Preparation technology of Si doped nano composite coating with ultrahigh hardness

A nano-composite coating and preparation process technology, applied in metal material coating process, coating, ion implantation plating and other directions, can solve the problem of low mechanical properties such as coating hardness, can not meet the service environment of parts, coating production Cost increase and other issues, to achieve the effect of excellent high temperature oxidation resistance, low cost and fast deposition rate

Inactive Publication Date: 2017-09-22

SHANGHAI ZENIX VACUUM COATING TECH

View PDF11 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the above literature, there is a problem that the mechanical properties of the coating are inconsistent with the cost of the coating. Some coatings have low mechanical properties such as hardness and cannot meet the increasingly deteriorating service environment of parts; while some coating materials with better performance , and the preparation process is relatively complicated, resulting in an increase in the production cost of the coating

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Login to View More

Abstract

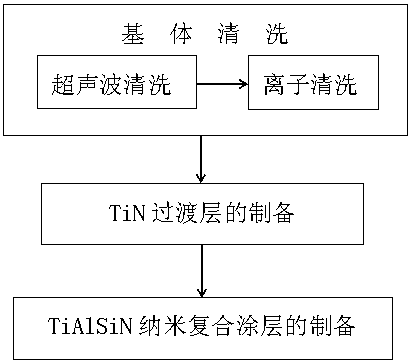

The invention discloses a preparation technology of an Si doped nano composite coating with ultrahigh hardness. The preparation technology comprises the steps of (1) matrix cleaning, including ultrasonic cleaning and ion cleaning; (2) preparation of a TiN transition layer: sending a matrix treated in the step (1) into a sputtering chamber, and carrying out deposition to obtain the TiN transition layer with the thickness of 100 nm to 200 nm; and (3) preparation of a TiAlSiN nano composite coating: carrying out deposition to obtain the TiAlSiN nano composite coating with the thickness of 2 <mu>m to 5 <mu>m on the matrix coated with the TiN transition layer through a TiAlSi composite target material controlled by a radio frequency cathode. The obtained TiAlSiN coating has hardness higher than 40 GPa, and has excellent high-temperature oxidation resistance and corrosion resistance, a coating preparation method has the characteristics of simple technology, high deposition speed, low cost, high bonding strength and the like, and has the advantages of high production efficiency, low energy consumption, relatively low equipment requirement and the like, and the coating can be adopted as a cutter coating of high-speed and dry cutting and a protective coating in other fields.

Description

A preparation process of Si-doped nanocomposite coating with ultra-high hardness technical field The invention relates to the technical field of surface modification engineering, in particular to a preparation process of a Si-doped nanocomposite coating with ultrahigh hardness, which is applicable to tool coatings of cutting tools and protective coatings in other fields. Background technique Cutting tools not only need to have high hardness and wear resistance, but also need to have good bending strength and impact toughness. The performance of these two aspects is contradictory and difficult to balance. Tool coating technology is a material surface modification technology developed in response to market demand in recent decades. The use of coating technology can effectively solve the contradiction between the hardness, wear resistance, bending strength and impact toughness of tool materials, and effectively improve The service life of the cutting tool is extended, so tha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C14/06C23C14/35

CPCC23C14/0641C23C14/0036C23C14/352

Inventor 张笑李伟刘京京

Owner SHANGHAI ZENIX VACUUM COATING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com