Self-lubricating wear-resistant composite film containing nano two-dimensional black-phosphorus and preparation method of composite film

A nano two-dimensional, composite film technology, applied in the field of self-lubricating and wear-resistant composite films containing nano-two-dimensional black phosphorus and its preparation, can solve the problems of lubricating performance degradation, wear-resistant life reduction, etc., and achieve high mechanical strength and service life The effect of long life and excellent self-lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

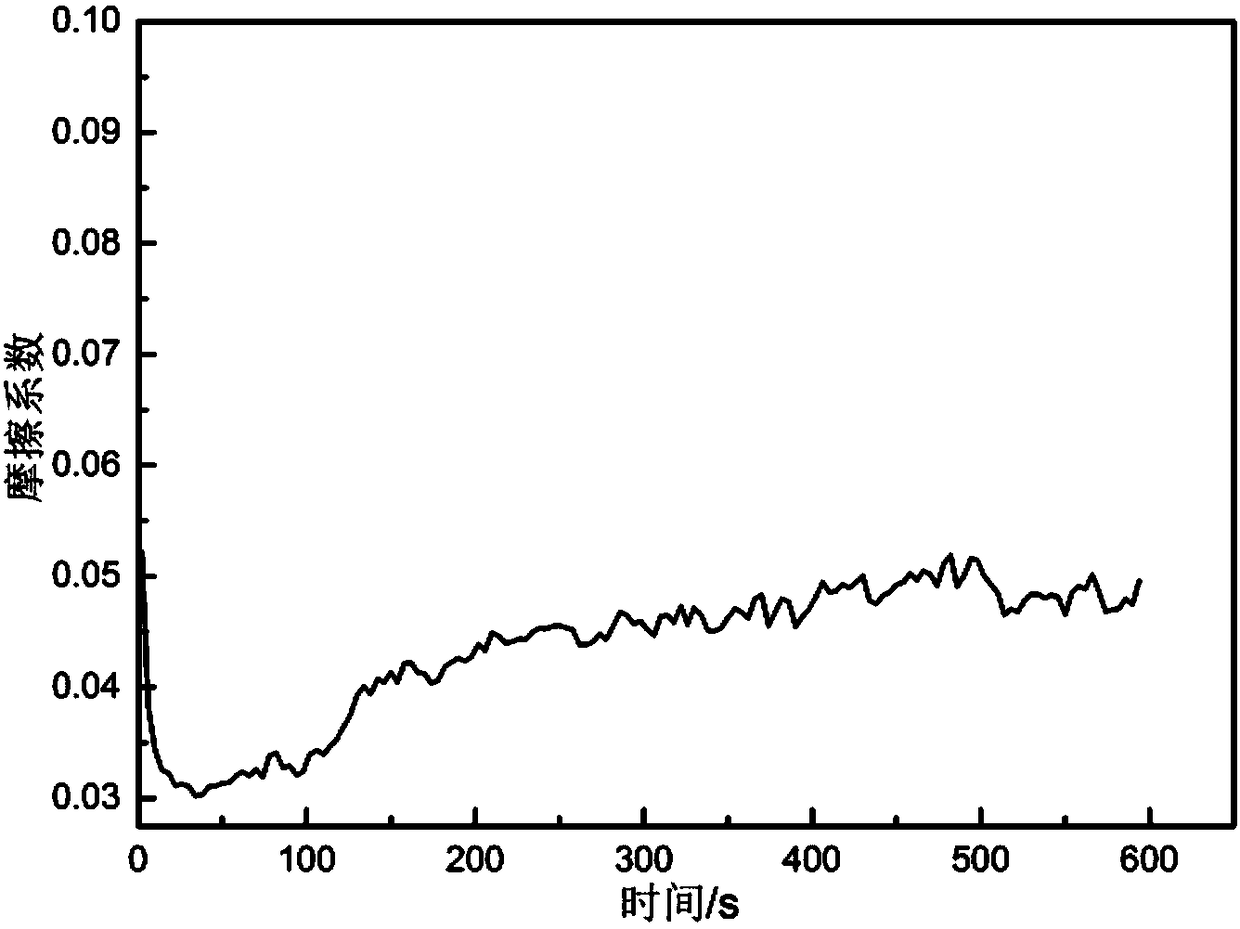

Examples

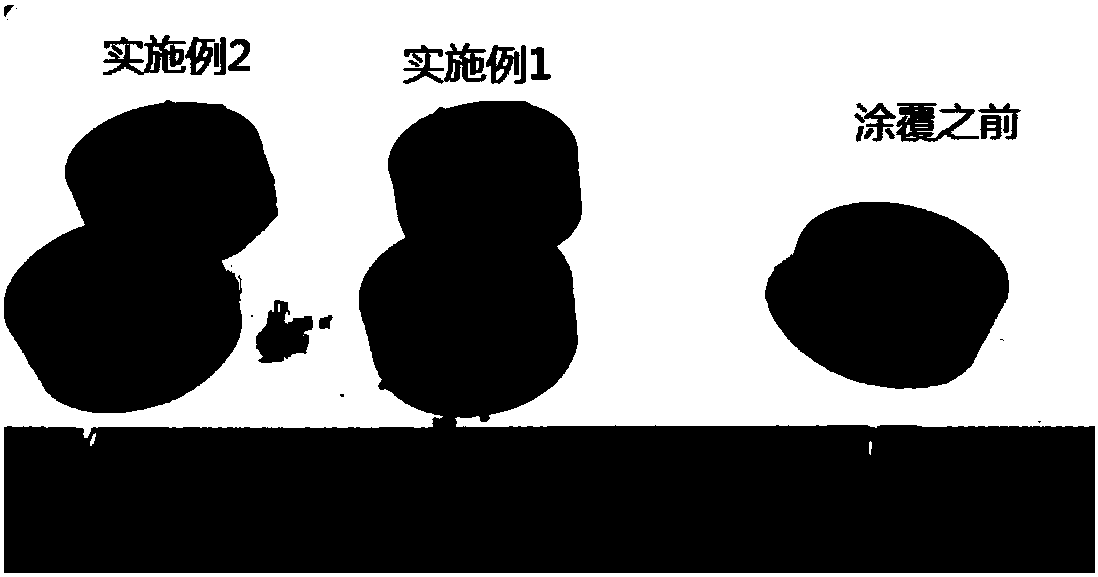

Embodiment 1

[0029] (1) The preparation process of nanometer two-dimensional black phosphorus composite material:

[0030] ① Preparation of black phosphorus and black phosphorus and graphite composite nanopowder:

[0031] Adopt star type ball milling method to prepare black phosphorus and black phosphorus and graphite composite nano-powder, take by weighing 4g red phosphorus, and red phosphorus: the powder of graphite (particle diameter<30nm) mass ratio=4 (3.2g): 1 (0.8g) Put it into a ball mill tank, select steel balls as quenched and tempered steel, the quantity ratio of steel balls with a diameter of 10mm and 5mm is 5:8, the mass ratio of steel balls to powder is 20:1, the speed of the ball mill is 350rpm, and the ball milling time is 20h.

[0032] ② Preparation of black phosphorus composite material solution:

[0033] a. Preparation of black phosphorus polytetrafluoroethylene aqueous dispersion mixed liquid: add an appropriate amount of deionized water to dilute the concentrated polyt...

Embodiment 2

[0039] (1) The preparation process of nanometer two-dimensional black phosphorus composite material:

[0040] ① Preparation of black phosphorus and black phosphorus and graphite composite nanopowder:

[0041] Adopt star type ball milling method to prepare black phosphorus and black phosphorus and graphite composite nano-powder, take by weighing 4g red phosphorus, and red phosphorus: the powder of graphite (particle diameter<30nm) mass ratio=7 (2.8g):3 (1.2g) Put it into a ball mill tank, select steel balls as quenched and tempered steel, the ratio of the number of steel balls with a diameter of 10mm to 5mm is 5:8, the mass ratio of steel balls to powder is 20:1, the speed of the ball mill is 550rpm, and the ball milling time is 18h.

[0042] ② Preparation of black phosphorus composite material solution:

[0043]a. Preparation of black phosphorus polytetrafluoroethylene aqueous dispersion mixed liquid: add an appropriate amount of deionized water to dilute the concentrated pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com