Iron-based powder

a technology of iron-based powders and atomised iron, which is applied in the direction of transportation and packaging, metal-working apparatuses, etc., can solve the problems of difficult sintering of fecral-powders, and achieve the effects of easy sintering, good high temperature oxidation properties, and good sintered structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0033]Seven different water atomised powders having the compositions of Table 1 were made by making a melt of iron and the desired alloying elements. The melt was thereafter water atomised whereby the powder formed from the atomized droplets upon solidification. The atomization was performed according to conventional water atomization technology. The resulting powders were extracted through a grid providing a maximum diameter of 75 μm.

[0034]For each powder sintered test samples were prepared. The sintered test samples and a reference sample having a 310B composition (25 wt % Cr+20 wt % Ni+2.5 wt % Si+bal. Fe) were subjected to a high temperature oxidation test described below. The material 310B was chosen as reference since it is known to possess good high temperature oxidation resistance.

[0035]The test samples and the reference sample were produced by filling a form (10 mm diameter and 2 mm thickness) with the powder of interest, followed by smoothing out the surface without compac...

example 2

[0045]Powder 2 and 3 were further tested at different oxidation temperatures. The following table shows the increase in weight relative to the reference 310B.

TABLE 2Powder 3Powder 2TestIncrease in weightIncrease in weighttemperaturerelative referencerelative reference[° C.](%)(%)REMARKS800462485043229002121950141410002013Terminated after 16hours

[0046]Table 2 shows that difference in oxidation resistance between samples containing Cu and Al and reference samples is further pronounced at temperatures above 800° Celcius. Furthermore, the composition having a Al content of 5.5% and a Cu content of 15% seems to have better oxidation resistance compared to the composition having 10 Al and 10% Cu.

example 3

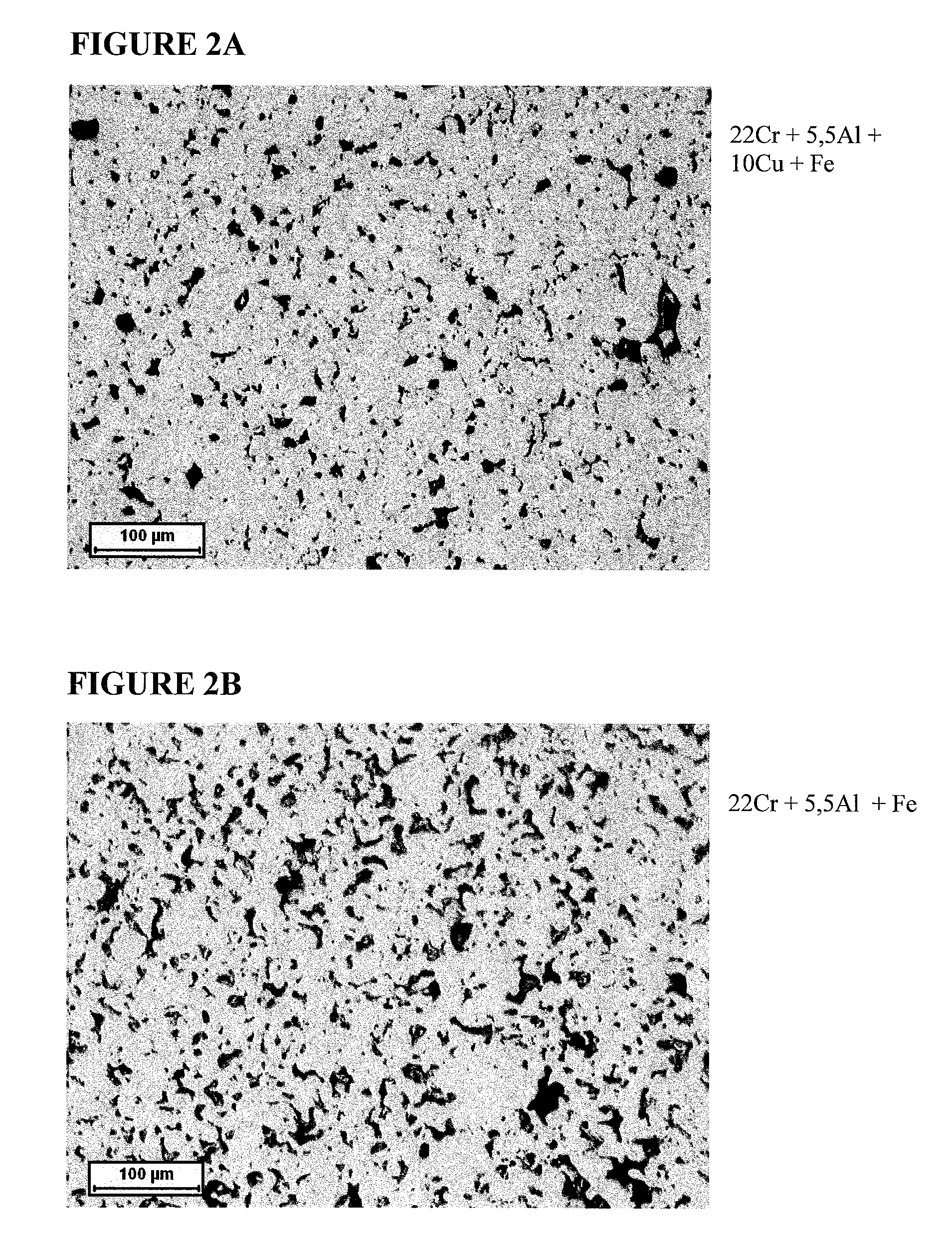

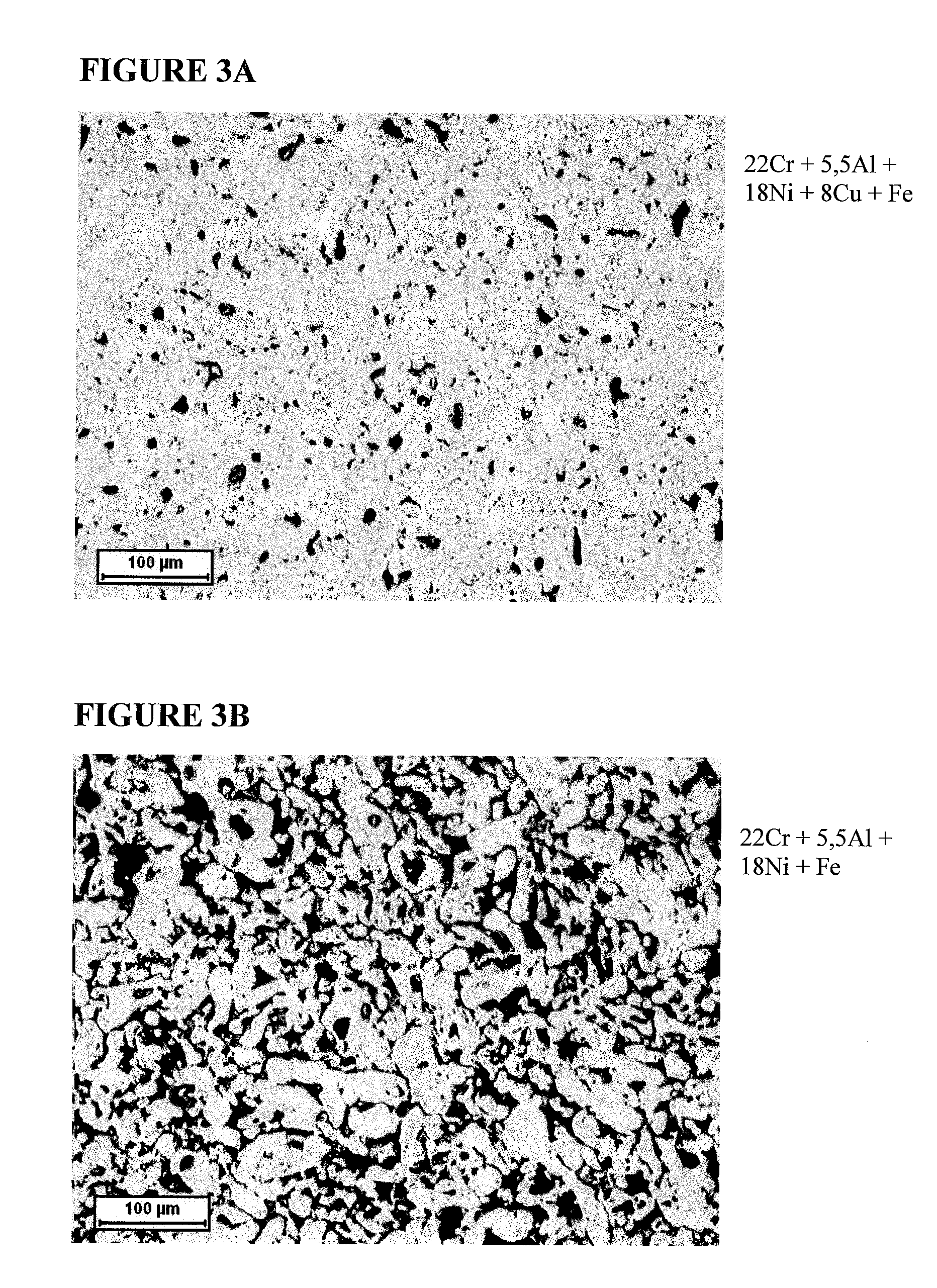

[0047]In order to evaluate the effect of added Cu-content with regard to sintered density, tensile strength and yield strength, four different powders having were compared. The powders were as in example 1 and 2 water atomized powders. The powders were mixed with 1% of Acrawax®. The mixes were compacted at a compacting pressure of 600 MPa into tensile test bars. The test bars were sintered for 30 minutes at 1320° Celsius in an atmosphere of 100% hydrogen. Sintered density, tensile strength and yield strength were measured. The results are shown in table 3.

TABLE 3ChemicalSinteredTensileYieldcomposition wt %,densityStrengthstrengthbalance Fe[g / cm3][MPa][MPa]22Cr + 5.5Al + 10Cu6.8758252222Cr + 5.5Al (ref.)5.7429525922Cr + 18Ni + 5.5Al + 8Cu6.7050741222Cr + 18Ni + 5.5Al (ref.)4.968769

[0048]The table 3 shows that the density and the mechanical properties of Al-containing Cr or Cr—Ni stainless steel powders increases considerably if the powder are pre-alloyed with Cu. This indicates much ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com