Nuclear power steel 18mnnimo and its preparation method

A technology of nuclear power, chemical composition, applied in the direction of electric furnace, furnace type, furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

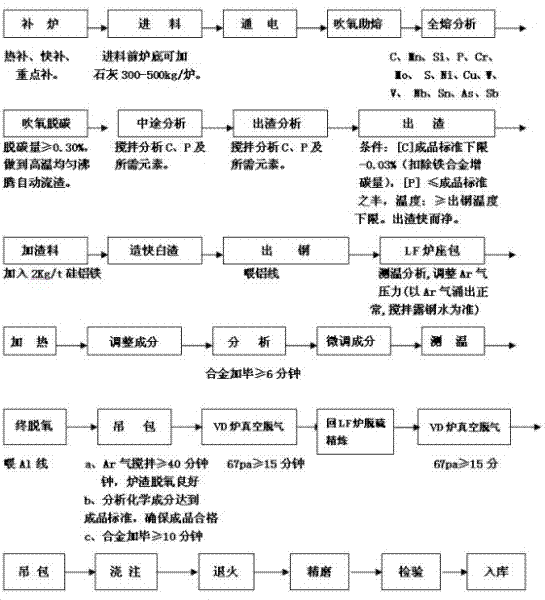

[0024] The present invention claims the preparation method of nuclear power steel 18MnNiMo, which is characterized in that it includes the following smelting steps of high temperature treatment technology in sequence: electric arc furnace smelting EF, ladle refining outside the furnace LF, vacuum degassing refining VD, and vacuum pouring. Specifically include the following steps:

[0025] (1) Furnace repair (mainly composed of magnesia, 200kg / furnace), feeding materials, blowing oxygen to boost melting after electrification, and performing oxygen blowing decarburization after full melting analysis, so as to achieve uniform boiling at high temperature and automatic slag flow, and the decarburization amount is greater than 0.30 %;

[0026] (2) Then carry out midway analysis and slag analysis, both of which are stirred to analyze C, P and the required elements; when the concentration of C in the analysis is -0.03% of the lower limit of the concentration standard required for the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com