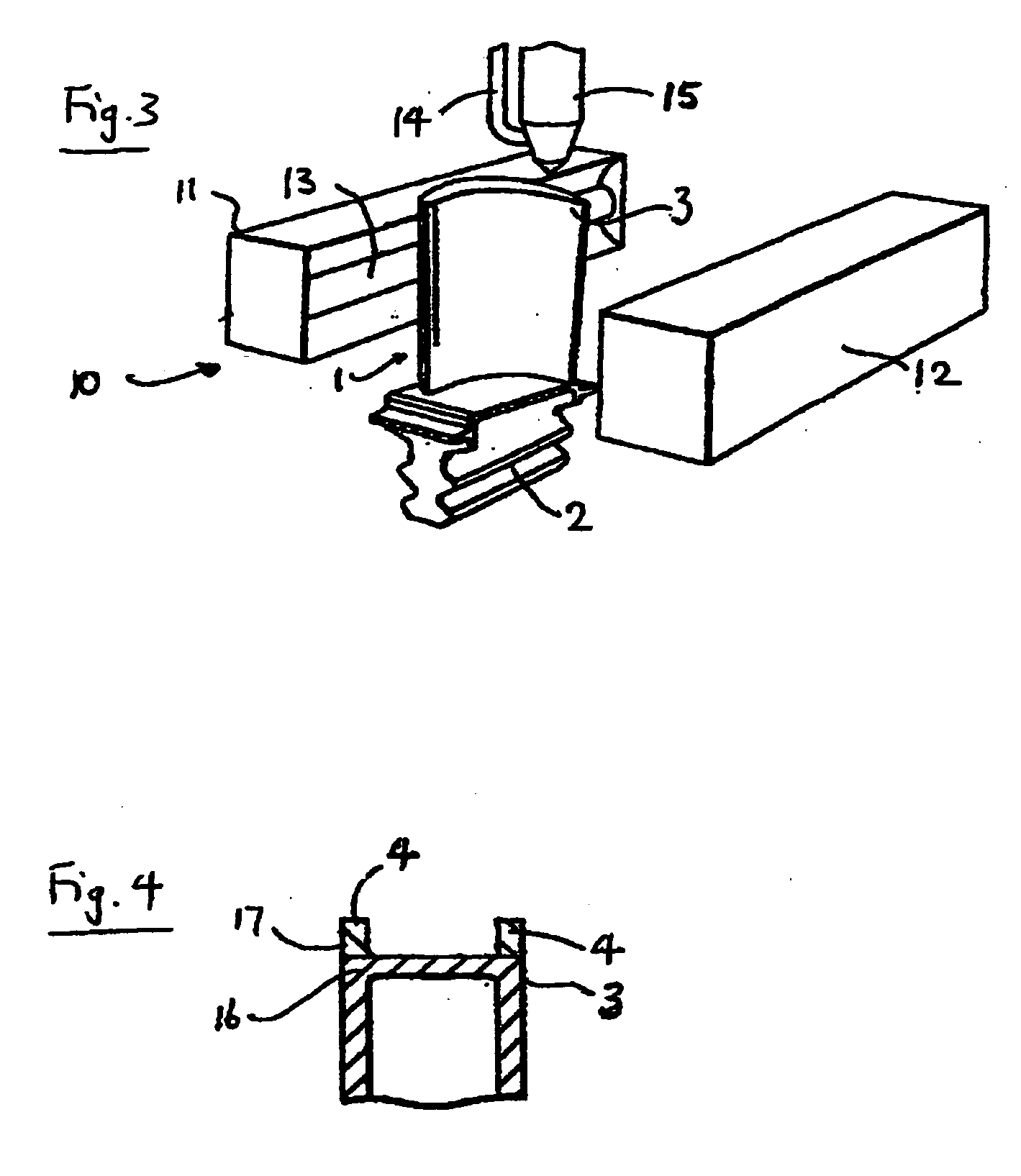

[0028] Referring to the drawings, in which like parts are designated alike, a turbine blade 1 of a gas turbine propulsion engine has a geometry which is generally conventional in the art. The blade 1 has a root 2 and a tip 3, the tip 3 being provided with a squealer comprising a peripheral wall 4. The squealer serves in operation to enclose a body of relatively cool air at the tip of the blade in the tip well bounded by the wall 4. Holes (not shown) in the tip of the blade provide for air flow communication between hollow chambers within the blade and the said body of relatively cool air.

[0029] The blade is preferably formed from a suitable high temperature material, such as an appropriate nickel-based superalloy of a type known in the art, and may be cast as single crystal or directionally solidified casting to promote the high temperature properties of the blade 1.

[0030] The wall 4 of the squealer tip is formed using the novel nickel alloy co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Composition | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com