Hafnium-free high-anti-oxidation Nb-Si-based alloy and preparation method thereof

An oxidizing, base alloy technology, applied in the direction of mechanical equipment, blade support components, engine components, etc., can solve the problems of no high-temperature oxidation resistance of alloys, complex preparation process, high Hf density, etc., and achieve excellent high-temperature oxidation resistance , good mechanical properties and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

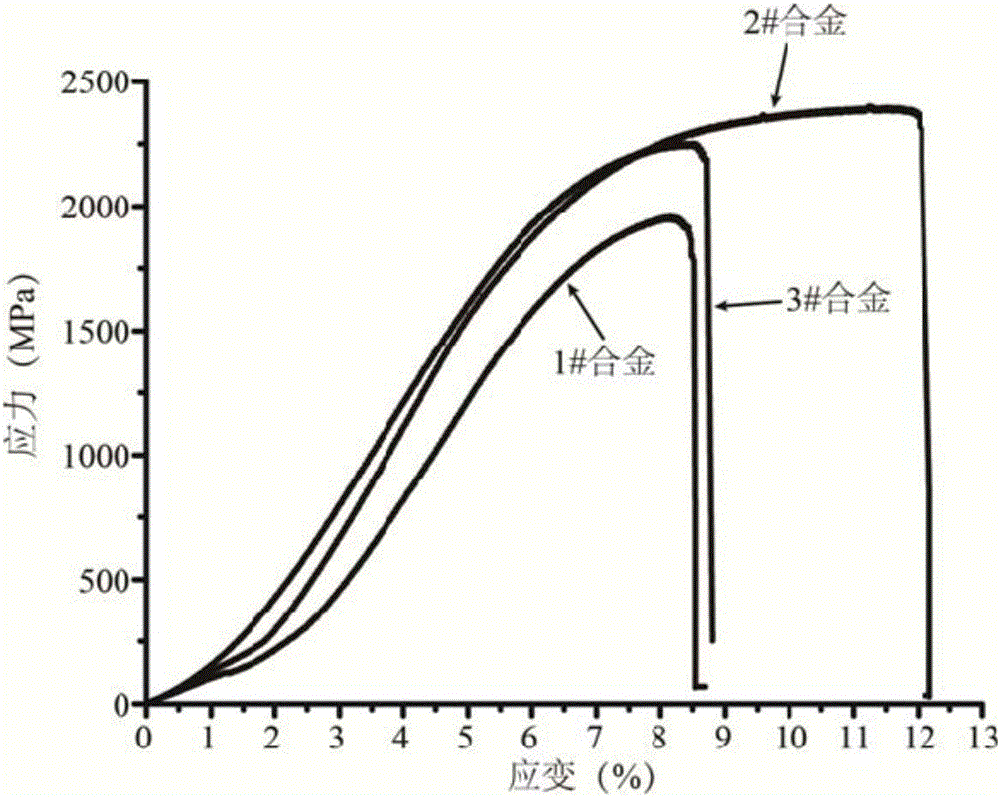

[0034] For various high-purity metals, 99.99wt.% Nb, 99.99wt.% Si, 99.8wt.% Ti, 99.9wt.% Cr, and 99.95wt.% Al are Raw materials, the alloy is prepared according to the composition ratio of Nb-14Si-20Ti-8Cr-3Al; the alloy is smelted by WS-4 vacuum non-consumable electric arc furnace. When smelting, first vacuum up to 6×10 -3 Below Pa, fill with argon to 0.4-0.6 atmospheric pressure, and then melt under the protection of argon. To ensure uniform alloy composition, each alloy sample was smelted 5 times. The smelted alloy ingots are cut into appropriate sizes according to different needs, and subjected to homogenization heat treatment at 1300°C for 24 to 240 hours in an argon atmosphere. Quenching in ice water to obtain Nbss / Nb containing 5 Si 3 / Cr 2 Nb-Si based superalloy material with Nb composite structure. The room temperature compressive strength of this alloy is 1957MPa (see image 3 Medium 1# alloy), the oxidation gain of 100h in the air exposure test at 1200°C is 9...

Embodiment 2

[0036] For various high-purity metals, 99.99wt.% Nb, 99.99wt.% Si, 99.8wt.% Ti, 99.9wt.% Cr, and 99.95wt.% Al are Raw materials, the alloy is prepared according to the composition ratio of Nb-14Si-20Ti-8Cr-5Al; the alloy is smelted by WS-4 vacuum non-consumable electric arc furnace. When smelting, first vacuum up to 6×10 -3 Below Pa, fill with argon to 0.4-0.6 atmospheric pressure, and then melt under the protection of argon. To ensure uniform alloy composition, each alloy sample was smelted 5 times. The smelted alloy ingots are cut into appropriate sizes according to different needs, and subjected to homogenization heat treatment at 1300°C for 24 to 240 hours in an argon atmosphere. Quenching in ice water to obtain Nbss / Nb containing 5 Si 3 / Cr 2 Nb-Si based superalloy material with Nb composite structure. The room temperature compressive strength of this alloy is 2401MPa (see image 3 Medium 2# alloy), the oxidation gain of 100h in the air exposure experiment at 1200°...

Embodiment 3

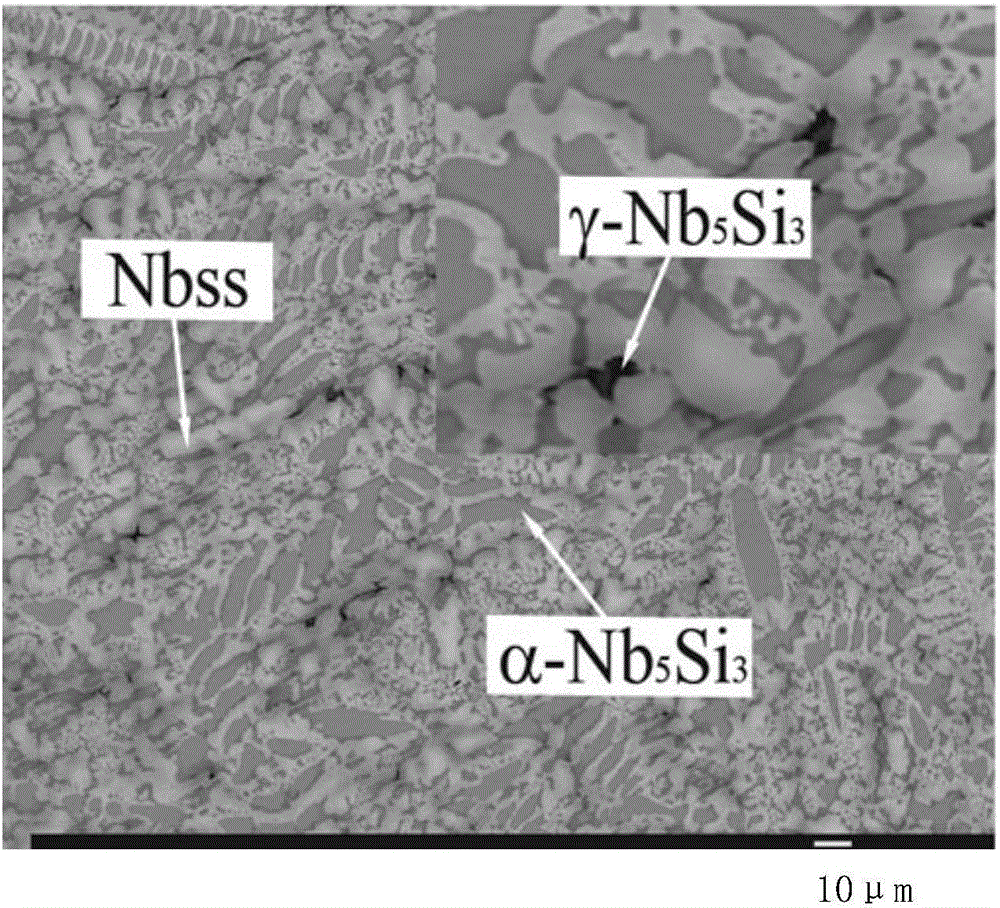

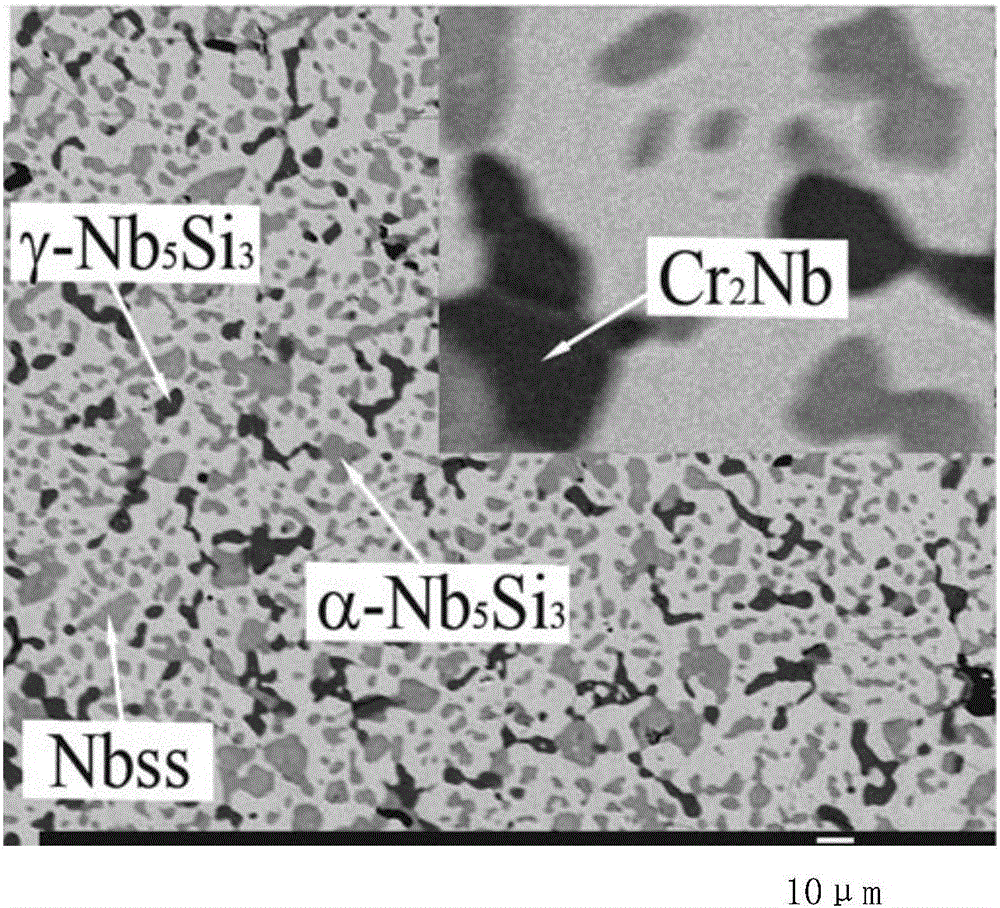

[0038] For various high-purity metals, 99.99wt.% Nb, 99.99wt.% Si, 99.8wt.% Ti, 99.9wt.% Cr, and 99.95wt.% Al are Raw materials, the alloy is prepared according to the composition ratio of Nb-14Si-20Ti-8Cr-7Al; the alloy is smelted by WS-4 vacuum non-consumable electric arc furnace. When smelting, first vacuum up to 6×10 -3 Below Pa, fill with argon to 0.4-0.6 atmospheric pressure, and then melt under the protection of argon. To ensure uniform alloy composition, each alloy sample was smelted 5 times. There are only Nbss phase and silicide phase (including -Nb 5 Si 3 and -Nb 5 Si 3 ) (see figure 1 ). The smelted alloy ingots are cut into appropriate sizes according to different needs, and subjected to homogenization heat treatment at 1300°C for 24-240 hours in an argon atmosphere. Quenching in ice water to obtain Nbss / Nb containing 5 Si 3 / Cr 2 Nb composite tissue (see figure 2 ) Nb-Si based superalloy materials. The room temperature compressive strength of this a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com