Preparing method for hexagonal boron nitride wrapping cobalt-nickel alloy

A hexagonal boron nitride, cobalt-nickel alloy technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of short circuit, soft heat conduction sheet material, etc., achieve low preparation cost, good tear resistance, good tear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 1 g of ammonium borate and 2 g of a mixture of cobalt nitrate hexahydrate and nickel nitrate hexahydrate, mix and grind at room temperature for 20 minutes. Put it into a tube furnace for calcination, rise to 700°C at a heating rate of 5°C / min, and keep at 700°C for 5h. The product obtained after calcination is washed three times with ethanol and water respectively, and then put into a drying oven to dry to obtain a product of few-layer hexagonal boron nitride-coated nano-nickel particles.

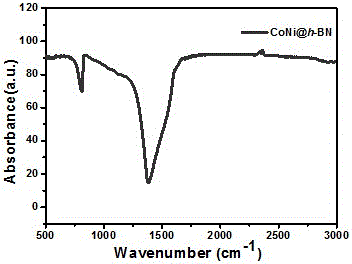

[0029] figure 1 It is the FTIR spectrogram of the few-layer hexagonal boron nitride wrapped nano-nickel particles prepared in this embodiment; the boron nitride infrared characteristic peak of the product can be seen from the FTIR spectrogram, which proves that the boron nitride is successfully prepared.

Embodiment 2

[0031] Weigh 1 g of sodium borohydride and 3 g of cobalt acetate and nickel acetate, mix and grind at room temperature for 10 minutes. Put it into a tube furnace for calcination, rise to 1200°C at a heating rate of 10°C / min, and keep at 1200°C for 1h. The product obtained after calcination is washed with ethanol and water respectively, and then put into a drying oven to dry to obtain a product of few-layer hexagonal boron nitride-coated cobalt-nickel particles.

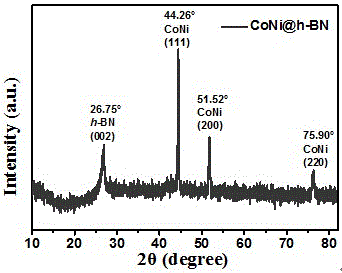

[0032] figure 2 It is the XRD spectrum of the hexagonal boron nitride-wrapped cobalt-nickel metal particles prepared in this example; the characteristic peaks of boron nitride and metal cobalt-nickel of the product can be seen from the XRD spectrum, which proves that the preparation of boron nitride-wrapped cobalt-nickel metal particles success.

Embodiment 3

[0034] Weigh 1 g potassium borohydride and 1.2 g cobalt chloride and nickel chloride respectively, mix and grind at room temperature for 10 minutes. Put it into a tube furnace for calcination, rise to 900°C at a heating rate of 5°C / min, and keep at 900°C for 5h. The calcined product is washed with ethanol and water respectively, and then put into a drying oven to dry to obtain a product of few-layer hexagonal boron nitride-wrapped nano-cobalt-nickel particles.

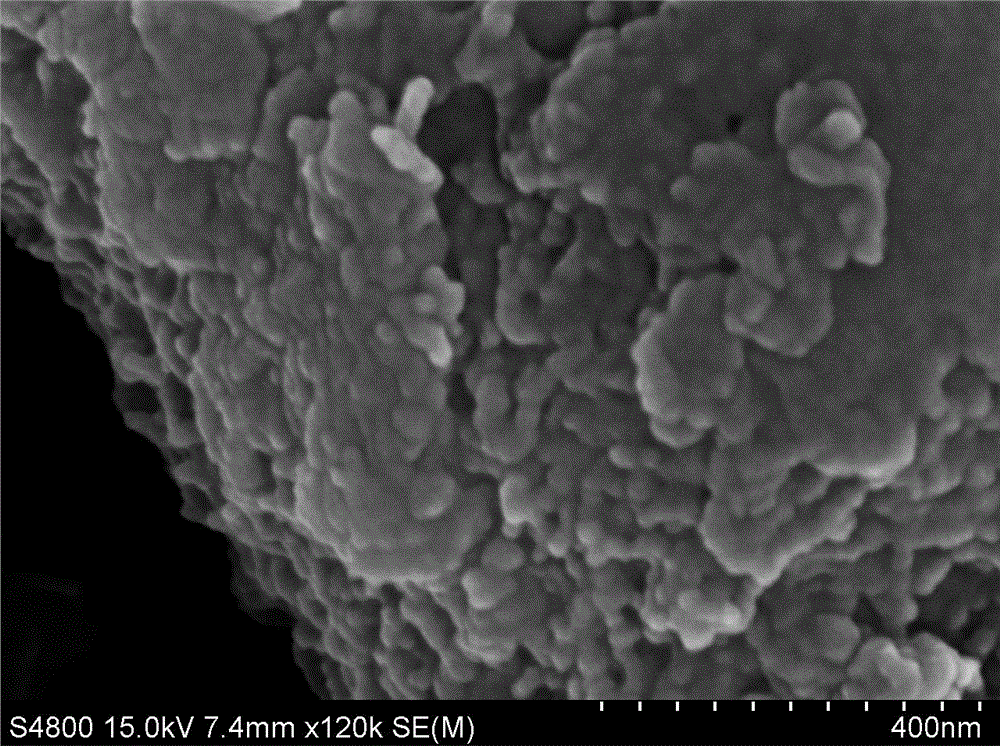

[0035] image 3 It is the SEM photo of the hexagonal boron nitride-wrapped cobalt-nickel metal particles prepared in this example; it can be seen from the SEM image that the hexagonal boron nitride completely wraps the metal cobalt-nickel particles, the number of layers of hexagonal boron nitride is ~10 nm, and the nano-nickel particles The diameter is ~50 nm, which proves that the boron nitride-coated cobalt-nickel metal particles were successfully prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com