TiSiN+ZrSiN composite nanometer coated cutting tool and preparation method thereof

A nano-coating and cutting tool technology, which can be used in coatings, chemical instruments and methods, metal material coating processes, etc., and can solve problems such as high equipment requirements and complex methods and processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

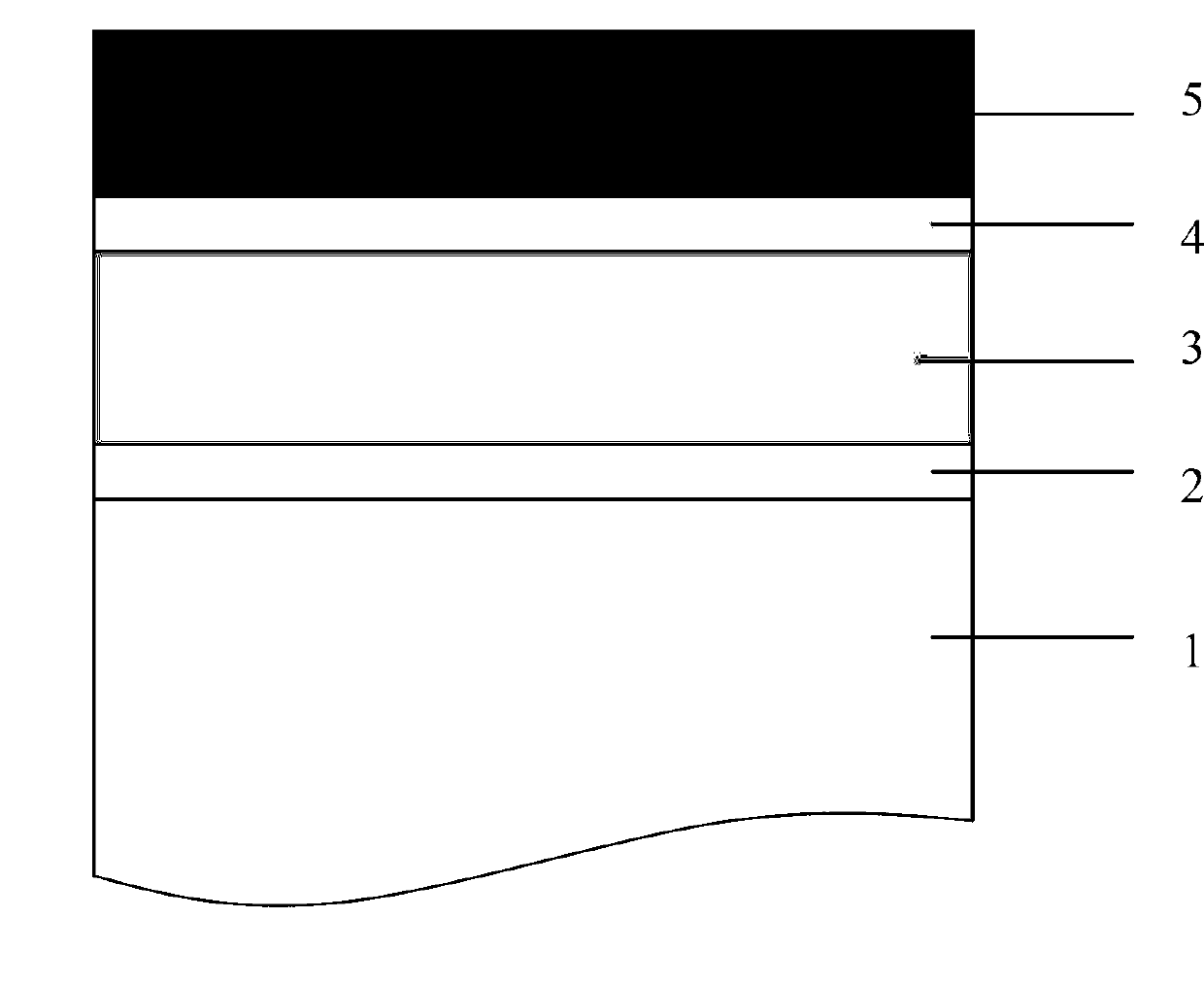

[0019] A TiSiN+ZrSiN composite nano-coating tool and its preparation method, the tool base material is YS8 hard alloy, the coating is a multi-layer structure, the surface of the tool is a ZrSiN layer, there is a TiZrSiN transition layer between the ZrSiN layer and the TiSiN layer, TiSiN There is a Ti transition layer between the layer and the substrate. The preparation method of TiSiN+ZrSiN composite nano-coating tool is the method of multi-arc ion plating + intermediate frequency magnetron sputtering co-deposition, and the specific preparation steps are as follows:

[0020] (1) Pretreatment: Polish the YS8 cemented carbide tool base material to the mirror surface, remove the surface contamination layer, put it in alcohol for ultrasonic cleaning for 15 minutes, and put it into the vacuum chamber of the coating machine after it is fully dried. The background vacuum of the vacuum chamber is 7.0×10- -3 Pa, heat to 250°C, keep warm for 30min;

[0021] (2) Ion cleaning: enter Ar g...

Embodiment 2

[0028] A TiSiN+ZrSiN composite nano-coating tool and its preparation method, the tool base material is W18Cr4V high-speed steel, the coating is a multi-layer structure, the surface of the tool is a ZrSiN layer, there is a TiZrSiN transition layer between the ZrSiN layer and the TiSiN layer, and a TiSiN layer There is a Ti transition layer between the substrate and the substrate. The preparation method of TiSiN+ZrSiN composite nano-coating tool is the method of multi-arc ion plating + intermediate frequency magnetron sputtering co-deposition, and the specific preparation steps are as follows:

[0029] (1) Pretreatment: Polish the W18Cr4V high-speed steel tool base material to the mirror surface, remove the surface contamination layer, put it in alcohol for ultrasonic cleaning for 15 minutes, and put it into the vacuum chamber of the coating machine after it is fully dried. The background vacuum of the vacuum chamber is 7.0×10 -3 Pa, heat to 200°C, keep warm for 30min;

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com