PVD nano multiple-layer coating for cutting stainless steel and preparation method thereof

A nano-multilayer, stainless steel technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Stainless steel (1Cr18Ni9Ti) is cut after depositing the common TiAlN coating and the nanometer multi-layer coating of the present invention respectively with the cemented carbide blade whose grade is YG8 and model CNMG120408.

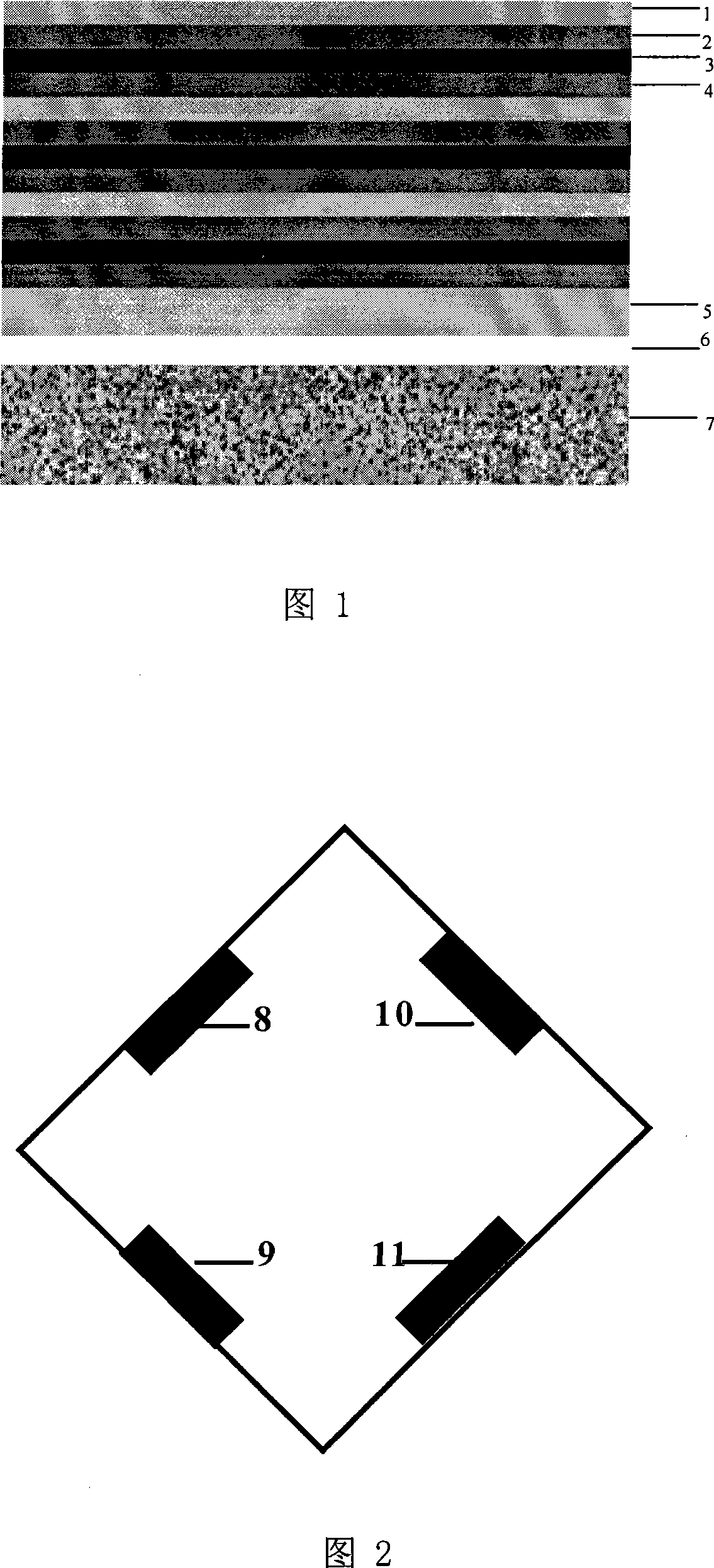

[0024] Referring to Figure 1, the specific manufacturing process is as follows:

[0025] (A), cleaning the surface of the cemented carbide substrate 7;

[0026] (A'): Depositing a metal Ti layer 6 with a thickness of 20-30 nm and a transition layer 5 of 20-40 nm TiN on the treated cemented carbide substrate 7;

[0027] (B), using 1 Ti target, 2 Ti x al 1-x Target and 1 piece of Ti y al 1-y target. During multi-target reactive magnetron sputtering, the placement positions of the four working targets are: Ti target and Ti target y al 1-y The targets are respectively placed in positions 8 and 10 of the vacuum chamber, and two Ti x al 1-x The targets are respectively placed in positions 9 and 11 of the vacuum chamber, and the vacuum degree ...

Embodiment 2

[0032] Stainless steel (1Cr18Ni9Ti) was milled after depositing common TiAlN coating and nanometer multi-layer coating of the present invention respectively with grade YG10 and model SEET12T3 cemented carbide inserts.

[0033] Referring to Figure 1, the specific manufacturing process is as follows:

[0034] (A), cleaning the surface of the cemented carbide substrate 7;

[0035] (A'): Depositing a metal Ti layer 6 with a thickness of 20-30 nm and a transition layer 5 of 20-40 nm TiN on the treated cemented carbide substrate 7;

[0036] (B), using 1 Ti target, 2 Ti x al 1-x Target and 1 piece of Ti y al 1-y target. During multi-target reactive magnetron sputtering, the placement positions of the four working targets are: Ti target and Ti target y al 1-y The targets are respectively placed in positions 8 and 10 of the vacuum chamber, and two Ti x al 1-x The targets are respectively placed in positions 9 and 11 of the vacuum chamber, and the vacuum degree of the vacuum ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com