High-toughness Fe-Al-Cr coating and preparation method thereof

A fe-al-cr, high-toughness technology, applied in the coating, metal material coating process, ion implantation plating, etc., can solve the health and safety problems of operators, strong light radiation, poor material toughness and other problems, Achieve excellent high temperature oxidation resistance, good transition bonding, and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The present invention is described in further detail below in conjunction with embodiment. However, for those skilled in the art, reasonable generalization and derivation can be made on the basis of the numerical values listed in the specific embodiments.

[0053] (1) Treat the surface of 20 steel with metallographic sandpaper, ultrasonically clean it, and dry it;

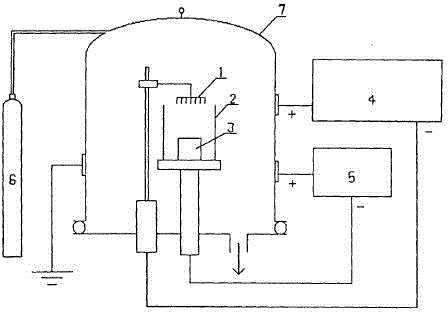

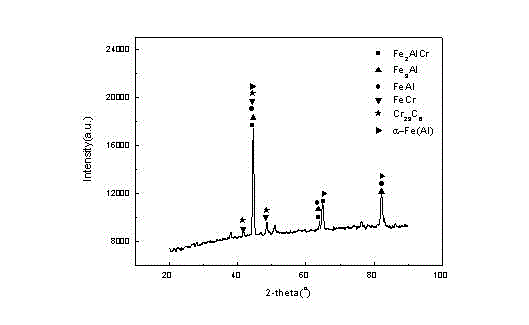

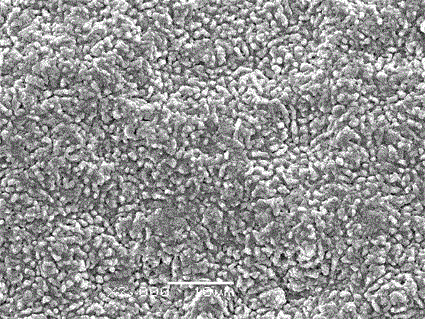

[0054] (2) Put the above-mentioned 20 steel and iron-aluminum-chromium alloy wire into the double-glow plasma surface alloying device, use 20 steel as the workpiece electrode, and use the disc-shaped mesh-shaped iron-aluminum-chromium alloy wire as the source electrode. The ratio of the source components is: Al: 4%, Cr: 25%, the balance is Fe, the diameter of the wire is 1.5mm, and the aperture of the mesh is 14 mesh. Adjust the distance between the two poles to 15mm.

[0055] (3) Vacuumize to 0.5Pa, send in argon, start the glow, and adjust the process parameters. The follow-up experiment was divided i...

Embodiment 2

[0071] (1) Treat the surface of 45 steel with metallographic sandpaper, ultrasonically clean it, and dry it;

[0072] (2) Put the 45 steel and iron-aluminum-chromium alloy wire treated above into the double-glow plasma surface alloying device, use 45 steel as the workpiece electrode, and use the mesh structure made of iron-aluminum-chromium alloy wire as the source electrode. The distribution ratio of the source electrode is: Al: 6%, Cr: 15%, the balance is Fe, the wire diameter is 1.0mm, and the mesh aperture is 10 mesh. Adjust the distance between the two poles to 25mm.

[0073] (3) Vacuumize to 0.5Pa, send in argon gas, start glow, and adjust the process parameters to . The follow-up experiment was divided into three phases.

[0074] The time of stage one is 1.5h, and the debugging process parameters are:

[0075] Source voltage: 950V;

[0076] Workpiece voltage: 650V;

[0077] Argon pressure: 38 Pa;

[0078] The time of stage two is 2.0h, and the debugging process pa...

Embodiment 3

[0089] (1) Treat the surface of Q235 steel with metallographic sandpaper, ultrasonically clean it, and dry it;

[0090] (2) Put the above-treated Q235 steel and Fe-Al-Cr alloy wire into the double-glow plasma surface alloying device, use Q235 steel as the workpiece pole, and use the mesh structure made of Fe-Al-Cr alloy wire as the source. The distribution ratio of the source electrode is: Al: 5%, Cr: 20%, the balance is Fe, the diameter of the wire is 1.2mm, and the aperture of the mesh is 12 mesh. Adjust the distance between the two poles to 20mm.

[0091] (3) Vacuumize to 1.0Pa, send in argon gas, start glow, and adjust the process parameters to . The follow-up experiment was divided into three phases.

[0092] The time of stage 1 is 1.0h, and the debugging process parameters are:

[0093] Source voltage: 900V;

[0094] Workpiece voltage: 600V;

[0095] Argon pressure: 35 Pa;

[0096] The time of stage two is 1.5h, and the debugging process parameters are:

[0097] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com