Pinion-and-rack type power steering gear valve element assembly

A power steering gear and rack-type technology, applied in the direction of fluid steering mechanism, etc., can solve the problems of large spool assembly jump, low function contribution, quality loss, etc., to meet the needs of loading and quality, and reduce production The effect of stable manufacturing cost and process quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

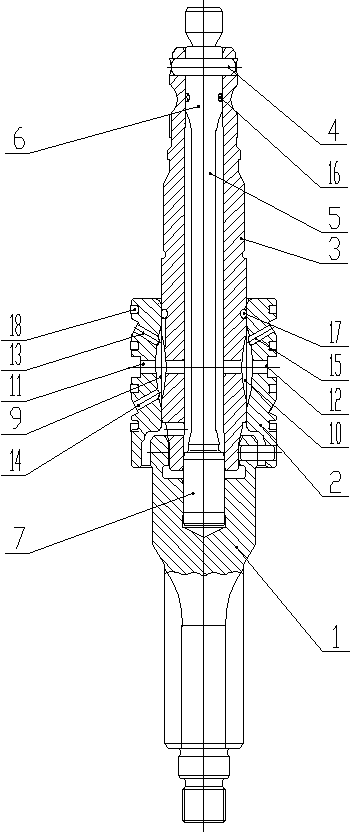

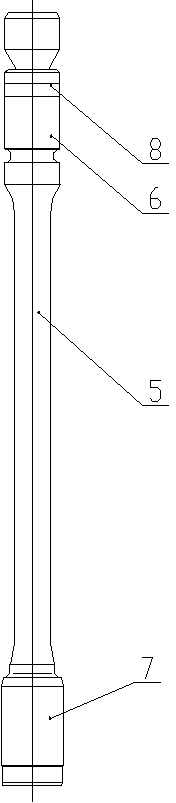

[0012] The rack and pinion power steering gear spool assembly consists of a gear shaft 1, a valve sleeve 2, an input shaft 3 and a torsion bar. An input shaft 3 is installed on the gear shaft 1 through a valve sleeve 2 , and a torsion bar is installed in the inner hole of the input shaft 3 through a cylindrical pin 4 ; a torsion bar sealing ring 16 is arranged between the torsion bar and the input shaft 3 . The torsion bar is composed of a torsion bar body 5, the two ends of the torsion bar body 5 are respectively provided with an upper torsion bar head 6 and a lower torsion bar head 7, the upper torsion bar head 6 is provided with a pin hole 8, and the upper torsion bar head 6 and There is a circular arc transition between the torsion bar bodies 5 ; and a stepped transition between the lower torsion bar head 7 and the torsion bar body 5 .

[0013] A blind groove A9 and a blind groove B10 are arranged correspondingly between the valve sleeve 2 and the torsion bar, and an oil i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com