Method for manufacturing brake disk mounted on axis

A manufacturing method and technology of brake discs, applied in the direction of brake discs, friction linings, mechanical equipment, etc., can solve the problems of difficult machining, easy deformation, long cycle, etc., and achieve good friction and wear performance and braking power Large and stable coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

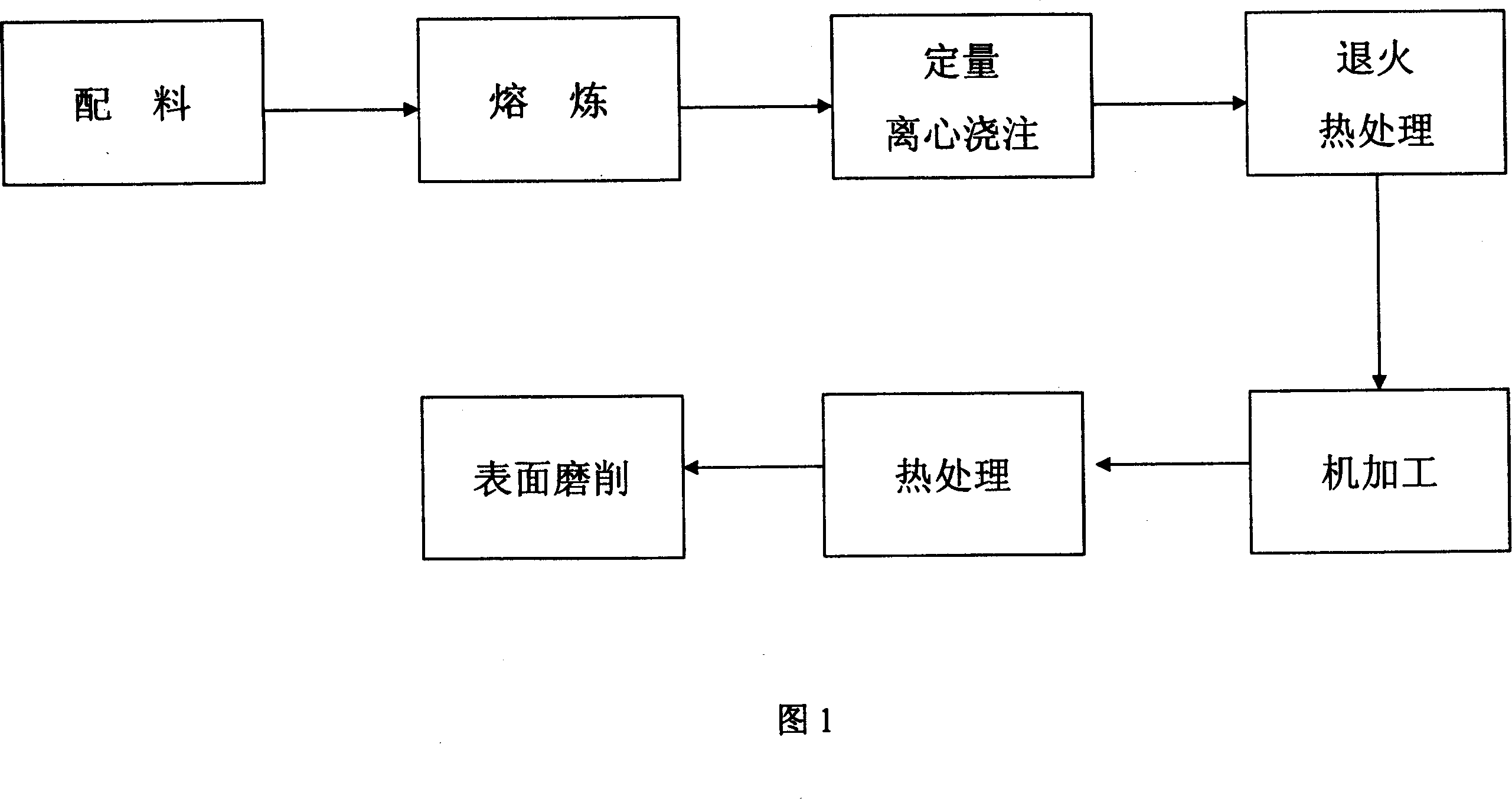

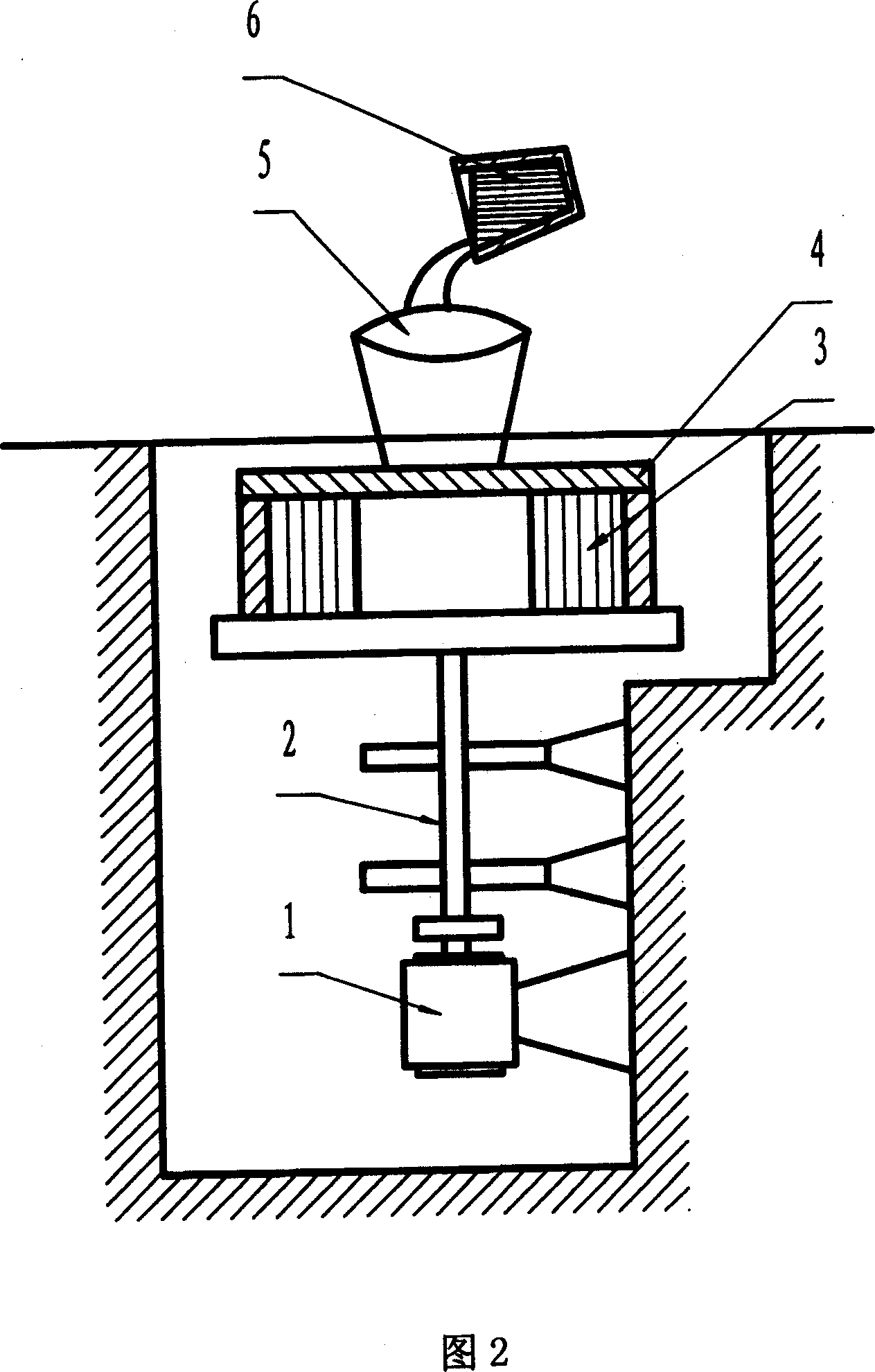

Method used

Image

Examples

Embodiment 1

[0042] A ingredient

[0043]Take the materials used in the production of shaft-mounted brake discs for backup, including 1.167 kg of chromium, 0.666 kg of manganese, 0.615 kg of molybdenum, 0.333 kg of silicon, 1.24 kg of nickel, 0.187 kg of copper and 100 kg of industrial pure iron. Carbon, sulfur, and phosphorus are three elements, so there is no need to add the above three elements, and it can be calculated that the above materials contain 0.187 kg of carbon, 0.024 kg of sulfur, and 0.031 kg of phosphorus;

[0044] B melting

[0045] According to the above ratio, put the industrial pure iron into the intermediate frequency furnace for smelting. After the industrial pure iron is melted, perform the first deoxidation treatment at a steel temperature of 1550°C for 21 minutes; then add copper, chromium, nickel, Molybdenum element, conduct the second deoxidation treatment for 31 minutes; then add manganese and silicon for the third deoxidation treatment, when the slag material ...

Embodiment 2

[0053] A ingredient

[0054] Take the materials used in the production of shaft-mounted brake discs for backup, of which

[0055] Chromium Cr is 0.01042~0.01354:1, Manganese Mn is 0.00521~0.01042:1, Molybdenum Mo is 0.00521~0.00729:1, Silicon Si is 0.00313~0.00625:1, Nickel Ni is 0.00937~0.01354:1, Copper Cu is 0.00104~ 0.00208:1, carbon C is 0.00156~0.00261:1, sulfur S is 0.00021~0.00026:1, phosphorus P is 0.00026~0.00035:1;

[0056] 1.2 kg of chromium, 0.614 kg of manganese, 0.7 kg of molybdenum, 0.5 kg of silicon, 1 kg of nickel, 0.2 kg of copper and 100 kg of industrial pure iron. Since the above raw materials contain three elements of carbon, sulfur and phosphorus in different procedures, no need Add the above three additionally, and it can be calculated that the above materials contain 0.15 kg of carbon, 0.02 kg of sulfur, and 0.03 kg of phosphorus;

[0057] B melting

[0058] According to the above ratio, put the industrial pure iron into the intermediate frequency f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com