Long basalt fiber reinforced PA6 composite material and melt impregnation preparation method thereof

A technology of basalt fiber and composite materials, applied in the field of composite materials, can solve the problems of increased manufacturing cost, high price of carbon fiber, and glass fiber reinforced PA can not fully meet the performance of use, so as to achieve excellent mechanical properties and friction and wear properties, and solve performance defects , The effect of simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

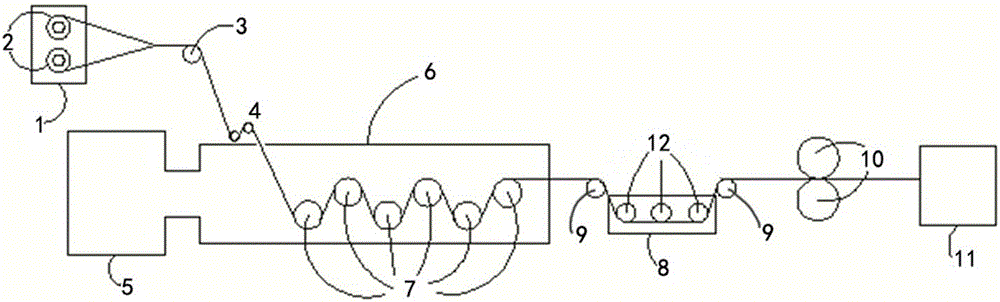

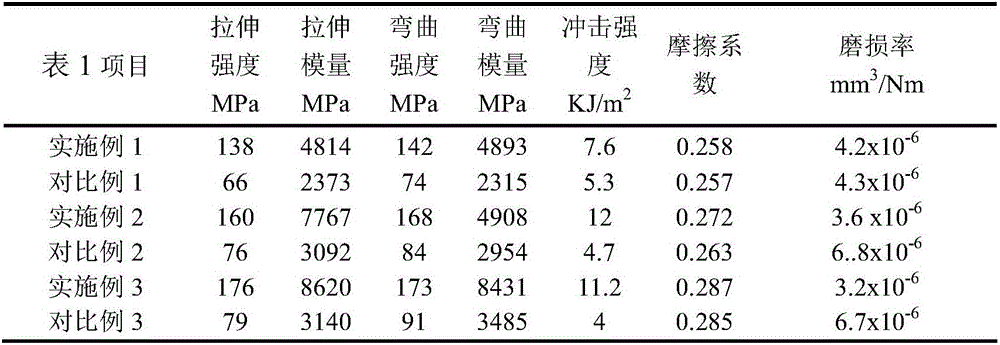

[0018] The fiber bundle is drawn out from the long fiber roll 2 on the support 1 and unrolled, and the guide roller 3 and the limit guide roller 4 are introduced into the temperature-controlling impregnation mold 6, and the supporting extruder 5 is connected with the temperature-control impregnation mold 6, Extruder 5 extrudes PA6 (80wt%) and γ-aminopropyltriethoxysilane (5wt%) into the temperature-controlling impregnation mold 6 (there are 2 impregnation rollers 7), and the temperature-control impregnation mold 6 The temperature was adjusted to 250° C., and the speed of the pulling roller 10 was set to 35 mm / s, so that the content of long basalt fibers was 15 wt%. The impregnated fiber bundles are introduced into the cooling water tank 8 for cooling, granulated in the pelletizer 11, and dried to obtain the long basalt fiber reinforced PA6 composite material. The resulting composite material was injection molded to obtain a standard sample, and the mechanical and friction and ...

Embodiment 2

[0020] The fiber bundle is drawn out from the long fiber roll 2 on the support 1 and unrolled, and the guide roller 3 and the limit guide roller 4 are introduced into the temperature-controlling impregnation mold 6, and the supporting extruder 5 is connected with the temperature-control impregnation mold 6, The extruder 5 extrudes PA6 (48wt%) and γ-glycidyl etheroxypropyl trimethoxysilane (2wt%) into the temperature-controlling dipping mold 6 (there are 5 dipping rollers 7 in total), and the temperature-controlling dipping mold The temperature of 6 is adjusted to 235° C., and the speed of the pulling roller 10 is set to 16 mm / s, so that the content of long basalt fibers is 50 wt%. The impregnated fiber bundles are introduced into the cooling water tank 8 for cooling, granulated in the pelletizer 11, and dried to obtain the long basalt fiber reinforced PA6 composite material. The resulting composite material was injection molded to obtain a standard sample, and the mechanical a...

Embodiment 3

[0022] The fiber bundle is drawn out from the long fiber roll 2 on the support 1 and unrolled, and the guide roller 3 and the limit guide roller 4 are introduced into the temperature-controlling impregnation mold 6, and the supporting extruder 5 is connected with the temperature-control impregnation mold 6, Extruder 5 extrudes PA6 (48wt%) and γ-isocyanate propyltriethoxysilane (3wt%) into temperature-controlling dipping mold 6 (there are 8 dipping rollers 7, and temperature-controlling dipping mold 6 The temperature is adjusted to 230 ℃, the speed of the traction roller 10 is set to 10mm / s, so that the content of long basalt fiber is 49wt%.The fiber bundle after impregnation is imported and cooled by cooling water tank 8, in pelletizer 11 Granulate, dry, then obtain long basalt fiber reinforced PA6 composite material. Gained composite material is injection-molded to obtain standard sample, and test obtains the mechanics and the friction and wear performance of composite materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com