Patents

Literature

68results about How to "Good resistance to high temperature oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

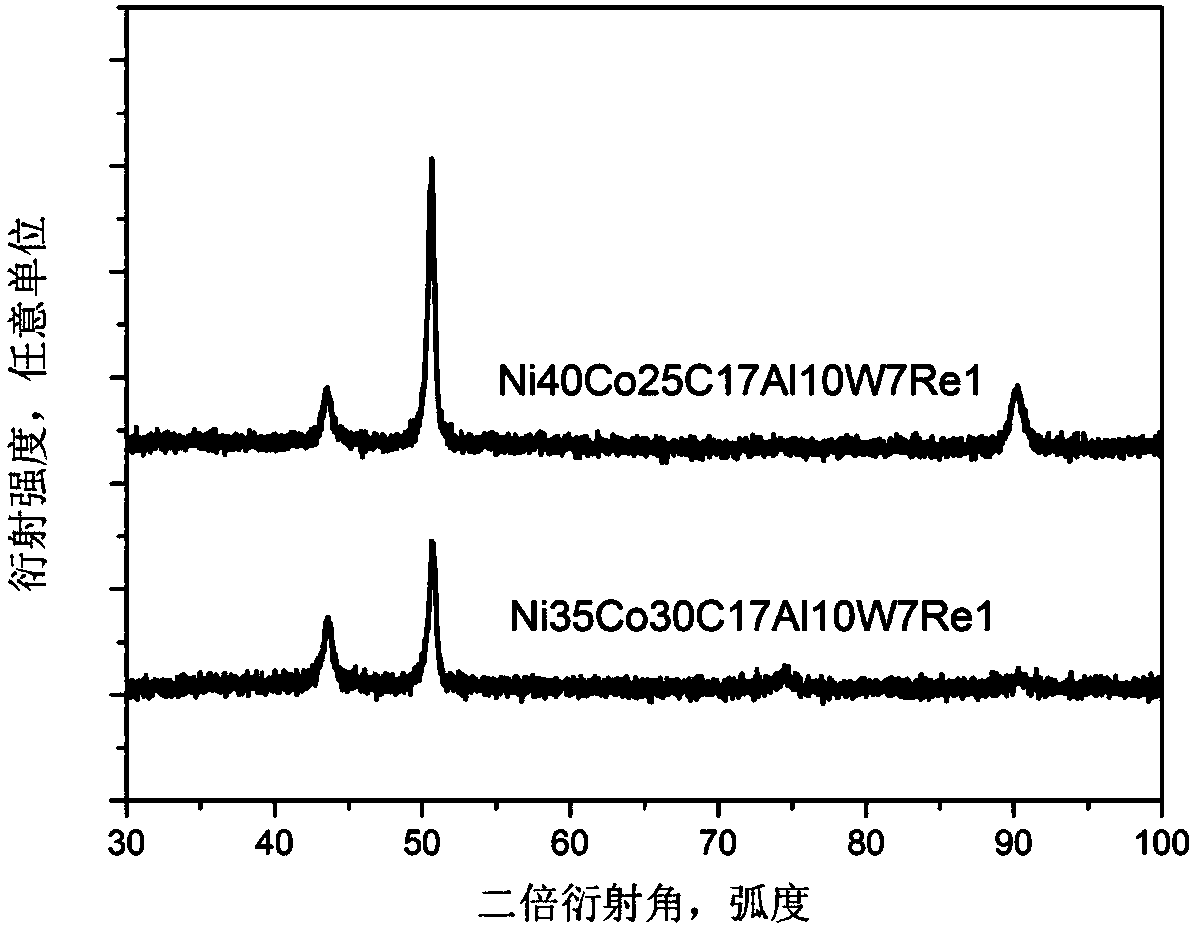

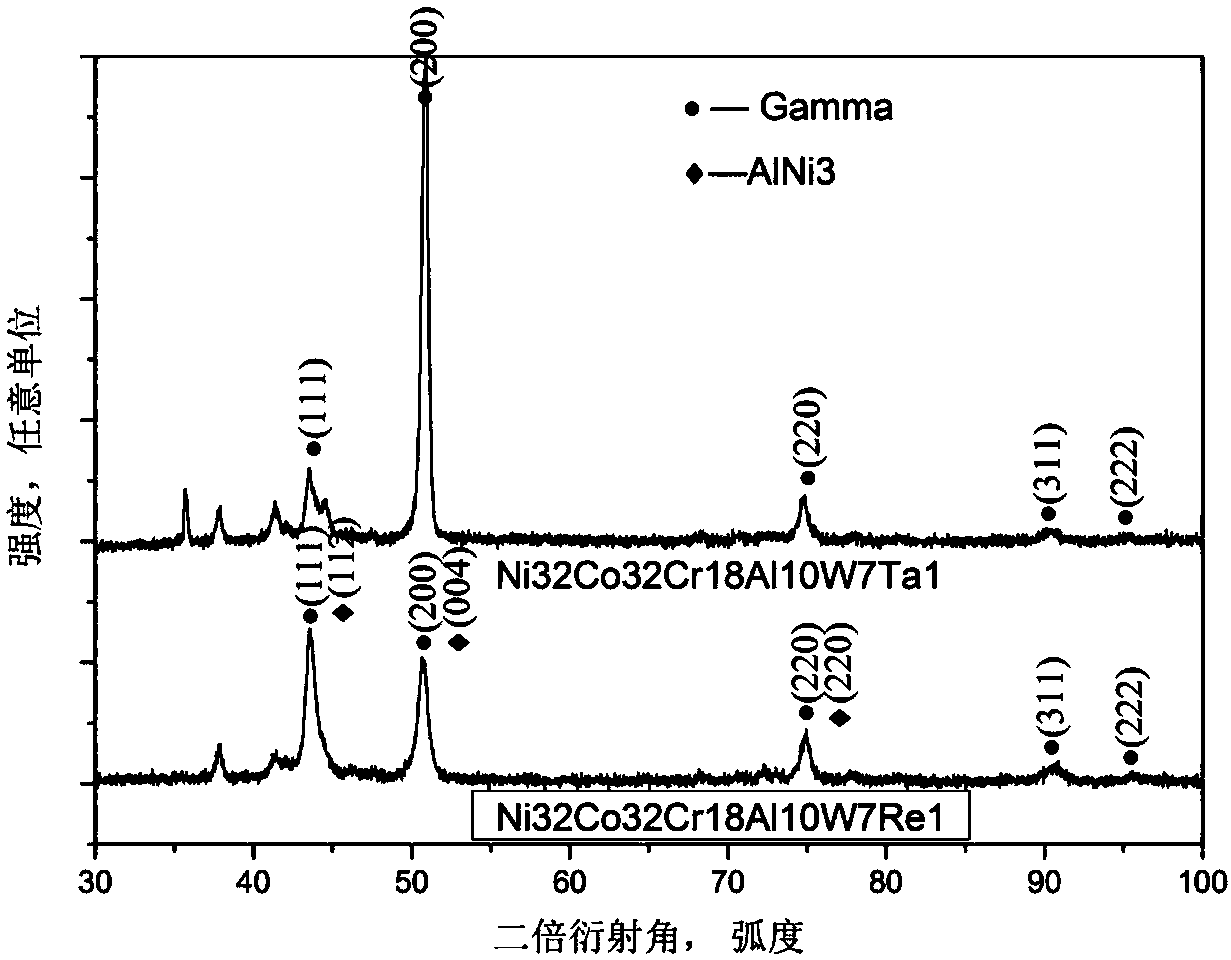

A Ni-Co-Cr-Al-W-Ta-Mo based high-entropy high-temperature alloy and a preparation method thereof

ActiveCN107747019AImprove high temperature strengthGood resistance to high temperature oxidationHigh entropy alloysRaw material

A Ni-Co-Cr-Al-W-Ta-Mo based high-entropy high-temperature alloy and a preparation method thereof are disclosed and belong to the field of high-entropy alloys. The chemical composition of the alloy isNiCoCr<c>Al<d>W<e>Ta<f>Mo<g>Rx, wherein R is one or two of Re and Ru. The method includes removing surface oxide skin of raw material metals by utilizing a mechanical-chemical combined process;cleaning the raw material metals by utilizing industrial ethanol and utilizing ultrasonic shaking; smelting the alloy by using a vacuum arc furnace; charging industrial argon when the vacuum degree is5*10<-2> Pa; after a master alloy is uniformly melted, injecting the alloy into a water cooling copper mould by utilizing a vacuum casting or suction casting device to obtain a high-entropy alloy rod; performing solution treatment at 1250 DEG C for 2-6 h; and then performing ageing heat treatment at 900 DEG C and 950 DEG C for 4-50 h. The disclosed alloy has excellent room-temperature and high-temperature strength, excellent resistance to high-temperature oxidation, and excellent creeping resistance, fatigue resistance and long-term tissue stability, is suitable for manufacturing hot end elements, such as blades and turbine discs, of aero-engines and gas turbines, and is used for engineering machines, special vehicles, coal, ore, railroads, and the like.

Owner:UNIV OF SCI & TECH BEIJING

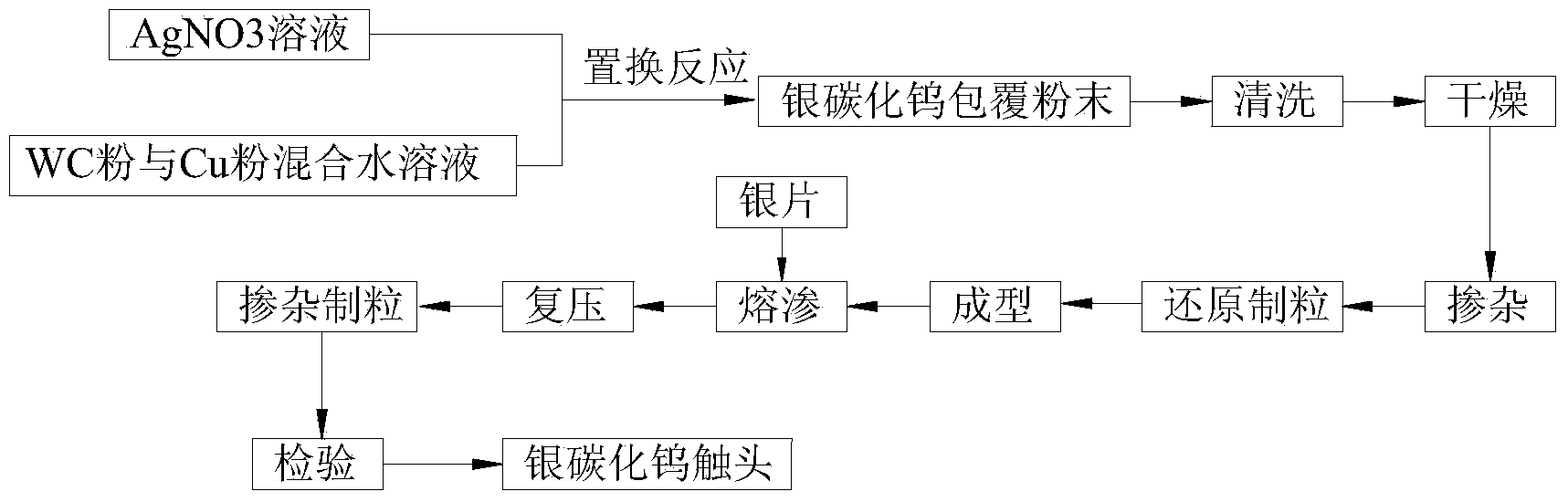

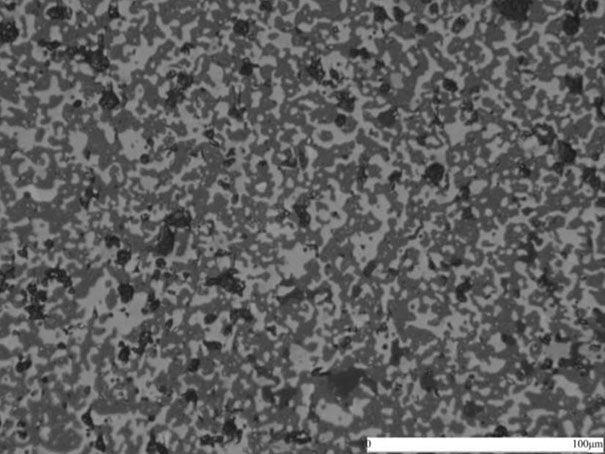

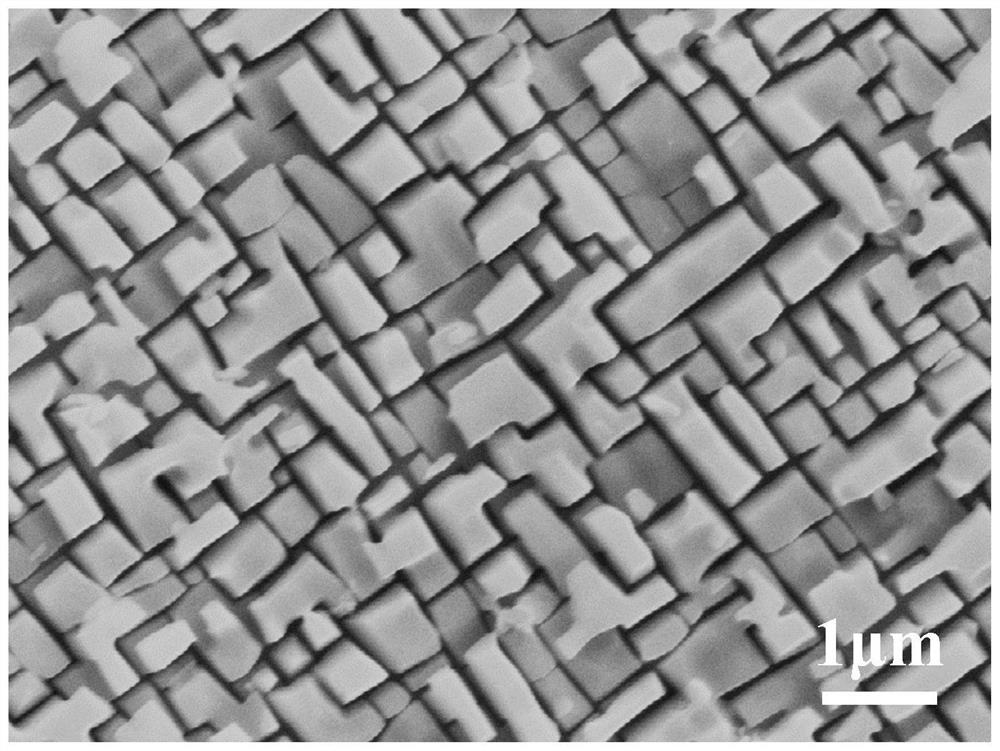

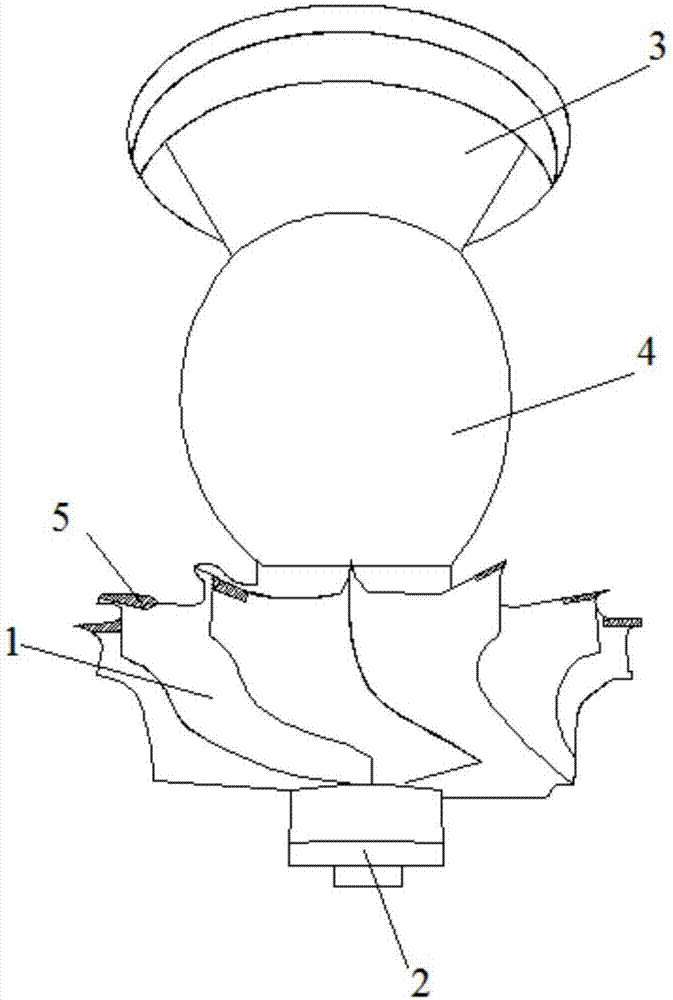

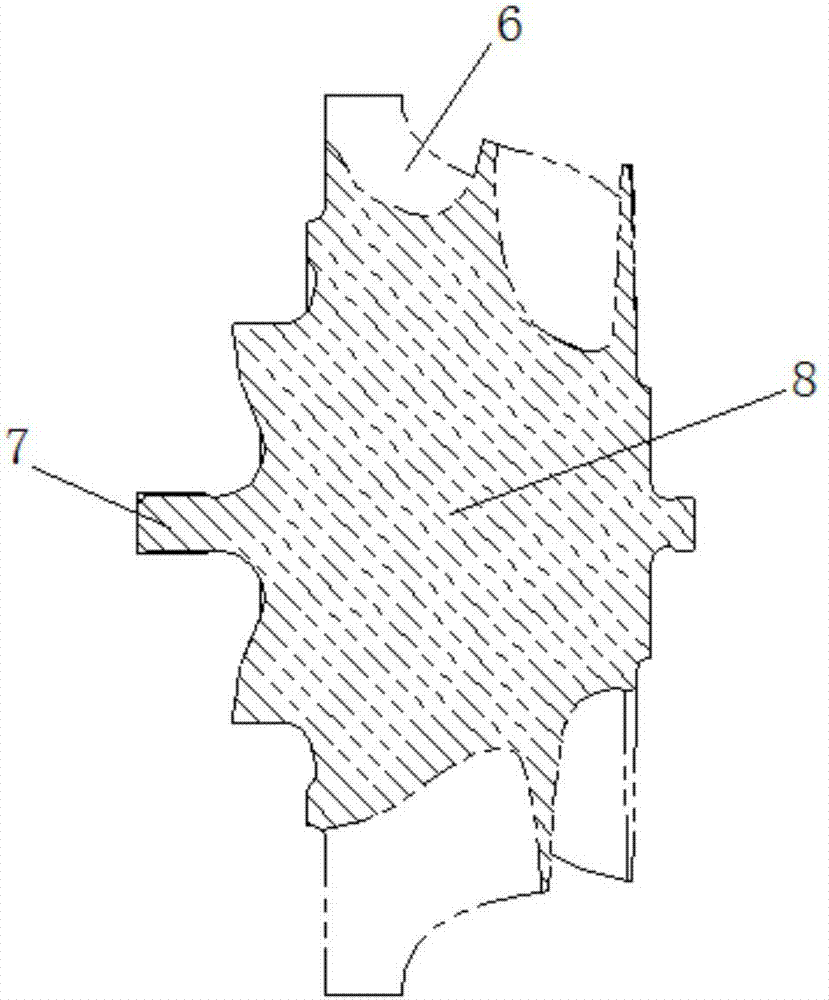

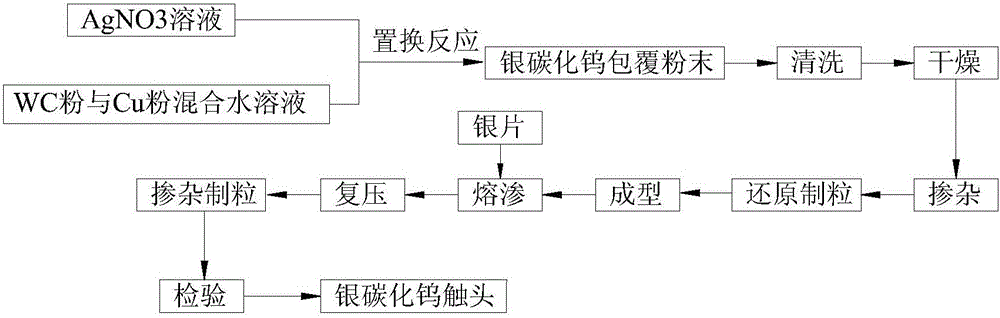

Method for preparing silver-tungsten carbide contact material from silver-coated tungsten carbide powder and silver-tungsten carbide contact material

ActiveCN103824710AHigh densityHigh hardnessContactsElectrical resistance and conductanceHigh density

The invention discloses a method for preparing a silver-tungsten carbide contact material from silver-coated tungsten carbide powder and the silver-tungsten carbide contact material. According to the technical scheme, a silver-tungsten carbide electrical contact is prepared from raw materials, i.e., a silver nitrate crystal and tungsten carbide powder, by a chemical coating powder preparation process and a liquid-phase infiltration process; the prepared silver-tungsten carbide electrical contact comprises the following components in percentage by weight: 38%-42% of tungsten carbide, 0-0.2% of additives and the balance being silver, wherein the additives are one or more selected from nickel, copper and zirconium. The silver-tungsten carbide contact material prepared by the method has the advantages of high density, high hardness, low and stable contact resistance, uniform metallographic structure, favorable high-temperature oxidation resistance, electric arc erosion resistance, wear resistance and the like.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

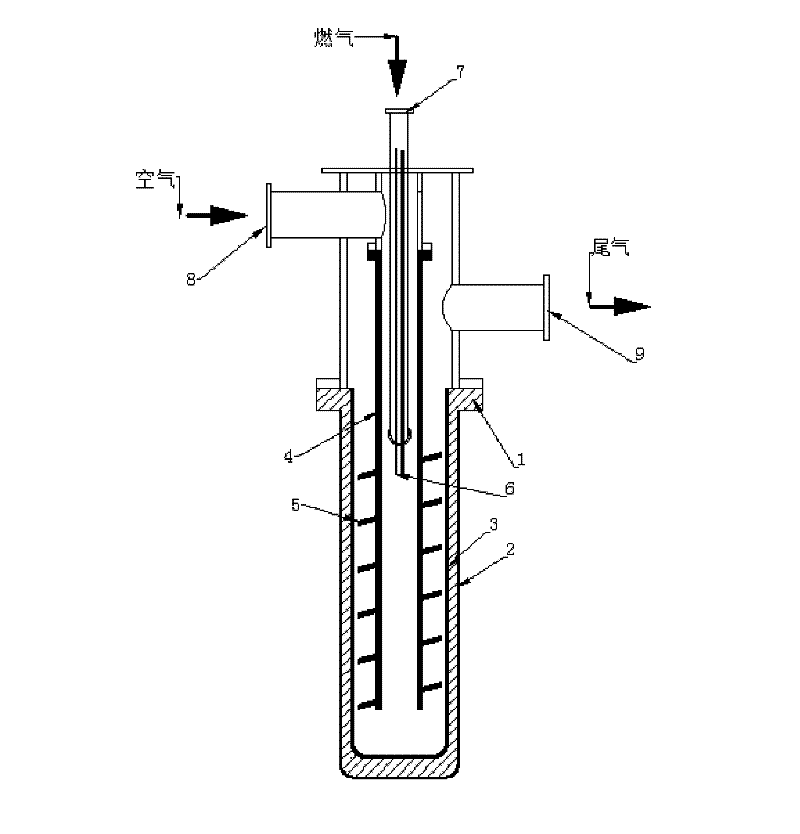

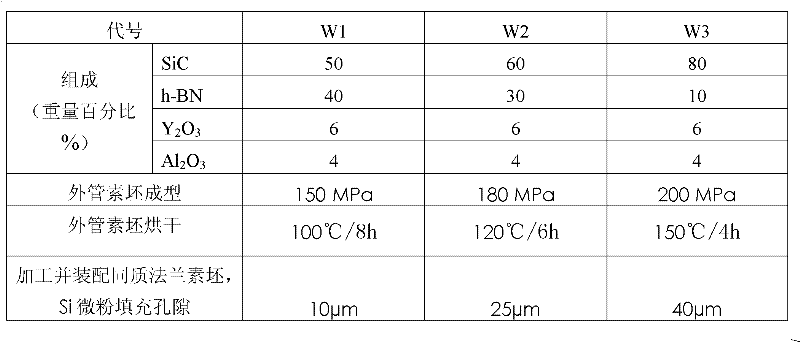

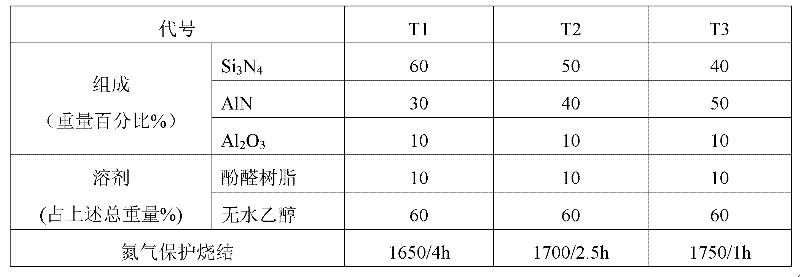

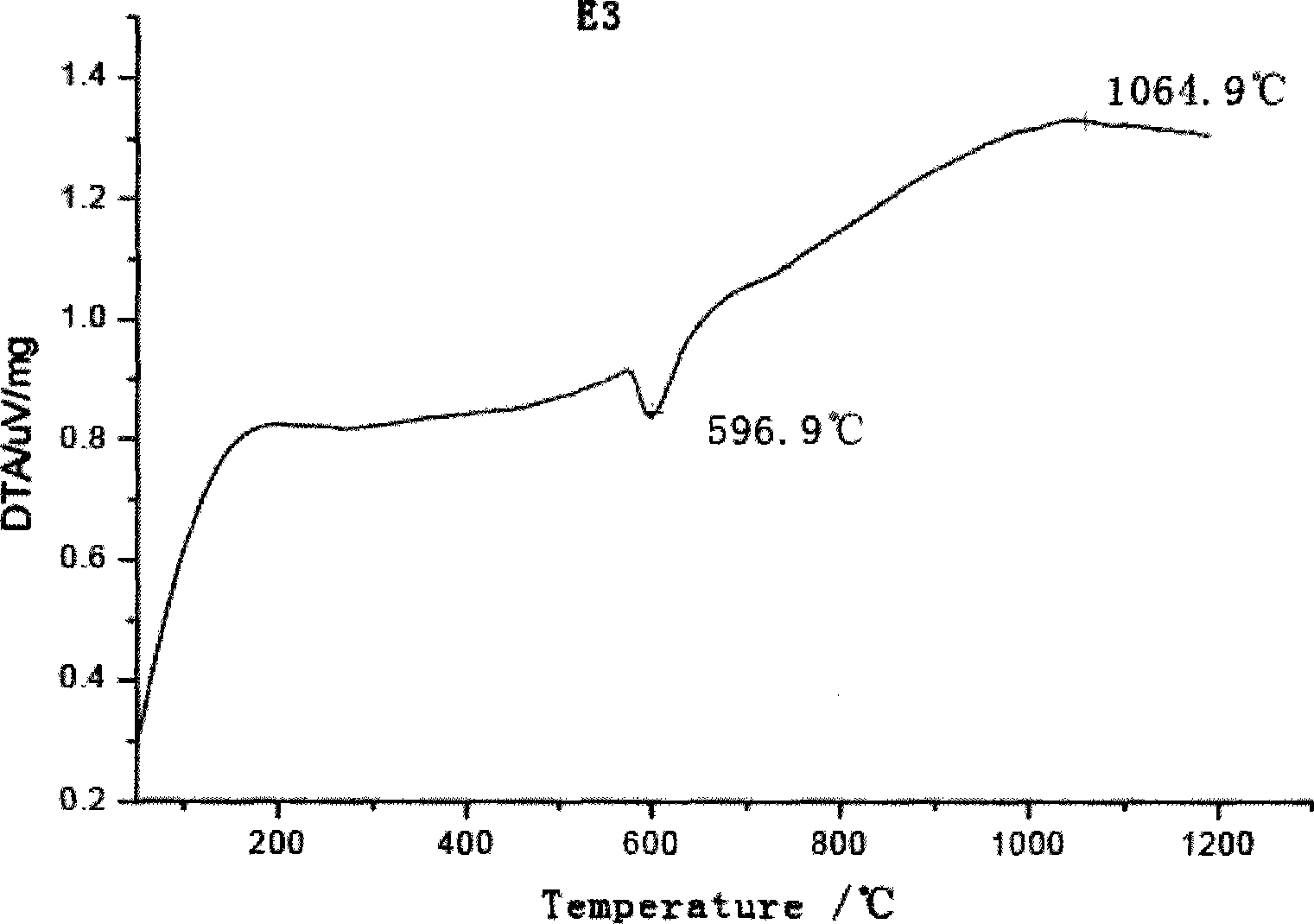

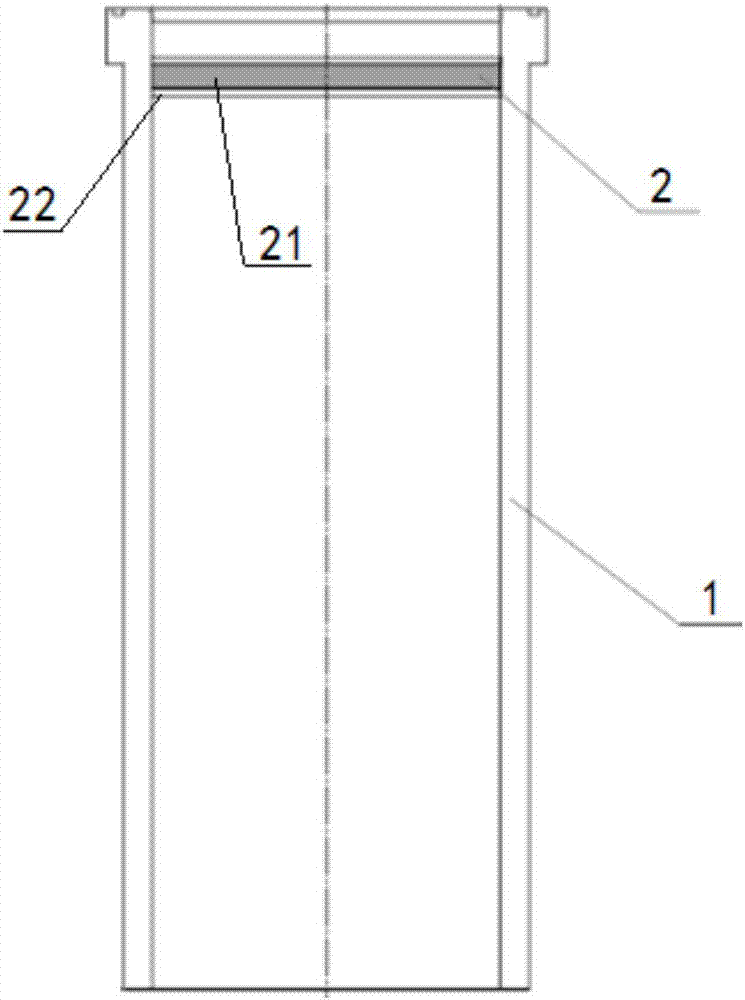

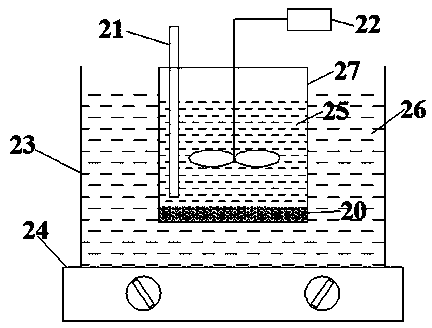

Immersed gas ceramic inner heater sleeve and preparation method thereof

InactiveCN102506429ASignificant resistance to melt infiltrationGood resistance to high temperature oxidationGaseous fuel burnerComposite ceramicOxidation resistant

The invention discloses an immersed gas ceramic inner heater sleeve and a preparation method thereof. The sleeve comprises an outer SiC composite ceramic tube and an inner SiC ceramic tube stretching to the bottom of the outer tube, wherein a SiO2 composite anti-oxidation layer is coated on an inner wall of the outer tube and a Si3N4 / AlN immersion-resistant layer is coated on an outer wall of the outer tube; an opening of the outer tube is provided with a flange communicated with a tai gas pipeline; one end of the inner tube extending out of the outer tube is in flange connection with a gas generating system; and an upper side face at one end of the inner tube extending out of the outer tube is communicated with a compressed air pipeline. The preparation method comprises the following steps of: preparing SiC composite ceramic serving as the outer tube; coating a Si3N4 / AlN composite coating on the outer wall of the outer tube and performing heat treatment, and coating a dense SiO2 anti-oxidation layer on the inner wall of the outer tube and performing heat treatment; and finally, preparing a SiC ceramic inner tube, siliconing, sintering and performing heat treatment. Compared with an electric heating system sleeve, the inner heater sleeve has higher safety and operating stability and can upgrade equipment on the conventional production base.

Owner:XI AN JIAOTONG UNIV

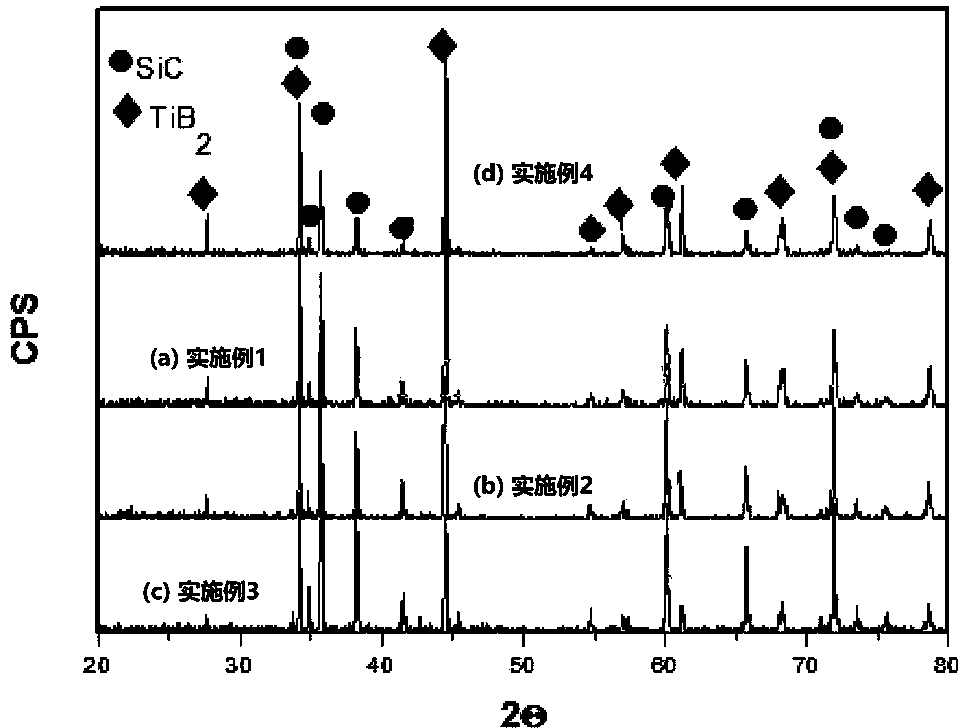

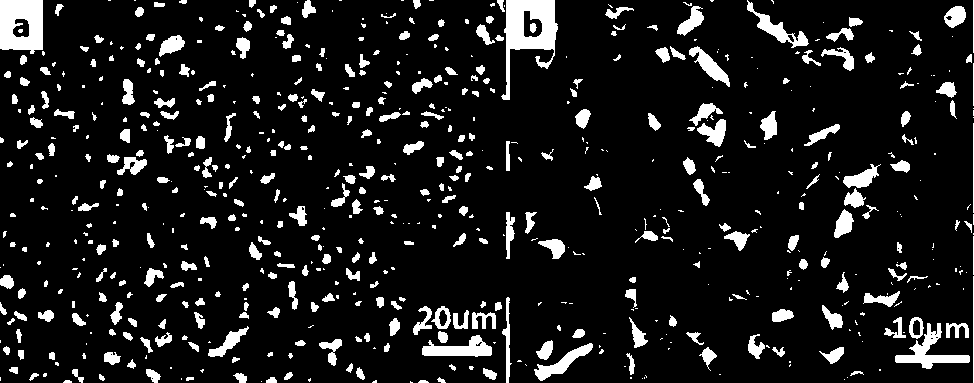

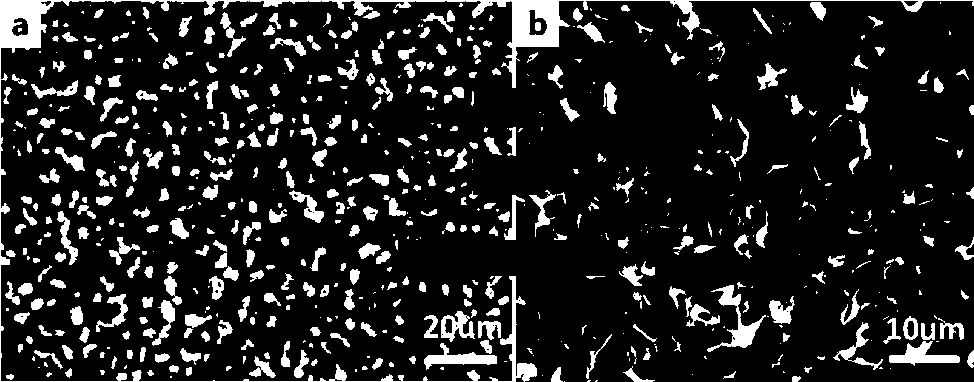

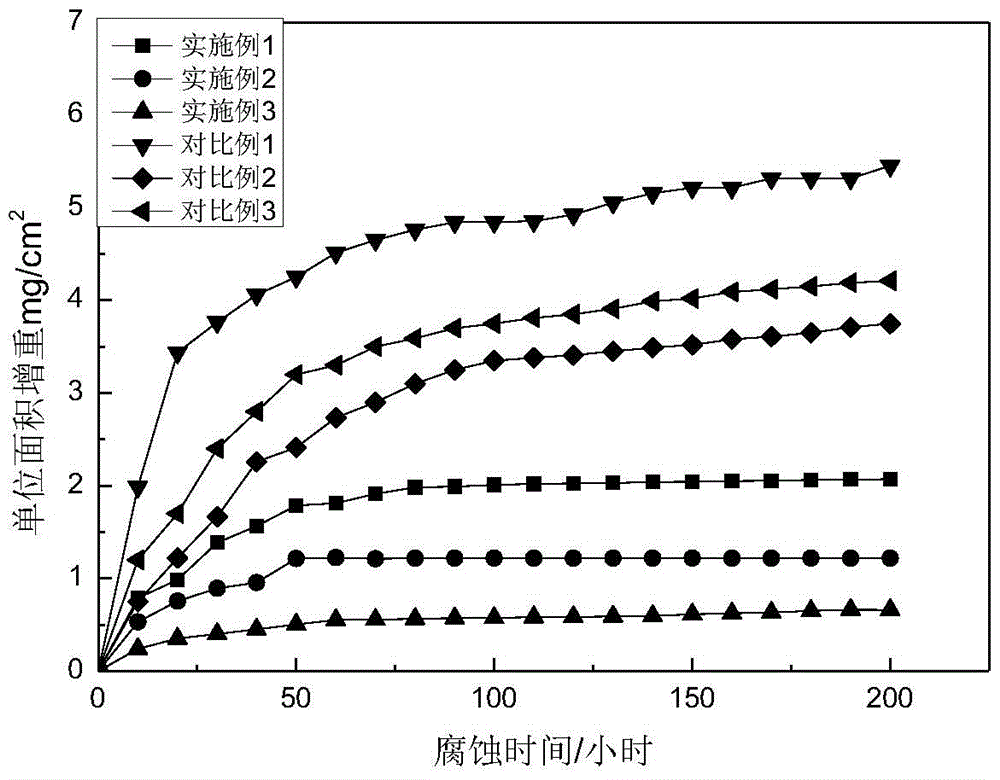

Preparation method of resistance-controllable silicon carbide ceramic

The invention relates to a resistance-controllable silicon carbide ceramic and a preparation method thereof, and belongs to the field of conductive ceramic materials. The resistance-controllable silicon carbide ceramic comprises a SiC powder, a B4C powder, a titanium source, a carbon source and a TiB2 powder according to a mass ratio of (40-80):(8-30):(20-70):(15-60):(25-55). The invention also provides the preparation method of the resistance-controllable silicon carbide ceramic. The preparation method comprises the following steps: burdening, sieving and granulating, compression molding, drying and sintering. According to the invention, the TiB2 high-conductivity ceramic component is directly or indirectly introduced into the SiC raw material, so the prepared SiC composite ceramic material has the advantages of controllable resistance, oxidation resistance, high hardness, wear resistance, high thermal conductivity, low thermal expansion coefficient, creep resistance and the like, andhas great practical prospects in the fields of electronic information wearable products, industrial wastewater electrocatalytic oxidation treatment, fuel cell electrodes, high-speed rail pantographsand the like. The preparation method has the advantages of simple process, low device requirement degree, low production cost, and convenience for batch production.

Owner:山东东大新材料研究院有限公司 +1

Cored wire for preparing nickel-based high-aluminum coating and coating preparation method of cored wire

ActiveCN105671471AHigh hardnessGood high temperature corrosion resistanceMolten spray coatingMaterials processingAluminum coating

The invention provides a cored wire for preparing a nickel-based high-aluminum coating and a coating preparation method of the cored wire, and belongs to the field of thermal spraying in material processing engineering. The cored wire comprises the following components in percentages by mass: 13-25% of Cr, 4-10% of Al, 3-6% of B, 3-6% of Si, and the balance Ni and inevitable impurities. A strip for the skin of the cored wire is a Ni80-Cr20 strip. When the nickel-based high-aluminum coating with good high-temperature corrosion resistance is prepared by electric arc spraying, conditions of a spraying process are as follows: current is 160-200 A, voltage is 28-34 V, pressure of compressed air is 0.4-0.6 MPa, and spraying distance is 190-210 mm. By the cored wire and the coating preparation method, the nickel-based high-aluminum coating with high hardness and good high-temperature corrosion resistance can be obtained.

Owner:BEIJING UNIV OF TECH

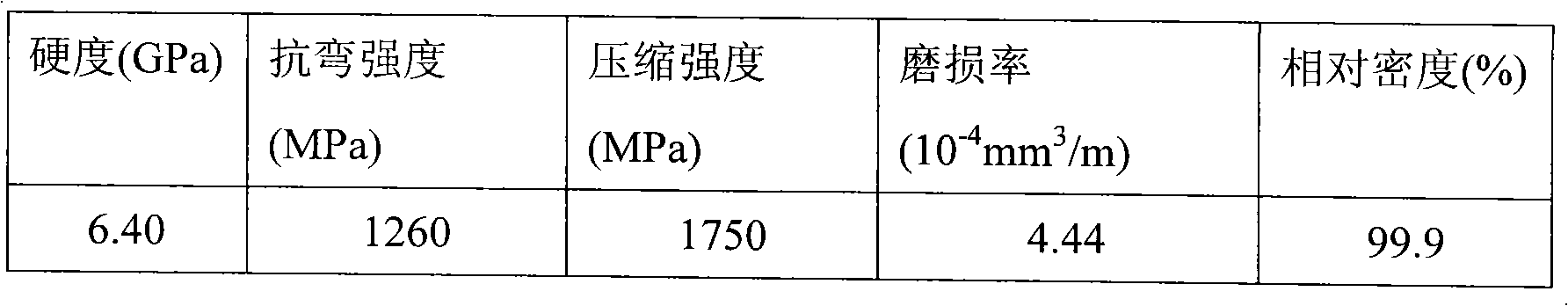

Preparation method of ferrum-aluminum titanium carbide composite material

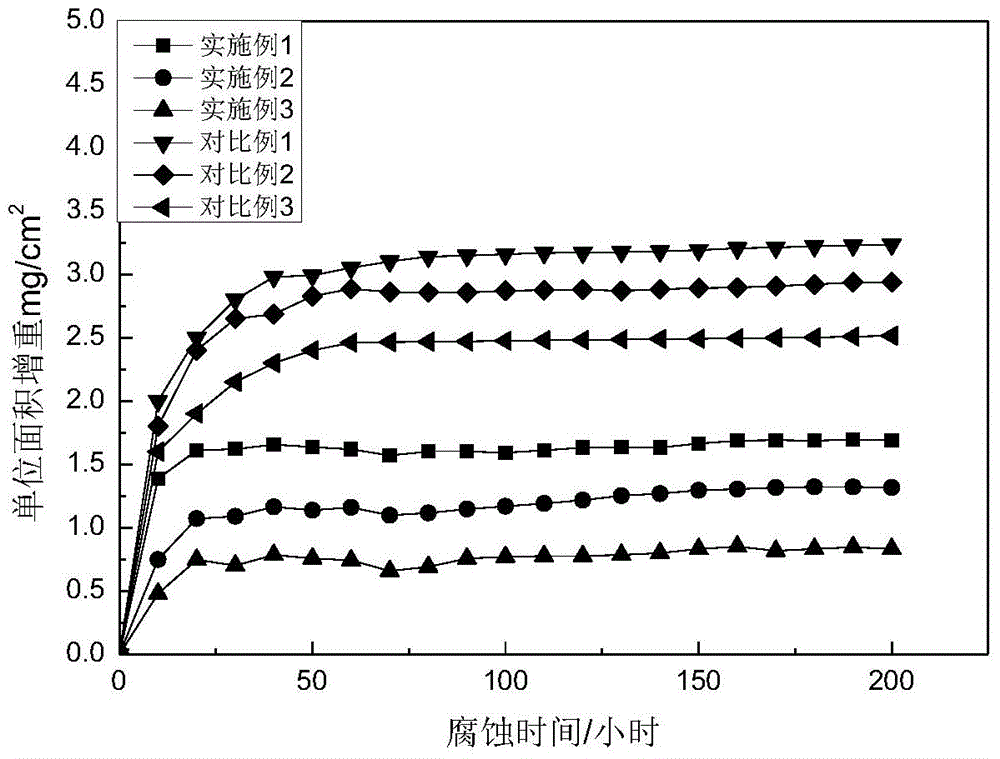

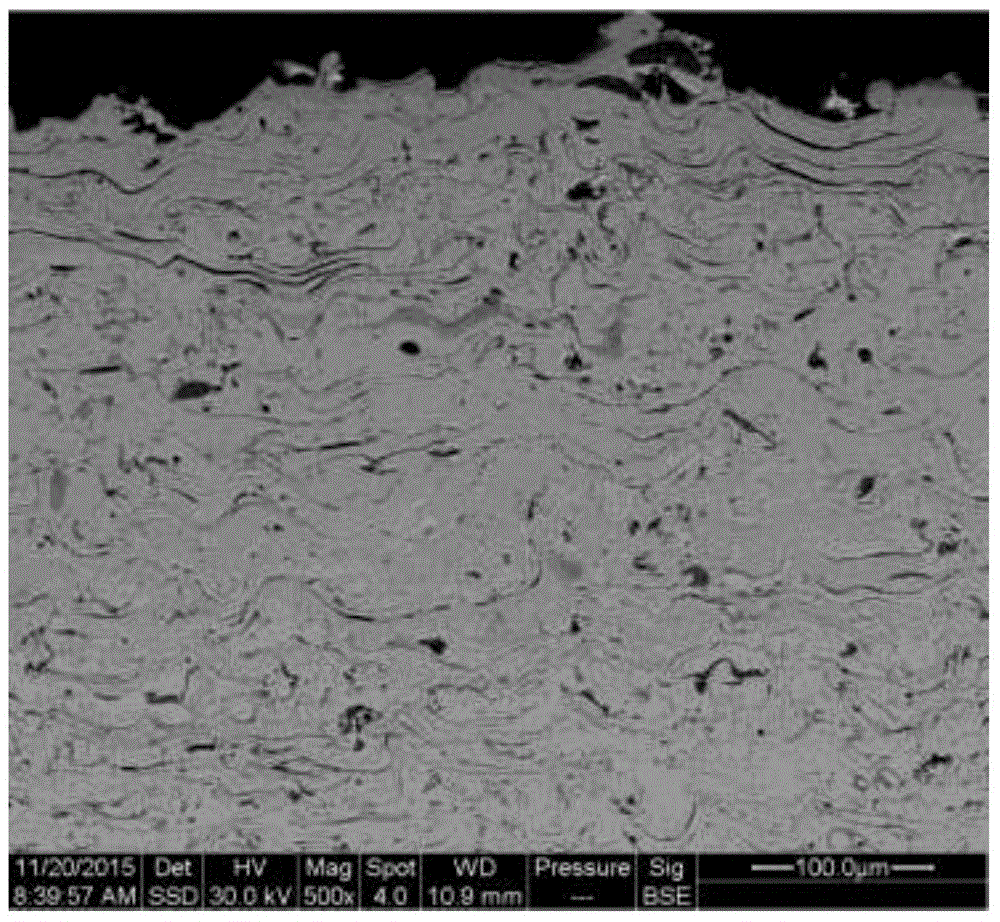

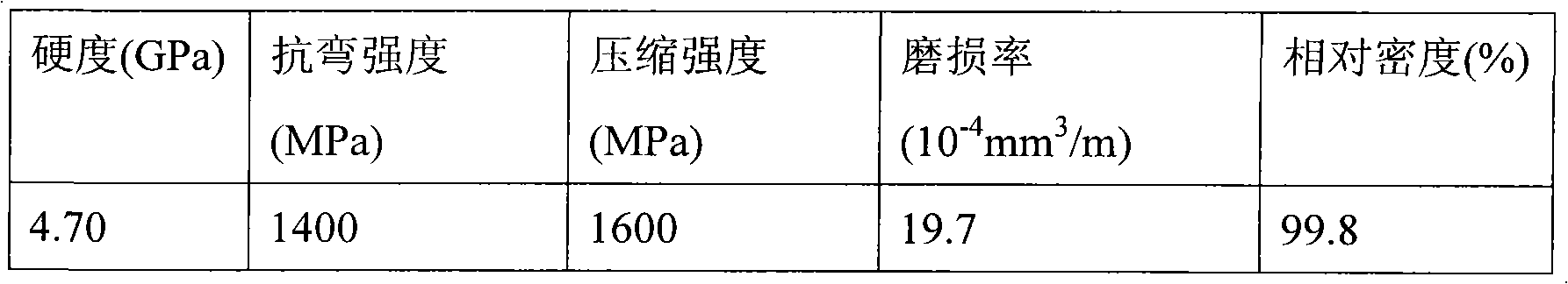

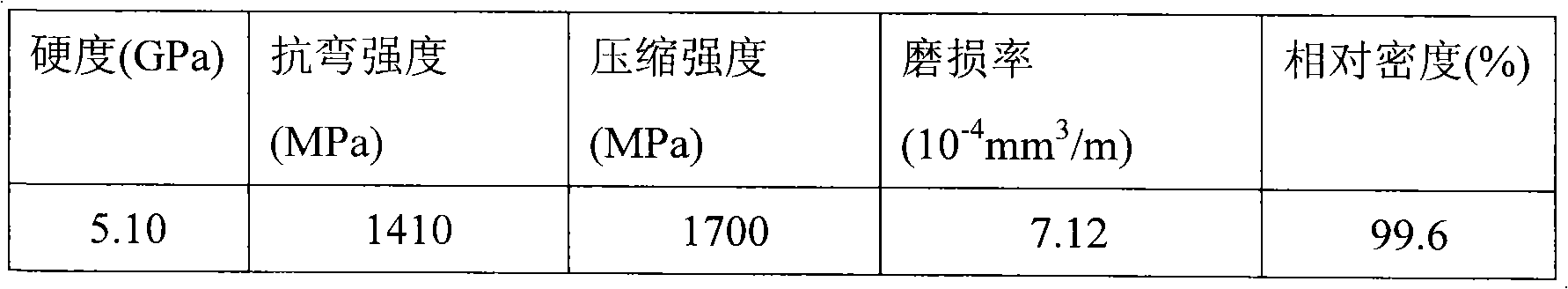

The invention discloses a preparation method of a ferrum-aluminum titanium carbide composite material. According to the preparation method, a TiC ceramic phase is added in order to improve the hardness, the strength and the abrasion resistance of a Fe3Al composite material. The composite material is excellent in chemical performance, has the hardness of 4.70 to 11.50Gpa, bending strength of 1000 to 1400MPa, compressive strength of 1600 to 1900MPa, and relative density up to more than 99%, and has outstanding resistance to high temperature oxidation, resistance to high temperature corrosion and high wear resistance, and is also a high-temperature structural material with important potential application. The preparation method is expected to being widely applied to the aviation field and the high-temperature wear resisting field, such as a high-temperature bearing, a shaft sleeve, a bearing bush and a seal component.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

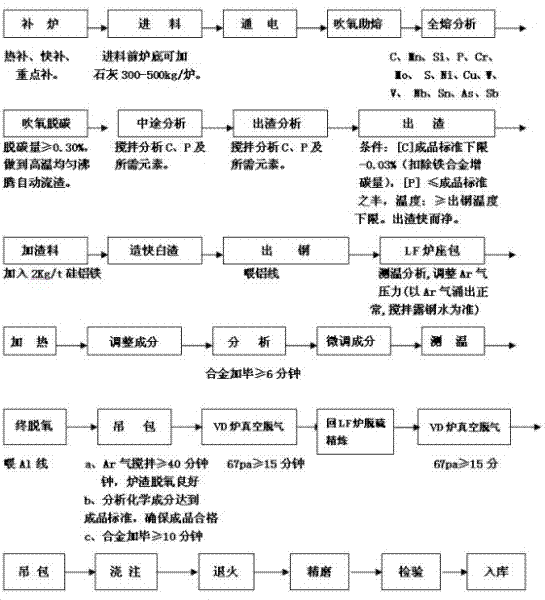

Nuclear power steel 18mnnimo and its preparation method

ActiveCN102260835AFully removedGood resistance to high temperature oxidationElectric furnaceProcess efficiency improvementElectric arc furnaceNuclear power

A nuclear power steel comprises the following chemical components of: by weight, 0.16-0.20% of C, 0.10-0.30% of Si, 1.35-1.50% of Mn, Cr being less than or equal to 0.15%, P being less than or equal to 0.006%, S being less than or equal to 0.005%, 0.65-0.80% of Ni, 0.45-0.55% of Mo, V being less than or equal to 0.02%, Cu being less than or equal to 0.08%, Co being less than or equal to 0.03%, Albeing less than or equal to 0.04%, As being less than or equal to 0.015%, Sn being less than or equal to 0.010%, Sb being less than or equal to 0.002%, B being less than or equal to 0.0003%, N being less than or equal to 130PPm, H being less than or equal to 1.5PPm, and the balance being Fe and inevitable impurities. The nuclear power steel provided by the invention is prepared by technologies ofthe electric arc furnace melting EF, out-of-furnace ladle refining LF, vacuum degasification VD, vacuum casting VC and the like, and has good comprehensive mechanical properties as well as cold bending performance.

Owner:浙江伟晟控股有限公司

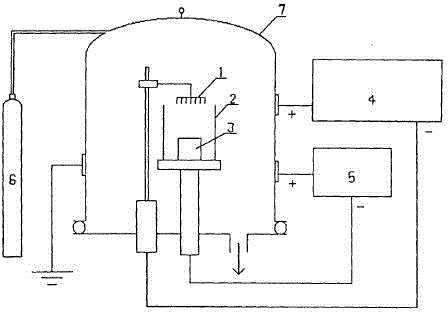

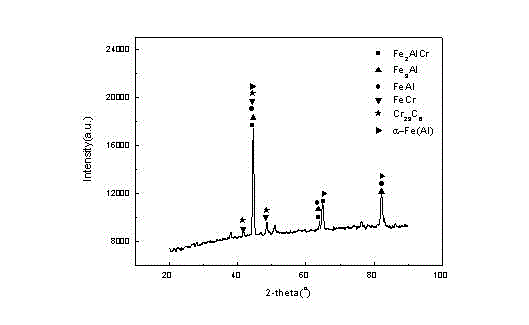

High-toughness Fe-Al-Cr coating and preparation method thereof

ActiveCN103147044AImprove toughnessNo mutation pointVacuum evaporation coatingSputtering coatingCoated surfacePhysical chemistry

The invention relates to a high-toughness Fe-Al-Cr coating and a preparation method thereof, belonging to the field of preparation of an Fe-Al intermetallic compound. The coating thickness is 20-30 mu m, and the coating and the matrix are bonded metallurgically. The Fe content is 60-65 wt% in the coating surface, and increases to 90-95 wt% in a gradient way in the surface depth direction; the Al content is 0-5 wt% in the coating surface, increases to 20-30 wt% in a gradient way in the surface depth direction, and decreases to 0-5 wt% in a gradient way as the depth increases; and the Cr content is 30-40 wt% in the coating surface, and decreases to 0-10 wt% in a gradient way in the surface depth direction. The coating is prepared by an ion sputtering deposition technique, and uses an iron-aluminum-chromium alloy wire as a target. The target is in a net disk structure of which the diameter is 10 cm, and is composed of 4-6 wt% of Al, 15-25 wt% of Cr and the balance of Fe; the diameter of the wire is 1.0-1.5 mm; and the pore size of the net material is 10-14 meshes. The coating provided by the invention has high toughness, and the toughness decreases in a continuous gradient in the surface depth direction without any abrupt point in the period.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

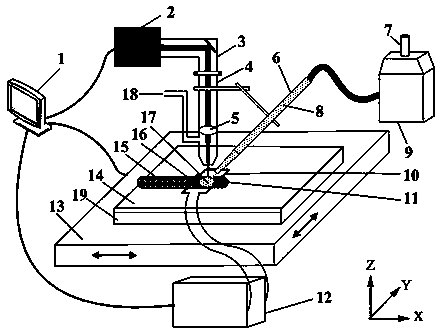

High chromium aluminum type high wear resistant arc spraying powder core wire material

InactiveCN101497977AGood resistance to high temperature oxidationGood high temperature corrosion-abrasion resistanceMolten spray coatingMetallic aluminumWear resistant

The invention relates to a high-hardness high-wear-resistant metallic composite electric arc spraying powder core wire which belongs to abrasion-resistance electric arc spraying powder cored wires used for the surface protection of metal materials. The high-hardness high wear-resistant metal composite electric arc spraying powder core wire belongs to the field of hot spraying in material processing engineering, is mainly used for the corrosion prevention and the abrasion resistance of a heating surface of a boiler in an electric power plant and has low cost. The high-hardness high wear-resistant metal composite electric arc spraying powder cored wire is characterized by comprising the powder core components according to percentages by weight of 28-30 percent of crome metal, 5.0-10 percent of metallic aluminum, 0.5-1.5 percent of silicon, 1.0-3.0 percent of carbon, 0.5-2.0 percent of rare-earth, and the rest is metallic iron. A metallic composite coating prepared by the high-hardness high-wear-resistant metallic composite electric arc spraying powder core wire contains a compact chromic oxide film which has favorable high-temperature oxidation resisting property as well as corrosion resisting and abrasion resisting properties, good thermal conduction, high bonding strength, as high as 870 DEG C of working temperature, HV500-550 of microhardness range and more than 50MPa of bonding strength. A preparation method of the high-hardness high-wear-resistant metallic composite electric arc spraying powder core wire adopts the prior processes of firstly rolling a low-carbon cold-rolled strip into a U shape, adding powder core powders which account for 30-40 percent of the gross weight of spraying wires into the U-shaped groove, closing the U-shaped groove and wrapping the powder cores in the U-shaped groove, drawing gradually and lightening through a wire-drawing die to lead the diameter to reach 3.0mm.

Owner:北京赛亿表面工程技术有限公司

High-temperature-resistant turbocharger turbine wheel

InactiveCN105603260AImprove high temperature performanceLight in massBlade accessoriesMachines/enginesTurbine wheelSuperalloy

The invention relates to a high-temperature-resistant turbocharger turbine wheel. The turbocharger turbine wheel comprises a turbine body, wherein the turbine body comprises a ceramic filling part and a metal layer arranged on an outer layer of the ceramic filling part; the metal layer is made of cobalt-based high-temperature alloy; and the cobalt-based high-temperature alloy consists of the following components (in percentage by mass): 0.15-0.3% of C, 8-15% of Ni, 15-25% of Cr, 10-15% of W, 0.3-1% of Mo, 0.5-3% of Nb, 0.3-1% of Ta, 0.1-0.8% of Ti, 0.003-0.008% of B, 0.1-0.8% of Zr, 0.05-0.5% of rare earth elements, not more than 3% of Fe and the balance of Co and inevitable impurity elements. According to the turbocharger turbine wheel, the high-temperature usage performance of the turbine wheel is improved to a certain extent and the effects of absorbing sound, reducing noise and reducing turbine wheel mass can be achieved.

Owner:NINGBO TIANGE AUTOMOBILE PARTS CO LTD

Re/Ru-containing monocrystal nickel-based superalloy with high temperature resistant capability and high creep resistance

InactiveCN104911407AHigh temperature capacityImprove thermal stabilityPolycrystalline material growthSingle crystal growth detailsOxidation resistantGas turbines

The invention relates to a Re / Ru-containing monocrystal nickel-based superalloy with high temperature resistant capability and high creep resistance, belonging to a new material with a special purpose. The alloy consists of the following components in percentage by weight: 5.6-6.4% of Al, 7.2-8.2% of Ta, 2.2-3.2% of Cr, 2.5-3.5% of Mo, 6.5-7.5% of Co, 3.8-4.6% of W, 4.2-4.8% of Re, 2.8-3.5% of Ru, 0.05-0.15% of Hf and the balance of nickel. The monocrystal nickel-based superalloy has good high-temperature oxidation resistance and the advantages of high temperature resistant capability, high creep strength, long service life and the like, and is applicable to the production of blades of the hot-end components of aero-engines and gas turbines.

Owner:SHENYANG POLYTECHNIC UNIV

Titanium alloy surface high-temperature-resisting coating and preparation method thereof

ActiveCN108220957AGood resistance to high temperature oxidationExcellent high temperature oxidation resistanceMetallic material coating processesAlloy surfaceHardness

The invention relates to a titanium alloy surface high-temperature-resisting coating and a preparation method thereof. The ingredient system of the original raw materials of the coating is (45-750%Al-(10-20)%Nb-(5-20)%Si-(0-15)%B-(0-20)%B4C-(0-10)%C. The manner of laser surface alloying is adopted, the in-situ generated high-temperature-resisting coating is prepared on the surface of a titanium alloy and is subjected to typical metallurgical bonding with a base body, and the coating has excellent high temperature oxidation and abrasion resistance; and meanwhile the thickness of the coating isgreatly increased, the problem that the thickness, hardness and abrasion resistance of the coating can hardly be improved in balance in the prior art is solved well, and good application prospects areachieved.

Owner:QINGDAO BINHAI UNIV

Titanium alloy composite capable of resisting high temperature oxidation and hot salt corrosion and preparation method thereof

InactiveCN109023479AReduce internal stressGood chemical stabilitySurface reaction electrolytic coatingMicro arc oxidationAlloy substrate

The invention discloses a titanium alloy composite capable of resisting high temperature oxidation and hot salt corrosion and a preparation method thereof. The titanium alloy composite comprises a titanium alloy substrate; a ceramic transition layer and an enamel coating are arranged on the surface of the titanium alloy substrate; the ceramic transition layer is located between the titanium alloysubstrate and the enamel coating; the ceramic transition layer is a micro-arc oxidation ceramic layer; and the enamel coating and the ceramic transition layer form a high-temperature protection gradient composite coating on the titanium alloy substrate. The titanium alloy composite is excellent in resistance to high temperature oxidation and high temperature hot salt corrosion and the gradient composite coating is good in chemical stability.

Owner:SICHUAN ENG TECHN COLLEGE

Al/NiCrAlY/Al2O3 compound coating, preparing method and application thereof

ActiveCN111378935AGood resistance to high temperature oxidationImprove moisture resistanceVacuum evaporation coatingSputtering coatingIon platingHeat treated

The invention discloses an Al / NiCrAlY / Al2O3 compound coating which comprises an Al layer, a NiCrAlY layer and an Al2O3 coating. The NiCrAlY layer and the Al2O3 coating are sequentially formed on the Al layer. The invention further discloses a preparing method of the Al / NiCrAlY / Al2O3 compound coating. The preparing method includes the steps that the Al layer and the NiCrAlY layer are sequentially deposited on a workpiece through a multi-arc ion plating technology, and an Al / NiCrAlY layer is formed; and heat treatment is conducted, an Al2O3 coating is formed on the surface of the Al / NiCrAlY layer, and the Al / NiCrAlY / Al2O3 compound coating is obtained. The prepared Al / NiCrAlY / Al2O3 compound coating has the good high-temperature oxidation resisting performance, damp and heat resisting performance and salt spray resisting performance and is suitable for surface protection of high-temperature and ocean environment key parts. In addition, the preparing method of the Al / NiCrAlY / Al2O3 compoundcoating is simple and easy to implement, and a very good application prospect is achieved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

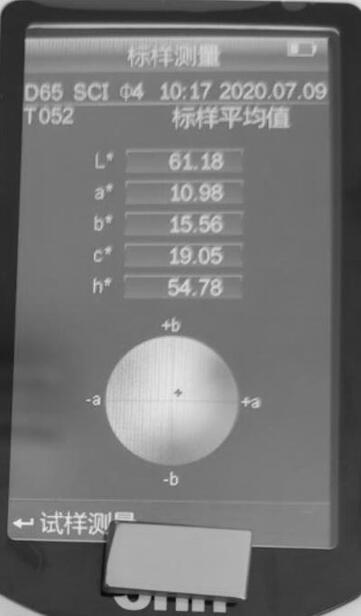

Preparation method of yellow conductive zirconia ceramic

The invention discloses a preparation method of a yellow conductive zirconia ceramic. The preparation method comprises the following steps: mixing zirconium oxide powder, conductive powder, a titaniumsource, a carbon source and an additive to obtain a mixture, mixing the mixture with a binding agent and a liquid medium to form slurry, and carrying out ball milling in a ball milling tank or grinding in a sand mill, wherein the mass ratio of the zirconium oxide powder to the conductive powder to the titanium source to the carbon source to the additive is (25-75): (0-60): (5-30): (5-20): (0-5).The color of the zirconia ceramic is soil porcupine, rose gold, khaki color or gradient color, and the resistivity is 0.3 [mu]Omega.m to 10 [mu]Omega.m. The preparation method disclosed by the invention is simple in process and convenient for batch production, and the composite conductive ceramic material has the advantages that the composite conductive ceramic material is a high-performance functional composite conductive ceramic material integrating electric conductivity, various yellow colors, metal electrical properties and ceramic structure properties, and is excellent in electric conductivity and adjustable in electrical resistivity.

Owner:山东东大新材料研究院有限公司 +1

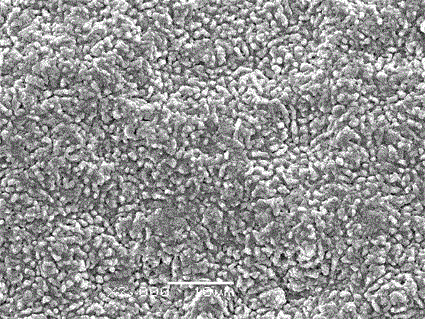

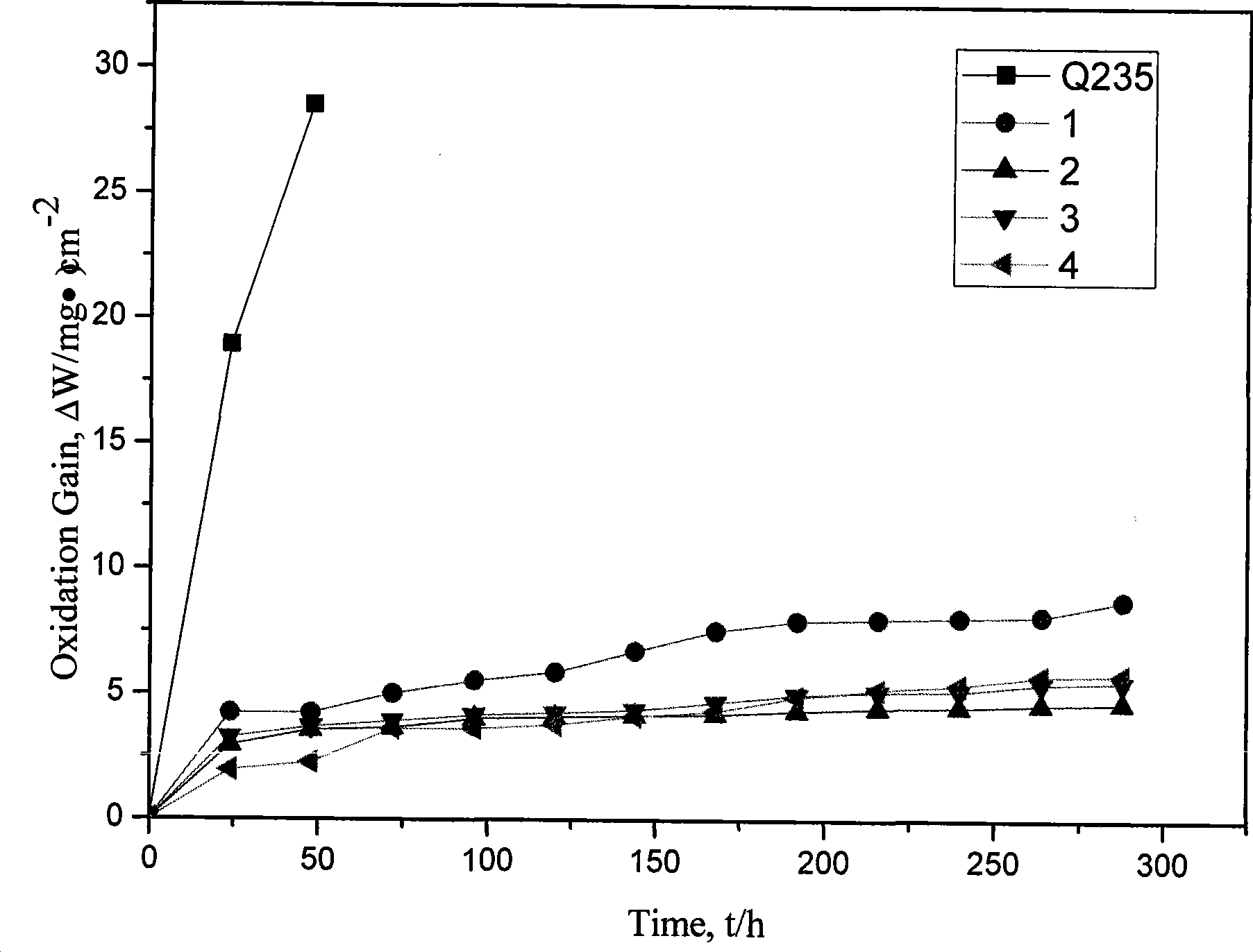

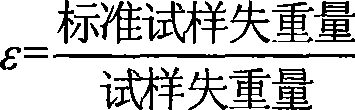

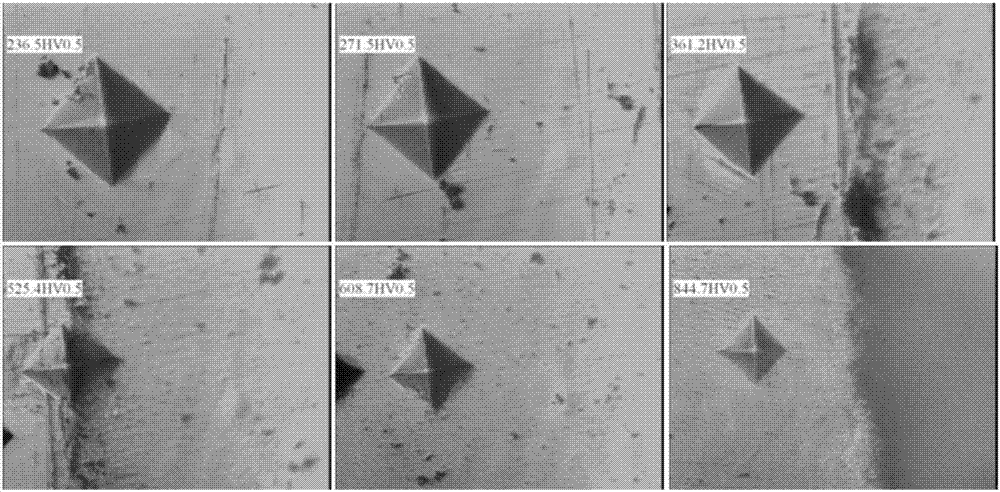

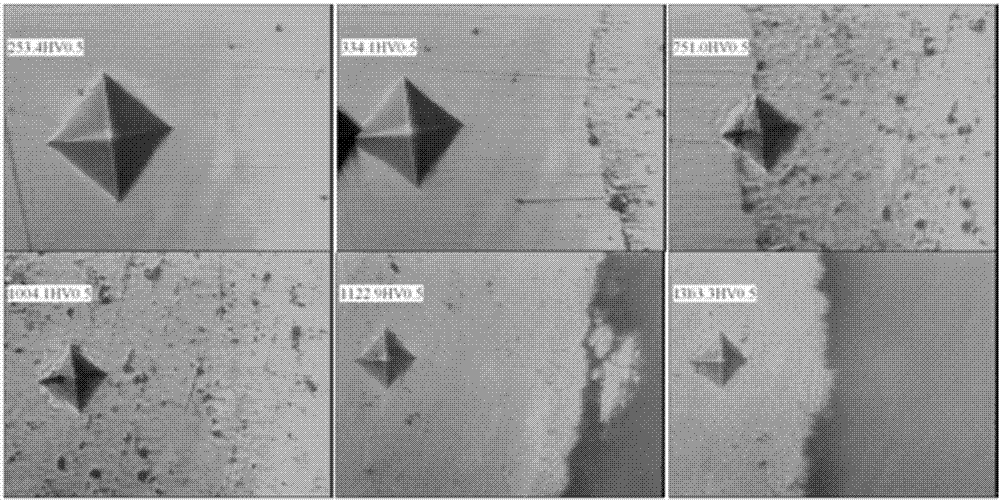

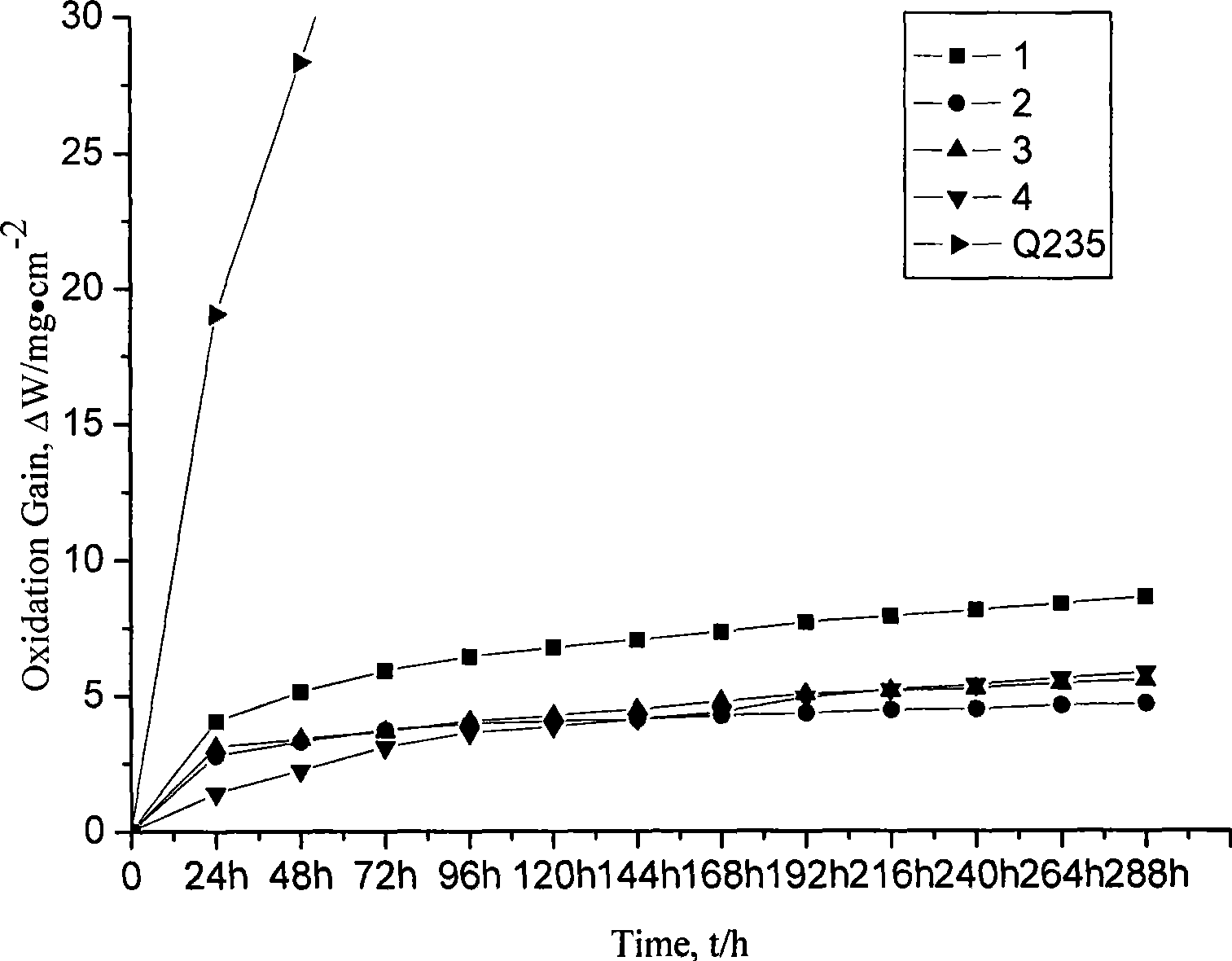

Powder core wire materials for preparing micro crystal and nanocrystalline coatings containing CrB by arc spraying

The invention provides a CrB-containing microcrystal and nanocrystalline powder core wire for arc spraying. The powder core wire belongs to the field of hot spraying in material processing engineering, and is mainly used in the industrial fields for anticorrosion and wear resistance and so on. The microcrystal and the nanocrystalline crystalline state alloy is a crystalline state material with small grains formed by restructuring the internal structure of an amorphous state material at a high temperature, and is integration of high strength, hardness, toughness, wear resistance and corrosion resistance, but no patent report on the microcrystal and nanocrystalline powder core wire is seen at home and abroad. The invention is a CrB-containing microcrystal and nanocrystalline powder core wire and is characterized by comprising the following powder core components in percentage by mass: 50 to 70 percent of chromium boride, 10 to 25 percent of Mo, 10 to 15 percent of TiC and the balance being Fe powder. The coating prepared by the powder core wire can be decomposed to generate microcrystal and nanocrystalline during high-temperature spraying, and the coating is uniform in structure, high in hardness with HV0.1 more than1,100, and good in wear resistance, and the relative wear resistance can reach 15.8 times of that of Q235 steel.

Owner:北京赛亿表面工程技术有限公司

Boron cast iron air cylinder sleeve carbon scraping ring coating and preparation and spraying method thereof

InactiveCN106978581AIncrease the amount addedReduce spalling or even failureMaterial nanotechnologyMolten spray coatingCarbon depositCast iron

The invention discloses a boron cast iron air cylinder sleeve carbon scraping ring coating and a preparation and spraying method thereof and belongs to the technical field of improvement of air cylinder sleeves. The boron cast iron air cylinder sleeve carbon scraping ring coating is arranged on the neck of an air cylinder sleeve. The carbon scraping ring coating is a nicr-Cr3C2 composite coating. Nicr alloy has excellent heat resistance, corrosion resistance, high-temperature oxidation resistance and other properties and also achieves a binding phase function. Cr3C2 has good high temperature hardness and high-temperature oxidation resistance and achieves a hard phase function. The component of the air cylinder sleeve is boron cast iron. According to the boron cast iron, boron is added into gray cast iron, and different-amount cast iron containing boron cementite or ledeburite structures can be obtained in a metallographic structure. With increase of the boron content, microhardness is improved, but adding of too much boron can also cause lowering of toughness. Through the boron cast iron air cylinder sleeve carbon scraping ring coating and the preparation and spraying method thereof, the problems that a large number of carbon deposits are very liable to be accumulated on the surface of a piston, and the structure of a carbon scraping ring part is low in hardness and is liable to damage can be solved.

Owner:安徽威龙再制造科技股份有限公司

Method for preparing high-strength and high-conductivity copper-based alloy coating by means of laser-induction hybrid cladding

InactiveCN102912342BOvercoming the problem of easy oxidation at high temperatureHigh thermal conductivityMetallic material coating processesEconomic benefitsAlloy coating

The invention discloses a method for preparing a high-strength and high-conductivity copper-based alloy coating by means of laser-induction hybrid cladding, which is characterized by comprising the following steps of: firstly, performing chemical nickel-plating treatment on a special copper-based alloy powder to form a nickel-coated copper-based alloy powder with a core-shell structure; secondly, performing oil removal, rust removal, surface activation and chemical nickel-plating treatment on the surface of a matrix; and finally, preparing the high-conductivity copper-based alloy coating on the surface of the matrix by means of laser-induction hybrid cladding. The method disclosed by the invention has the advantages of being high in machining efficiency, low in cost, good in technical and economic benefits, and has a wide application prospect in the surface reinforcement and repair of fields of aeronautics, astronautics, automobile, metallurgy, electricity and the like, in which aluminium and aluminium alloy, magnesium and magnesium alloy, and copper and copper alloy are widely used.

Owner:NANCHANG HANGKONG UNIVERSITY

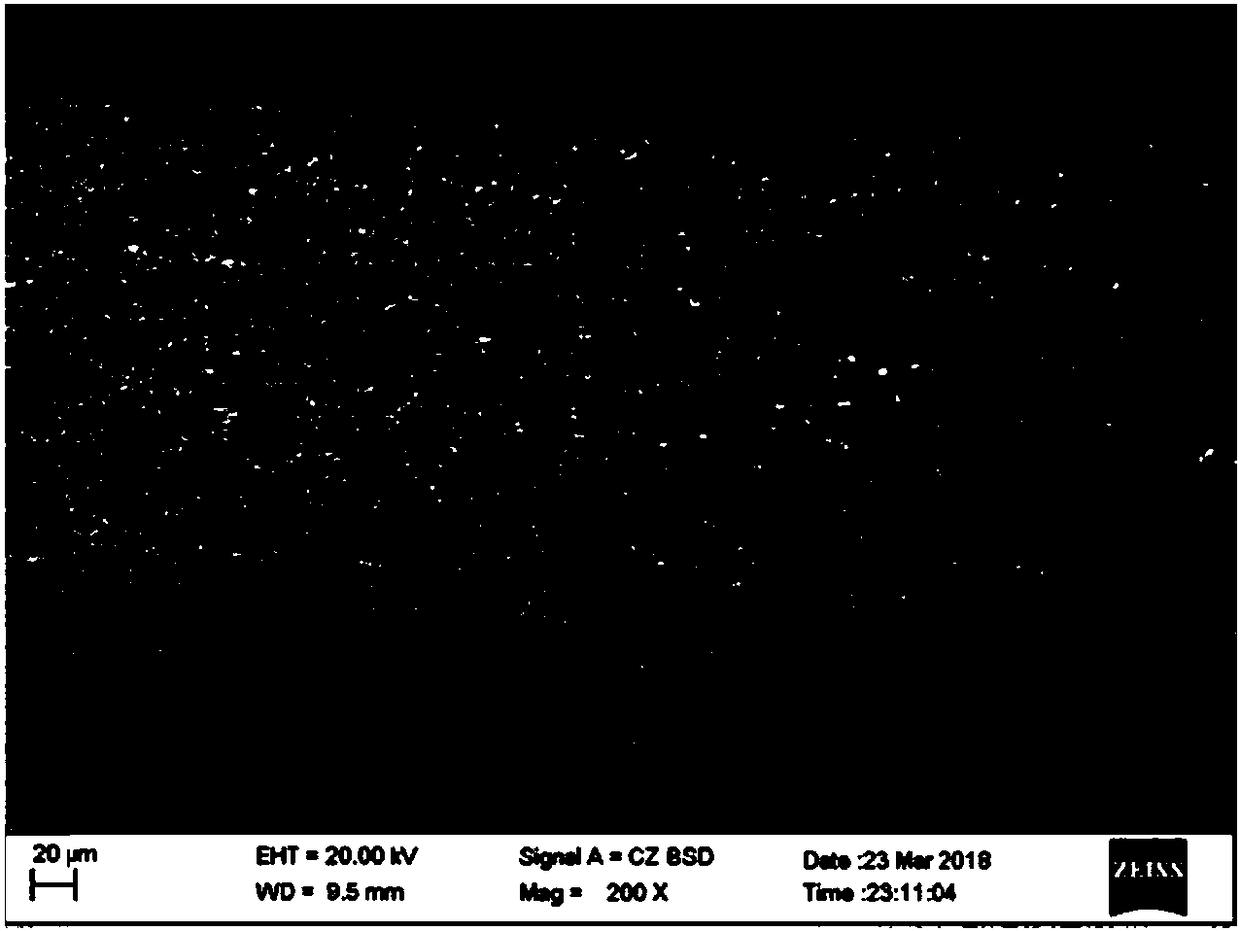

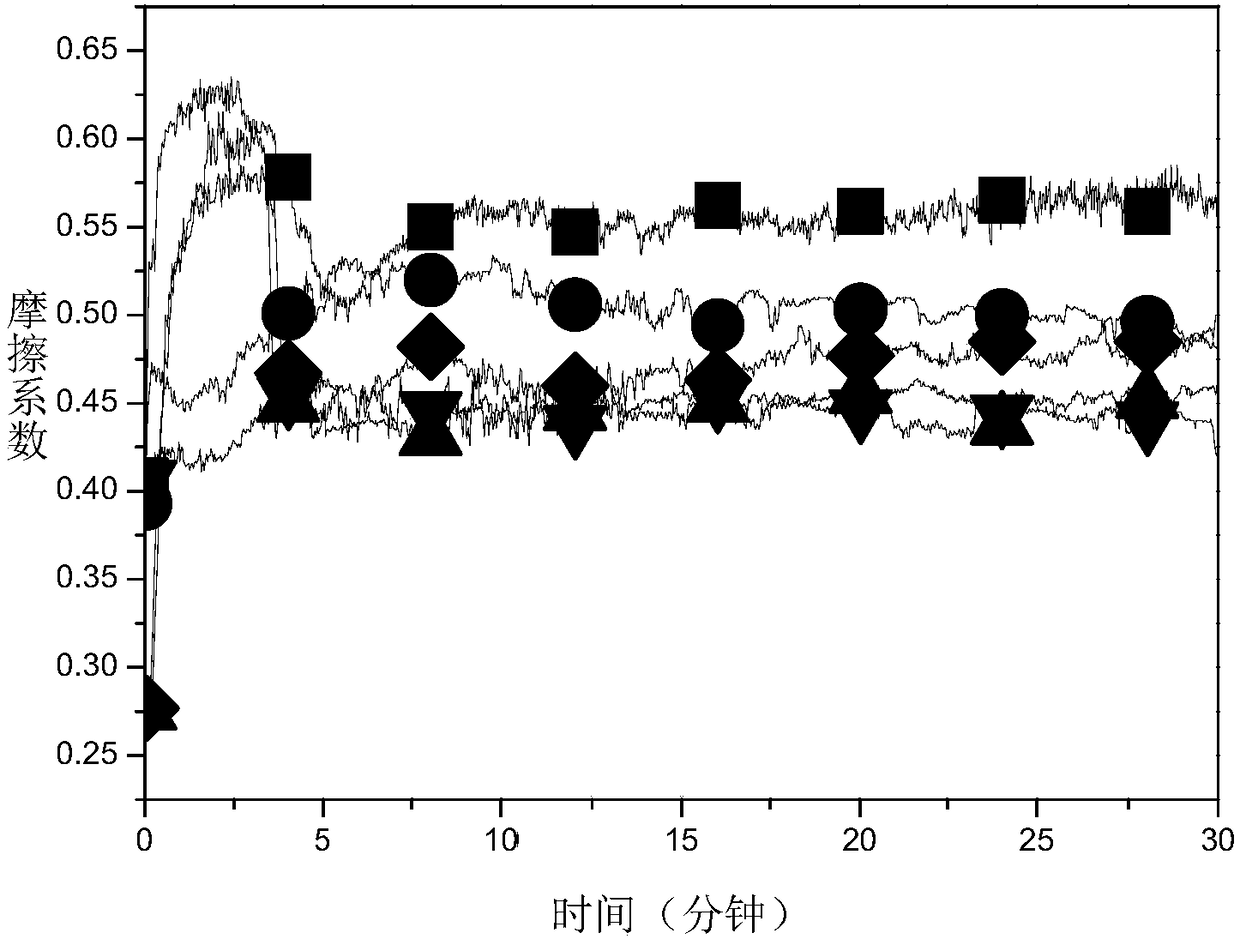

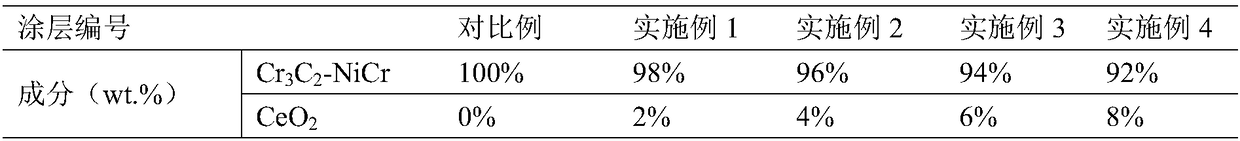

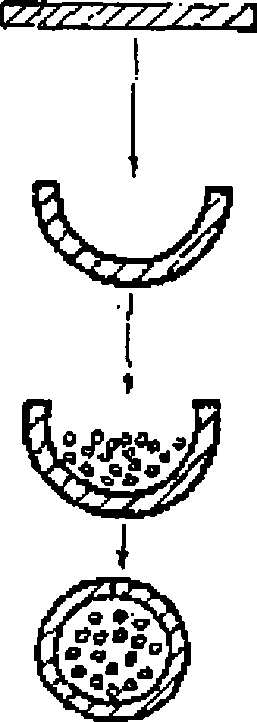

Preparation method of rare earth oxide doped high temperature oxidation resisting and abrasion resisting coating for H13 steel surface protecting

The invention discloses a rare earth oxide doped high temperature oxidation resisting and abrasion resisting coating for H13 steel surface protecting and a preparation method of the coating. Accordingto the method, an active combustion-high velocity air fuel (AC-HVAF) technology is adopted for spraying powder on a base body (H13 steel) to form the composite coating; and the powder comprises Cr3C2-NiCr powder and nanometer CeO2 powder, the doping content of the nanometer CeO2 powder is 2-8 wt%, and the balance is the Cr3C2-NiCr powder. The coating prepared through the method is compact in structure and uniform in distribution, a flattened structure is achieved, and the coating is closely combined with a boundary. Besides, after doping of the nanometer CeO2 powder, the tissue compactness ofthe coating is further improved, the porosity is reduced, the defects of non-molten matter, micro cracks and the like are less, better high temperature oxidation resisting performance and abrasion resisting performance are both achieved, and the high temperature oxidation resisting performance and the abrasion resisting performance of the H13 steel in the using process can be improved easily.

Owner:GUANGDONG ZHENGDE MATERIAL SURFACE TECH

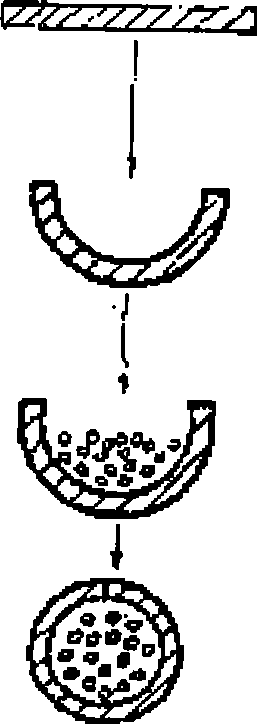

High-chromium type high temperature oxidation-resistant arc spraying powder core threaded material

InactiveCN101368254AGood resistance to high temperature oxidationGood high temperature corrosion-abrasion resistanceMolten spray coatingOxidation resistantSteel belt

The invention relates to a high-chromium anti-high temperature oxidation electric arc spraying powder core wire, which belongs to anti-high temperature oxidation electric arc spraying powder core wire used on the surface of a metal material. The invention belongs to the field of hot spraying for processing materials and is mainly used for protecting and repairing the flue of the converter and the coal powder boiler of the boiler of an electric plant. The anti-high temperature oxidation electric arc spraying powder core wire is characterized in that the weight percentages of the components of the powder core are as follows: 70 to 90 percent of metal chromium; 4 to 9 percent of ferroboron; 0 to 5 percent of metal aluminum, and the rest is metal nickel. The preparation method adopts the prior art that a 430 stainless steel belt is firstly rolled into a U shape; then the powder of the powder core accounted for 39 percent of the weight of a spraying wire is added into a U-shaped slot; the opening of the U-shaped slot is closed so as to coat the powder core t inside the opening; a drawing die is used for gradually pulling and lightening; a diameter reaches 3.0mm. An electric arc spraying prepared by the product has the advantages of high anti-high temperature oxidation performance and high rigidity, thus being capable of meeting the working situation requirements for the gas hood of the converter to run.

Owner:贵州振邦新材料科技有限公司

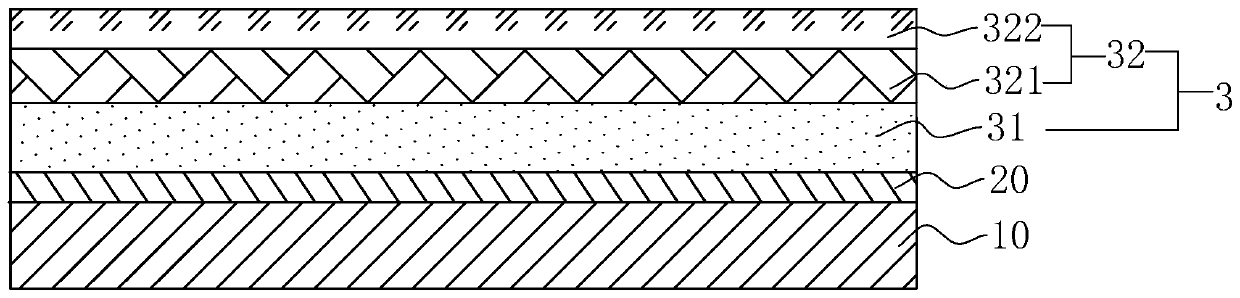

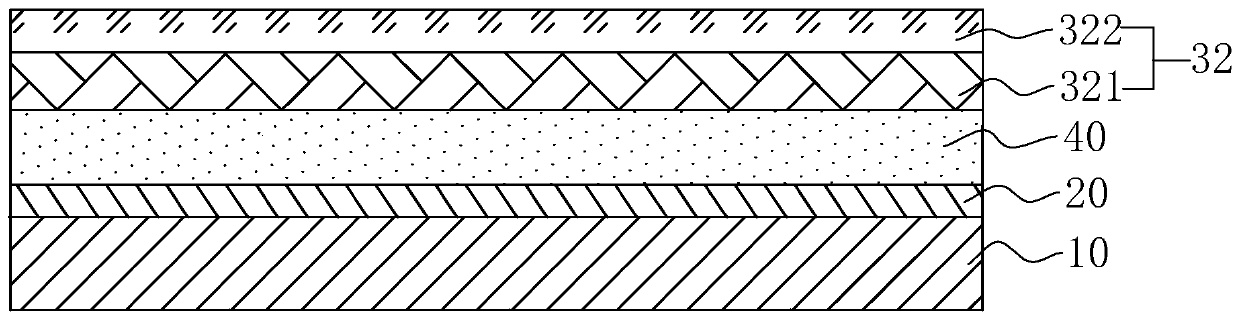

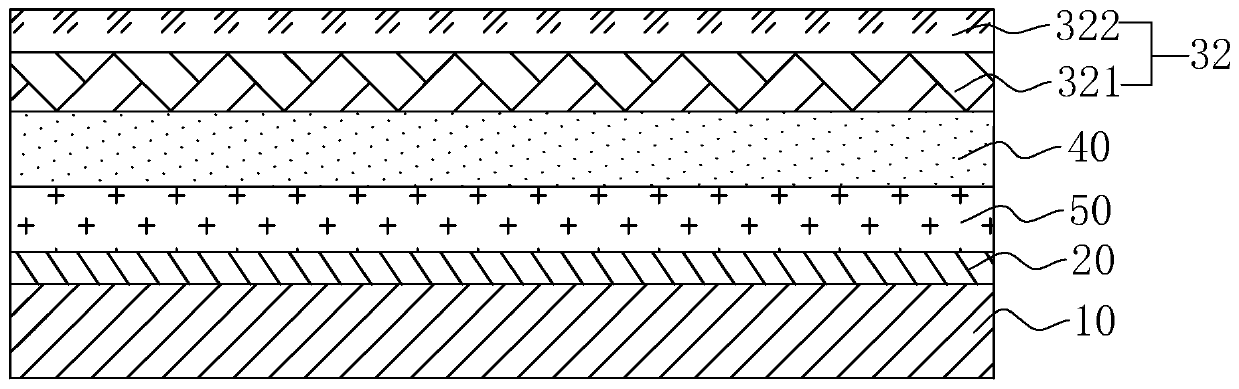

Soft film-coated color plate and production process thereof

InactiveCN110948966AColorful color changeRich functionalityLamination ancillary operationsNon-macromolecular adhesive additivesChemical treatmentFiber

The invention discloses a soft film-coated color plate and a production process thereof and relates to the technical field of plates for household appliance shells. The key points of the technical scheme are that the soft film coated color plate comprises a metal substrate, a chemical treatment layer formed on a surface of the metal substrate, and a hot melt adhesive fiber textile material layer arranged on the chemical treatment layer, the hot melt adhesive fiber textile material layer is composed of a hot melt adhesive layer and a fiber textile material layer, the fiber textile material layer is composed of a fiber fabric layer and a PU film layer, one side of the hot melt adhesive layer is in contact with the chemical treatment layer, and the other side of the hot melt adhesive layer isin contact with the fiber fabric layer. The hot melt adhesive fiber textile material is attached to the metal substrate to form the film-coated color plate, glue and paint are not used, VOC emissionin the production environment can be reduced, and therefore the soft film-coated color plate with the appearance having soft high-grade texture, colorful color changes, rich functionality and excellent durability is obtained.

Owner:青岛河钢复合新材料科技有限公司 +1

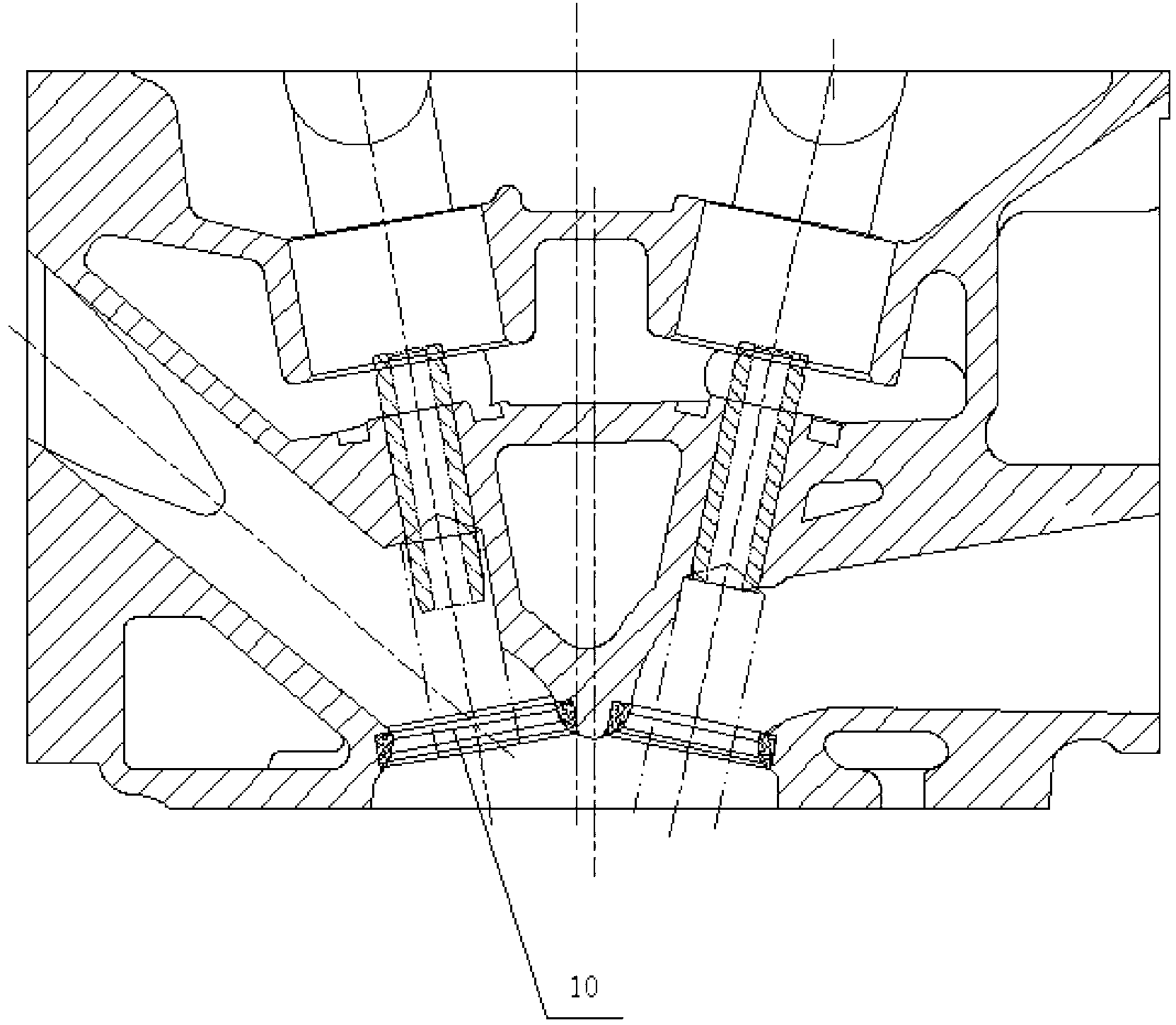

Intake/exhaust valve seat of ethanol gasoline engine

ActiveCN103216288ASolve abnormal wearSolve the deformationMachines/enginesLift valveExhaust valveInlet valve

The invention discloses an intake / exhaust valve seat of an E25 ethanol gasoline engine. The intake / exhaust valve seat comprises a primary working area and a secondary working area, wherein the primary working area comprises the following chemical compositions in percentage by weight: 0.8-1.4% of C, 1.5-3.0% of Ni, 6.9-9.0% of Mo, 3.2-6.0% of Cr, 5.0-8.0% of Co, 0-1.5% of Cu, no more than 2% of other impurities, and the balance of Fe; and the secondary working area comprises the following compositions in percentage by weight: 0.9-1.4% of C, 0.5-2.0% of Cr, 0-3.0% of Cu, no more than 2% of other impurities, and the balance of Fe. According to the intake / exhaust valve seat disclosed by the invention, an intake valve seat is pressed in the intake duct of a cylinder cover, and an exhaust valve seat is pressed in the exhaust duct of the cylinder cover, so that the intake / exhaust valve seat can achieve the effects of heat transfer, sealing, valve cold / hot shock resistance, high temperature resistance, high pressure resistance and the like, and has favorable heat conduction performance, high-temperature oxidation resistance and the like.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

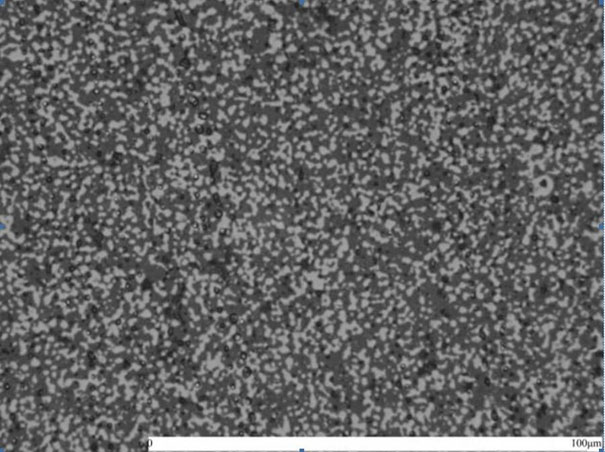

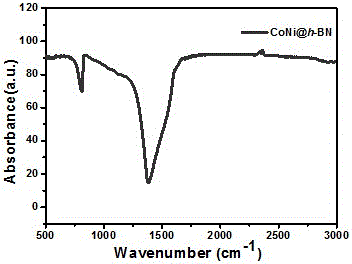

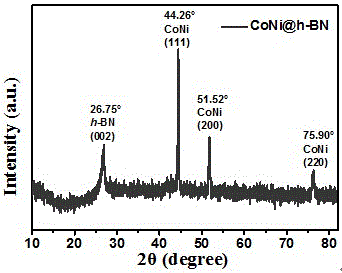

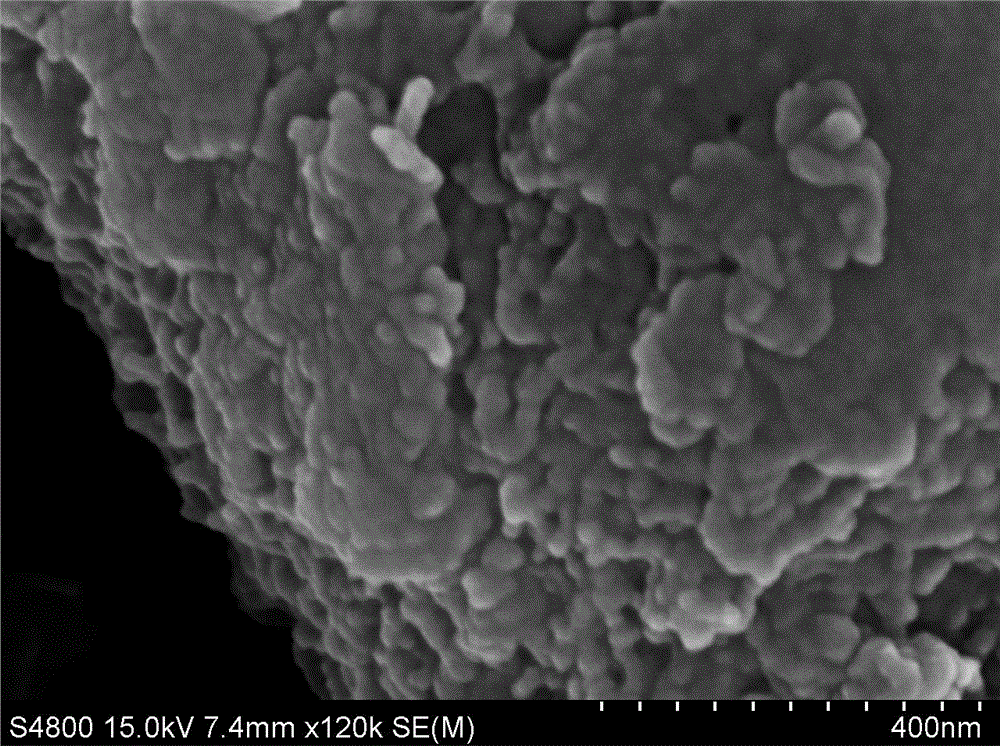

Preparing method for hexagonal boron nitride wrapping cobalt-nickel alloy

InactiveCN105921761AReduce craft production costControllableTransportation and packagingMetal-working apparatusHexagonal boron nitrideCobalt nickel alloy

The invention belongs to the technical field of preparing of nanometer materials, and particularly relates to a preparing method for a hexagonal boron nitride wrapping cobalt-nickel alloy material. A precursor of hexagonal boron nitride and a precursor of a cobalt-nickel alloy compound are mixed to be ground according to a certain molar ratio, and under the nitrogen condition, hexagonal boron nitride wrapping nanometer cobalt nickel particles are prepared in a high-temperature roasting manner; and according to the method, raw materials are cheap and easy to obtain, the cost is low, the preparing method is easy to operate, and high pressure and strong oxidants involved in preparation of methods like an arc discharge method are avoided. The production yield is high, defects are few, and the hexagonal boron nitride wrapping nanometer cobalt-nickel alloy nano particles have the higher heat conduction performance, high-temperature oxidation resistance performance, good soft magnetic performance and insulation performance.

Owner:JIANGSU UNIV

Hardfacing alloy containing silicon and chromium composite ceramic phases and manufacturing process thereof

ActiveCN103737196AGuaranteed hardnessGuaranteed wear resistanceMetallic material coating processesPlasma welding apparatusComposite ceramicBall mill

The invention provides a hardfacing alloy containing silicon and chromium composite ceramic phases and a manufacturing process thereof. The hardfacing alloy is characterized that ingredients of the hardfacing alloy comprises 10-20 percent of chromium, 0.5-5 percent of silicon, 1-4 percent of nickel, 5-10 percent of carbon, balance ferrum and inevitable impurities. The manufacturing process of the hardfacing alloy includes the first step of carrying out calculation and mechanical mixing on ferrochromium powder, molybdenum powder, nickel powder, graphite and reduced iron powder according to element mass percent, mixing all the powder evenly in a dry-type ball milling mode through a ball grinding mill to enable the granularity of the powder to reach 60-160 meshes, and taking out the powder, the second step of drying the powder in a drying oven for one to two hours and then enabling the temperature in the oven to cool down to the indoor temperature, and the third step of adding the powder into a powder feeder and then carrying out plasma arc surfacing on the powder to form a hardfacing layer. The manufacturing process is easy to operate, the kinds of the additive alloys are fewer, and the obtained hardfacing alloy is low in cost, good in binding performance between the hardfacing layer hard phases and base materials and not prone to falling off, and has the advantages of high hardness, high abrasion resistance and high temperature oxidation resistance.

Owner:辽宁谱瑞科技有限公司

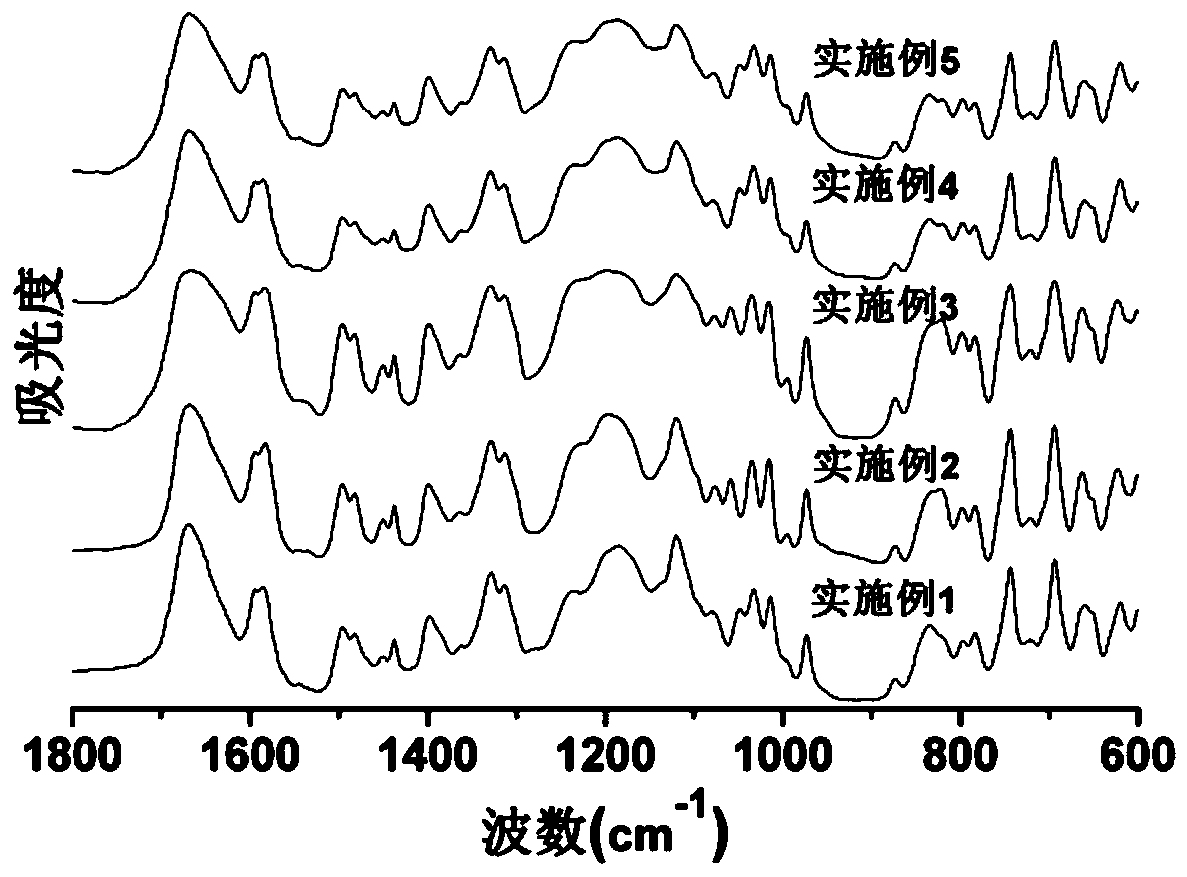

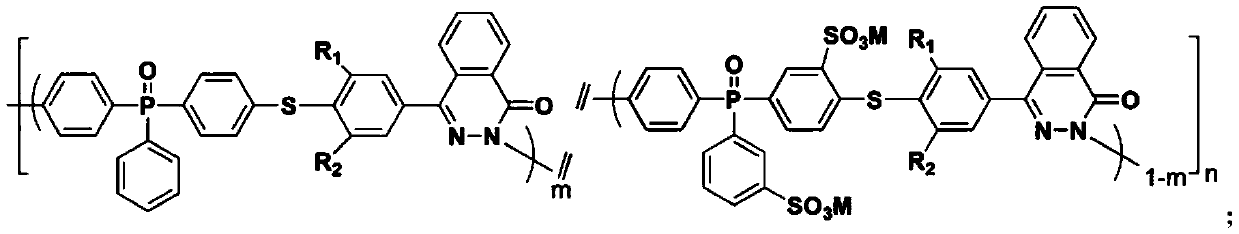

Phthalazinone-containing disulfonated poly(arylene thioether phosphine oxide), and preparation method and application thereof

ActiveCN110358087AHigh molecular weightImprove thermal stabilityWater/sewage treatment bu osmosis/dialysisFuel cellsPolymer sciencePhosphine oxide

The present invention relates to a phthalazinone-containing disulfonated poly(arylene thioether phosphine oxide), and a preparation method and an application thereof. The above polymer is prepared byhigh-temperature copolymerization of reactants which are a phthalazinone structure-containing bisphenol monomer, a dihalo triphenylphosphine oxide monomer and a disulfonated dihalo triphenylphosphineoxide monomer in a reaction medium mainly composed of a polar solvent or a polar solvent with an alkali metal base or a salt thereof as a catalyst. Compared with polymers in the prior art, the polymerof the invention has the advantages of large molecular weight, good thermal stability, good mechanical properties, small swelling property in an aqueous solution, and good high temperature oxidationresistance. The polymer can be used as a matrix material for proton exchange membranes, and has a good application prospect.

Owner:SHANGHAI INST OF TECH

Thermal spraying nickel base material

InactiveCN103469143ASolve Surface Protection ProblemsImprove joint strengthMolten spray coatingThermal sprayingMetallic aluminum

A thermal spraying nickel base material is characterized in that a medicine core comprises, by mass, 56-74% of metallic nickel, 22.0-27.0% of metallic chromium, 5-9% of metallic aluminum, 2-4% of metallic copper, 4.0-7.0% of metallic iron, 2.0-3.5% of metallic titanium, 2-6% of boron, 2-6% of magnesium and 0.5-1% of yttrium. The thermal spraying nickel base material protects the surface of petrochemical equipment under the conditions of high-temperature flushing and high-temperature corrosion, has the excellent capabilities of preventing corrosion of NaCl, KCL, NH, NOx, H2S and SO2, and has the advantages of being very good in abrasion-resisting performance and the like. Holes in a coating do not need to be sealed, and the operational cycle of a biomass boiler can be obviously prolonged.

Owner:林金松

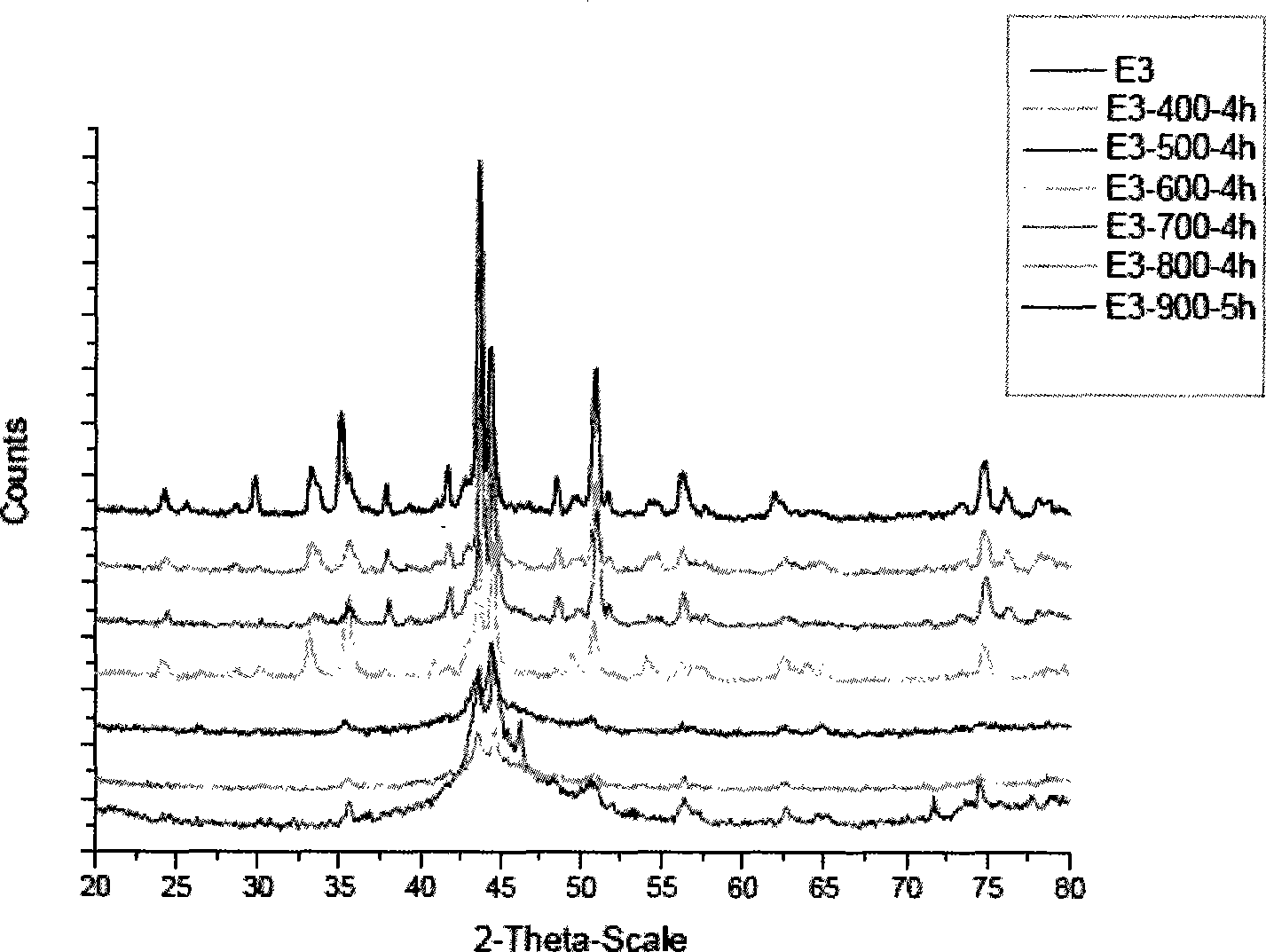

Gamma'-Ni3Al-based low-cost high-temperature alloy reinforced by precipitation of high-content square nano particles and preparation method

The invention provides a gamma'-Ni3Al-based low-cost high-temperature alloy reinforced by precipitation of high-content square nano particles and a preparation method. The gamma'-Ni3Al-based low-cost high-temperature alloy reinforced by precipitation of the high-content square nano particles comprises Ni, Co, Al, Ta, Ti, Nb, Cr, Mo and W elements. The alloy comprises the following elements in percentage by mass (wt.%): 0.5 to 12.6 percent of Co, 5.5 to 5.8 percent of Al, 3.0 to 3.3 percent of Ta, 0.8 to 0.9 percent of Ti, 1.5 to 1.7 percent of Nb, 2.5 to 5.6 percent of Cr, 2.5 to 5.1 percent of Mo, 4.9 to 9.7 percent of W and the balance of Ni. According to the gamma'-Ni3Al-based low-cost high-temperature alloy reinforced by precipitation of the high-content square nano particles and the preparation method provided by the invention, through alloy component design, coherent precipitation of ordered gamma'-Ni3 (Al, Ta, Ti and Nb) nanoparticles in a cubic form on an FCC-gamma matrix is achieved, the volume percentage content of the gamma' nano particles is higher than 75 percent, obvious coarsening does not occur after long-term aging at 850 to 900 DEG C, and the high-temperature structure stability is high, so that the alloy has excellent high-temperature mechanical properties, high-temperature oxidation resistance and corrosion resistance; and meanwhile, the series of gamma'-Ni3Al-based high-temperature alloy does not adopt expensive elements such as Ru and Re, the preparation process is simple, the material cost is greatly reduced, and the gamma'-Ni3Al-based high-temperature alloy is a novel Ni-Co-based high-temperature alloy.

Owner:DALIAN UNIV OF TECH

Turbine rotor of micro gas turbine and casting method thereof

ActiveCN107457358AImprove organizational stabilityGood resistance to high temperature oxidationFoundry mouldsFoundry coresInlet temperatureMicro gas turbine

The invention discloses a turbine rotor of a micro gas turbine. The turbine rotor is made of a K4002 high-temperature alloy. The invention further discloses a method for casting the turbine rotor of the micro gas turbine by utilizing the K4002 high-temperature alloy. According to the turbine rotor of the micro gas turbine, the K4002 high-temperature alloy is adopted as the material of the turbine rotor, under the conditions that the inlet temperature of the turbine is 1200K and the rotating speed of the rotor of a core engine is 45000 rpm, long-time operation of the micro gas turbine can be ensured, and the work is reliable; according to the method for casting the turbine rotor of the micro gas turbine, filling of blades can be guaranteed, and the problem of misrun is solved; and a ball type casting system is adopted, so that looseness is prevented, and cracks are prevented from being generated.

Owner:XIAN TONGLING POWER

Method and product thereof for preparing silver tungsten carbide contact material from silver-coated tungsten carbide powder

ActiveCN103824710BHigh densityHigh hardnessContactsElectrical resistance and conductanceSILVER NITRATE CRYSTALS

The invention discloses a method for preparing a silver-tungsten carbide contact material from silver-coated tungsten carbide powder and the silver-tungsten carbide contact material. According to the technical scheme, a silver-tungsten carbide electrical contact is prepared from raw materials, i.e., a silver nitrate crystal and tungsten carbide powder, by a chemical coating powder preparation process and a liquid-phase infiltration process; the prepared silver-tungsten carbide electrical contact comprises the following components in percentage by weight: 38%-42% of tungsten carbide, 0-0.2% of additives and the balance being silver, wherein the additives are one or more selected from nickel, copper and zirconium. The silver-tungsten carbide contact material prepared by the method has the advantages of high density, high hardness, low and stable contact resistance, uniform metallographic structure, favorable high-temperature oxidation resistance, electric arc erosion resistance, wear resistance and the like.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

Intake/exhaust valve seat of ethanol gasoline engine

ActiveCN103216288BImprove thermal conductivityGood resistance to high temperature oxidationMachines/enginesLift valveExhaust valveChemical composition

The invention discloses an intake / exhaust valve seat of an E25 ethanol gasoline engine. The intake / exhaust valve seat comprises a primary working area and a secondary working area, wherein the primary working area comprises the following chemical compositions in percentage by weight: 0.8-1.4% of C, 1.5-3.0% of Ni, 6.9-9.0% of Mo, 3.2-6.0% of Cr, 5.0-8.0% of Co, 0-1.5% of Cu, no more than 2% of other impurities, and the balance of Fe; and the secondary working area comprises the following compositions in percentage by weight: 0.9-1.4% of C, 0.5-2.0% of Cr, 0-3.0% of Cu, no more than 2% of other impurities, and the balance of Fe. According to the intake / exhaust valve seat disclosed by the invention, an intake valve seat is pressed in the intake duct of a cylinder cover, and an exhaust valve seat is pressed in the exhaust duct of the cylinder cover, so that the intake / exhaust valve seat can achieve the effects of heat transfer, sealing, valve cold / hot shock resistance, high temperature resistance, high pressure resistance and the like, and has favorable heat conduction performance, high-temperature oxidation resistance and the like.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com