Technology of high polymer material post-grouting squeezed cast-in-place pile

A high-polymer, post-grouting technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problem that the grouting pipe is easy to be coagulated by the cement slurry, the shape and character are not easy to control, and the grouting effect is affected by the properties, etc. It can achieve the effect of avoiding the extrusion and expansion of mechanical equipment construction technology, which is conducive to environmental protection and energy saving, and avoids collapse of holes and excessive soil at the pile end.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The protection scope of the present invention is not limited only to the description of this embodiment.

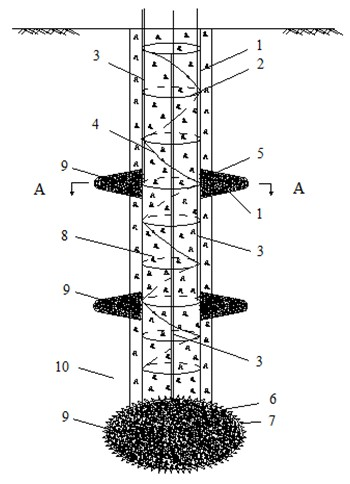

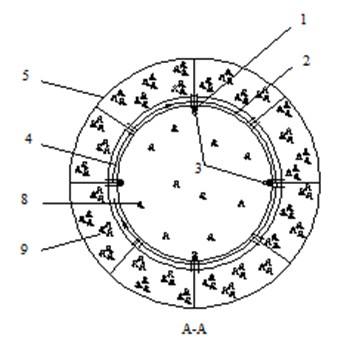

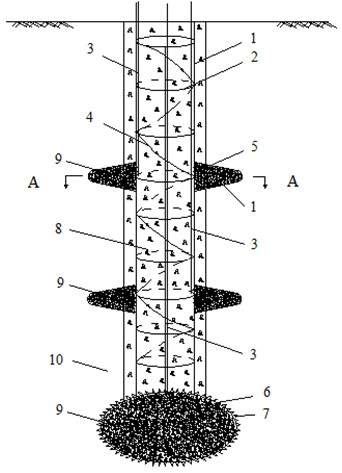

[0022] like figure 1 and figure 2As shown, during implementation, firstly, the pile driver is in place, the hole is dug by the conventional bored pile forming process, and the mud wall is used to protect the wall. The diameter of the pile body is 300-1000 mm, and the depth is 10-35 m; assemble the reinforcement cage The main reinforcement 1 and reinforcement 2, and the rigid grouting pipe 3 is bound inside the main reinforcement 1 of the steel cage, and the flexible grouting pipe 4 with grouting holes is wound spirally on the outside of the main reinforcement 1 and reinforcement 2 of the reinforcement cage along the depth direction of the reinforcement cage The rigid grouting pipe 3 is a steel pipe with an outer diameter of 10-25 mm and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com