Al/NiCrAlY/Al2O3 compound coating, preparing method and application thereof

A composite coating and coating technology, applied in the coating, metal material coating process, ion implantation plating and other directions, can solve the problems of low bonding force and high stress of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] An Al / NiCrAlY / Al provided by the embodiment of the present invention 2 O 3 The preparation method of the composite coating, including:

[0028] Al layer and NiCrAlY layer are sequentially deposited on the workpiece by multi-arc ion plating technology to form Al / NiCrAlY layer;

[0029] Al formation on the surface of Al / NiCrAlY layer by heat treatment 2 O 3 coating to obtain the Al / NiCrAlY / Al 2 O 3 Composite coating.

[0030] In some specific embodiments, Al / NiCrAlY / Al 2 O 3 The preparation method of the composite coating, including:

[0031] The workpiece is placed in the vacuum chamber of the coating equipment, and the Al layer and the NiCrAlY coating are sequentially deposited on the workpiece by the multi-arc ion plating technology until the Al / NiCrAlY layer is formed. and self-formed Al on the surface of Al / NiCrAlY layer by subsequent heat treatment 2 O 3 coating.

[0032] In some embodiments, the process conditions used for depositing the Al layer includ...

Embodiment 1

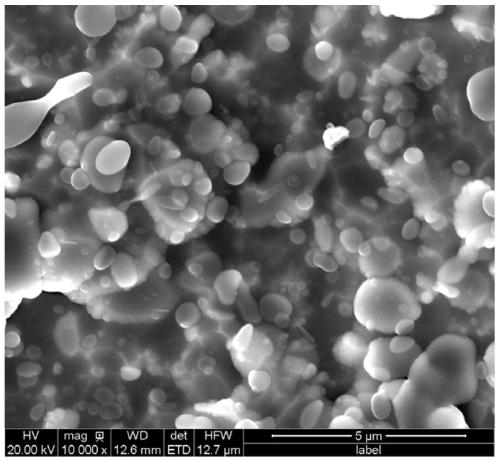

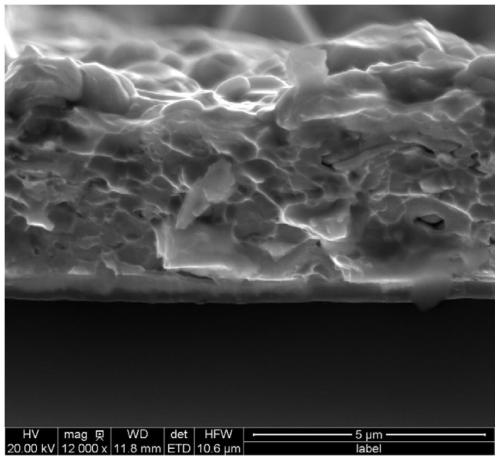

[0061] The embodiment of the present invention provides an Al / NiCrAlY / Al 2 O 3 Composite coating, the composite coating is deposited alternately with Al layer and NiCrAlY layer on the surface of the workpiece, and self-forms Al on the surface of the composite coating through subsequent heat treatment 2 O 3 coating. The thickness of the Al layer is about 0.4 μm. The thickness of the Al / NiCrAlY composite coating is about 5 μm.

[0062] The Al / NiCrAlY / Al 2 O 3 Composite coatings can be prepared as follows:

[0063] (1) Cleaning, degreasing and surface activation of the workpiece surface. Firstly, the workpiece is ultrasonically cleaned and degreasing with solvents such as ethanol and acetone, and the sample is cleaned more than 2 times until it is cleaned. Then put it into the vacuum chamber of the coating equipment at 180 ℃ ~ 210 ℃, and perform surface activation treatment on the workpiece. Argon gas was used for the surface activation treatment of the workpiece, wherei...

Embodiment 2

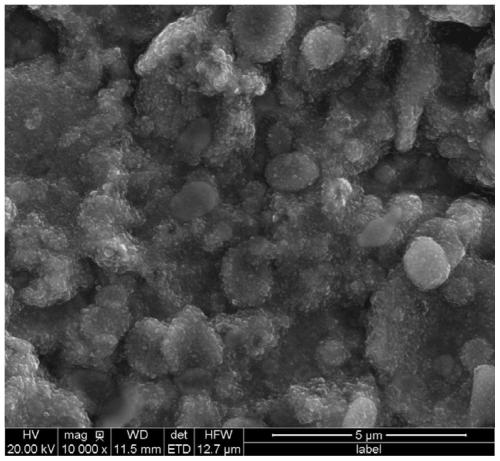

[0075] The embodiment of the present invention provides an Al / NiCrAlY / Al 2 O 3 Composite coating, the composite coating is deposited alternately with Al layer and NiCrAlY layer on the surface of the workpiece, and self-forms Al on the surface of the composite coating through subsequent heat treatment 2 O 3 coating. The thickness of the Al layer is about 0.4 μm. The thickness of the Al / NiCrAlY composite coating is about 8 μm.

[0076] The Al / NiCrAlY / Al 2 O 3 Composite coatings can be prepared as follows:

[0077] (1) Cleaning, degreasing and surface activation of the workpiece surface. Firstly, the workpiece is ultrasonically cleaned and degreasing with solvents such as ethanol and acetone, and the sample is cleaned more than 2 times until it is cleaned. Then put it into the vacuum chamber of the coating equipment at 180 ℃ ~ 210 ℃, and perform surface activation treatment on the workpiece. Argon gas was used for the surface activation treatment of the workpiece, wherei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com