Gamma'-Ni3Al-based low-cost high-temperature alloy reinforced by precipitation of high-content square nano particles and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Ni-0.50Co-5.52Al-3.09Ta-0.82Ti-1.58Nb-2.66Cr-4.91Mo-9.40W (wt.%) alloy

[0020] Step 1: Alloy Preparation

[0021] First, high-purity metal materials are used, and the ingredients are prepared according to the mass percentage. 100g of the mixed material is put into a vacuum arc melting furnace and smelted repeatedly at least four times to ensure that an alloy ingot with a uniform composition is obtained; then, the alloy is solidified by using a muffle furnace. Water quenching after solution treatment, the solution temperature is 1300°C, and the time is 15h. The purpose of solution treatment is to reduce or eliminate the composition segregation of the tissue and dissolve the inhomogeneous precipitated phase; finally carry out 500h at a temperature of 900°C Water quenching after aging treatment.

[0022] Step 2: Alloy structure and mechanical properties test

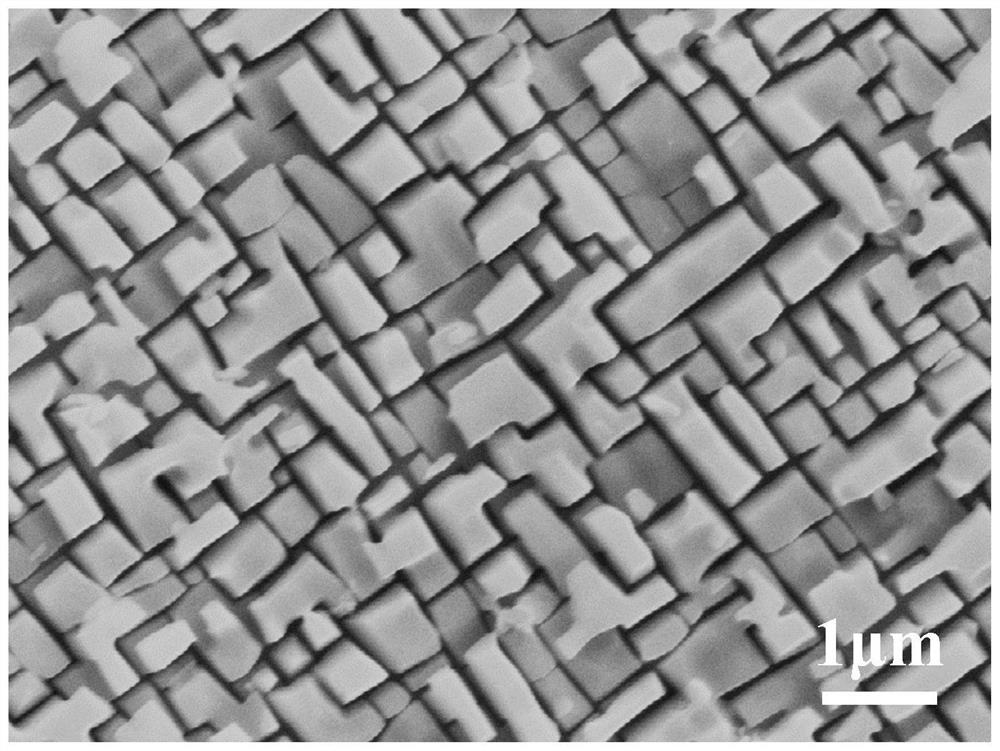

[0023] Using metallographic microscope (OM), scanning electron microscope (SEM), transmission ele...

Embodiment 2

[0025] Embodiment 2: Ni-0.50Co-5.78Al-3.23Ta-0.85Ti-1.66Nb-5.57Cr-2.57Mo-4.92W (wt.%) alloy

[0026] Step 1: Alloy Preparation

[0027] First, high-purity metal materials are used, and the ingredients are prepared according to the mass percentage. 100g of the mixed material is put into a vacuum arc melting furnace and smelted repeatedly at least four times to ensure that an alloy ingot with a uniform composition is obtained; then, the alloy is solidified by using a muffle furnace. Water quenching after solution treatment, the solution temperature is 1300°C, and the time is 15h. The purpose of solution treatment is to reduce or eliminate the composition segregation of the tissue and dissolve the inhomogeneous precipitated phase; finally carry out 500h at a temperature of 900°C Water quenching after aging treatment.

[0028] Step 2: Alloy structure and mechanical properties test

[0029] Using metallographic microscope (OM), scanning electron microscope (SEM), transmission ele...

Embodiment 3

[0030] Embodiment 3: Ni-6.03Co-5.52Al-3.08Ta-0.82Ti-1.58Nb-2.66Cr-4.90Mo-9.40W (wt.%) alloy

[0031] Step 1: Alloy Preparation

[0032] First, high-purity metal materials are used, and the ingredients are prepared according to the mass percentage. 100g of the mixed material is put into a vacuum arc melting furnace and smelted repeatedly at least four times to ensure that an alloy ingot with a uniform composition is obtained; then, the alloy is solidified by using a muffle furnace. Water quenching after solution treatment, the solution temperature is 1250°C, and the time is 18h. The purpose of solution treatment is to reduce or eliminate the composition segregation of the tissue and dissolve the inhomogeneous precipitated phase; finally carry out 400h at a temperature of 850°C Water quenching after aging treatment.

[0033] Step 2: Alloy structure and mechanical properties test

[0034] Using metallographic microscope (OM), scanning electron microscope (SEM), transmission ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com