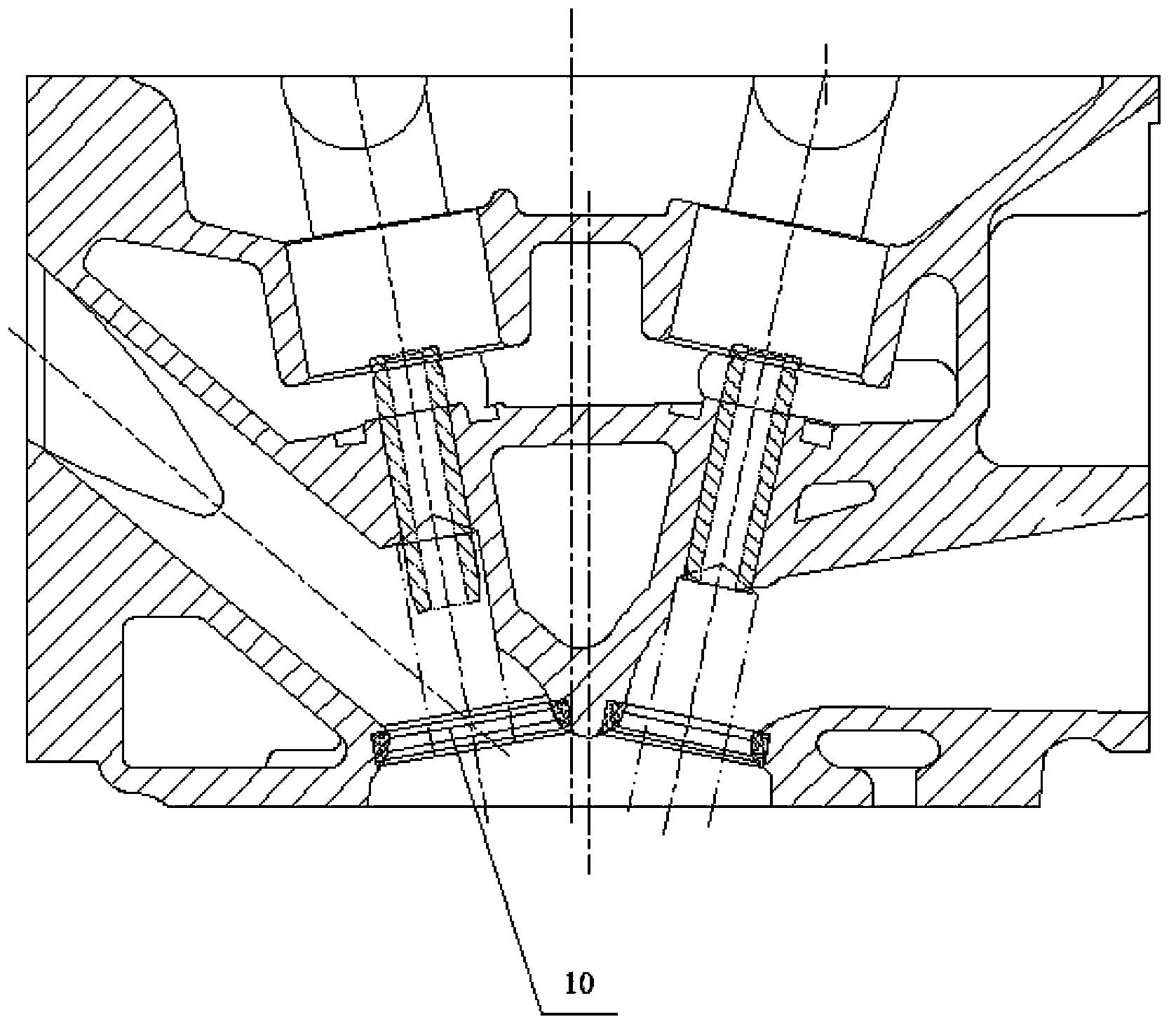

Intake/exhaust valve seat of ethanol gasoline engine

A technology for ethanol gasoline, intake and exhaust, applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as obvious corrosion of metal copper, intake and exhaust valve seat materials cannot meet the needs of ethanol gasoline combustion, and achieve Good heat conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

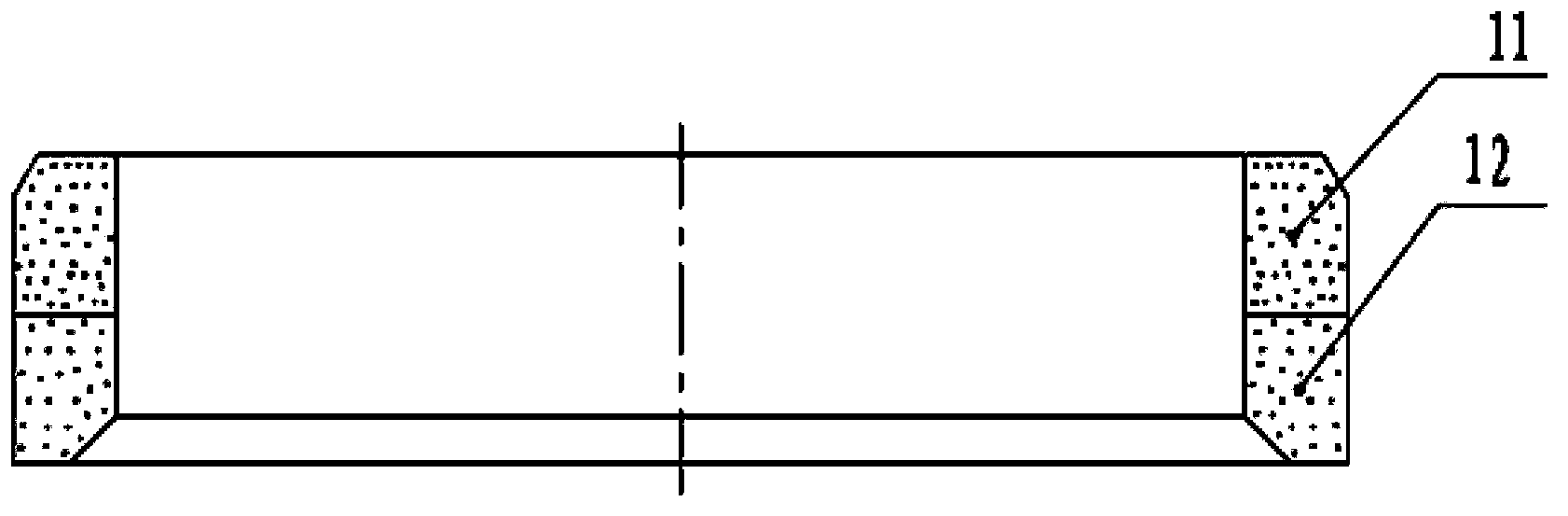

Embodiment 1

[0024] In embodiment 1, the chemical composition (percentage by weight) of the main working area 12 is: C1.0%, Ni1.6%, Mo7.5%, Cr4.0%, Co6.5%, Cu1.0%, other impurities ≤2%, the balance is Fe; the chemical composition (weight percentage) of the secondary working area 11 is: C1.1%, Cr1.5%, Cu2.0%, other impurities≤2%, and the balance is Fe.

Embodiment 2

[0025] In embodiment 2, the chemical composition (percentage by weight) of the main working area 12 is: C1.2%, Ni2.0%, Mo8.0%, Cr5.0%, Co8.0%, Cu0.5%, other impurities ≤2%, the balance is Fe; the chemical composition (weight percentage) of the secondary working area 11 is: C1.2%, Cr1.0%, Cu2.5%, other impurities≤2%, and the balance is Fe.

Embodiment 3

[0026] In embodiment 3, the chemical composition (percentage by weight) of the main working area 12 is: C1.4%, Ni1.8%, Mo7.0%, Cr7.0%, Co7.5%, Cu1.5%, other impurities ≤2%, the balance is Fe; the chemical composition (weight percentage) of the secondary working area 11 is: C0.9%, Cr2.0%, Cu1.5%, other impurities≤2%, and the balance is Fe.

[0027] In the above examples, the components with less than 2% other impurities are mainly the components contained in the raw materials (powder metallurgy materials). Common components include alloy components such as sulfur, silicon, vanadium, tungsten, and lead, which may be one of them. One or several types may also contain other ingredients. The composition and content of the specific ingredients are related to the iron ore mined. When manufacturing the intake and exhaust valve seat rings 10, the above ingredients can be controlled at a weight percentage of less than 2%.

[0028] The test results of the above-mentioned various embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com