Preparation method of resistance-controllable silicon carbide ceramic

A technology of silicon carbide ceramics and resistance, which is applied in the field of conductive ceramic materials, can solve the problems of uncontrollable and high resistivity of silicon carbide ceramics, and achieve the effects of reducing resistivity, improving electrical conductivity, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

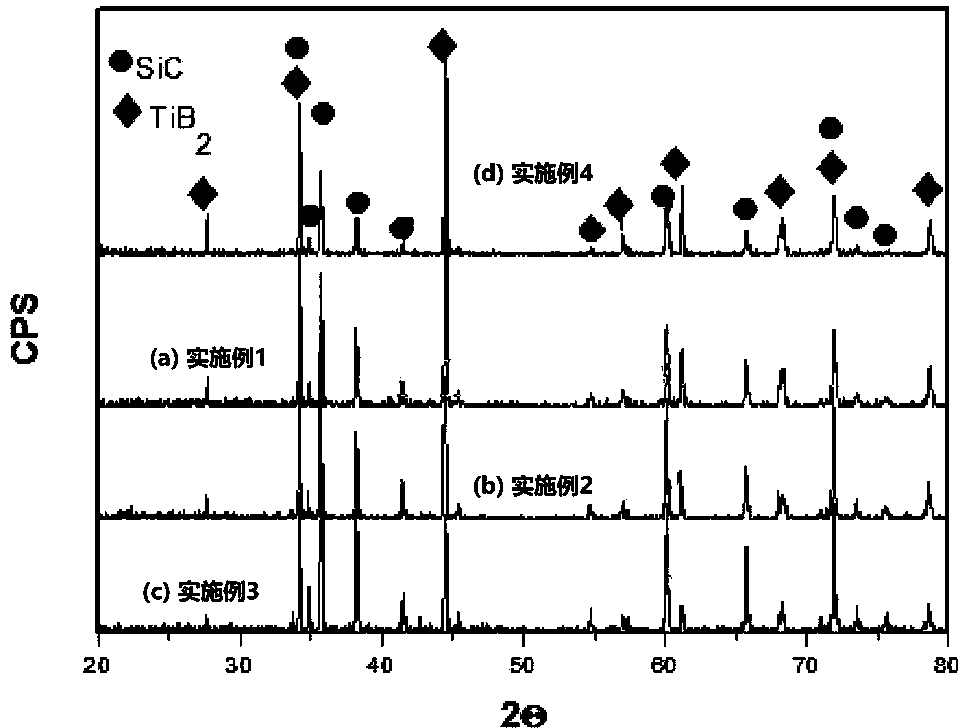

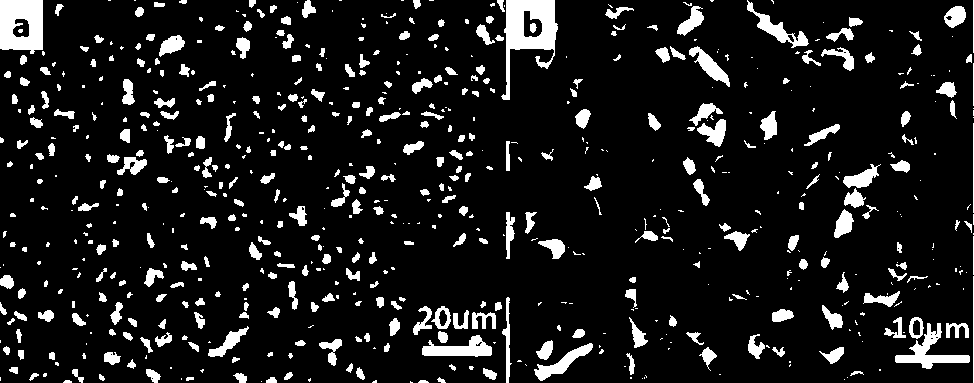

[0060] Embodiment 1 A resistance controllable silicon carbide ceramic and its preparation method

[0061] A preparation method of resistance controllable silicon carbide ceramics, the steps are as follows:

[0062] (1) According to the mass ratio, SiC powder, B 4 C powder, titanium powder, carbon black, TiB 2 Powder=80:8:20:15:25, mixed with PVA solvent with a mass concentration of 3.0% to form a slurry, and ball milled in a ball mill tank for 12 hours;

[0063] The 3.0% PVA solvent is configured into a solution for the PVA binder and deionized water, and the mass fraction of the PVA binder in the solution is 3.0%;

[0064] The SiC powder, B 4 C powder, titanium powder, carbon black, TiB 2 The mass ratio of the total mass of the powder to the total mass of the 3.0% PVA solvent is 80:100;

[0065] (2) Spray granulation of the ball-milled slurry;

[0066] (3) Put the granulated powder into the mold, and mold it with a press at a pressure of 50 MPa to obtain a green body; ...

Embodiment 2

[0072] Embodiment 2 A resistance controllable silicon carbide ceramic and its preparation method

[0073] A preparation method of resistance controllable silicon carbide ceramics, the steps are as follows:

[0074] (1) According to the mass ratio, SiC powder, B 4 C powder, TiCl 4 , soft white sugar, TiB 2 Powder=65:13:35:32:35, mixed with 5.0% PVB binder-ethanol solution in a ratio of 100:100 to form a slurry, and ball milled in a ball mill tank for 15 hours;

[0075] (2) After the ball-milled slurry is dried in a 60°C drying oven, the powder is manually ground and crushed, and granulated through a 60-mesh sieve;

[0076] (3) Put the granulated powder into the mold, and mold it with a press at a pressure of 100MPa to obtain a green body;

[0077] (4) Put the pressed ceramic green body into a 120°C drying oven to dry and discharge the moisture in the body;

[0078] (5) Put the green body into vacuum sintering, keep it at 1550°C for 90min, and when it reaches the sintering ...

Embodiment 3

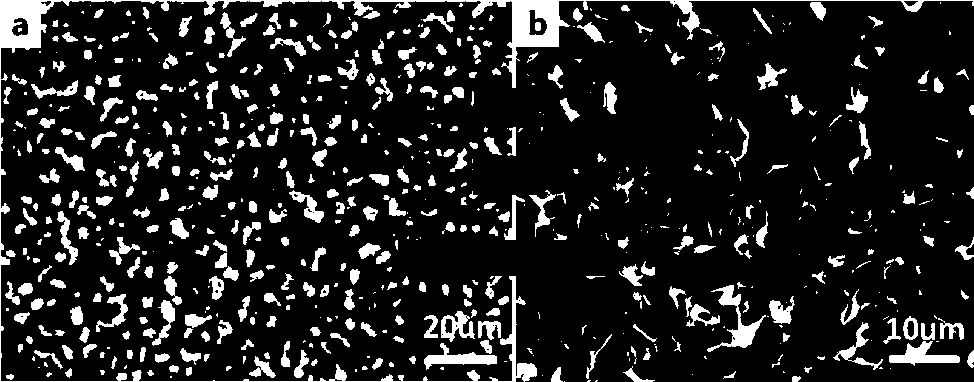

[0082] Embodiment 3 A resistance controllable silicon carbide ceramic and its preparation method

[0083] A preparation method of resistance controllable silicon carbide ceramics, the steps are as follows:

[0084] (1) According to the mass ratio, SiC powder, B 4 C powder, Ti powder, graphene, TiB 2 Powder=55:20:50:45:42, mixed with 2.5% phenolic resin binder and medium acetone to form a slurry (can be changed to: 100: 120 to form a slurry), milled in a ball mill tank for 12 hours;

[0085] (2) After the ball-milled slurry is dried in a drying oven at 80°C, the powder is manually ground and crushed, and granulated through a 100-mesh sieve;

[0086] (3) Put the granulated powder into the mold, and mold it with a press at a pressure of 200MPa to obtain a green body;

[0087] (4) Put the pressed ceramic green body into a 250°C drying oven to dry and discharge the moisture in the body;

[0088] (5) Put the green body into vacuum sintering, keep it at 1650°C for 60min, and whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com